Why Pellets Formulation Is On The Rise?

Taking medicines orally is always the gold standard of drug administration. This is because every individual favors their convenience and safety first. Traditionally, tablets or capsules are widely accepted medications and are available in single unit and multiple unit dosage forms. Have you ever heard about Pellets? Why are Pellets gaining popularity? Why pellets are the best alternative for oral drug delivery?

Today, we are going to talk about what you need to know about pellets for your manufacturing business. First, we are going to start with what exactly they’re.

1.What Exactly Pellets are?

You must have noticed certain medicines that are made up of small, rounded, free-flowing, and compressed forms of substances. For instance, Proton Pump Inhibitors (PPIs). Yes, they are known as pharmaceutical pellets.

Pellets can be dispensed in the form of tablets or capsules for the treatment of various physiological ailments. The average size of the pellet varies from 0.5 to 2.0 mm.

In pharmaceutical sciences, pellets are extensively investigated to get a fully controlled and delayed release response of the drug in the gastrointestinal tract.

2.When Did Pellets Come Into Existence?

The term ‘Pellet’ has been employed by a number of industries. For instance, pharmaceutical, nutraceutical, fertilizers, and iron ores. This technique came into the ‘Pharmaceutical Industry in the 1950s for the controlled release of therapeutic medication for an extended period. Later in the 1970s, the significant benefits of pellets were identified such as efficiency, mechanism of action, and specificity. With time, more research was conducted to address innovative techniques and methods of manufacturing (process and machines). The trend of advancement is expected to grow more in the future.

3.What Pellets are Made of?

Beside, drug ingredients that offer therapeutic relief, pellets have the following constituents:

| Binders | These bridging agents are adhesive substances that are added during pelletization for preserving pellet integrity and increasing the binding force of powder particles. |

| Granulation Liquid | This is incorporated during the wet massing process for improving the cohesiveness of granules for the subsequent spheronization process. |

| Lubricant | The friction between particles and walls of containers is decreased by using lubricants. These agents also aid in the discharge of pellets in the machine. |

| Spheronization Enhancer | They are essential for increasing the binding strength, integrity, and plasticity of formulation. These materials also amplify the spheronization process of pellets. |

| Filler | It is utilized in pellet formulation for making up bulk volume of the required dosage. |

| Ph Adjusters | The substances or buffers that improve the stability of drugs in gastrointestinal tract are pH adjustors. |

| Surfactants | These are used in pellet formation for enhancing the wetting characteristics of ingredients and they also lower the strain between fluids and drugs. |

| Separating Agents | The breaking of pellets into individual constituents is aided by the use of separation agents. These excipients stop pellets from drawing each other due to charge development. |

| Release Modifiers | The release of drug is determined by the type of release modifier. The water soluble release modifiers boost the release of drug while gelling modifiers lessen the drug discharge from pellets. |

4.How are Pellets Formulated?

Pellets are routinely used in medication formulation. Some important techniques used in pellet manufacturing include:

Dry Mixing

In first step, powders are blended with each other to attain a uniformly distributed mixture.

Wet Massing

The second stage involves wet granulation fluid for forming a wet or plastic mass.

Extrusion

The pressure is used for shaping wet mass granules into rod-shaped particles having same diameter and shape at the extrusion step. These rod particles are called extrudes.

Spheronization

The rotation of the frictional plate at the Spheronization step fracture extrudes into small fragments that are of similar length and diameter. Then they are rounded by frictional force.

Drying

At this stage, pellets are dried by the evaporation of moisture.

Screening

This is an optional step in which pellets are passed through a sieve for screening of same sized products.

Coating

Various supplementary agents are coated on pellets for aesthetic or practical purposes at this optional stage.

5.Applications of Pellets

Pellets have versatile applications in the pharmaceutical industry for instance:

| Immediate Release Pellets | These pellets are beneficial for patients who are seeking immediate release. When medications are delivered in pellet form, they have a larger area and dissolve much faster than capsules or tablets. |

| Sustain Release Pellets | Sometimes patients require drug action at a constant rate, so sustain-release pellets are best for this situation. These beads are slowly absorbed in the blood and provide relief over an extended period. |

| Delayed Release Pellets | Delayed release pellets offer better protection to acidic drugs as they readily move from the stomach to the small intestine. These are advantageous in the intestinal therapeutic regime as they have rapid dissolution in intestine thus providing quick effects. |

| Dose Variation | Pellet capsules are valuable in capsule filling because of their good flow. The manufacturer can easily vary the dosage of medication by just changing the size without going through lengthy reformulation. |

| Incompatible Drugs | By using pellets in capsules, chemically incompatible drugs can be blended and formulated as a single dosage. |

6.Do You Think Granules and Pellets Are Same?

Granules are created by the progressive formation of tiny particles till an optimized form is achieved. Pellets are an agglomerated form of fine particles or granules. They are small, spherical, and free-flowing particles with several therapeutic advantages. Of course, their appearance is much better and superb than granules.

Agglomeration is the process of making granules and pellets. But they are different in size and texture, for instance, granules are porous and irregular in shape, but pellets are low porous with high consistency in terms of uniformity and shapes.

7.What are the ‘IDEAL PROPERTIES’ of Pellets?

The desirable properties of pellets are:

Uncoated Pellets

- They must be uniform, smooth textured with a spherical structure.

- Pellets must have an optimum size that varying in between 600 to 1000µm.

- Pellets must possess good hardness and low friability.

- Ideal pellets demonstrate good flow characteristics.

- It must have the ideal physical strength and high integrity.

- They possess high bulk density.

Coated Pellets

- All above properties must be demonstrated in coated pellets as well.

- They have desirable drug-releasing effects for the specific site of action.

- It must be evenly distributed to enable the controlled release of a drug.

8.Why Pellets Formulation Is on The Rise?

The reason behind the wide acceptance of pellets formulation is their unexceptional therapeutic response at the desirable site of action and obtaining maximum benefits within the estimated time period. Although its manufacturing is far more complicated as compared to the single dosage form. But due to their maximum advantages, it is preferred to use.

Pellets are considered as the alternative to achieve therpaeutic response due to following reason:

IMPROVED DRUG ABSORPTION

One of the prime therapeutic property of pellet is maximum absorption and efficasy at the site of action. When it comes in contact with GIT tract secretions, it swells and breakdown into small particles and distributes the APIs.

AN EVEN DISTRIBUTION OF APIs

Pellets smoothly enters to GIT when administered orally and distributes its ingredients equally to get an efficient outcome; this effect minimize the risk of side effects caused by drugs over-dosing.

NO GASTROINTESTINAL TRACT IRRITATION

There are various drugs that causes GI mucosal damage. This is due to high acid content of drug that may harm the mucosal layer of your stomach. However, the pellets are very small in structure carrying minute active content, it is easy to alter the formulation of acid sensitive content like erythromycin.

MASKING BITTER TASTE

No body prefer taking bitter medicines, pellets are ideal where masking of bitter medicine is required. For this, various methods are employed to hinders the bitter taste of medicine like adding sweeting agents, good flavors and coating.

SAFE AND RELIABLE

All pellets carrying potential drug content designed in a low sized particles. This lead to induce zero to none side effects. Hence, that is why it is preferred form of oral administration among patients.

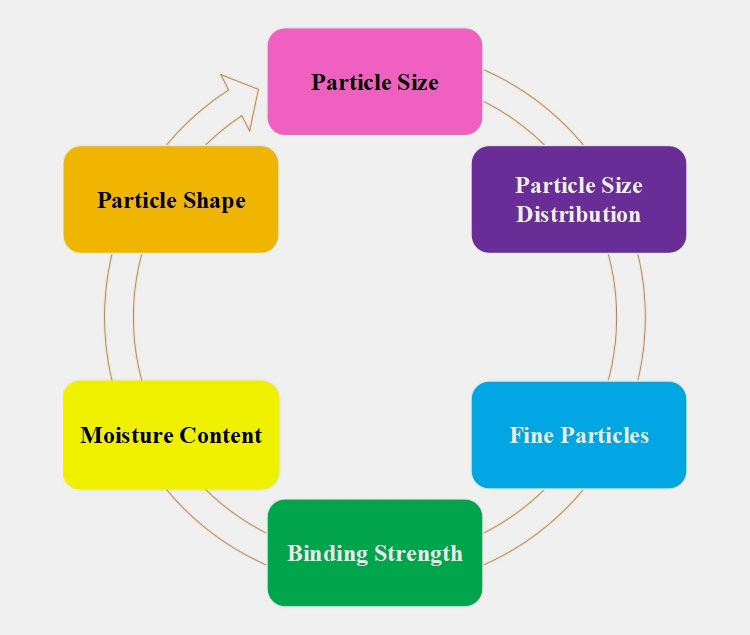

9.6 Most Critical Process Parameters of Pellets Are?

An understanding of critical process parameters for pellet formations helps to minimize the batch variations and cause superior product development. Some critical parameters that influence pelletization are:

Particle Size

The differences in particles size of various ingredients lead to poor blend quantity and uneven size of extrudes.

Particle Size Distribution

It is important that there should be minimal disparity in particle size distribution since this can result in large yield of target sized pellets.

Fine Particles

Oversized or agglomerated particles are created due to excessive use of fluids at wet massing stage which influences particle binding in pellets.

Binding Strength

The binding force between particles must be optimized as it alters the hardness profile of pellets thus affecting their drug dissolution.

Moisture Content

This is the main parameter that impacts size and shape of pellets. Pellets will have a larger size if there is more moisture in them. It also friability of pellets and in turn their disintegration.

Particle Shape

The particle shape must be spherical because asymmetric particle geometry will affect the downstream coating process.

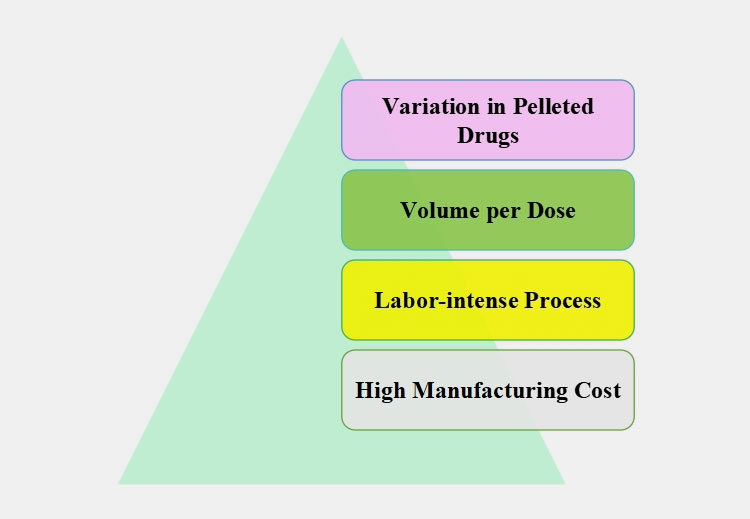

10.What Challenges Pellets Brings?

Like another dosage form, the manufacturing process of pellets is filled with challenges. Some difficulties in pellet formulation are:

Variation in Pelleted Drugs

Diverse active ingredients are used for pelletization process, so every formulation step is modified with respect to that particular ingredient in order to attain preferred outcome and this complicates the multistep manufacturing of pellets.

Volume per Dose

Pellets have a higher volume per dose because of their recommended bulk density than tablets. So, the quantity of coating solution needed for pellets will also rise.

Labor-intense Process

As mentioned, extrusion- spheronization is a multiphase process requiring trained staff for supervision and monitoring. This technical complexity burdens the workforce.

High Manufacturing Cost

Pellet production necessitates specialized equipment that can be quite pricey. Moreover, labor wages further add expenses to already costly manufacturing.

CONCLUSION

WHY PELLETS FORMULATION IS ON THE RISE? Hereby concluded that pellet is a versatile and promising technique of the oral dosage form. Due to numerous advantages, pellets have gained popularity in the modern era of pharmaceutical sciences and are anticipated to play a lead role in the pharma world.

Do you have queries in your mind? Send us a short message to get in touch with our High-Tech experts Right Now.

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine