What Is The Relationship Between Main Compression And Pre-Compression Of High-Speed Tablet Pressing Machine?

Have you noticed the different compression force and pre-compression in tablet pressing work? What is the relationship between main compression and pre-compression of high-speed tablet press? Do you want to know the reasons or want to know more about tablet pressing machine?

After reading this post, you may have all your questions about main compression and pre-compression force of high-speed tablet press answered. Besides, you will also know more about tablet pressing machine here. Come on and have a reading and you may become the processor in tablet pressing world.

1.What Is High Speed Tablet Pressing Machine?

AIPAK High Speed Tablet Pressing Machine

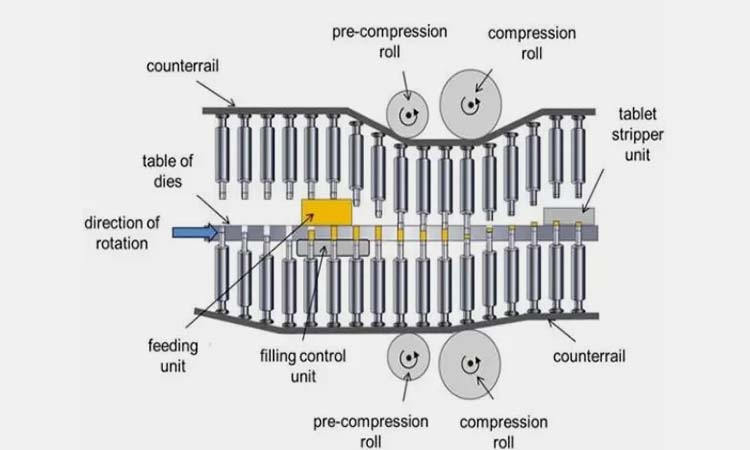

High speed tablet pressing machine is the machine which is applied for the manufacturing of tablets of various size and type. High speed tablet pressing machine is flexible and versatile and you may find its applying in pharmaceutical industry, chemical industry, supplementary industry and so on.

High speed tablet pressing machine is fully automatic and easy to operate. With the help of it, you can have the quick and reliable tablets production. The little adjusting of parameter and easy operating make the perfect tablet pressing work. High speed tablet pressing machine benefits us in a comprehensive way.

2.What Is Tablet Compression Forces And KeyCompression Force?

What is tablet compression forces and key compression force? Here are the comprehensive knowing about compression forces of high speed tablet pressing machine.

Pre-compression force

Pre-compression force is the tablet pressing process which began before the main compression force. The applying of pre-compression force helps exhaust air of medical powder which can help make the great preparation for the later tablet pressing work. Pre-compression force is light and may not make powder sticking.

Main compression force

Main Compression Force-Sourced:technotes

Main compression force is the main force applied for tablet pressing work. This force is strong enough for the tablet forming. It in some way decides the appearance of your tablets products. You should make the careful adjusting and inspecting of main compression force.

Post-compression force

Post-compression force is also an important step of tablet pressing process. This force proves the strength and completeness of your medical tablets. Post-compression force is also the important force for the whole compression force.

3.What Is The Relationship Between Main Compression And Pre-Compression Of HighSpeed Tablet Pressing Machine?

What is the relationship between main compression and pre-compression of high-speed tablet press?

Complementary functions

Complementary Functions-Sourced:yenchen

Pre-compression function

The main role of pre-compression is to perform initial compaction of the material before it enters the main compression stage. It can eliminate some of the air in the material, reducing the distance between the material particles and forming a more compact structure.

This creates favorable conditions for the subsequent main compression process. Pre-compression allows the material to be more easily compacted during the main compression, reducing pressure fluctuations in the main compression stage and improving tablet stability.

Main compression function

The main compression further compacts the material that has undergone pre-compression, achieving the required hardness, density, and size specifications, resulting in tablets that meet quality standards. Main compression is the key step in determining the final tablet quality, as the pressure applied directly affects various performance indicators of the tablet.

Interrelated pressure values

Pressure Values-Sourced:midwestinstrument

Generally, the pre-compression pressure is a part of the main compression pressure, typically ranging from 20% to 50% of the main compression pressure. The specific ratio depends on factors such as the material’s properties, particle size, flow, and the specifications and quality requirements of the tablet.

For example, for materials that are loose and flow well, the pre-compression pressure can be relatively low, perhaps 20% - 30% of the main compression pressure; for materials that are hard and have poor flow, the pre-compression pressure may need to be increased to 30% - 50% of the main compression pressure.

Mutual influence of pressure adjustment

Pressure Adjustment-Sourced:steamboatsprings-realestate

Impact of pre-compression on main compression adjustment

If the pre-compression pressure is insufficient, the material will require higher pressure during the main compression stage to achieve compaction, which could increase the load on the main compression system and may even cause the main compression pressure to exceed the equipment’s capacity or the material’s tolerance, leading to issues like tablet cracking or sticking.

Conversely, if the pre-compression pressure is too high, the material may become over-compacted during pre-compression which reduces the adjustable pressure range for the main compression stage and affecting tablet quality.

Feedback of main compression on pre-compression adjustment

Compression Adjustment-Sourced:bhagwatipharma

The compression effect of the main compression stage also affects the adjustment of pre-compression. If, after the main compression, the tablets exhibit insufficient hardness or disintegration, it may be necessary to increase the pre-compression pressure to enhance the initial compaction of the material.

If the tablets show cracking after main compression, besides checking the main compression pressure, the pre-compression pressure may also need to be adjusted to optimize the pre-compression effect and reduce internal stress concentration in the tablets.

Coordination of time and speed

Coordination Of Time And Speed-Sourced:pharmacy-machines

During the operation of a high-speed tablet press, the time and speed of pre-compression and main compression need to be coordinated. If the pre-compression time is too short or the speed is too fast, it may not fully achieve the intended effect of pre-compression.

If the pre-compression time is too long or the speed is too slow, it will affect production efficiency and may cause material accumulation at the pre-compression section. The time and speed of the main compression must also match with the pre-compression to ensure that the material is effectively and promptly compressed into tablets after pre-compression, resulting in stable tablet quality.

4.What Industry Can Tablet Pressing Machine Be Applied?

What industry can tablet pressing machine be applied? Here are the industry you may find tablet pressing machine applying.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:dezshira

Pharmaceutical industry is the industry which makes the frequent use of tablet pressing machine. You may find the pressing of tablets of various type and kinds. For the different size and shape, you can make the easy handling. In all, pharmaceutical industry makes the frequent adoption of tablet pressing machine.

Supplementary industry

Supplementary Industry-Sourced:consumerlab

Supplementary industry is booming in current market. Here are various medicine type in supplementary market. And the colorful and sleek tablets and pills are all made with your tablet pressing machine. The reliable tablets can help transfer the medicine with best effect.

Food industry

Food Industry-Sourced:ohnuts

You would never ignore the use of tablet pressing machine in food industry. Here are various candy you may seek the tablet pressing machine for help. Tablet pressing machine can make mint candy, milk candy and various candy with high efficiency and accuracy.

Chemical industry

Chemical Industry-Sourced:roseray

The great pressing ability can also be applied for chemical industry. For the representative chemical products like dish washing tablets, detergent tablets and so on, you may make the flexible and easy handling with tablet pressing machine.

5.How Can Tablet Pressing Machine Benefit You?

Tablet pressing machine makes the comprehensive benefits for you. And here are the main advantages.

Easy to use

Easy To Use-Sourced:support

Tablet pressing machine is easy to use. The simple filling of the essential parameter and the important feature setting can help you begin the tablet pressing machine. The easy operation can help you make the great and qualified pressed tablets products.

High flexible

High Flexible-Sourced:news.mit

You may apply your tablet pressing machine to make the various types of products. The high flexibility promotes the production of various types of products. The great flexibility can save you a lot in time, budget and energy.

Large production

Large Production-Sourced:thomasprocessing

You may have the large production from your tablet pressing machine. The high efficiency and automatic tablet pressing work help you deal with your large production in short time.

Quality prove

For the various tablets products, you can all have the quality of your tablet proved with tablet pressing machine. The tablets from your tablet pressing machine can have the hygiene, quality and many things proved there.

6.What Factors Affect Compression Force?

Compression force is so important in tablet pressing process. What factors affect compression force?

Powder properties

Powder Properties-Sourced:azom

Different powder makes different request on compression force. The chemical and physical feature of powder property make different affect for the compression force of your machine. You should make the serious inspecting of powder size, shape, flow and so on here.

Machine settings

The setting of machine on speed, dwell time and so on can also make effect on powder pressing force. For the suitable machine setting, you should make several try of machine settings for your suitable tablets setting.

Tablet formulation

Tablet Formulation-Sourced:nytimes

Tablet formulation covers the medicine powder, binder, excipients and so on. Different formulation makes different components which can also affect your tablet pressing machine’s compression force.

7.What Else You Should Pay Attention To While Pressing Tablets?

How to make the real qualified pressed tablets products? Here are the things you should pay attention to besides compression force while pressing tablets.

Formulation

Formulation makes the affect for your pressing tablets work. Different formulation covers different active pharmaceutical ingredients, excipients, filler, binder, lubricants and so on. You should thus pay attention to your formulation while pressing tablets.

Tablet pressing machine

AIPAK Tablet Press Machine

Tablet pressing machine decides the tablet pressing products quality. Tablet pressing machine with high quality, great efficiency and hygienic standard can help you make the reliable pressed tablets. The different condition of your tablet pressing machine should also be paid attention to for your tablets products manufacturing.

Manufacture environment

Manufacturing Environment-Sourced:theonpharma

Manufacturing environment should also be paid attention to while pressing tablets. Temperature and humidity make influence for your tablets pressing process. Both medicine feature and machine performance will be affected here.

Regulatory standard

The violation of your regulatory standard makes your tablets products forbidden in market. You should obey your regulatory standard for the smooth circulation of your tablets products in market. For different locals and place, there is different regulatory standard.

8.Why There Is The Rapid Growth Of Tablet Pressing Machine?

Have you ever noticed the rapid growth of tablet pressing machine in our current market? Have you ever wondered the reasons?

Technique developing

Technique Developing-Sourced:psi-software

With the developing of technique and pharmaceutical industry, here is the fast developing in the machines applied for medicine manufacturing. Tablet pressing machine should catch time and adopt new technique for the prove of your tablets products quality and effect. Technical developing makes great benefits and takes better quality for your medicine manufacturing.

New regulation

New Regulation-Sourced:cato

There is new and strict regulation in tablet pressing manufacturing and medicine manufacturing. The new regulation makes the best for people’s health and safety. And there are the machines which suit the new regulation for higher efficiency and more save on manufacturing cost.

More concern on medicine

After covid20, there is more concern on medicine safety and effect. There is thus the rapid growth on medicine manufacturing machine. The advanced tablet pressing machine can prove the products quality and effect. The more and more concern on medicine promote the developing of tablet pressing machines.

9.What Are The Common Support Equipment Of Tablet Pressing Machine?

For the more efficient tablets products manufacturing process, here are some equipment you may apply for the efficient work.

Bin blender

AIPAK Bin Blender

Bin blender is the type of machine which makes the even and efficient mixing of various types of powder and granules. The main components of tablets cover API, binder, filler, lubricates and so on. The even mixing of the various products is the base of qualified and reliable tablets products.

Tablet coating machine

AIPAK Tablet Coating Machine

You may have found the coating of some tablet products. But have you ever wondered the method of coating? Tablet coating machine is the reason. Coating can make the better appearance, taste and more stable and strong crust for the outside influence. And tablet coating machine can make the efficient and even coating work for your tablets products.

Tablet counting line

AIPAK Tablet Counting Line

Tablet counting line make the one stand work of counting tablets, packing tablets and so on. It saves your further energy in making the accurate counting and packaging work. For tablets or products of various size, shape and kind, tablet counting line makes the outstanding work. Tablet counting line usually applies bottle or sachet for help.

Blister packaging machine

AIPAK Blister Packaging Machine

Blister pack provides the packaging of better sealing, protection and storing. Blister packaging machine gives the reliable and qualified work of making the tidy, efficient and clean packaging. With the plastic or aluminum sealing part, your tablets products can maintain the best condition.

Cartoning machine

AIPAK Cartoning Machine

For sachet, bottle or blister, there is the need of making carton as the last step for better transportation, storing and sales. The cartoning machine can handle container of various size and shape. It can always fill products in carton with high efficiency. Cartoning machine makes series of work like carton folding, filling and sealing.

Conclusion

What is the relationship between main compression and pre-compression of high-speed tablet pressing machine? Do you have your answers? Now, you may have all your questions about main compression and pre-compression force of high-speed tablet press answered. For any problem or question, you can have no hesitate to contact AIPAK now!

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine