Why Is Dry Granulator Machine Considered One Of The Best Pharmaceutical Processes?

In recent years, the quality of the pharmaceutical industry has continuously increased . In order to promote the great development of the pharmaceutical industry, it is very important to improve the technology and quality of its upstream pharmaceutical equipment.

Among them, in the pharmaceutical process of traditional Chinese and Western medicine, dry granulator machines play an indispensable role.

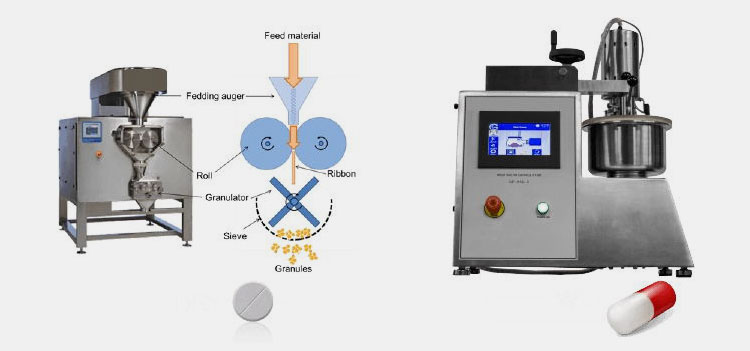

It is reported that the dry granulator machine is a new granulation method developed after the second-generation granulation method "one-step granulation”, which is capable of directly compressing pharmaceutical powders into granules.

Compared with wet granulation, dry granulation requires less equipment, less maintenance costs, less floor space, and less production and processing costs. In addition, dry granulation has simpler processing technology than wet granulation, thus reducing the link of GMP demonstration.

Some technicians have introduced that dry granulation has advantages such as low energy consumption compared with wet granulation.

"Granulation does not need to add any additives and binders; after granulation, the product has uniform particle size, high bulk density, and good flow performance. After granulation, it is easy to store and transport, with flying dust and less waste and it is also easy to control volume, porosity and specific surface area.

Especially for some drugs that are afraid of water or alcohol can not be dissolved, as well as antibiotics, drugs with strong heat sensitivity are afraid of heating, the proportion of traditional Chinese medicine extract can not meet the requirements, and can not add adhesives or excipient drugs, must be completed by dry granulation process.

(20-60 mesh with starch as standard) During the granulation process, the color of the material will be different. Generally, the color of the material will be different from the original powder after dry granulation.

Because the surface area of the powder is larger than that of the granules, the reflection of light is also affected. The difference is that the bulk density of the pressed particles is higher than that of the original powder, so the color of the particles will also deepen.

Under normal circumstances, the greater the pressure on the pressure roller, the darker the color will be. The pressure acting on the pressure roller is not only the pressure of the oil pump, but also related to the feeding speed and tabletting speed.

Under the condition of a certain pressure and tablet speed, the faster the feeding speed, the greater the pressure between the pressing wheels, and the smaller the vice versa. Similarly, under the condition of a certain pressure and feed speed, the slower the tablet speed, the greater the pressure between the pressing wheels, and the smaller the vice versa.

Therefore, the customers should choose a better pressure and speed according to the actual situation of the material when using the dry granulator so as to improve the one-time yield of the product on the basis of ensuring the product performance.

The dry granulator machine uses a new roll control technology, which enables the process parameters of dry granulation to be adjusted repeatedly to produce high-quality granules.

Compared with the wet granulator, the main advantage of the dry granulator is that the raw material can be formed without adding water or binder during the granulation process, and it is suitable for materials with low moisture content.

The formed product is in irregular granular or block shape, and does not require drying, which reduces the waste of resources and labor, and can effectively improve the stacking ratio of raw materials. It is an equipment worthy of advocacy.

In the production process of pharmaceutical granulation, dry granulation is widely used, and with the continuous improvement of pharmaceutical granulation requirements, the technical requirements of pharmaceutical companies for dry granulator machines will also become higher and higher.

Experts say that cleanliness and functional flexibility will be the common goals of the industry.

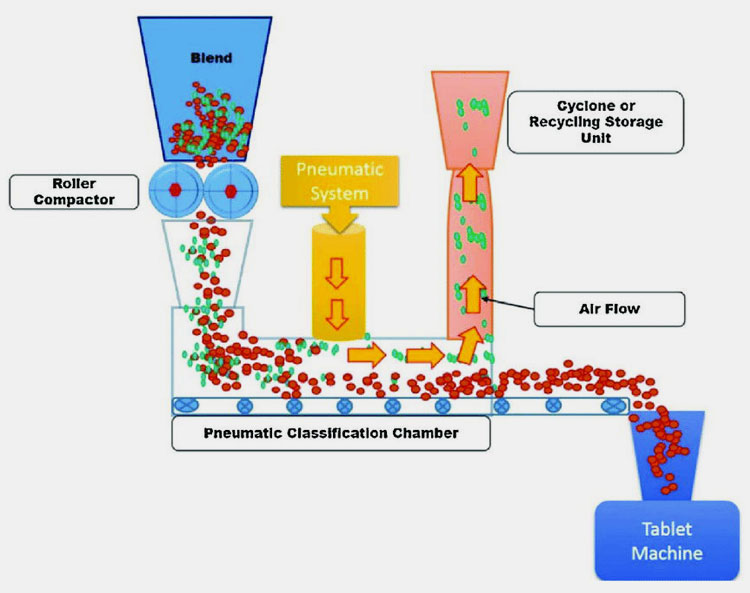

In the future, dry granulator machines will meet the requirements for cleanliness and functional flexibility. For example, a completely closed dry granulation system can reduce dust pollution in the production process, thereby reducing the risk of pollution and pollution.

With a modular design, the entire granulation device can be disassembled with only a few tools, which is convenient for all modular units. It can be cleaned, and the screw and press roller can be easily replaced to suit different granulation tasks.

According to industry professionals, the dry granulator machines can also choose different angles of granulating knives according to the different properties of the customer's materials.

In the granulation process, the material discharge is guaranteed to be smooth, which solves the phenomenon that the material will not turn upwards, roll up, and rotate during the granulation process.

The appliance of new granulating technology greatly improves the granulating efficiency of the traditional Chinese medicine and the quality of the end product.

Therefore, in the development process after the granulator, you should pay attention to technological innovation, and not short to meet the cleanliness and flexibility requirements of the pharmaceutical industry.

Dry granulation is environmentally friendly and clean, saves the drying environment, and reduces pollution emissions. It is one of the most widely used and promising pharmaceutical processes at present.

The dry granulator machine can effectively prevent dust leakage, reduce the possibility of pollution, reduce the purification area, and more in line with the GMP requirements of drug production.

With the continuous expansion of the pharmaceutical industry, especially the continuous advancement of the industrialization of traditional Chinese medicine, the dry granulation process and equipment will be further promoted.

Some related production industries should constantly strengthen technology research and development, improve the current problems of granulation equipment and better meet the needs of the market.

It is reported that there are many dry granulator machine production manufacturers and their equipment can basically meet the pharmaceutical market’s demands.

Nonetheless, related companies lack investment in technology research and development and innovation, and domestic equipment still has poor stability and high failure rate, such as broken rolls, water leakage, dislocation of rolls, large dust production, low yield, difficult cleaning, and unstable pressure.

Just as the saying goes “Long, Long had been my road and far, far was the journey” In terms of technological transformation and innovation of dry granulation, dry granulator manufacturers still need to continue to explore.

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine