What You Need To Know About High Shear Mixer Granulator?

Dry method high shear mixer granulator is a new type of granulating technology. By contrast to the wet method high shear mixer granulator, it has the characteristics of less equipment use, low cost, small footprint and more environmental. Currently, the dry method high shear mixer granulator is widely used in pharmacy, food, chemical industry and other industries’ granular making. It is especially suitable for granulation of materials that are easily decomposed, failed or agglomerated when exposed to moisture and heat.

In terms of applications in the pharmaceutical industry, the dry method high shear mixer granulator can be used to produce pharmaceutical granules, traditional Chinese medicine pharmaceutical granules, granules for direct hits with antimicrobial substances, animal medicinal granules, powder preparations for dialysis, etc.

According to industry introduction, dry method high shear mixer granulator is commonly divided into 4 parts, powder supply, precompression, tabletting and whole granulating. Among this process, in the powder supply part, the dry powder entrance into the hopper through the feeding port. With the function of broken bridge device and pre-pressed vanes, the powder evenly enter into the horizontal screw feeder to ensure even screw filling and smooth feeding.

In precompression part, the powder is compulsively sent into the precompressed occlusal area by the horizontal screw. After that the precompression wokr has been done.

In tabletting part, the powder after tabletting will be sent into the rotary press roll room, it will be extruded into ribbon-like flakes under the action of pressure at both ends.

In the whole granulating part, the formed flakes enter the granulating device, and under the action of the granulating knife, they are crushed into granules to complete the granulation work.

At present, with the continuous development of automation and intelligent technology, intelligent dry method high shear mixer granulators start to appear in the market. According to manufacturers’ introduction, comparing to the traditional single channel granulating box, the intelligent high shear mixer granulator increases the are of the sieve mesh, which enlarges the contact area between the sieve mesh and the material under the condition of the same granulation frequency conversion speed. And it also can screen out more particles.

In addition, the increased volume of the granulation box can significantly improve the ability to handle sifted particles. While improving the speed of the three components of cutting, tabletting and feeding, it also effectively improves the overall production capacity of the dry granulator.

Besides, the dry method high shear mixer granulator enterprise constantly continues to carry out research on intelligent automation technology and promote the equipment for continuous production so that it can greatly improve the production capacity. The dry high shear mixer granulator built by it is automatically controlled by PLC, which can adapt to different requirements, and the yield is greatly improved.

With the quick speed development of pharmaceutical, food , chemical industry, the scale of their market has been expanded at the same time, so the demand for related equipment will also continue to expand. The dry method high shear mixer granulator has a bright development prospect. As far as the situation of our domestic dry method high shear mixer granulator, the market share of the domestic dry method high shear mixer granulator increases significantly. This also proves the strength of the domestic dry high shear mixer granulator from the side. However, with the continuous change of requirements, the domestic dry granulation equipment also needs to be constantly updated.

So, where will the dry high shear mixer granulator industry develop in the future? The industry believes that in the future, dry high shear mixer granulators will be required to meet the requirements of cleanliness and functional flexibility. On the one hand, creating a completely closed dry granulation system can reduce dust pollution in the production process, thereby reducing the risk of pollution.

On the other hand, the modular design will be more flexible, the entire granulation device can be disassembled with only a few tools, it is convenient to clean all the modular units, and the screws and pressing rollers can be easily replaced to suit different granulation tasks.

Specifically, in which aspects should the equipment be improved? The following aspects can be used as a reference

Materials saving

For granulating enterprises, only to save energy and resources, can you further realize the enterprise cost reduction. At present, some companies are doing research on the granulation mechanism of rotary granulator, including granulator, vacuum conveyor, hopper, circular vibrating screen, second vacuum conveyor, finished product barrel, return barrel, dust collector, collector Material barrel, raw material barrel, mixing barrel, control cabinet, third vacuum conveyor and fourth vacuum conveyor.

This high shear mixer granulator can automatically return the residue to the granulator for reproduction in real time and continuously while the granulator is working, which greatly increases the producing efficiency and the qualification rate. What’s more, it also succeeds in avoiding the materials waste and it can better remove the mixed material powder in the finished particles, and further reduce the waste of materials at the same time.

Production simplifying

With the fierce competition of particle industry, the mass production mode requires enterprises to simplify the production and improve production efficiency. This also prompts granulator manufacturers to improve equipment to meet market demand.

For example, Aipak has developed a new HLSG Series High Speed High Shear Mixer Granulator. The machine includes bottom trough, turning drum, feeding drum, connecting plate, discharge box, curved plate, bottom plate, top plate, feeding assembly, buckets, hoards, top covers, back panels, screens, slides, selection components and support components. It greatly simplifies production steps, saves time and effort, and greatly improves production efficiency.

HLSG Series High Speed high shear mixer granulator

Defective ratio reducing

For granulation production enterprises, the longer life of the product own, the more the production cost of the enterprise can be saved. However, according to customers' reports, during the use of the equipment, adverse reactions often occur, resulting in equipment failure and affecting production.

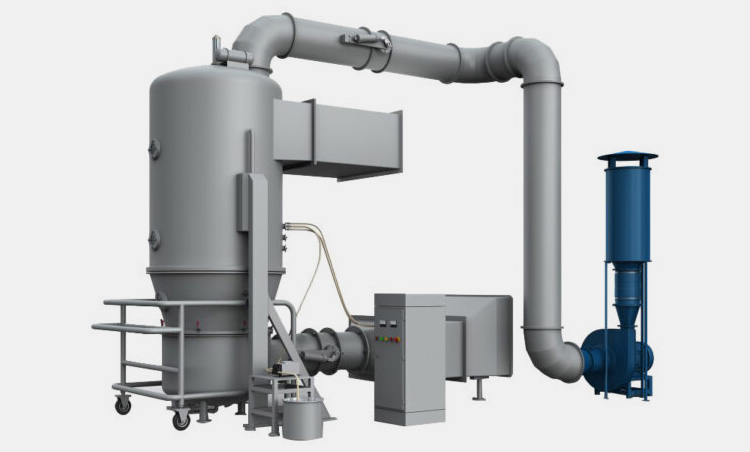

At present, the FL Series Fluidized High Shear Mixer Granulator Drier developed by a company has a bottom plate, a seat block, a column, a top block, a top frame, a pin, a connecting frame, a sliding plate, a sleeve, a spring, a second sleeve, a connecting plate, a flat plate, Swash plate and linkage assembly. In addition, the connecting rod assembly includes a second connecting plate, a seat piece, a second pin shaft, a swing rod, a third pin shaft, a second swing rod, a second seat piece and a fourth pin shaft.

It is reported that this newly outlet deceleration structure is able to automatically slow down the falling speed of particles and change the falling directions. It avoids collisions between particles, successfully reduces the defective ration and production cost.

FL Series Fluidized high shear mixer granulator Drier

Fitness Improving

For some small and medium-sized enterprises, the single use range of the high shear mixer granulator is not conducive to saving the production cost of the enterprise, so it is necessary to improve the adaptability.

For example, GHL Series High Speed High Shear Mixer Granulator, this machine includes base, box plate, second box plate, side plate, pallet, second side plate, support, bushing, second support, second shaft sleeves, pin sleeves, turning assemblies and pressing assemblies.

It is reported that the center distance of the new two pressing rollers can be adjusted according to the inner diameter of the ring die, thereby improving the adaptability, and the operation is simple and convenient, and the scope of application is expanded.

GHL Series High Speed High Shear Mixer Granulator

In addition to the above two directions and related methods, environmental protection has always been the direction that every industry, including the dry granulator industry, should strive for. Enterprises need to continuously reduce equipment energy consumption to meet the requirements of energy conservation and environmental protection.

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine