What You Must Know About Cartoning Machine For Medicine?

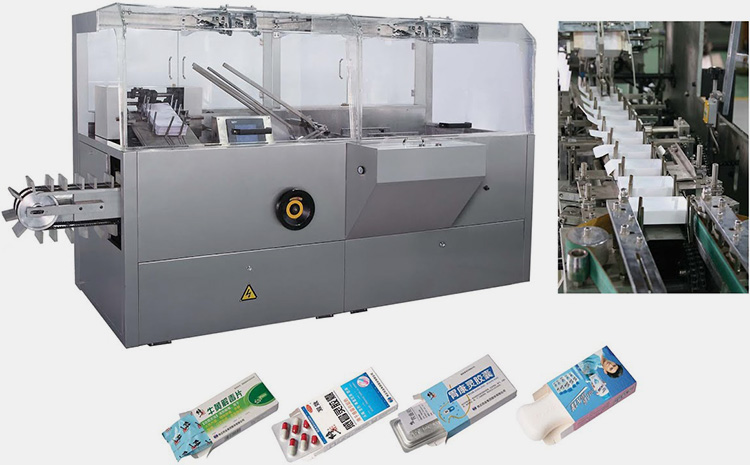

During the process of pharmaceuticals productions, in order to minimize the pollution caused by manual operation and reduce the costs, the cartoning machine for medicine had played a great effect.

It is a kind of packaging machinery, mainly suitable for the pharmaceutical industry. Its scope includes medicine plates, oral liquid, ampoule bottles and so on. In addition, the cartoning machine for medicine is also widely used in food, daily chemicals, hardware, auto parts, plastic and other industries.

In general situation,the cartoning machine for medicine can automatically complete the folding work of instructions, box unfolding, box packaging, printing batch number and box sealing.

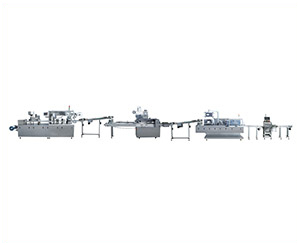

With the improvement of pharmaceutical machinery technology an the deepening of equipment automation, intelligence and humanization concept, the future of cartoning machine for medicine’s development is observed by many people and manufacturers.

What you need to know is that the speed of the world's advanced automatic packaging machines can reach 450 cases per minute. The box warehouse reserved by the cartoning machine is 1.5-2.0m, which can store about 800 boxes.

With the advancement of technology, the concepts of automation, intelligence and humanization have gradually deepened. You must analyze the development direction of the cartoning machine for medicine from the aspects of human-machine interface and control system.

The design of human-machine interface promotes the development of cartoning machine for medicine’s high speed, automation and personalization.

You know that a friendly human machine interface is a constant factor in every device. As far as the cartoning machine for medicine is concerned, the design of a human-machine interface not only needs to embody automatically intelligence, but also needs human considerations.

Because the human-machine interface is the intermediate medium between the user and the computer, the main purpose is to realize the effective of information exchange between the human-machine.

Therefore, in the user login interface, start interface, automatic operation interface, manual operation interface, parameter setting interface, alarm interface and data report, the designer should carry out a comprehensive and careful study.

Taking the manual operation interface as an example, a human-machine interface in the cartoning machine for medicine is generally divided into 3 operations, which include running control operations, mandatory operations, and normal operations.

Generally speaking, the running control operation is mainly aimed at the selection of staring, stopping and moving of the cartoning machine for medicine.

Mandatory operations such as strong suction box, strong suction drug board, etc.; and like the suction box, suction instructions, etc. belong to the normal class of operation. These operations are the content that designers need to cover in the design of manual operation interface.

If a company has a good design for the human-machine interface of the cartoning machine for medicine, actually it can achieve the requirements of high speed in box packaging, automatic operation and personalized interface to some degree. It also lets the customers supervise the process in real-time and proceed with dynamic management.

If more companies pay attention to this design, the automatic intelligence and humanization level of cartoning machine for medicine will be improved, and pharmaceutical companies will also obtain considerable benefits.

The control system design makes the cartoning machine for medicine more flexible and maintainable

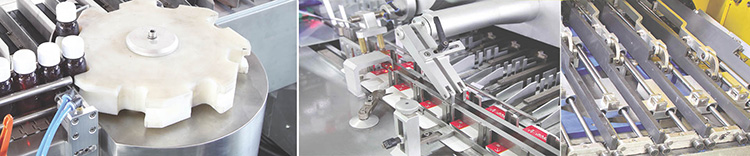

It is reported that the requirements for control system in cartoning machine for medicine mainly have four aspects. Automatic detection function. Even if the equipment is more automatic and intelligent, there will be mistakes, and drugs are used to save people.

Therefore, as for the automatic detection function, the cartoning machine for medicine needs to realize the effect of no drug board under the manual, no manual, no box suction, no carton alarm or stop, the product in the box is not in place to alarm or stop.

Second, the human-machine interface, many detailed instructions are proceeded in this aspect.

A brief summary is to be able to achieve effective information exchange between man and machine, data acquisition, equipment control, parameter regulation, signal alarm and other functions.

Third, the speed of box packaging. An important factor to test whether a device has equipped with rate is the speed. The same is true the cartoning machine for medicine.

Fourth, operation mode. For the drag board packing machine, the operation mode mainly includes automatic operation and manual operation.

If the relevant companies can study the control system, it can not only improve the performance, flexibility and maintainability of the equipment, but also optimize the operator's experience of the equipment.

There are cartoning machine for medicine manufacturers said, if they adopt the PC simulation in the R & D process, it can also shorten the equipment research and development in the middle and it is also easy to offline debugging of the program so as to improve the reliability of the whole system so that the cartoning machine for medicine can be better produced.

When you know the two major development directions of the cartoning machine for medicine, the most important thing is to deal with the most likely problems of the cartoning machine for medicine in daily use, that is, the problem of empty boxes and bad boards.

How to solve the problem of empty boxed?

First, the back end of the cartoning machine is equipped with a metal sensor, which automatically removes empty boxes;

Second, if an automatic checkweigher is installed, the difference in the weight of the medicine plate is still obvious, and whether there is an instruction manual can also be detected here;

Third, photoelectric induction can also be used, which is usually installed before the medicine board is put into the box, but there is one case that it does not work, that is, the (possibly empty) bag that needs a pillow bag cannot be completely excluded, and it can be changed to height detection. However, this part is prone to problems.

In addition, the situation of bad boards may be difficult to detect. Imaging can be used before entering the box, or it can be controlled by the aluminum-plastic process.

Bad boards can only be processed in an aluminum-plastic machine, and a camera can be added, but the price is different according to the accuracy.

In order to invest more high-quality and high-tech automatic cartoning machines, cartoning equipment companies must not only consider technical factors, but also comprehensively consider all aspects of the problem from the perspective of the system.

For example, it is necessary to consider not only the product itself, but also the impact on the system and the environment; it is necessary to consider not only the technical field, but also economic and social benefits, both the current and the long-term development.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine