What is Gummy Formula?

Gummies bears are always legendary. Full of flavors gummies with sweet and sour taste taps directly your taste buds with joy. Making gummies is never an easy task. Consumers are now becoming more and more demanding about their products. Some prefer gelatin-based gummies while others don't. So, smart manufacturers must keep this demand in balance to rise in their business. What is Gummy Formula? It's time to buckle up for some interesting gummy formulas.

Read on to explore the gummy formula for gelatin, and pectin gummies.

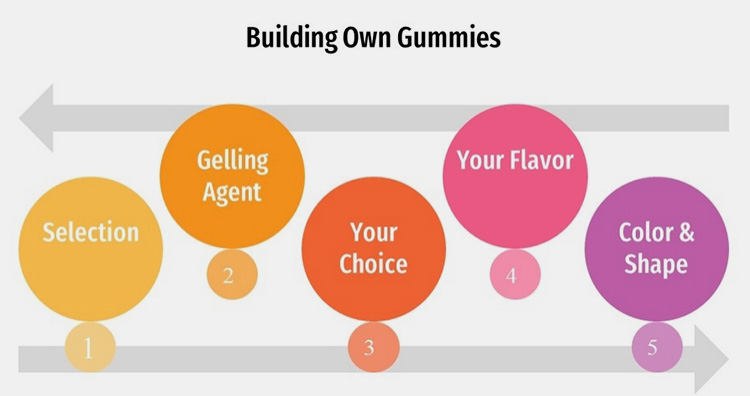

1.How To Build Own Gummy Formula?

Making your own gummy formula might seem daunting, but if thouroughly understand the insight process, you can instead make effrots to produce your customized formulation. Yes! You can do it. Before making gummy formula just go through below following technicalities first.

A ROADMAP TO GET YOUR GUMMY FORMULA

Selection of Material

The first step of formulating gummies is to set your goal whether you want a chewy textured sweet gummies or a medicated one. At this point you play with ingredients before proceeding with formulation.

Gelling Agent

Gummy bear is all about gelling agents. This entity is responsible for booming the consistency, texture, flexibility, and stability of your product.

Traditionally, animal-based gelatin is derived from collagen, which is flavorless and colorless. For vegans, there are many plant based options to add in a formula like a pectin, carrageenan, agar, and xanthan gum, etc., Such gelling agent enhances the fruity flavors and can be used as sugar free gummies. What is your objective?

Your Choice

Why commit to a single gelling ingredient? If you are curious and curious to perform experimentation then try a mixture of gelling ingredients to get a new target product either for business purpose or make it for yourself.

Your Flavor

There is an infinite number of delicious gummy flavors. Select your flavor whether artificial or directly from plant extract to obtain a big gulp flavor.

Your Color & Shape

It is important to have a fruity flavor to entice gummies. Side by side, color and shape have a significant role too. There are a variety of gummy molds available in the market or online to get your personalized one. Similarly, redefining the spectrum of colors can enhance your formulation that would be loved by your consumers.

2.What Are The Desired Categories In Gummy Formula?

There are a number of factors behind formulating gummies. Many of you are formatting for nutritional purposes. In fact, this is the latest trend to design and developing nutritional gummies relevant to specific demographic trends.

For e.g: Is your gummy formula for improving immunity? Try vitamin C, vitamin B12 as an active pharmaceutical ingredient.

Are you developing gummies for beauty? We suggest Vitamin B complex

Are you suffering from bone pain? Try Vitamin D

Are you tired of high blood cholesterol? Add plant sterol recommended by doctors all over the world.

Formulating gummies for weight loss? Add fiber, probiotics, and apple cider to limit your hunger cycle.

3.What Is Gelatin Gummy?

Do you know why the gummy bear is a popular global sweet? This is because of gelatin that makes them shiny, soft, chewy, and elastic, that tender in the mouth and gives you an intense burst of flavors.

Gelatin is an essential ingredient for making gummies. It is regarded not for sole function but for variety of significant health benefits. In chewy gummy bears, gelatin acts as an incredible emulsifier and stabilizing agent giving a refreshing mouthfeel with long-lasting flavors releasing.

4.How To Formulate Gelatin Gummies?

The step-by-step formulation of gelatin gummies is as followed:

STEP 1: Gelatin Melting

Hydrate gelatin in the warm water at 70°C temperature. The mixing equipment determines the temperature; the entire procedure may take 10 to 15 minutes to yield a cleared hot solution.

STEP 2: Cooking

Heat all the ingredients e.g., water, sugar, malt syrup, citric acid, sodium citrate, colors, and flavors till you get a thick syrup. To extend the shelf life of gummies, you may add glycerol (0.7kgs) into the blend.

STEP 3: Mixing

Add gummy syrup into gelatin solution with gentle agitation using a vacuum blender (prevents air bubbles). Blending should be done till the gelatin is dissolved completely.

Step 4: Deposition

Deposit the prepared blend into the production batch within 30 to 40 minutes. If stay longer, acidic content will reduce the gelling strength.

5.What Is Pectin Gummy?

Pectin gummies are introduced in recent years as a better substitute for gelatin. Pectin was first discovered in the 1790s by Louis Nicolas, which took about three decades in isolation by a French scientist named Henri Braconnot. This was a turning point when he revealed pectin is mainly responsible for congealing effects that enable gelling when boiled with sugar. Pectin gummies are soft, and viscous with a fresh feeling when in the mouth.

Pectin gummies are polysaccharides and water-soluble substances mainly obtained from the cell wall of vegetable and fruit extracts. Unlike gelatin, these gummies are not affected by heat.

6.How To Formulate Pectin Gummies?

The formulation of pectin gummies is mentioned below:

STEP 1: MELTING

Melt the acidic content such as sodium citrate, citric acid, pectin, and sugar in the water of about 70 ℃ and keep mixing. Pectin and sugar enhance gelling strength.

Melt the ingredients of syrup such as sugar, glucose syrup, citric acid, and malic acid.

STEP 2: MIXING

When both ingredients get the same consistency and uniformity; syrup into pectin solution and blend gently till you get a uniform consistency. Stir gently the melted material till it boils. After boiling down to 108℃, stop heating. At this point, you may add pigment and flavors.

STEP 3: DEPOSITOR

Now slurries are prepared to pour into the assigned depositor.

7.Gummy Gelatin Formula Vs Gummy Pectin Formula

Formulating ingredients of a basic gummy recipe includes Gelatin OR Pectin, Sugar, Water, Corn syrup, Citric Acid, Flavouring agents, and Colouring agents.

Ⅰ.Gummy Gelatin Formula

FOR GELATIN

| Material Name | Weight in Kilograms | Weight in Grams |

| Warm Water | 28.3 | 28300 |

| Gelatin | 10.1 | 10100 |

GUMMY SYRUP

| Material Name | Weight in Kilograms | Weight in Grams |

| Water | 8.4 | 8400 |

| Sugar | 28 | 28000 |

| Malt Syrup | 28.1 | 28100 |

| Citric Acid | 0.6 | 600 |

| Hot Water (With citric acid) | 0.4 | 400 |

| Citrate Sodium | 0.01 | 10 |

| Colors | To suit | - |

| Flavors | 0.2 | 200 |

Ⅱ.Gummy Pectin Formula

FOR PECTIN

| Material Name | Weight in Kilograms | Weight in Grams |

| Sugar | 6 | 6000 |

| Sodium Citrate | 0.5 | 500 |

| Citric Acid | 0.46 | 460 |

| Pectin | 1.7 | 1700 |

FOR GUMMY SYRUP

| Material Name | Weight in Kilograms | Weight in Grams |

| Water | 15 | 15000 |

| Sugar | 46.4 | 46400 |

| Glucose Syrup | 30 | 30,000 |

| Citric Acid | 0.37 | 370 |

| Malic Acid | 0.2 | 200 |

| Pigment | To suit | - |

| Flavors | 0.2% | 0.2% |

Ⅲ.Gummy Bear Ingredients

GELATIN

Gelatin is a protein obtained from animal skin, bones, and ligaments. They are further divided into two types: Type A (from pork origins) and Type B (extracted from beef), depending on your choices you can select any of the two. Gelatin is the primary gelling agent, increasing its concentration would result in good gel strength which would retain the gummy’s structure.

PECTIN

Although pectin is also a gelling agent, you can say it’s the choice of customers going for vegan options. Pectinis a carbohydrate extracted from the cell walls of plants. However, pectin has many speculations to formulate, such as requiring a high amount of sugar and taking care of temperature limits. Pectin reduces the setting time of gummies, which is a major manufacturing cost.

SUGAR

Sugar is also a main ingredient in your gummies. Sugar comprises of about 75% dry weight of your gummy candies. Sucrose provides the moisture locking, sweetness, and softness of a gummy’s structure. Excess levels might result in sweating and stickiness, and insufficient quantities may cause dryness and hardness.

WATER

Water is also a mandatory ingredient. You need to add warm water for the dissolution of Gelatin or Pectin. It affects the final version of your gummies, too much water can cause improper consistency and microbial contamination.

CORN SYRUP

Corn syrup is a highly functional ingredient that prevents the crystallization of sugars.

CITRIC ACID

Citric acidplays the role of a pectin-based gummy. This gelling agent adjusts the pH of the mixture. While using other gummy bases, it serves as a taste enhancer.

FLAVORING AGENTS

Confectioneries generally employ artificial flavors. Food acids such as Citric Acid and Malic Acid are added as flavor enhancers and also to develop gel structure.

COLORING AGENTS

Artificially derived and natural both colors are used to aesthetically please your sight of gummy candy. Blue#1 and Red#40 have good compatibility with food ingredients. Red cabbage, B-Carotene, and acid-proof cochineal extract have to do with Candy’s formulations.

8.What Formula Adjustment Prevent Gummies from Sticking?

Keeping gummies from sticking can solve operational headaches that sustain the production cycle. Implementing the best approach and right gummy making machine can prevent your gummy from sticking together.

Correct Ingredient Proportion

For example:pectin gummy formula:

| Material Name | Weight (kg) |

| Water | 15 |

| Sugar | 46.4 |

| 84% glucose syrup | 30 |

| Citric acid | 0.37 |

| Malic acid | 0.2 |

| Pigment | Appropriate amount |

| Flavor | 0.2% total |

Too much or too little ratio of ingredients could potentially lead to sticking. A correct ratio of ingredients can balance this problem.

Avoid Too Much Water Activity

Too much water activity can give a slippery and wet texture; during packaging, gummies could stick together.

Familiarize With Ingredients

Various substances have alternative melting and freezing points; you may refer literature review and ask the supplier when sources ingredients for gummy production. This helps you to determine the melting temperature and preventive measures.

Use Gummy Coating

Adding cornstarch and wax to your gummy formula can prevent them from sticking. This step is followed when gummies are fully prepared and have been ejected from molds. Their moderate amount won’t affect its taste and uniformity.

9.Problems and Troubleshoot your Gummy Formula

From sweets to medicines, manufacturers are progressively marketing new trends in gummy formulation, but the decision to make gummies from gelatin or pectin has brought them to a crossroads.

Despite many authentic methods and new equipment, there are still some manufacturing complications. Discuss below are some important gummies-associated problems & solutions.

Sticking and sweating is the most common problem associated with gummies. Indeed, this is a manufacturing fault when you deal with gelatin-based gummies.

Luckily, a scientific approach has successfully provided the solution; excessive content of reducing sugar is the cause of this problem. Moreover, high humectant content followed by inadequate drying time is also one of the reason. Hence, an optimum level of reducing sugar with sufficient drying time must be provided.

Sometimes, manufactured gummies are so hard than normal gummies.

Fortunately, this problem has an easy solution. You can rehydrate gummies in warm water till you find the desired consistency. However, high content of gelatin or pectin may be the cause of this problem.

Gummy bears weight variation occurs during manufacturing. To avoid this problem, set the machine for uniform deposition and replace the defected molds with a new one.

There is a problem with pectin gummies that produce an undesirable cloudy look. This problem can be avoided if you gently pour the syrup mixture into the pectin solution with proper mixing.

Crystallization or graining may have appeared in corn syrup. This problem might be occurred due to the low content of glucose. For this, a proper level of gelling agent must be assessed. Humectant levels must be adjusted higher to avoid the occurrence.

CONCLUSION

While many folks think that making gummies requires plenty of ingredients and skills. However, reading ‘What is a gummy formula?’ would definitely have answered you. In the above discussion, we delve into prime ingredients used in industrial preparation along with their optimum weights. If you have confusion or need expert counseling; we are here to guide you! Contact us to know more.

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine