What Is Difference Between PVC and PVDC?

Are you looking to get the best plastic for your manufacturing? But getting confused to select which one as in market you have to choose between PVC and PVDC. Unless and until you don't have information about the distinction between both types of plastics, it is no way to purchase the right one. That's why we are here to answer What Is The Difference Between PVC and PVDC?

Whether it is the production of industrial pipes, building material, or packaging, the use of plastic is inevitable. This material mainly comes from PVC and PVDC both of which are composed of different elements. Their composition along with advantages, disadvantages, and uses will be explored below. So, keep reading to get all of them!

1.What Is Pvc?

Various PVCpipes- Picture Courtesy: eupegypt.com

PVCsimply stands for Polyvinyl chloride which is a thermoplastic material. It is made up of resin which is its main component. It is known for its high durability, strength, and resistance to all types of inorganic chemicals.

Polyvinyl chloride can be used along with other additives to enhance its structural properties such as elasticity, fire retarding, and microbe prevention. It is affordable and popularly used in a range of industries for construction, manufacturing, and medical applications.

2.What Is PVDC?

PVDC film rolls with blister packs- Picture Courtesy: cypharmapacking.com

Synthetic plastic polymers are routinely used for product manufacturing. And one of these plastic polymers is PVDC. Ralph Wiley, a chemist discovered this polymer in 1933. Previously, it was commonly used in the packaging of food products as plastic wraps. Now, it is substituted with more preferred plastic forms, such as low-density polyethylene.

Still, now, it is frequently applied as a water-proof coating to biaxially-oriented polypropylene (BOPP) polyethylene terephthalate (PET), and PVCfilms. This helps to lower oxygen, water, and flavor permeability and increase the appeal of films. You can use it in your home for cleaning screens, filters, furniture, etc. You will also find it in doll hairs, fishnets, and photographic films.

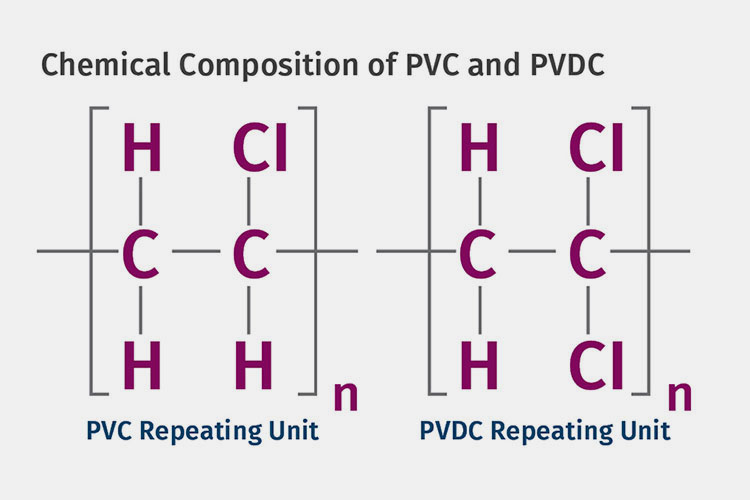

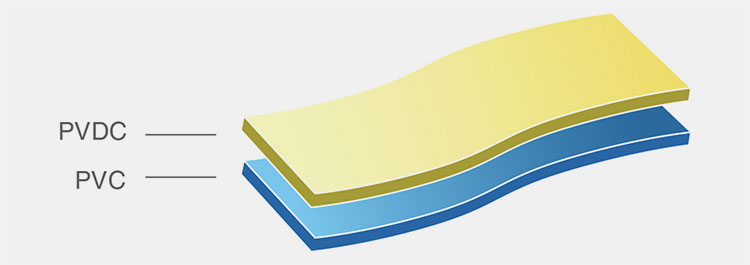

3.What Is Difference Between PVC andPVDC- Composition?

Chemical composition of PVC& PVDC- Picture Courtesy: ptonline.com

Yes, besides obvious spelling differences, PVC and PVDC are significantly different from each other in their composition. PVCis formed by a chemical reaction called polymerization. During this reaction, small molecules of vinyl chloride are linked together to create a long assembly of recurring chloroethene blocks. PVCchain is formed by a single chlorine atom monomer as shown by the general formula (C₂H₃Cl).

On the other hand, PVDC is formed by the linking of monomers- vinylidene chloride. Its repeating block has a general formula (CH₂=CCl₂). As indicated by the formula, it contains double the amount of chlorine as compared to PVC.

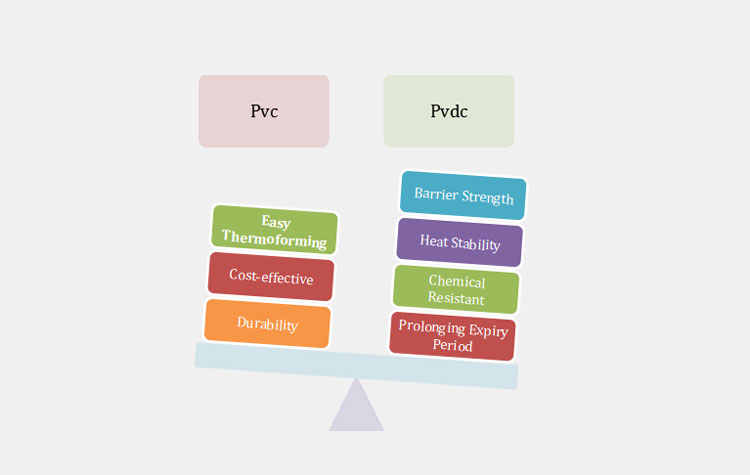

4.What Is Difference Between PVC andPVDC- Advantages?

Despite being nearly identical in structure and composition, there are some huge differences in both of these synthetic plastic polymers when their advantages are studied. You would be probably wondering what are those advantages. So, without delay, let’s dive straight into their advantages comparison.

Pvc

Easy Thermoforming

PVCthermo formed pipes- Picture Courtesy: adtech.co.uk

It is way easier to soften and mold PVCowing to its low softening temperature. In this way, you can think of PVCas more flexible and shapable. It has outstanding shaping properties that make it compatible to use in packaging where bending or shaping is required.

Cost-effective

You would’ve considered the cost of raw materials when buying, as it can affect the operation cost. So, you’ll find it exciting that PVCis a more pocket-friendly and economical material in comparison to PVDC. Therefore, it is preferred packaging material.

Durability

Worker cutting PVCpipe- Picture Courtesy: piedmontplastics.com

PVCis known for its exceptional durability which makes it best against corrosion, breakage, grease. It can endure extreme climate conditions thereby suitable for buildings.

PVDC

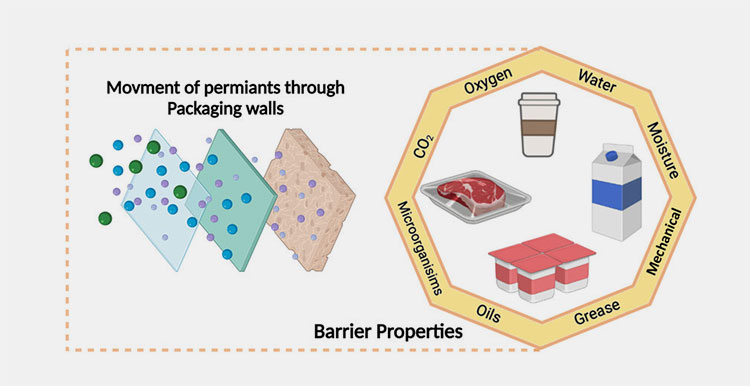

Barrier Strength

Breads wrapped in high barrier PVDC film- Picture Courtesy: shinerinc.com

It is one of the most important features when it comes to packaging. And in this aspect, PVDC seems to outshine PVC. Why is that? Because of the high chlorine content of PVDC. This makes the PVDC more resistant to environmental culprits, such as oxygen, water vapors, odors, light, etc.

Heat Stability

PVDC cling wrapping over food- Picture Courtesy: restaurantware.ae

Not only this, PVDC has more heat resistance than PVC, so the former has high sealing and melting temperature. You’ll normally encounter a PVDC layer in product packaging where elevated heat protection is needed. Numerous industrial experts advise using PVDC for high-heat utilities.

Chemical Resistance

Beakers with chemicals- Picture Courtesy: hpp.arkema.com

Industrial manufacturers in various industries are always worried about their product damage owing to harsh chemicals, especially acids and bases. There is good news for them. PVDC material is perfect for its extraordinary chemical resistance and protection against harsh chemicals and bases. It also safeguards inner contents against oxidizing agents.

Prolonging Expiry Period

PVDC has superior barrier properties, so it is regularly used for extending the useability period of numerous products. PVDC is the best way to optimize the shelf-life of moisture-sensitive drugs and food products. This polymer is superior in protecting products against degradation, spoilage, and waste.

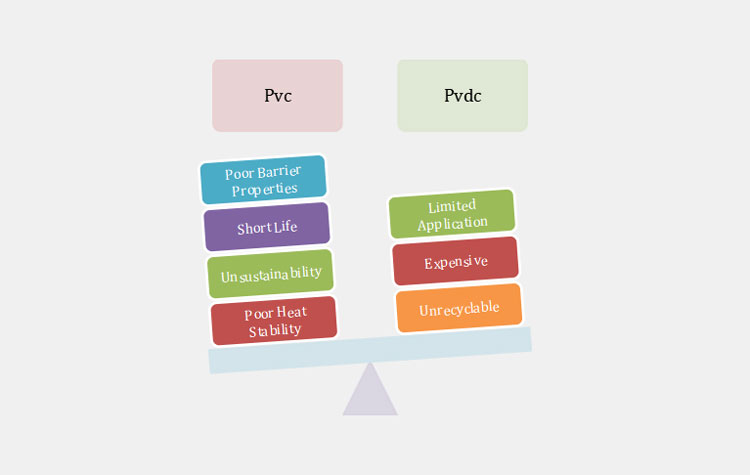

5.What Is Difference Between PVC andPVDC- Disadvantages?

PVC and PVDC, both have disadvantages but there is a difference between those pitfalls. Some of the differences among the downcomes of them are listed below:

Pvc

Poor Barrier Properties

Barrier properties of Pvc- Picture Courtesy: researchgate.net

As you know there is less proportion of chlorine in PVC, so, it doesn’t have much barrier impermeability against these agents. PVCfilms and wraps are only used when moderate resistance against alcohol, bases, UV, or acids is required.

Short Life

PVChas moderate protective traits and, thus, is utilized for packaging products that don’t require high protection. This renders it of no use when you require long-term storage of sensitive items. However, it is best when the product is used or consumed in a short period.

Unsustainability

Unsustainability presentation idea- Picture Courtesy: zerowastero.com

PVCcontains contagions like phalates, lead and cadmium which can cause severe health problems and lead to a variety of fatal diseases like cancer and asthma. It can give rise to environmental pollution by increasing amount of cadmium and lead when emblazed.

Poor Heat Stability

Temperature icon- Picture Courtesy: pvcconduitmanufacturer.com

Compared to PVDC, PVChas very poor heat stability as a result of which it cannot endure extreme temperature.

PVDC

Limited Application

It is harder to bend PVDC than PVCdue to the inherent chemical structure of PVDC. Therefore, it is commonly used for coating PVCfilms and is often used for packaging and coverings thereby limiting its applications.

Expensive

The advanced barrier characteristics of PVDC make it pricier and premium quality. However, PVDC in spite of its exceptional benefits, is more expensive.

Unrecyclable

Not recyclable vector- Picture Courtesy: publicsquare.com

Since PVDC has higher chlorine content, subsequently, it is difficult to recycle it. PVDC releases higher quantities of chlorine and toxins in the air, which reduces its sustainability. Also, its disposal is more of a hassle. It takes a long time to decompose this plastic polymer.

6.What Is Difference Between PVC andPVDC-Machines For Processing?

There are several machines for processing PVC and PVDC in food, medical, and hardware industry. These are described below in detail:

Thermoforming Machine

AIPAK HVR-320A Thermoforming Machine

Thermoforming machine is an excellent machine to process PVC and PVDC for packaging purposes. It has long and durable stainless steel body with other components comprising film roll, control panel, moulds, and heat system. It performs the function automatically by unwinding film from roll for forming, feeding material into it, tightly sealing. During packaging step, the machine suck air from packages to remove out the presence of oxygen which may degrade quality of products. It is widely used for snack food, meat, and vegetables etc.

Blister Packaging Machine

AIPAK DPP-150E Automatic Rotary Blister Packaging Machine

Blister packaging machine is an advanced equipment designed to pack tablets and capsules in blister packs usually made up of PVDC. It has complex structure made up of different components including main frame, film holder, PLC interface, heating system, and film pulling and moulding mechanism. It follows simple steps of unwinding film, molding it into blister shapes, filling the moulds, and applying upper aluminum foil after which these blister packs are sealed.

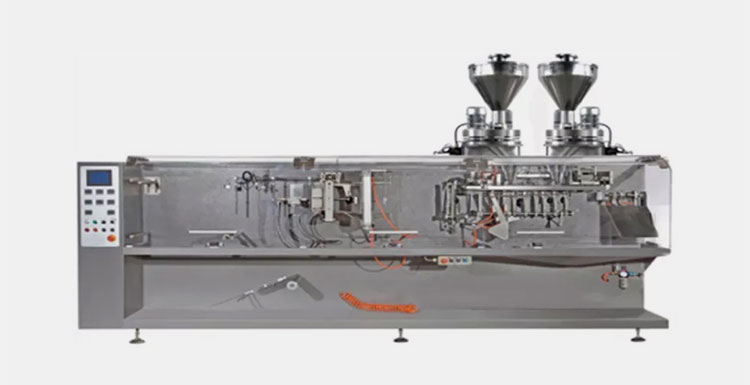

FFS Packaging Machine

AIPAK APK-210D Horizontal Automatic Flat Pouch Coconut Sachet Machine

Form, Fill, and Seal packaging machine is another equipment used to process PVC and PVDC for flexible packages such as pouches and sachets. It has excellent performance to undertake multiple tasks simultaneously including film unwinding, bag forming, filling, and sealing. The machine is best suitable to pack food, medicine, and chemical powders, granules, as well as liquids into flexible bags.

Vacuum Packaging Machine

Allpack- DZ-400/T Single Chamber Vacuum Packaging Machine

Vacuum packaging machine is a sophisticated and compact design machine utilized for the packaging of PVC and PVDC films and wraps sealing. It has an enclosed chamber where filled film packages are placed for oxygen removal and tight dealing in order to enhance the shelf life of products. It is widely used in bakeries, restaurants, markets, and home kitchens for fresh food and readymade food etc.

7.What Is Difference Between PVC andPVDC- Uses?

PVC and PVDC are both plastic materials, yet they differ in their uses due to the qualities each posses. Some of the key applications of PVC and PVDC are as follows:

Pvc

Construction Industry

Engineer at construction site- Picture Courtesy: constructiontuts.com

Affordability and high strength of PVCis now helping it replace the traditional construction materials such as ceramics, metal, wood etc. It is now extensively used in construction industry for flooring, insulation on electrical wires, window frames, and sewage pipes.

Textile Industry

PVCfabrics- Picture Courtesy: fabricwholesaledirect.com

The use of PVCis also prevalent in textile industry for various purposes. For instance, Polyvinyl chloride fabric is used in the production of sports bags, raincoats, and jackets etc.

Automotive Industry

PVCapplication over car- Picture Courtesy: lazada.com

Construction of automotives such as cars, aeroplane, and other automobiles needs rigid plastic material like PVCfor seats, window frames, and engines. Thus, the automotive industry has become another application of Pvc.

PVDC

Pharmaceutical Industry

Pharmaceutical blister packaging- Picture Courtesy: jornen.com

PVDC has excellent properties again oxygen, moisture, and heat which are always required for the safe packaging of pharmaceutical products like capsules and tablets. Therefore, it is used for blister packaging, bags, and bottles etc.

Food Industry

Food wrapping- Picture Courtesy: istockphoto.com

In the food industry, numerous fabricated products, junk food, and snacks are packed in flexible bags and pouches which are supposed to retain the aroma and freshness of food. Therefore, PVDC can withstand gases, resist heat, and keep the quality of products for long time. One of the major examples includes the use of cling wraps and saran wraps which are made using PVDC.

Electronic Industry

Various electronics- Picture Courtesy: A Star Cargo Ltd

PVDC is also used in the electronic industry for coating over screens, wires, tapes, and household and kitchen appliances such as microwave, refrigerator, and deep fryer etc.

8.What Is Difference Between PVC andPVDC- Quality Standards?

As PVC and PVDC are commonly used in food, medicine, and other industries, it is necessary to have certain principles under which their production should be regulated. These are as follows:

FDA & ISO logo- Picture Courtesy: usa.pharmablock.com

International Organization for Standardization (ISO)

ISO is an international quality standard which provides significant guidelines for both PVC and PVDC to ensure safety. For this purpose, various standards are developed including ISO 14001, ISO 15270, ISO 15314, and ISO 22766. They deal with the environmental sustainability, decomposition, and recycling of PVC and PVDC which must be followed.

Food And Drugs Administration (FDA)

FDA is USA based agency dedicated to the quality manufacturing of equipment and products related to food and drugs. As PVCis used in equipment construction and PVDC in food and pharmaceutical packaging, it is crucial to comply with the guideline’s setup by FDA.

Good Manufacturing Practices (GMP)

There are certain rules established by GMP which must be followed while the production of PVC and PVDC. These include raw material quality control, adoption of safe methods for manufacturing, quality testing, and proper documentation of produced products.

9.What Is Difference Between PVC andPVDC- Factors To Consider?

Let's suppose you are in need of plastic material for manufacturing purposes, and you are intending to purchase it. However, in the market you are caught in a dilemma as the supplier has asked you to choose between PVC and PVDC. In such cases, you just need to consider a few factors which will help you select the most compatible one. These include:

Application

Blister packaging for capsules- Picture Courtesy: uniworthllp.com

The foremost thing you need to look for is the application which means the type of production you are carrying out. For instance, if you are manufacturing automotives and construction materials and in need of rigid plastic then PVCis the best option. On the other hand, if your concern is plastic with high barrier properties for packaging then PVDC is perfect one.

Temperature

Another important factor is considering the temperature at which material will be kept. In addition, electrical wires used inside buildings have less exposure to heat which can be coated by using PVDC. However, if the temperature is extreme, then PVDC is the best choice due to its resistance to high temperature.

Cost

Cost estimation- Picture Courtesy: happay.com

While choosing between PVC and PVDC, cost must be considered. If you are ready to make big investment with good results, then PVDC is suitable for expensive price. However, if you want to go with cost-effective solution then PVCis reliable whose qualities can be imbued.

UV Exposure

PVC& PVDC material- Picture Courtesy: bilcare.com

In many cases, products are exposed to ultraviolet radiation which can degrade the quality over time. So, it is better to consider this aspect which works best with PVDC due to its excellent resistance to UV against PVCwhich has poor resistance properties against UV.

Conclusion

To wrap up this blog bost, let us confirm did you know What Is Difference Between PVC and PVDC? Well, we hope so! The importance of PVC and PVDC is unmatchable in the fast paced world where reliance on other materials like metal, wood, and ceramics is reducing. Therefore, both of these widely used in food, medical, and other major industries. However, there are certain critical differences prevailing between both and it is crucial to understand them thoroughly. It will help you make best choice for you. If you are eager to learn more or want machines for processing PVC and PVDC then don't forget to visit our website. Thank you!

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine