What Impact Particle Size Have On Tablet Compression?

Have you ever wondered the forming and compressing of tablets? How to make the even and forte tablets for pharmaceutical use? Does particle size affect your tablet compression? Tablets are so important in your daily life. Here you may find the comprehensive answer of tablet compression.

What machines are applied in tablet compression? What impact particle size have on tablet compression? What technique are applied for tablet compression? What may affect your tablet forming in tablet compression? You may have the relative questions answered here. Come on and have a reading!

1.What Is Tablet Compression?

Tablet Compression-Sourced:goerlich-pharma

There are various tablets on pharmaceutical market as the great media for medicines. The tablets are tough and compact. You may guess the manufacturing of tablets already. The tablets are formed with great compression in the certain shape. Tablet compression is the complex, precise and organized procedure.

In tablet compression, it has the technique of compression and forming to make the tough and shaped tablets. It can be made with large production and you may have your own design in it. The factors which affect tablet compression varied and you may find the particle size, compression and so on affect production.

2.What Industry Can Tablet Compression Be Applied?

Tablet compression can be applied in many industries and you may find the technique applied in pharmaceutical industry, supplementary industry, cosmetic industry and food industry.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:huadapharma

Tablet compression is widely applied in pharmaceutical industry. You may find pills, tablets and the various types of medicines made in tablet compression. For various types and shape, there are tablet compressing machines for the easy handling.

Supplementary industry

Supplementary Industry-Sourced:vitaquest

There are various types of supplementary products and various kinds of supplementary tablets. For the various nutraceutical material, you may always find the nice dealing from tablet compression.

Cosmetic industry

Cosmetic industry applied the tablet compression for some its products manufacturing. There are compressed tablet facial mask, powder, cream, gel and such cosmetic products manufacturing.

Food industry

Food Industry-Sourced:stock.adobe

In food industry, there are chewable tablets, effervescent tablets and various kinds of candy which all need tablet compression for the food products manufacturing. The hygienic and consistent manufacturing process can prove the high quality of your products.

3.What Machines Are Applied In Tablet Compression?

What machines are applied in tablet compression? What are their kinds and the difference? Come on and have a check of tablet press machine!

Single punch tablet press machine

AIPAK Single Punch Tablet Press Machine

Single punch tablet press machine can deal with the various kinds and types of tablets with the simple replacement of punches. It can make the consistent production and have the energy saved greatly and make great job in hospital, lab and so on. For large production, it may be powerless for the large scale produce.

Flower basket tablet press machine

AIPAK Flower Basket Tablet Press Machine

Flower basket tablet press machine is also the tablet pressing machine for the small scale production. It is essential in pharmaceutical, cosmetic and many industry. You may have your tablet pressed by hand and by powder. It is flexible and have the speed, tablet thickness and material adjusted.

Rotary tablet press machine

AIPAK Rotary Tablet Press Machine

Rotary tablet press machine is more efficient and automatic compared with the above tablet press machine types. It is capable of making the round, irregular and engraved tables according to your design and shape. The closed housing and stainless steel material enable the large production and high speed producing.

High speed tablet press machine

AIPAK High Speed Tablet Press Machine

High speed tablet press machine is the most efficient and automatic tablet press machine. You may find its wide application in pharmaceutical industry, food industry, cosmetic industry and so on. The reasonable structure, GMP standard and easy operating make it welcomed in large production in world.

4.What Impact Particle Size Have On Tablet Compression?

As you know, tables are made mainly with particle. Do you know the impact particle size have in tablet compression?

Filling uniformity

Filling Uniformity-Sourced:setylose

The size of the particles affects the filling of the tablet press. For the large particle size, the gaps between the particles will be large. The uneven filling will easily occur during the filling process. This may make unqualified standards.

For the small particle size, the gaps between particles are relatively small and can be packed more closely, which is beneficial to the uniformity of filling and makes the tablet weight more stable. However, too small particles may cause new problem like increased friction between particles and poor fluidity.

Tablet density and hardness

Tablet Density And Hardness-Sourced:merlin-pc

Particle size makes the significant impact on tablet density and hardness. The large particle size will make the high porosity and low density. The few contact points between large particles makes the loose combination and low hardness.

The smaller particle sizes can be arranged more closely. The tablets pressed in this way have a higher density and a relatively larger hardness. However, if the particle size is too small, the tablet may be too hard which may affect disintegration and dissolution.

Disintegration and dissolution properties

Disintegration And Dissolution Properties-Sourced:qbdgroup

Particle size is an important factor affecting their dissolution performance. Small particle size can increase the specific surface area of the drug and increase the contact area between the drug and the dissolution medium. After the tablet disintegrates, the drug is able to dissolve more quickly in the fluids of the gastrointestinal tract.

However, if the particle size is too small, agglomeration may occur which may affect the effective dissolution of the drug. Small particles may adsorb for the high surface energy. After agglomerates disintegration, the drug particles may not be effectively dispersed in the dissolution medium and has the dissolution rate of the drug reduced.

Liquidity

Particle size is closely related to the flow of particles. Large particle sizes have better flow for the small friction and smooth flowing in hopper and conveying pipeline. Great flow can ensure the continuous production.

Particles with smaller particle sizes are prone to electrostatic adsorption which causes poor flow. This may also cause the unstable drug filling speed and bridging phenomenon which has drug blocked at the hopper outlet and cannot fill the die hole normally. The efficiency of manufacturing and tablet quality will be affected.

5.What Factors Decides The Quality Of Compressed Tablet?

What affect the quality of compressed tablet? The qualified tablet should be forte and efficient. And here are the factors which decides the compressed tablet quality.

Powder properties

Powder Properties-Sourced:azom

Powder properties depend on flow which is affected mainly by particle size and shape. Besides, high friction has an adverse effect on powder properties which may be caused by bridging effects and uneven flow. Inhomogeneous particle size may also cause material segregation and results uniformity problems. Powder properties make a lot affect on compresses tablet.

Compression behavior

Compression Behavior-Sourced:karkhana

Visco-elastic properties of the raw material affect the compression work. The compaction process is the compression and shaping of a two-phase system. The compressed tablet quality depends on the compression and shaping of the powder material, decompression, ejection and subsequent scraping off the lower punch.

6.WhatTechnique Are Applied For Tablet Compression?

Tablet compression is not the complex work. And here are the two techniques applied mainly in tablet compression.

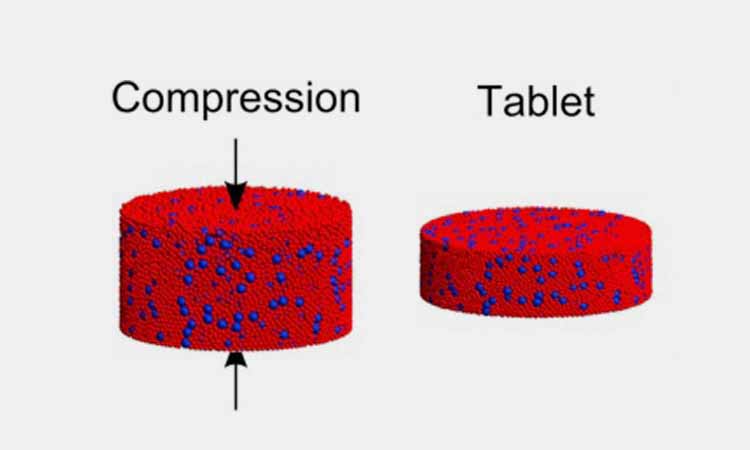

Compression

Compression-Sourced:ima

When external mechanical forces are applied to powdered material, the overall volume will generally decrease due to the following effects. The initial compression is usually accompanied by a closer rearrangement of the powder particles, which in most case is the main mechanism for the initial volume reduction. Compressed tablet is made from this kind of compression.

Forming

Forming-Sourced:sciencedirect

Your compressed tablet should be formed for forte and better performance. Most pharmaceutical granules is consist of small crystallites or have particles formed in a random manner. The unaligned crystal faces increase material's resistance to plastic deformation. You should apply machines for the standard forming.

7.What Is The Deforming In Tablet Compression?

There are the great forming of tablet compression and also deforming of tablet compression. And here are the great example of deforming in tablet compression.

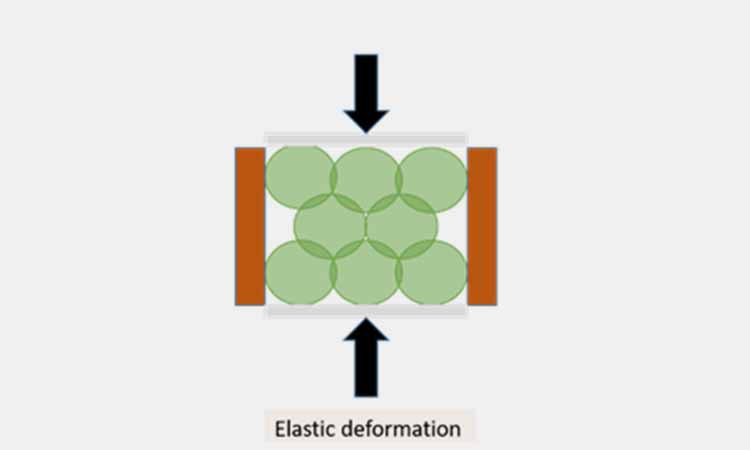

Elastic deformation

Elastic Deformation-Sourced:mdpi

If the deformation is largely self-recovering after the load is removed and behaves like rubber, the deformation is called elastic deformation. All solids undergo some elastic deformation when subjected to external force. For several pharmaceutical materials, elastic deformation becomes the dominant compression mechanism within the maximum force range encountered in practice.

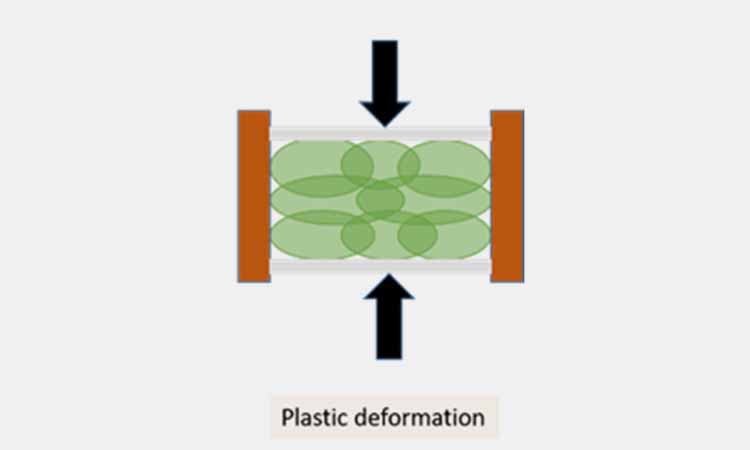

Plastic deformation

Plastic Deformation-Sourced:mdpi

For some powdered solids, the reaching of elastic limit or yield point cause the deformation which may recover immediately when the applied force is removed. In these cases, the reduction in total volume is due to plastic deformation and viscous flow of the particles. The particles are squeezed into the remaining voids.

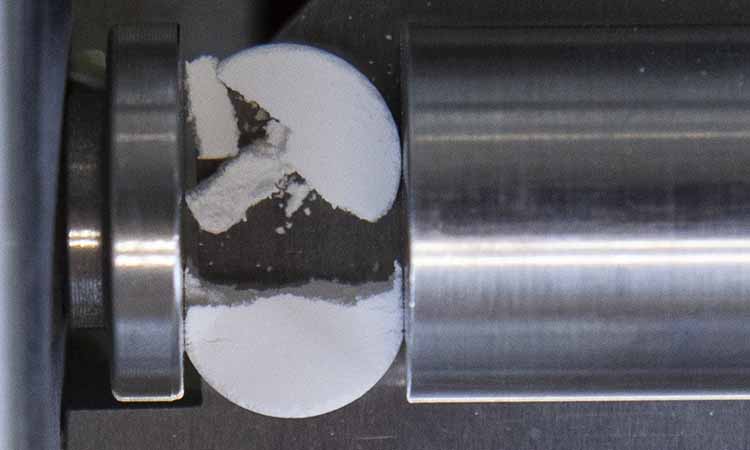

Brittle fracture

Brittle Fracture-Sourced:elsevierhealth

With large shear strength, the particles may fracture preferentially and has the smaller fragments help fill adjacent voids. Brittle fracture is most likely to occur in hard and brittle particles. The tendency of a material to deform in a particular way depends on the lattice structure.

Microcompression

Microcompression refers to the plastic deformation of small particles. Tiny protrusions sheared off from larger, highly irregular particles may lead this. You can solve it from particle shape.

8.What Is The Main Technique Of Tablet Forming In Tablet Compression?

For tablet forming, there are two main techniques which are widely applied in various industry.

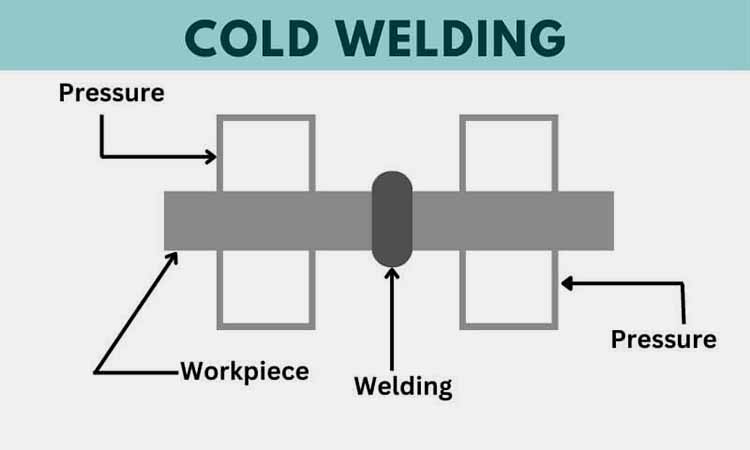

Cold welding

Cold Welding-Sourced:electronicshub

When the surfaces of two particles are brought close enough, their free surface energy leads to a strong attraction which is known as cold forming. Cold welding is applied in pharmaceutical industry, metallurgy industry and so on.

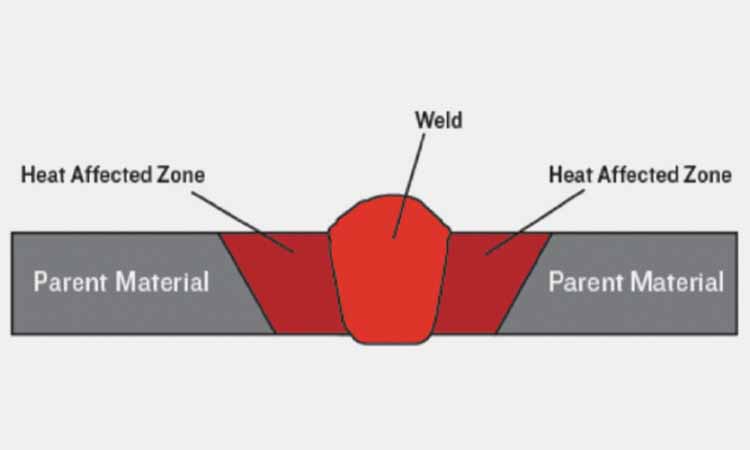

Heat welding

Heat Welding-Sourced:inspectioneering

Considerable frictional heat will increase local temperature and cause melting of the particle contact area. The melt solidifies produce a fusion bond which leads to an increase in the overall mechanical strength. This is the forming way of heat welding.

Matrix

Tablet can also formed by the plastic deformation components or matrix. Matric can be applied to release the internal pressure and have the tablets formed stably. You may also applied it for your tablet compressing.

Adhesive

Adhesive-Sourced:pharmaeducation

Adhesive is used to bond and adhere the particle surface firmly. You may find the various adhesive on market for different medicine type use.

9.What May Affect Your Tablet Forming In Tablet Compression?

For tablet forming in tablet compression, there may exist factors which affect your tablet work. And here are the factors.

Moisture

Moisture-Sourced:shreeshyamjiminerals

Moisture is present in nearly all capsule and tablet formulations It can significantly affect the behavior of these ingredients as well as the finished product. When the moisture content of the powder surface is sufficient to fill the remaining voids in the bed, any further porosity reduction will lead the moisture to be squeezed out to the tablet surface.

High loads

High Loads-Sourced:justdial

Processes such as compressing, rolling, and extrusion all involve the application of large compressive forces which can cause significant deformation of the solid particles. When the compaction force reaches its maximum value, a massive solid structure with a certain overall strength will be formed.

Friction

There are inter-particle friction and mold wall friction. When particle rearrangement ceases, this effect dominates at high pressures. Friction is particularly important in compressing operations.

Die wall lubrication

Die Wall Lubrication-Sourced:chemtrend

Most pharmaceutical tablet formulations require the lubricant to reduce friction with the die wall. The role of a die wall lubricant is to insert a low shear strength film at the interface between the tablet and the die wall.

Pushing force

Radial mold wall force and mold wall friction also affect the ease which compressed tablet can be ejected from the mold. The hard pushing may lead the break of compressed tablets.

10.How To Make The Forte Compressed Tablets?

How to make the forte compressed tablets? Here are the factors you may obey for the manufacturing.

Material

Material-Sourced:cadmach

To make the forte compressed material, you should first get the great and high qualified natural material. The relative manufacturing methods and adhesive or other ingredients should also conform to the medicine type to make the forte compressed tablet.

Machine

AIPAK Table Press Machine

You should get the tablet press machine which has the great performance and high efficiency. The high qualified tablet press machine is the base for your forte compressed tablet manufacturing.

Environment

Tablet Manufacturing Environment-Sourced:senieer

As mentioned above, you should make the great environment for the forte compressed tablet manufacturing. Besides moisture, you should also take the force, friction, lubrication and so on into your consideration.

11.Will Specific Material Affect The Tablet Forming?

Material of course affects tablet forming. And here are the specific materials which affect tablet forming.

Crystal type

Crystal Type-Sourced:shutterstock

The crystal type of particular material affects its molding behavior under considerable external forces. Materials with a cubic lattice arrangement are easier to form than materials with a rhombohedral lattice. The lattice planes with the greatest separation are more susceptible to plastic deformation for the weaker bonds of planes.

Thermal conductivity of material

Many pharmaceutical materials have low specific heat and poor thermal conductivity. The heat transferring from the contact point is slow. Thermal conductivity of material can also affect the tablet forming.

Surface contaminants

Surface Contaminants-Sourced:asbestos

The compression process is affected by surface. Clean surfaces are brought into close contact. Brittle fracture and plastic deformation would produce clean surfaces, while the compression forces ensure that these surfaces remain in close contact.

Conclusion

What impact particle size have on tablet compression? You may have your own answers. Here is the comprehensive guide about tablet compression and its relative knowledge. If you have any question or problem about the particle size’s affect on tablet compression and tablet compression, contact AIPAK right now.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine