What Kind Of Crushing Equipment Should Be Used To Crush Hard Materials?

Recently, I saw someone a forum said: "the company trial production of a new variety of API, after drying, the completed material is as hard as stones, with a portable crusher effect is very poor, with a swing crusher machine and crusher have tried, but also still not." So he asked, there is no good crushing equipment recommended?

Regarding this, some experts replied, "so hard, or first from the front of the crystallization process to find the cause, so hard will not affect the solvent residue ah."

There are also people who believe that the use of fluidised bed-to-jet airflow crusher to crush harder materials works well. It is recommended to use a crusher to crush and then use a vertical screenless crusher to crush.

Others said that the granularity requirement is not too big, you can consider hammer crushers, which are cheaper than airflow; also, you can pass a sieve to see before drying, and it may not be so hard after drying.

So, for the above-mentioned several crushing equipment, the difference between which in the end?

Portable crusher

Portable crushers are easy to carry. However, because of its small output, it is suitable for individuals, families or small shops.

Swing crusher

The swing crusher has a precise structure, small size, light weight, high efficacy, no dust, clean and hygienic, easy to operate, beautiful shape, and both power saving and safe, can quickly complete the coarse and fine powder, so that the production of drugs and other drugs to meet GMP requirements, suitable for small batches of Chinese medicine, precious herbs and other materials crushed. However, it is not convenient to carry.

Pulveriser

This kind of crusher is suitable for pharmaceutical and other industries, and can process hard and difficult to crush materials, including the crushing of Chinese herbs, etc. It can also be used as a supporting equipment for the pre-processing of micro crushers and ultra micro crushers. It has the advantages of low working noise, high efficiency, reliable working performance and product quality, safe operation, drug hygiene and low loss.

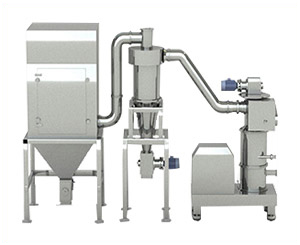

Fluidised Bed Collision Airflow Pulveriser

The airflow pulveriser has a wide range of applications and a high fineness of finished product. Typical materials that can be pulverised are: super hard diamond, silicon carbide, metal powder, etc. As this pulveriser can be made into an inert gas protected machine by changing the air source from ordinary air to inert gases such as nitrogen and carbon dioxide, it is also suitable for the pulverisation and classification of flammable and explosive materials, such as oxidation. However, the cost of this equipment is relatively high.

At present, the market airflow mill is mainly divided into flat airflow mill, fluidised bed to spray airflow mill, circulating tube airflow mill, to spray airflow mill, target airflow mill several types, and the relevant people mentioned the fluidised bed to spray airflow mill is more widely used.

Hammer mill

It is understood that the hammer mill is a necessary equipment for the pre-production of pharmaceutical and food industries. It has a wide range of versatility, can adjust the fineness of the crushing, with high production efficiency, low energy consumption, the use of safety, easy maintenance and other advantages, so it has been favoured by all walks of life.

The hammer stone crusher mainly relies on the impact effect to crush the material. Its working principle is that the material into the hammer mill, suffered the impact of the high-speed rotary hammer head and crushed, crushed materials from the hammer breakers hammer head to obtain kinetic energy, from the high speed to the frame body baffle, screen bar, and at the same time the material hit each other, was crushed several times.

Materials smaller than the gap of the screen bar will be discharged from the gap; individual larger materials, will again experience the impact of the hammer head on the screen bar, crushed by grinding and squeezing, the material is hammer broken machine hammer head from the gap, so as to obtain the required size of the product. Hammer crushers on the market are relatively inexpensive.

Don't forget to share this post!

Crusher Machine Related Products

Crusher Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine