What Stainless Steel Is Food Grade

When you do the cooking or taking bills, you may be aware of the stainless steel in your room. Stainless steel has a rapid development and is now widely used in our daily life thanks to its high strength, easy cleaning, anti-corrosion and cheap price. Your food is contacting with stainless steel frequently. So are they safe?

Can you assure the safety of stainless steel applied in your food or medicine processing? Will they release harmful substance which eaten by you and affect your body. Don’t worry, you can believe the stainless steel used in these field as it is all food grade and do no harm for your body.

So what stainless steel is food grade? What place does the food-grade stainless steel used. How to choose the suitable stainless steel for your use? They are not complicated questions and all can be answered in this post. Come on and read!

1.What Is Stainless Steel And Food-Grade Stainless Steel?

Stainless Steel Food Sealing Machine-Sourced:packagingstrategies

Stainless steel is a kind of alloy which make a combination of iron, silicon, carbon, manganese, nitrogen and so on. The qualified stainless steel should have chromium of more than 10.5% and carbon of more than 1.2%. Stainless steel has many different types but similar features of cheap, easy-cleaning, corrosion-resisting and strong.

Food-grade stainless steel is the type of stainless steel which used particularly for utensils of machine with high hygiene standard like sifter machine, bin mixer, tube filling machine and so on. It is safe and saves your worry of swallowing chemical elements with food, medicine or drink. You can see the widely use of food-grade stainless steel in kitchen, medicine industry and food industry.

2.Grade Of Stainless Steel

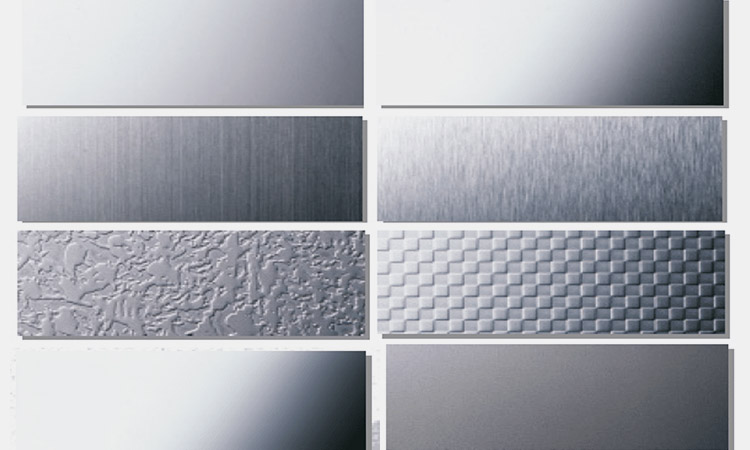

Types Of Stainless Steel-Sourced:aspillagahornauer

You can find the various grade system of stainless steel like, British standards, international organization for standardization, European standard, German standard, Chinese standard. The grading system gives little information about element composition. And here are some common stainless steel grades.

| Grade | Applying field | Feature |

| 301 | Automobile, construction,aerospace and other field. | l It composed by 17% chromium and 7% nickle basically and has three levels of hardness for choose. |

| 302 | Automobile, jewelry, construction and other field. | l It composed by 18% chromium and 8% nickle basically and can resist oxidizing environment and organic acid. |

| 303 | Transporting, machinery, aerospace and other field. | l Its composition is similar to 303 stainless steel and be applied to parts which are heavily machined for its highly-resisting. |

| 304 | Food, household, construction and other field. | l It composed by 9%-11% nickels and 18%-19% chromium. It’s most common and used in food industry for its durability, stability and safe. |

| 305 | Electrical, textile, chemical and other field. | l It composed by 18% chromium and 8% nickel basically. It accepted low rate of hardening work and is nonmagnetic. |

| 309 | Paper, thermal treating, construction and other field. | l It is austenitic stainless steel type and is thus nonmagnetic. But it has great resisting for corrosion, heat and oxidation. |

| 316 | Food, laboratory, ship, textile and other field. | l It is generally composed by 16%-18% chromium, 10%-14% nickel and other elements like carbon and molybdenum. It has higher price but safer. |

| 317 | Paper, chemical, textile and other field. | l It has low carbon and better corrosion resisting ability compared with the same 300 series stainless steel. |

| 321 | Aerospace, chemical, construction and other field. | l It has the adding or titanium and niobium and is thus stronger. The corrosion resistance is similar to 304. |

| 403 | Machinery, precise parts, power generation and other field. | l It has chromium joined greatly for its composition and make excellent resisting for corrosion and oxidation. |

| 405 | Ship, transporting, construction and other field. | l It is particularly used for welding and can hardly get hardened when get cooling from high temperature. |

| 410 | Machinery parts, surgical instruments, kitchen utensils and other field. | l It is composed by 11.5%-13.5% chromium. It can be processed though has hardened. |

| 416 | Precise parts, motors and other filed. | l It can be processed most easily as free-machining material. But its weldability is not outstanding. |

| 420 | Food industry, machinery industry and other field. | l It has the 12% chromium basically and can be processed by various thermal treatments and welding. |

| 430 | Kitchen appliance, surgical instruments, hand tools and other field. | l It is composed by 16%-18% chromium and other elements like carbon or nickle. The low joining of nickle and molybdenum make it cheaper. |

| 440 | Surgical instruments, machine parts, hand tools and other field. | l The high percent of carbon in 440 stainless steel makes it strongest, hardest and best resisting after heat processing. |

3.What Stainless Steel Is Food Grade?

The stainless steel has so many different grade, but the type specially of food-grade is rare. Here are the food-grade stainless steel types.

304 stainless steel

Product Of 304 Stainless Steel-Sourced:nxrproducts

304 stainless steel is the material most frequently used in kitchen. The higher percent of chromium and nickle endowed it bright and neat appearance. It is thus easy cleaning and maintaining. Your kitchen may has the prep tables, utensils and flatware as 304 stainless steel. It may change its features when contacting salt or chlorides.

316 stainless steel

Product Of 304 Stainless Steel-Sourced:solaireinfraredgrills

316 stainless steel used in kitchen and has no restriction on resisting salt, chlorides and other chemical elements. The better resisting made it price higher and application field wider. You may have cookware, kitchen appliance or grills as 316 stainless steel.

420 stainless steel

Product Of 420 Stainless Steel-Sourced:udolife

420 stainless steel is the hardest and strongest type of stainless steel used in kitchen and food field. It has high level of chromium which makes great corrosion resisting ability. Its hardness, magnetic property and corrosion resistance made it ideal material for blade of food-related machines.

430 stainless steel

Product Of 420 Stainless Steel-Sourced:ntsmart

The less participation of nickle decrease its price but the general chromium level in it proves the strength of it. Its corrosion resisting ability is not that good and may easily affected by acid or sulfur. You may see their application in less corrosive places like buffer line, prep table or flatware.

4.Where Can Food-Grade Stainless Steel Use?

Food-grade stainless steels are used in many places. As there is need of contacting products with steel, there is the need for food-grade stainless steel.

Pharmaceutical industry

AIPAK Capsule Filling Machine

Pharmaceutical related machine has the stricter request on material use. The applying material should be strict, safe and stable for the high hygiene standard of pharmaceutical industry. You can find the vial filling machine, blister packing machine, tablet counting machine and the frequent pharmaceutical machine with food-grade stainless steel use.

Food packaging industry

Vacuum Packaging Machine-Sourced:jawfeng

Food-related machines like crusher machine, sifter machine, bin machine, vacuum emulsifying mixer, tube filling machine and stick packing machine have a great need for food-grade stainless steel which stand the corrosion of certain level of acid or other friction. The suitable adoption improves your efficiency greatly.

Liquid filling industry

AIPAK Ampoule Filling Machine

Liquid filling machine is frequently used in our beverage filling, cosmetic product filling and any liquid has filling need. It also adopts food-grade stainless steel for its high efficiency, nice precise and great hygiene. Your lotion,essence, ampoule, eye drops are filled by this kind of machine.

Semi-solid processing

AIPAK Suppository Filling Machine

Semi-solid products are ointments, pasta, creams and so on. Its packaging has a great requirements in pollution-free environment. Food-grade stainless steel makes the outstanding job in cleaning and maintaining hygienic environment. The adoption for semi-solid processing in tube filling machine and suppository filling machine benefits manufacturing greatly.

Solid processing industry

Aipak Granulator Machine

The solid processing is needed in many industries. You have flour, capsules, fertilizer which all need solid processing in our daily use. The solid processing machine like crusher machine, sifter machine, granulator machine and so on which applied the food-grade stainless steel is more durable, stable and thus make better performance in these places.

Nutrition packaging

AIPAK Effervescent Tablets Packaging Machine

The varied nutrition products like vitamin, gummy, popping boba, effervescent tablets and so on have the different features and need extra care in its packaging. Food-grade stainless steel is so adjustable and can thus applied in nutrition packaging for its fluent and efficient processing and packaging.

5.The Benefits Of Using Stainless Steel In Food Industry

The widely use of food-grade stainless steel in food and pharmaceutical industries showed you the outstanding advantages of it in this field. Its shining tips are as follow.

Corrosion resistance

Corrosion Resistance-Sourced:lingayasvidyapeeth

Food-grade stainless steel is particularly invented to make rust-free and corrosion resisting material. The adding of chromium and molybdenum is the key of its corrosion-resisting ability. This is particularly for kitchen use as it is safe and keep appliance clean.

Easy-cleaning and maintaining

Stainless Steel Cleaning-Sourced:blueland

The bright and smooth appearance of a material is of course easier to clean and maintain compared with the rust and rough appearance. Food-grade stainless steel is the former one and can save you much energy in cleaning and maintaining.

High strength

Stainless Steel Strength-Sourced:chemsealinc

Food-grade stainless steel is forged with extremely high strength. It can hold the weight of bulk of food and can also run the huge and bulky machines. The bulky and strong material is the solid foundation of food or pharmaceutical industry.

No-reactive surface

No-Reactive Surface-Sourced:silcotek

Stainless steel isn’t all stable and make no reaction to any elements. They may change their features for acid, sulfur or oxidation. But food-grade stainless steel, which has the further invented and forged, has stable feature and makes no reaction to the above factors.

Low cost

Low Cost-Sourced:stock.adobe

Food-grade stainless steel has so many benefits and low price. In a long run, you can save a lot money if you adopted products of stainless steel, as its features reduce the maintaining cost greatly.

6.Does Food-Grade Stainless Leash Chemical In Using?

Chemical Leashing-Soured:foodnavigator

Stainless steels are non-toxic and has no affect in pharmaceutical or food industry use. It won’t leash chemicals in the application. But when it used as container or cookware, the contacting with concentrated acid, sulfur or nitric may induce the release of nickel or chromium. But the leashed chemical is too little to affect your body.

Food-grade stainless steel is safe for most people in most condition. It will leash enough chemicals to affect your body only if it contacts the extremely concentrated acid, sulfur or nitric. And it won’t affect you as you won’t treat your food-grade stainless steel with it.

7.How To Choose The Most Suitable Food-Grade Stainless Steel?

There are various food-grade stainless steel type for you. Are you confused by the complicated choose? Here are the simplified selection guide for you.

Feature

Stainless Steel Feature-Sourced:bullionpipe

The various food-grade stainless steels, though have the same main type, showed different features. The strength, corrosion resisting ability and magnetic features all varied. 316 stainless steel which stand sulfur, acids and alkalis and 410 stainless steel which is normal in this field, which is your expected features.

Application

Stainless Steels Application-Sourced:alroys

What industry you are in? What kind of products you made? If it’s about the blade parts of machine, you should get the food-grade stainless steel with greater strength and sharper features. If it’s about tableware or flatware, the material you adopted should has excellent ability in resisting corrosion.

Budget

Budget-Sourced:educause

Price of food-grade stainless steel varied. 430 stainless steel is cheaper than 316 stainless steel. In appropriation, you can take 430 stainless steel for using.

8.What You Should Care When Using Food-Grade Stainless Steel?

The food-grade stainless steel can’t keep its stability with no care. You can prolong the life of your food-grade stainless steel with great care.

No steel brush cleaning

Steel Brush-Sourced:sandpaperamerica

Steel brush is widely used for deep cleaning which can clean the hard-removing or embedded residues. But the steel brush cleaning can break the surface of food-grade stainless steel and affect it performance.

Temperature limitation

Melting Stainless Steel-Sourced:marlinwire

Food-grade stainless steel is strong but not invincible. Its melting point is high enough for most food processing need. But the extreme cold temperature can break or wrap it easily. The material become fragile in that condition.

Welding affection

Welding Stainless Steel-Sourced:workshopinsider

You should adopt the precise welding methods as the normal one will destroy the oxid layers and change the features of food-grade stainless steel.

Right maintenance

Stainless Steel Maintenance-Sourced:grove

Keep your food-grade stainless steel in the new and suitable condition can prolong its life. The most easy and safe way of cleaning your food-grade stainless steel product is clean or dry it with damp cloth by water or food safe stainless steel cleaner. The frequency and using material depends on the condition.

Conclusion

What stainless steel is food-grade? After reading this post, I believe you must have your own answers. The application of food-grade stainless steel affects most of our family, the deeper understanding of it will benefit you in using and making. If you have any other questions, don’t hesitate, contact us now!

Don't forget to share this post!

Vacuum Emulsifying Mixer Related Posts

Vacuum Emulsifying Mixer Related Products

Vacuum Emulsifying Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours