Why Are Gummies Acidic?

Who doesn't love gummy candies? We all love eating sweet, appealing, and stretchy gummies. Maybe none of you ever thought about how it is prepared; what kind of ingredients inside it make it the most delicious treat?

The popularity of gummy is not only limited to kids, the younger even the older population love taking it. In this blog Why are gummies acidic, we will discuss the major and essential ingredients that are used to make gummies.

Moreover, the role of acidic ingredients in the formulation with health-related effects will also be discussed.

So be ready to dive into an interesting topic related to gummies. We tried our best to present the article with vibrant illustrations and useful conversation that will help you learn more about acidic gummies. Let’s explore!

1.What is gummy acid?

Gummies- Picture courtesy: Gift from Nature

The gummies acids are known as food acids which are mainly derived from natural food sources such as vegetables or fruits. However, they are also synthesized by some chemical processes as known as manufactured gummies acids, for example: manufactured citric acid or MCA.

In gummies making process, you need to add gummy acid for 1 to 2% depending on the composition of the process. Gummies acids are associated with so many properties when added to gummies formulation.

For example, it will enhance the fruity flavors, pH, preservation, etc of your product. Thus, the purpose of gummies acid is to induce and improve tangy flavor, maintaining the pH of the product which mainly ranges between 3 to 5, and giving the properties of gelling.

2.Why are gummies acidic?

Adding acidic elements to the gummy enhances not only the taste or sourness but it helps in offering other benefits. That is why a specific percentage of acidic ingredients must be added to every gummy manufacturing procedure. Let's have a look at the different advantages gummy acid provides you.

Giving a magical taste

Taste enhancer- Picture courtesy: symega

Whenever you eat gummies, you feel amazing sourness incorporated with sweetness. Such kind of flavor or taste you might have only experience when consuming a real fruit. This is the purpose of adding gummies acid to the product. Many of you love the taste of citric acid in a way they are addicted to it. So, whenever you are thinking of brain-stimulating candy, the created sourness and tartness in gummies acid from citric acid will fulfill a mouth-watering treat.

Improve the freshness and quality of gummies

Improves freshness and quality

As we already talked about the role of gummy is not only to improve the taste or flavor but also to help in increasing the quality of gummy's life.

This specific percentage of its ingredient in gummies helps in the inhibition of microbial growth, as well as the progression of fungus or any unwanted microbial invasion. Therefore, it is also considered a good natural preservative agent.

Offering a smooth and uniform texture

Smooth texture

When you add acidic ingredients in gummies formulation, it improves the stability and consistency of the gummy formulation. This is because the acidic ingredients are mostly derived from the peeling or the cell wall of the fruit peel which also acts as a jellying agent. Therefore, it helps in the bonding of the entire ingredients used in the gummy’s preparation. Consequently, giving good strengthening and stability effects making the overall texture very smooth.

3.What are the different types of acids used in acidic gummies?

There is not a single gummy acid used for the creation of gummies. Rather the following list of ingredients used in the gummy formation depends on your choice. Come on have a look.

Citric acid

Citric acid- Picture courtesy: Intentionaleating.net

Sources

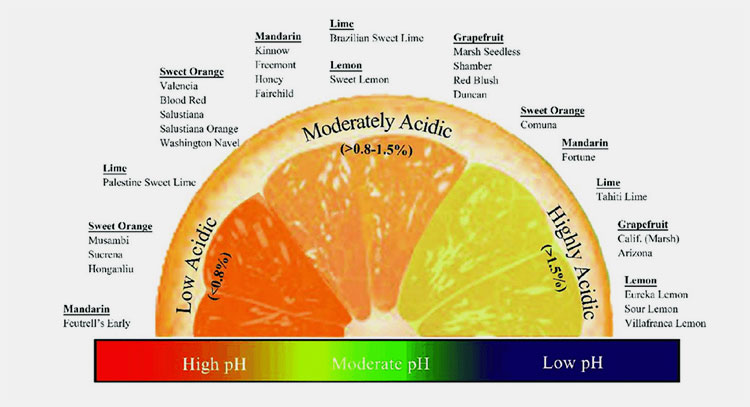

Certain citrus fruits such as oranges, lemons, strawberries, and cherries are enriched with citric acids adding the mouth puckering effects.

The pH mainly ranges from 3 to 3.5 and it can produce more enhancing effects when you use citric acid in a combination of fruits like apples, pears, etc.

Citric acid HOC(CH₂CO₂H)₂ is considered the ‘king of sourness’ and is commonly used as a secret ingredient in various food-related products. Of course in gummies, citric acid is the one of prime ingredients that provide a sour punch in your mouth.

This is actually a weak organic acid and you can mainly derive citric acid from citrus fruit. You can imagine that the incorporation of citric acid in gummies is just like pouring vinegar on a vegetable salad or any other stirred food. They are mainly available in the powder form you can add to gummies as a required percentage which is mainly 2 to 4% of total composition.

If you are planning to make a gummy bear with a yellow lemon flavor we would suggest you try a citric acid lemon flavor, you will never feel disappointed.

Malic Acid

Malic acid- Picture courtesy; KAA timex

Sources

The components are derived from natural fruits such as apples, grapes, pears, cherries, berries, etc, which have a pH that ranges between 3 to 3.2.

When you are consuming gummies with unstoppable bites, that’s the percentage of malic acid (C4H6O5) that enhances the amazing fruity flavors.

It has sweet and tartness effects, which is why when you add in formulation, your gummy candies are known as extreme candy. Many gummies are mostly labeled with a warning to consume a certain amount; in case of overconsumption can produce side effects, for example, mouth sourness.

Due to more sweet effects, it is a preferable option to citric acids many times. If you compare the tartness level of malic acid with citric acid, it is considered to be having a lower tartness.

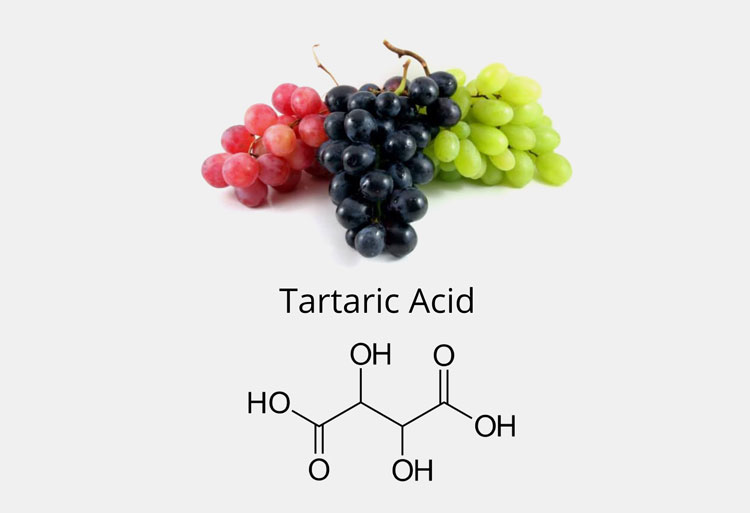

Tartaric acid

Tartaric acid in gummies formulation- Picture courtesy: Radio 786

Sources

The tartaric acid (C4H6O6) is mainly obtained from grapes, lime, and tamarinds. They’re known to have high levels of tartaric acids although bananas, pears, apples, and avocados are also known to have sufficient concentrations of tartaric acids. It has a pH limit of 2.55 to 2.58.

This is known as a water-soluble food acid which is used in gummy candies to obtain tartiness effects. Side by side, adding tartaric acid helps in offering a strong fruity flavor to the formulation. Many people love tartaric acid due to more sourness properties and they are addicted to it. The ingredients give an amazing flavor of lime and grapes.

In Europe, many wine manufacturing industries use tartaric acid, in the process of fruit fermentation, especially from grapes. But in the food industry, it is mainly used for the making of confectionaries and gummy candies. When it comes to know about it solubility it shows a limited dissolution rate in a low-temperature

Ascorbic Acid (Vitamin C)

Ascorbic Acid (Vitamin C) in gummies formulation- Picture courtesy: The nutrition source

Sources

The high concentration of ascorbic acid is found in fruits and vegetables such as oranges, lemons, papaya, strawberries, mangoes, bell peppers, etc. The pH range of ascorbic acid is 3.5 to 4.

Ascorbic acid (C6H8O6) Which is also known as vitamin C is a weak organic acid related to the monosaccharide’s family. You will be amazed to know that ascorbic acid is known as a secret of Mediterranean diets. They are mainly present in citrus fruits and possess a sweet and sour taste.

This also offers good health-related properties, for example, helping in the scurvy treatment, giving you a good skin glow, anti-aging and so much more.

In the food industry, if the formulation is composed of ascorbic acid, it means it has high antioxidant properties. Also, its presence offers greater stability in terms of an extended shelf life and protecting the formulation. That is why health-related companies are mainly composed of ascorbic acid as their major ingredient.

Fumaric Acid

Fumaric Acid- Picture courtesy: Periodical by knowledge

Sources

It is naturally present in some fruits, mushrooms, lichens, and fungi. It possesses a pH range of 3.2.

This is an essential ingredient that is known as an integral element of the plants. It possesses high hydrophobic properties. By this, it offers long-lasting sourness and fruity flavor to gummies.

The percentage of fumaric acid (C4H4O4) in gummies is less, this is because of provides maximum strengthening effects in a low concentration. One is the main benefits of fumaric acid as it lowers the cost of manufacturing. In various formulations, it is known to be a good substitute for tartaric acid in many formulations.

Moreover, the taste of fumaric is very similar to citric acid That is why it is occasionally used as a substitute for citric acid.

Phosphoric acid

Phosphoric acid- Picture courtesy: Eat This Much

Sources

This is mainly derived from the rocks of phosphates. The estimated pH of phosphoric acid is 3.5 to 4.6.

Phosphoric acid (H3PO4) is the synthetic acid used in gummies. This is the synthetic inorganic acid which is used in food products. It is the best-known second most broadly used acid in the food industries worldwide.

This is mainly known as a food additive ingredient that provides a sharp tangy taste with greater stabilizing effects. For food formulation, it is used in jams, candies, sauces, etc. This is mainly used in the formation of cola and carbonated drinks. For gummies, when you’re formulating cola gummies, it is a must-added ingredient.

4.What is the level of pH in gummies acidic?

The level of pH in gummies acidic- Picture courtesy: Commerce drive dental

The pH level of gummies acidic can be measurable. The commonly sour gummies are shown to have more acidity levels than less sour gummies. The gummies acidic with mildest range sourness have a pH of 4.0. Whereas it keeps on gradually increasing as you increase the level of tartness in their ingredients.

The level of pH for extremely sour gummies candies is noted in between 3.0 to 2.0. They have ability to super-hold your taste buds with a more sticky texture and induce sourness when it is in your mouth. Just wow! So, your mouth and taste buds are kept on the acidic gummies till it is in your mouth.

5.Which acid is more popular in gummies acidic? Citric acid or malic acid?

Citric acid and malic acid: Which is better?

In commonly used gummies acidic ingredients are ‘citric acid and malic acid’. Both ingredients are added as good flavorants and texture-inducing components. But what is better for your formulation; must be assessed from below comparison table below.

| Points | Citric acid | Malic acid |

| Flavor | Stringent sour flavor is associated with citric acid. | It has a sourness with a sweet taste. |

| Smoothness | It offers your stability with elasticity. | It gives more softness and gummy chewiness. |

| Price | This is a broadly available ingredient with less cost. | Malic acid compared to citric acid is expensive. |

| Origin | Citric acid origin is from citric fruits and vegetables. | They are commonly available in apples and pears. |

| Which is more acidic? | Citric acid is more acidic with a pH of 2.2. | Malic acid is less acidic and has a pH of 3.4 with mild acidity than citric acid. |

6.How to make gummy acid?

Gummy acid making- Picture courtesy: candypros

Making of gummy acid is comprised of a series of production steps. There are two main points you should keep in mind for successful gummy acid formation. First, the right formulation, the right proportion, and the right production line machines. When you’re fully assured that all points are fully satisfactory, we assure you that your gummy acid will be fantastic. Have a look at the formulation steps.

Step 1: Preparation & estimation of gummy ingredients

Ingredients- Picture courtesy: Industrial meeting.club

In this step, you need to select the gummy ingredients and make it ready for the formulation. There are the following essential ingredients that are used in gummy acid, for example:

| Gelatin | This is the major ingredient that provides elasticity, chewiness, and jelly-like consistency to gummies. Without gelatin, you can’t make gummies, and it is mainly used from plant-based sources such as pectin, starch, and agar, Conventionally, gummy bears mostly had animal-based gelatin but now with time, it has been replaced with natural sources thus hooked to a broad acceptance profile. |

| Water | This is the main medium through which various ingredients are to be mixed. |

| Sweetening agents | If you noticed, gelatin substances do not have any taste. Nor sweet, nor sour, then how gummies are sweet? This is all because of adding sweetening agents. In this matter, sucrose, corn syrups, or glucose are added to make gummies sweet and delicious. |

| Flavorant | Various types of flavoring agents are available around the world which is used in gummies depending on your choice. It is up to you to pick either a synthetic flavoring agent or a natural. For example, vanilla flavor, lemon, orange, etc. |

| Acidulants | Gummy acids are incomplete if you skip the acidulants. These are actually the substances that improve the acidity level or improve the pH of gummies.

They are having sour and tartness that boost your taste buds. For example, all the above-mentioned gummy acids such as citric acid, malic acid, fumaric acid, etc come in this category. You can pick the acidulant depending on the specificity of the gummies. |

Step 2: Mixing & Melting

AIPAK gummy acid melting & stirring machine

The real show of gummy acid formation starts when you pour all the ingredients into the gummy acid melting machine. Here, you can set the temperature where all the ingredients safely and gradually melt.

Your equipment must be promising enough that can keep melting the components without overheating them, the unit must be capable of content stirring the thick solution for uniform distribution of all ingredients with high-temperature control. The ideal temperature used during the process is suggested in between 80 to 100°C.

Step 3: Gummy acid depositing

AIPAK gummy acid depositing machine

The hot slurry of gelatin and other ingredients is now prepared and transferred to the main unit known as the gummy acid depositing machine. Its name tells everything, the machine offers you excellent features which the heating pipes connecting the unit with a molding tray. The slurry which is stored in the hopper is poured in a specific amount into the molds of any shape (bear, star, heart, etc).

Once the molds are filled, with the help of chain transmission it moves away, and the next molding unit comes towards the filling plungers.

Step 4: Cooling & demolding

AIPAK cooling tunnel

The filled gummy acid depositing trays are now transferred to another prime unit known as a cooling tunnel. The major objective is to lower the temperature of the slurry and make it fix a shape. The standard temperature used in the cooling tunnel is around 5-10°C. In the cooling tunnel, gummies setting takes some minutes, whereas, if you’re using room temperature, then it may take hours.

The machine is also designed with demolding features and a brush that ensures smooth and flexible demolding of prepared gummies for further procedure.

Conclusion

The elements of acid in gummies play a significant role in elevating many properties. Firstly, it helps in making a good and smooth texture. Secondly, it protects the gummy's composition by preserving the potency, and flavors. Thirdly and most importantly, the level of tartness is achieved by the addition of acidic ingredients. Thus, this is the best way to get all the benefits from adding a proportion of acidic ingredients. As a manufacturer, this is your responsibility to realize and prefer those ways that will make your gummies more appealing. For that reason, the AIPAK team always welcomes you to offer assistance in manufacturing the gummies formulation, requiring promising machines under affordable range, or needing guidance in technical issues. Please contact us now.

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine