What Is Unit Dose Packaging?

With the development of modern medical care and the continuous improvement of people's consumption levels, unit dose packaging has begun to emerge and the demand continues to increase.

Unit dose packaging is not only widely used in the medical industry, but also has certain applications in the food industry and chemical industry. Such packaging solutions are lightweight, environmentally friendly and highly efficient for today's consumers.

Unit Dose Packaging-sourced: packworld

You may be reading this article and wondering whether your product should use unit dose packaging. Don't worry, explore this article - what is unit dose packaging, to help you explore the possibilities and find the corresponding answers.

1.What Is Unit Dose Packaging?

Unit Dose Packaging-sourced: auburnrx

Unit dose packaging means the packaging that is designed to hold a quantity of certain product intended for administration or use as a single dose. It is widely applied in the pharmaceutical industry, food industry, chemical industry and daily cosmetics industry.

This packaging is widely available including sugar, preserves, seasonings, etc. in food, as well as various skin care products, makeup, medicines, beverages, supplements, etc. in supermarkets, pharmaceuticals, and cosmetics stores. The unit dose packaging provides specific products in convenient, single sizes for consumer use.

For businesses and consumers, the unit dose packaging solution has more advantages than other packaging methods. This packaging method can increase market penetration and snipe consumer preferences. For consumers, this packaging method means more convenience, portability and less waste.

2.What Are The Applications Of Unit Dose Packaging?

The unit dose packaging solutions are ubiquitous and widely used, bringing great convenience to consumers and reducing waste to protect the planet.

Pharmaceutical Industry

Pharmaceutical Industry-sourced: quora-Kurt Wideski

In the pharmaceutical industry, the unit dose packaging means that the packaging of individual doses of a drug in containers which preserve the identity and integrity of the drug from the point of packaging to administration and which are properly labeled pursuant to rules of the board.

Oral Solids

Oral Solids-sourced: aphenapharma

The unit dose packaging in oral liquids includes blister packages, strip packages and pouch packages.

The front of the blister packages has an opaque and non-reflective backing. This flat package facilitates the printing of tablet information. The reverse side is a transparent blister, allowing patients to see the contents clearly.

The strip packages are the flexible and thin packaging mostly made up of plastic, aluminum or paper. They are mostly used in pharmaceutical industry for performing packing of pills, tablets and capsules.

Paper Packages-sourced: amerilabtech

The pouch packages are opaque and non-reflective on one side. This kind of packaging makes it easy for you to tear from any point or multiple locations. The serial number on the packaging facilitates patient traceability.

Injectable

Injectable-sourced: europeanpharmaceuticalreview

The unit dose packaging in injectable is compact in design and convenient in size. It is generally measured in milliliters and is suitable for calibration. Injectable built-in space allows for the addition of additional medications.

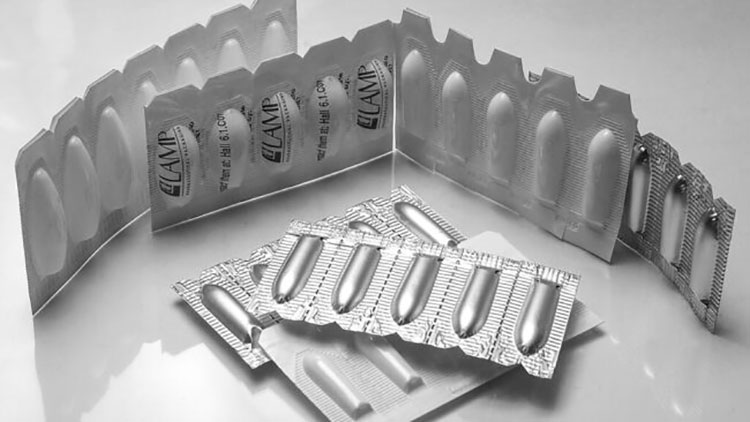

Suppositories

Suppositories-sourced: researchdive

Suppositories are the advanced dosage form intended for effective and efficient delivery of drug into the body of the patients with the unit dose form. They are given to the patient through the openings of the body other than mouth such as vagina, urethra or rectum.

Food Industry

Food Industry-sourced: sarongpackaging

The unit dose packaging is everywhere including in restaurants (sugar, preserves and condiments), supermarkets. They provide specific product sizes and sizes for food products which is convenient for consumers to choose, use, store and carry.

Powdered Drinks

Powdered Drinks-sourced: cingm

The unit dose packaging of powdered drinks provides consumers with a meal or one-time dose that can be easily poured into a cup or water bottle especially for infant formula, the amount of brewing can be precisely controlled.

Condiments

Condiments-sourced: landpack

The unit dose packaging is common packaging for sugar, spices, salt, oil, vinegar, and sauces. Consumers like the portability of unit-dose packaging.

Snacks

Snacks-sourced: nayazvariety

Many samples, prepared dishes, etc. favor the unit dose packaging. For example, chocolate, biscuits, bread, nuts, dried fruits, bacon, soy products, jelly, etc.

Cosmetic Industry

Cosmetic Industry-sourced: comimages

A large number of products in the cosmetics industry now use only unit dose packaging. Products include but are not limited to perfume, cologne, lotion, gel, cream, soap, shower gel, shampoo, facial cleanser, essence, eye cream, foundation, concealer, lipstick, etc.

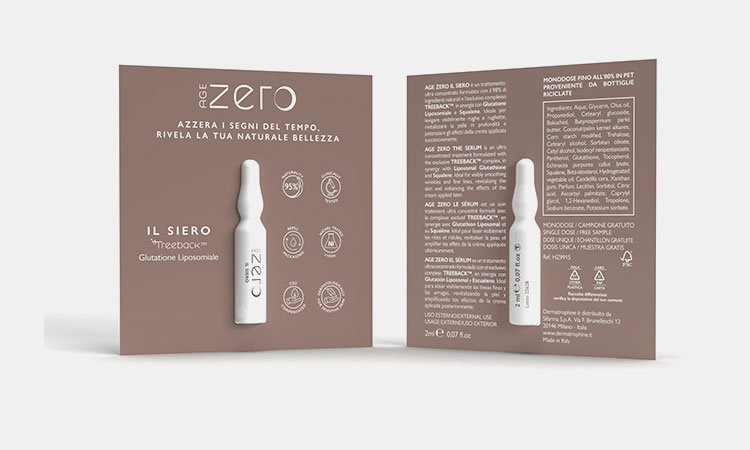

Skin Care Products

Skin Care Products-sourced: media

By selling in the form of unit dose packaging, consumers can open up sales channels through trial psychology. This unit dose packaging method is enthusiastically sought after by consumers.

Makeups

Makeups-sourced: rodpub

Makeups are the most popular cosmetics. By using unit dose packaging to enable consumers to find products that suit them, the waste caused by consumers choosing wrong products can be greatly reduced.

Daily Chemical Industry

Daily Chemical Industry-sourced: sodii

Daily chemical products are products that come into direct contact with the skin and body. This requires that products must be adequately protected from external sources and contamination.

The unit dose packaging protects and maintains the integrity of all ingredients. The main products include hand sanitizer, disinfectant, dish soap, shampoo, shower gel, conditioner, toilet cleaner, etc.

Disinfectant Products

Disinfectant Products-sourced: packmedia

Disinfectants products will react chemically with strongly alkaline products. Therefore, using unit dose packaging can ensure product integrity and improve safety in daily life.

Cleaning Products

Cleaning Products-sourced: newswire

The unit dose packaging of cleaning products are ideal for business trips or short stays.

3.What Are The Common Packaging Materials For Unit Dose Packaging?

The packaging materials used for unit dose packaging and bulk packaging are the same. But now most countries are promoting the use of environmentally friendly materials as packaging materials, although the cost is higher.

PP

PP-sourced: silganunicep

The material is lightweight, compact and protects contents from sunlight, humidity, temperature, air and packaging processing. Materials will not deteriorate during the shelf life of the contents. And no toxic substances are produced over time. Even when burned, no toxic gas will be produced.

PE

PE-sourced: silganunicep

PE is a high-quality unit dose packaging material. This material is well suited to thermoforming processing methods. You can customize unit dose packaging shapes and sizes with different requirements according to customer needs. It is also incompatible with the contents and will not cause any chemical reaction.

Aluminium Foil

Aluminium Foil-sourced: appletonwoods

Aluminum foil is a material that is directly rolled into thin sheets from metallic aluminum. It is widely used in medicine or drug unit dose packaging, especially pill or capsules thermoforming & blister packaging.

Bio-plastic

Bio-plastic-sourced: medicalplasticsnews

Bio-plastics are plastic materials produced from renewable biomass sources such as vegetable oils, cornstarch, straw, wood chips, sawdust, recycled food waste, etc. Its advantages are environmental protection, recyclability, degradability, and the ability to avoid plastic pollution.

Plastic Resin

Plastic Resin-sourced: terracastproducts

Plastic resin is widely used in blow-fill-seal unit dose packaging. It can change shape and hardness by heating and cooling. It can meet the needs of almost all unit dose packaging products.

4.What Are The Shape And Form For Unit Dose Packaging?

The unit dose packaging system is very important. When selecting the unit dose packaging, it is important to understand the product yield, volume and size of the drug. Different packaging requirements will bring unnecessary storage space requirements for packaging inventory.

For bag unit dose packaging, there are several choice for you:

V-shape Sachet

V-shape Sachet-sourced: v-shapes

Whether liquid or powder, using v-shape’s unit dose packaging optimizes the storage space of the contents while ensuring a longer shelf life. Thanks to the special "dropper" opening, it ensures better control over the dosage and distribution of the medicine.

Bar-shape Stick

Bar-shape Stick-sourced: cingm

The bar-shaped stick is packaged as a single dose, making it easy for consumers to pick up and apply. But it will not be sold as a unit to the end customer, but will require secondary packaging to facilitate shipping and restocking.

For bottle unit dose packaging system, you can choose:

Twist-tip Vials

Twist-tip Vials-sourced: lfofamerica

The twist-tip vials are cost-efficient unit dose packaging without any loss of product integrity. It is designed with a one-piece twist-off plastic squeeze cap. By twisting off the plastic squeeze cap, the contents of the vial can be poured out easily.

Custom Unit Dose Packaging

Custom Unit Dose Packaging-sourced: silganunicep

The custom unit dose packaging is the blow-fill-seal expertise to create your custom units. It can produce your custom unit dose packaging according to your requirements by using blow molding process.

For board unit dose packaging system, there are two for your choice:

Blister Packs

Blister Packs-sourced: capsulcn

The blister packs are widely used for protecting drugs against external factors such as humidity and contamination for extended periods of time. It is easy to print and peel off, has a non-reflective backing and provides UV protection to drugs.

Strips

Strips-sourced: lskbfoils

Strips are the unit dose packaging for drugs that continuous strip of flexible material, typically made of aluminum or plastic.

5.What Are The Types Of Unit Dose Packaging?

In the pharmaceutical industry, the unit dose packaging includes:

Thermoforming & Cold-form Blister

Thermoforming & Cold-form Blister-sourced: packagingeurope

The thermoforming & cold-form blister are all called as blister packaging which are widely applied in the pharmaceutical industry for packing the unit dose of tablets and capsules into the blister packs. They are made of aluminum foil, which is safe and effective. They can prevent ultraviolet rays and can be peeled off at will, making them very convenient for consumers to use.

Strip Packs

Strip Packs-sourced: capsulcn

Strip packs are the flexible and thin packaging mostly made up of plastic, aluminum or paper. The packing provides protection to these products and save them from environmental impacts like bacteria, fungi and other microbes with the unit dose.

Small Bottles

Small bottles are useful for performing the unit dose packaging of liquids and oils. They are widely used for various products including eye drops, disinfectant, iodine, saline, alcohol, glue, moisturizer, serum, eye cream, etc. It is designed with different sizes such as 5 ml, 10 ml, 15 ml, 20 ml, and so on.

Vials

Vials-sourced: kosmeticaworld

Vials are usually the glass & plastic vessel or bottle to store the unit dose or single dose of the medication in the form of liquids, powders, or capsules. They can be used as scientific sample vessels.

Ampoule

Ampoule-sourced: valmaticsrl

Ampoule are the small sealed vials that are used to contain and preserve a sample or a unit dose of product, usually a solid or liquid. Ampoule is usually made of glass or plastic. Modern ampoule is most commonly used to contain pharmaceuticals and chemicals that must be protected from air and contaminants.

Suppositories

Suppositories-sourced: farmores

Suppositories are the advanced dosage form intended for effective and efficient delivery of drug into the body of the patients with the unit dose form. They are given to the patient through the openings of the body other than mouth such as vagina, urethra or rectum.

In the food industry, the unit dose packaging includes:

Stick Packs

Stick Packs-sourced: aranow

Stick packs are the long and thin stick packaging pouches that can hold the unit dose for your use. They are widely used for packaging powders, liquids, semi-liquids, gels and so on. The narrow design can help people to hand-hold and use.

Sachets

Sachets-sourced: aranow

Sachets refer to a small closed container made of paper or plastic, containing a small amount of something with the unit dose or single dose, usually enough for only one occasion, like a small bag or packet. Its shape is basically rectangular or square. They can be applied for packaging different powders, condiments, liquids, and granules.

Flexible Pouches

Flexible Pouches-sourced: proampac

Flexible pouches are types of packages made from flexible materials that are elastic and are easily formed after they are filled with a product. The are single-use bags with your unit dose contents which are made of metal foil, plastic, and occasionally, paper. They are used for packaging everything from snack foods to industrial liquids.

Pyramid Bags

Pyramid Bags-sourced: pmpmachinery

The pyramid bags are perfect for filling and packaging the unit dose of snacks and treats including cookies, popcorns, chocolates, candies, nuts, dried fruits, and so on.

Cups

Cups-sourced: proampac

The cups for unit dose packaging are widely used for packaging of water, yogurt, milk, coffee, sauce, beverages, cream, etc.

In the daily cosmetics industry, the unit dose packaging includes:

Tubes

Tubes-sourced: vitalitymedical

Tubes or soft tubes are widely applied in the daily cosmetics industry for unit dose packaging of lotion, essence, eye cream, hand cream, body lotion, hand sanitizer, disinfectant, shower gel, shampoo, foundation, isolation cream, concealer, etc. This unit dose of tubes are often used as the trial packs or gifts, etc.

Pods

Pods-sourced: thespruce

Pods are often used as the travel or business packagings for holding your detergents.

This single-dose packaging method is very convenient for consumers to use during travel, business trips or trials. Because it is very portable, lightweight and has a small dosage, it is very suitable for short-term use. High utilization efficiency and low cost.

6.What Are The Benefits Of Unit Dose Packaging?

In the medical context, the unit dose packaging provides many benefits for convenient and accurate administration of medication regimens:

Dosage Testing and Compliance

Dosage Testing and Compliance-sourced: biobide

Reduces errors or missed doses to ensure dose detection and dose compliance. Each pill or capsule is individually packaged in a blister pack, making it easy for you to track and manage your medication intake.

Convenience and Accuracy

With unit dose packaging, you can easily maintain your medication regimen. Your medication plan can be customized according to your own needs, including daily or different time dosage requirements. Printing dates on packages can improve medication accuracy.

Protective Effect

Protective Effect-sourced: thedieline

Each pill or capsule is protected in its own blister and does not come into contact with air until it is taken. Unit dose packaging can always protect the potency and effectiveness of drugs.

By choosing unit dose packaging, you can simplify medication administration, reduce the risk of errors and ensure prescription compliance. It provides a convenient and accurate solution to your medication regimen.

In the food industry, the unit dose packaging can bring you a better experience:

Longer Shelf Life

Longer Shelf Life-sourced: epicurpharma

Compared with traditional bulk packaging, the unit dose packaging has a longer shelf life.

Easy to Transport

The unit dose packaging takes up less storage space and is easier to transport.

Humanize

Product packaging should always serve consumers rather than for sales purposes. The design of the unit dose packaging is more humane and aims at human needs.

In the cosmetics industry, the unit dose packaging can bring you:

Portable

Cosmetics are used frequently, so there is a high demand for portability. The unit dose packaging can provide precise dosage for each time or daily need of cosmetics, making it easy to use.

Reduce Waste

Reduce Waste-sourced: emagazine

The shelf life of many cosmetics begins to count down after they are opened. Generally, they must be used within 6 months after opening. The unit dose packaging is convenient for users to use up within the shelf life and can reduce waste.

Trial Experience

The most important thing when it comes to skin care products and cosmetics is to try them out. Because it is a product that directly contacts the skin, and everyone's skin type is different, the products and effects they require are different. The unit dose packaging brings a great trial experience to consumers.

In daily chemical industry, it can bring you the benefits of:

Hygiene

Hygiene-sourced: futurelearn

The unit dose packaging provides consumers with a safe, hygienic product until it is used and ensures that the product has not been tampered with.

Saving

Accurate dosage can bring consumers a precise dosage experience that is suitable for each need, and can save materials and reduce waste.

Storage

Take your product anywhere and store it where you need it. The unit dose packaging can reduce storage and is easy to carry.

7.What Are The Equipment Used For Unit Dose Packaging?

The equipment used for unit dose packagings differs from contents and products you need to pack. There are various machines that can fulfill your different needs:

Thermoforming Machine

The thermoforming machine can transform different types of transforming materials like plastics etc into a proper shape usable item. They are widely used for capsules and tablets packaging.

Thermoforming machines use a heating process to mold different types of materials so, that you can easily pack different kinds of items in those products.

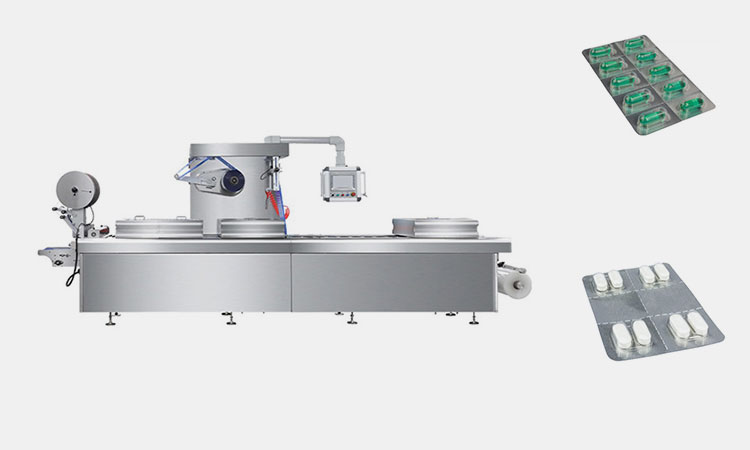

Blister Packaging Machine

Blister packaging machines are automated systems designed to fill blister packs with products and seal them, creating a secure package. The blister pack is created by forming a cavity on the plastic substrate, typically using a thermoforming process. Most of the tablet blister packs and capsule blister packs are packed with the blister packaging machine.

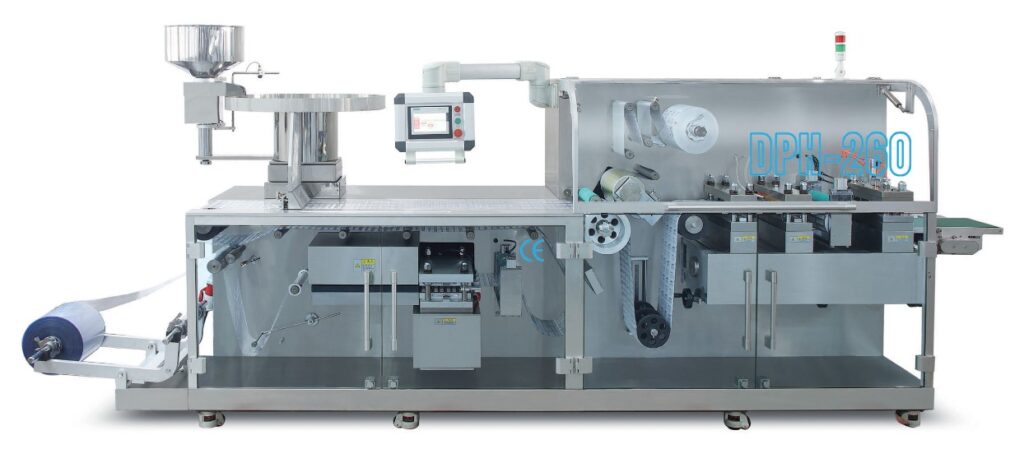

Strip Packing Machine

Strip packing machines are mostly used in pharmaceutical industry for performing packing unit dose or single dose of pills, tablets and capsules. Strip packing medication dosages to be enclosed between two sheets forming mostly of plastic or aluminum.

Other than pharmaceutical industry, strip packing machines are also used in confectionary, cosmetic and chemical industry.

Tablet Packing Machine

Tablet packing machine is specially applied for filling and sealing the tablets and pills in of food, medicine, chemical and agriculture into the unit dose packagings. Tablet packing machine adopts the automatic filling and sealing with the compound materials such as paper, aluminum foil, nylon, etc.

Sachet Machine

Sachet machine can pack the unit dose or single dose of different powders, condiments, liquids, and granules into the sachets. They are usually sealed on three or four sides.

The sachets are usually used for single-dose applications of multiple products such as instant coffee, condiments, medicinal powders, shampoos, face creams, etc.

Stick Packing Machine

Stick packing machine is designed for stick packing for producing stick packaging pouches automatically and fill your products into them, besides, the sealing and cutting operations are as well. They can perform the unit dose stick packaging with a variety of products such as powders, granules, liquids and pastes.

Triangle Bag Packing Machine

Triangle bag packing machine can quickly and efficiently fill contents into triangle bags. This machine can be used for a range of products, including powdered mixes, liquids, and granular materials into the unit dose of triangle packages. It can also handle different size bags, allowing for maximum flexibility in production.

Ampoule Filling Machine

Ampoule Filling Machine-sourced: AIPAK

Ampoule filling machine is mainly used for filling and sealing ampoule bottles under aseptic conditions with the unit dose packaging.

It adopts step-by-step transmission system to automatically complete the separation and feeding of bottles, forward nitrogen charge, filling of medicine, post nitrogen charge, preheating, wire drawing and sealing and other processes.

Suppository Filling Machine

Suppository filling machine can perform the unit dose of suppository packaging for preparing the shells of the suppositories and filling the drug material in them. They are widely applied in the pharmaceutical industry. This dosage form is given to the patient through the openings of the body other than mouth such as vagina, urethra or rectum.

Tube Filling Machine

Tube filling machines are widely used in the pharmaceutical, cosmetic, and food industries due to their high accuracy and speed of operation. They are applied for filling and sealing the ointments, creams, and pastes into the unit dose soft tubes efficiently and precisely.

8.Unit Dose Packaging VS Bulk Packaging

Whether to use unit dose packaging or bulk packaging has been a topic of ongoing debate in different industries. Many manufacturers do not use unit dose packaging because of cost, but using unit dose packaging overall can be safer and more efficient.

| Image | Unit Dose Packaging | Bulk Packaging |

| Concept | Designed to hold a quantity of certain product intended for administration or use as a single dose. | Refers to packaging and selling goods in large quantities rather than in individual or small batches. |

| Efficiency | l Eliminate assignment tasks from tedious pharmacy workload;

l Improves utilization and can be taken or used in divided doses without waste; |

l Increases the workload of the pharmacy, such as drug distribution, counting, repackaging, etc.;

l Reduces utilization rate and easily cause waste; |

| Costs | l Production process more cumbersome, uses more materials, and requires more machines and manpower;

l Consumes more, require more storage space, and cost more; |

l Production process is simple, uses less materials, and requires less human and machine involvement;

l Less consumption, less storage space required, and less cost; |

| Label Advantages | l Easier to identify missed doses by marking each dose unit;

l Enable better customer relations, inventory management and treatment outcomes; |

l Adopts a unified label management system, which will increase the pharmacy's management costs;

l Easy for patients to miss medication, thus affecting the effectiveness of the product; |

| Counterfeit | l Makes counterfeiting more difficult;

l Must be exactly the same as the medicine; l Identification through independent product barcodes, manufacturers, expiration dates and batch numbers can reduce or even avoid product counterfeiting; |

l Counterfeiting is relatively easy;

l Unified product barcode, manufacturer, expiration date and batch number; l The procedures in the production and packaging process of products are relatively simple, making it easy to produce counterfeit and illegal products; |

| Cost Saving | l Improves consumer and patient compliance because it is convenient to use and the dose is easy to identify;

l Improves cost-effectiveness and reducing long-term costs by preventing adverse events for consumers; |

l Easy for consumers or patients to forget to use or take the medicine, resulting in missed doses;

l Although the short-term cost is reduced, it increases the risk of use and produces adverse events, thereby increasing the long-term cost; |

Unit Dose Packaging-sourced: duraprohealth

Bulk Packaging-sourced: paxiom

Conclusion

Unit dose packaging is versatile and can bring huge benefits to companies and users. It can not only bring convenience to different industries. You have found the answer from this article "what is unit dose packaging". If you have more questions or you want to cooperate with such a packaging company, please be sure to contact us!

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours