What Is IP Rating? Why It Is Important?

Not only you but machines are also susceptible to being damaged in a dusty environment. Electronic machines are designed for such places are varying with certain levels of protection that ensures your and the system’s safety. Just like cats, machines also don’t favor being prodded in water.

However, not every piece of equipment has an equal level of protection against the intrusion of solid or liquid objects. When you choose machinery not suitable for your working environment could lead to damage to the unit itself and also to your workers.

For this, industrial standards are developed such as IP Rating.

What is IP rating? Why it is important? This article is designed to describe the possible details of IP rating and its considerable importance.

Table of Contents

Ⅰ.What Is An IP Rating?

An IP rating is also known as ‘Ingress Protection Rating’ or ‘International Protection Marking’. This represents the capability of the product to withstand liquid and dust intrusion.

This is a two- digits system where its specification defines the protection rate associated with manufactured products.

The first digit represents the protection rate against solids, whereas the second digit represents liquids. A third letter describes other information that is most often not employed but ignored.

Moreover, an IP rating demonstrates the effectiveness of compact electrical enclosures. Such a system blocks the entry of foreign particles such as dust, moisture, liquid, or accidental contact.

Ⅱ.Why Is An IP Rating Important?

Many electronic products advertise "water-resistant" or "waterproof" features. But how do you know whether they are the same as they indicated? During deciding whether or not to install a component, the IP rating is highly useful.

The IP rating is critical when selecting to mount products in a dry and clean environment versus a damp and/or dusty one. It indicates the degree of protection provided. IP codes indicate the degree of protection provided to users from mechanical or electrical parts, as well as the degree of protection provided against dust, dirt, and other harmful foreign bodies.

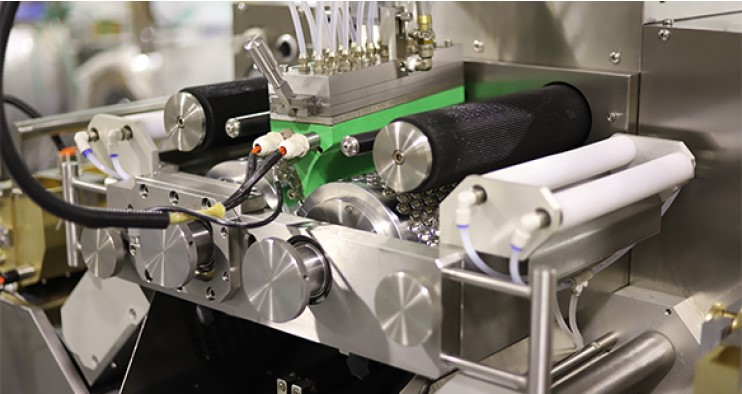

Ⅲ.What Types Of IP Ratings Are Found On Packaging Machines?

Pneumatic and electrical enclosures on most packing machines are IP Rated. Circuit boxes, cabinets, and any other enclosed construction that protects internal electrical and pneumatic equipment fall into this category. When exposed to solid objects or liquids, these components can misbehave, fail, or injure operators.

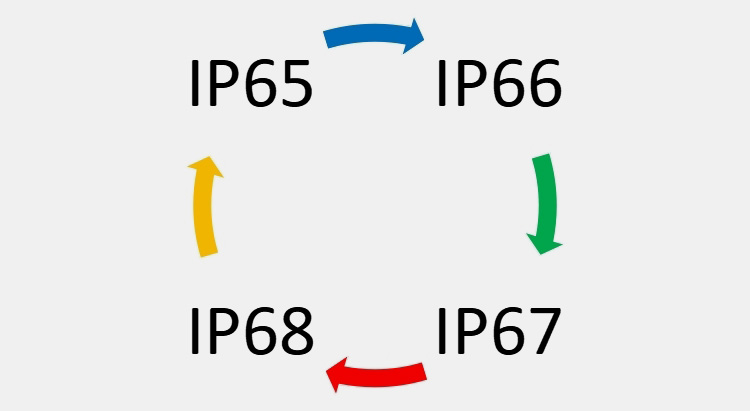

Packaging machines, for example, require an electrical cabinet to hold all of the electronic components necessary to power and run the machine. These cabinets are frequently assigned one of the following IP ratings:

- IP65: Dust-tight and resistant to low-pressure water jets

- IP66: Dust-tight and resistant to strong water jets

- IP67:Dust-proof and water-resistant for a certain time and depth.

- IP68:Dust-proof and waterproof to the point of submersion.

After the machine manufacturer carefully assesses the packing environment, the type of IP Rating required for packaging equipment enclosures will be selected.

Ⅳ.How Do You Read an IP Rating Guide Chart?

The IP rating chart contains a range of letters and numbers within it, each letter and number possessing its meaning. The IP ratings are frequently displayed in the format as shown in the figure or something similar.

In the IP rating guide chart, the numbers after IP denote the level of sealing, which might range from minimal protection to complete dust and water protection.

The first digit in the IP Rating will be a value between 0 and 6, indicating the degree of protection against solid object entry, the value 6 is completely sealed against dust. That isn't to imply that dust won't get into the gadget; nevertheless, it won't get into the device in sufficient quantities to cause damage.More simply, the first number indicates the degree of protection against solid object entrance. However, the second number represents the level of moisture resistance.

The IP rating's second digit will be a value between 0 and 8, indicating the level of moisture resistance at various intensities, angles, depths, and pressures of exposure or immersion.

FOR EXAMPLE:

In the IP65 rating.

- The first number is 6, which indicates the enclosure is dust-tight and denotes how resistant to solid particles a device is.

- The second rating is 5, which denotes the enclosure is water jet resistant.

In the IP rating code, the rating 1 and 2 employ dripping water and should protect your device from a little spill. Water sprayed onto the device at varied pressures for varying lengths of time is protected by numbers 3 through 6. Depending on how well the device performed.

Ⅴ.Explain An IP Rating Guide Chart?

A four-character IP rating is the most common format. There may be five in some exceptional circumstances. The first two letters, I and P, stand for the Ingress Protection, or how well it keeps things out. After IP letters, the first digit has a maximum value of 6, which indicates how well it protects against tiny solids (dust, sand, etc.). However, the second digit has a maximum value of 8, it represents the liquid or water resistance rating.

The below table is the rating guide chart which explains each number of the code, it would be referred to for the ratings of relative protection of electrical enclosures.

| IP RATING GUIDE CHART | |||

| 1st Digit: Solids | 2nd Digit: Liquids | ||

| Code | Explanation | Code | Explanation |

| 0 | Unprotected. No protection against solids or dust. | 0 | Unprotected. No protection against liquids. |

| 1 | Protection against solid objects greater than 50 mm. | 1 | Protection against drops of water |

| 2 | Protection against solid objects greater than 12.5 mm. | 2 | Protection against drops of water at a 15° angle. |

| 3 | Protection against solid objects greater than 2.5 mm. | 3 | Protection against drops of water at a 60° angle. |

| 4 | Protection against solid objects greater than 1.0 mm. | 4 | Protection against splashes from any angle. |

| 5 | Protection against ingress of dust sufficient to cause harm. | 5 | Protection against low-pressure water jets from any angle. |

| 6 | Dust-tight. Complete protection against ingress of dust. | 6 | Protection against powerful jets of water and rough seas. |

| 7 | Protection against submersion in water, 30 min. at a depth of 3 ft. | ||

| 8 | Protection against permanent submersion, up to a 13 ft. depth. | ||

Ⅵ.What Is The Significance Of IP Rating When Choosing A Packaging Machine?

The IP Rating of an enclosure is vitally crucial when choosing the correct packaging machine for the desired purposes, especially in the food or pharmaceutical business.

Dusty Working Condition

Will you prefer snacks or beverages packed in a dusty atmosphere?

Particulates generated when a product is in motion can create havoc on packaging machinery's exposed electrical and pneumatic components.

Although dust management measures can assist reduce the amount of particulate in the air, dust can still get through poorly sealed enclosures.

To deal with such applications, a strong IP rating of 5to 6 should be considered. Waterproof enclosures aren't as important in this setting, so the liquid IP rating doesn't have to be as high.

Moist Working Condition

In pharmaceutical and food packaging applications, protection against liquids such as water and cleaning solutions is also critical.

Many food packaging equipment, such as those for cheese, meat, or sticky confectionery, may need to be cleaned regularly, and the packaging machinery must be rated to survive whatever wash-down process is necessary.

Liquid IP ratings of 5to 8 are recommended for moist settings. The robust IP rating is less necessary and does not need to be as high in this type of environment.

Dusty and Wet Environments

This includes locations where dust protection is necessary as well as protection from water jets, as well as conditions where enclosures must be dust-proof and water-resistant.

In such conditions, a total IP rating of 55 - 68 should be considered for a packing machine if the packaging environment is both dusty and needs rigorous wash-down processes.

Conclusion

To understand the IP rating, it is necessary to first realize the context in which the object is being utilized. How much dust, moving solids, and water is present, how fragile the item or equipment is, the possible injury to it if exposed to these elements, and the potential danger to you if you happen to come into contact with it, are all factors to consider.

The IP rating is very crucial for actuators, although there is also a lot of diversity in this category. Determine the purpose of your actuator, such as whether it will be submerged in water or surrounded by flying wood. Wants To Know More? We are here to guide you- Please contact us right now to avail FREE guidance.

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine