When Using Syrup Filling Machine-These Operations Can Not Be Ignored

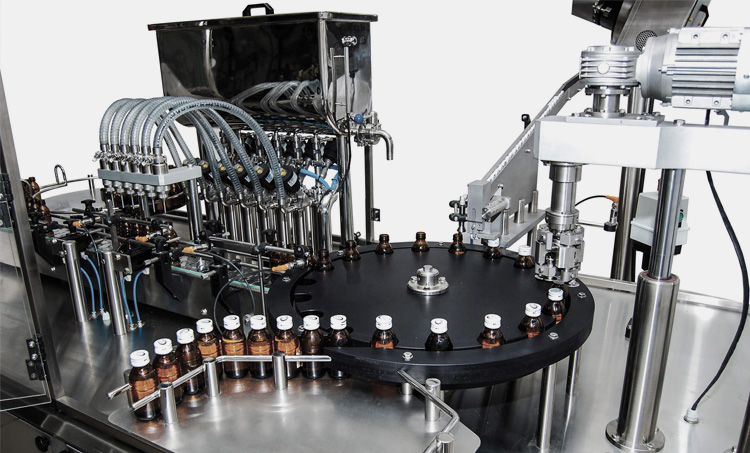

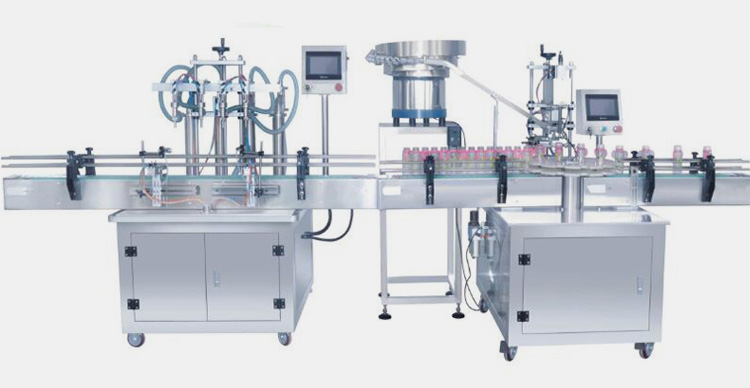

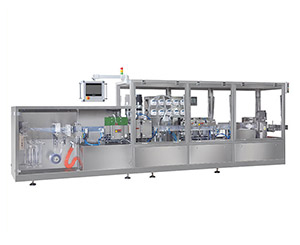

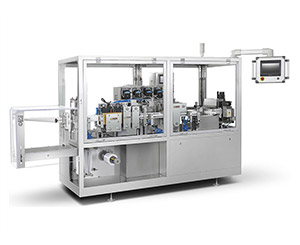

Syrup filling machine is a filling machine that is specially designed for new oral liquid easy-pull bottle.It is composed of a bottle washing and drying machine and a filling and splitting machine, which can automatically complete the bottle washing, drying, filling and sealing of the oral liquid.

The syrup filling machines have many characteristics, for example, filling capacity, preventing dripping, high filling accuracy; frequency conversion stepless speed regulation, adjustable production speed, different production speeds can be selected; can automatically display the counting function; stable performance, easy maintenance.

In addition, you need to add the lubricating oil into all the lubricating sites, rotating the machine by using the handle, checking the machine whether it is running in the correct direction, and the machine must be grounded.

Before using the equipment, you need to do a good job in the relevant adjustment work. You need to adjust the perfusion component. The function of the perfusion component is to make the liquid pass the drug dispenser, the one-way valve, and the needle to be delivered to each easy-to-pull bottle in time.

The needle must enter the bottle mouth properly, and the filling time must also to be appropriate.

"The side cam A can be adjusted to rotate forward or reverse so that the needle is inserted into the bottle mouth as soon as the empty bottle enters the toothed position.

And the needle is lifted before leaving the toothed position." The equipment personnel said that for the adjustment of the filling time, the cam B can be adjusted. Turning the adjustable needle forward or reverse into the bottle mouth begins immediately and stops filling before the needle leaves the bottle mouth.

Additionally, the feeding half should be adjusted, and the bottle blocking plate A on the feeding half should be adjusted upward to shorten the bottle feeding stroke; if it is adjusted downward, the bottle feeding stroke should be extended.

Adjust the positioning bottle position left and right to align the bottle position when the movable teeth are running, so that the bottle can be smoothly fed into the positioning teeth.

For the adjustment of the upper wall, when rolling bottles of different specifications, you just need to put the bottles of this specification on the tray, holding the cross arm with one hand, and loosen the nut on the left side of the cross arm with the other hand to make the cross arm drop or rise.

When you know the position of the capping head and the bottle cap about 20 mm, tighten the nut, and then use the random wrench to close the support ring to the cross arm and then lock the support ring.

When the operator wants to adjust the V-shaped block, he can put the bottle into the lower V-shaped block, loosen the two screws on the support block, and move the bottle and the lower V-shaped block together until the capping head is in contact with the lower V-shaped block. After the caps are aligned, tighten the two screws on the V-block.

There are also many points to pay attention to when adjusting the capping head. If the cap is not rolled tightly, unscrew the capping head locking nut and unscrew the capping head counterclockwise, and then tighten the upper fixing nut.

The lid is rolled too tightly, and there is a phenomenon of rotary cutting of the bottle cap. You need to unscrew the locking nut of the upper rolling lid head and enter the upper rolling lid head in a clockwise direction, and then lock the upper fixing nut.

If the lower edge of the bottle lid is not tightened tightly, the eccentricity of the three cutter heads can be appropriately adjusted according to the actual situation.

It is also necessary to pay attention to the maintenance of the syrup filling machine. The machine must be kept clean, and it is strictly forbidden to have oil stains, liquid medicine or glass debris on the machine to avoid damage to the machine.

The specific maintenance work is as follows:

First, because the syrup filling machine is a product with a high degree of automation, you should pay attention to the uniform size of the easy-to-pull bottle, bottle pad and bottle cap when using the machine.

Second, before the equipment is running, it is necessary for you to use the crank handle to rotate the machine whether there is any abnormality in its rotation.

Third, if you need to adjust the equipment, you should pay attention to the proper use of tools, and it is strictly forbidden to use too large tools or excessive force to remove parts to avoid damaging the parts or affecting the performance of the machine.

Fourth, you should clean the syrup filling machine regularly to ensure that there is no obvious oil stain, liquid medicine or glass debris on the machine, so as to avoid machine damage.

Fifth, during the production process of the syrup filling machine, the liquid medicine or glass debris should be removed in time.

Sixth, all parts of the surface of the machine should be cleaned once before the shift, and clean lubricating oil should be added to each activity department.

Seventh, regularly scrub the syrup filling machine, especially the places that are not easy to clean in ordinary use or blow it with compressed air.

Therefore, the machine should remove the liquid medicine or glass debris in time during the production process; before the shift, all parts of the machine surface should be cleaned once, and clean lubricating oil should be added to each activity department. It should be wiped once a week, and the places that are not easy to clean in normal use should be wiped or blown with compressed air.

With the rapid development of science and technology, China has also made certain achievement in the automatic syrup filling machine. Although there is still a certain gap compared with the advanced level of developed countries, its breakthrough in the technical bottleneck is still gratifying.

The oral liquid is easy to take and it can meet the patients’ needs so that it has a capacious market to develop. What’s more, with the continuous expansion of the market demand, the syrup has broad development prospects.

In the face of huge market opportunities, oral liquid filling machine companies should seize the opportunity, continuously introduce and cultivate new talents, and introduce advanced technologies at home and abroad, so as to promote the industry to achieve greater technological breakthroughs and meet the use of more people.

Don't forget to share this post!

Syrup Filling Machine Related Posts

Syrup Filling Machine Related Products

Syrup Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine