What Factors May Affect Your Wet Granulation?

Wet granulation is the technique applied frequently in various industries. And how much you know about wet granulation in pharmaceutical industry? Do you know that wet granulation is essential for many medical products? The better knowing of wet granulation in pharmaceutical industry is so helpful for you.

Why you need wet granulation in pharmaceutical industry? What are the advantages of wet granulation? What factors may affect your wet granulation? How to control the size and particle in wet granulating process? What is the wet granulation process? Here are the solution for all the above questions. Come on and have a reading!

1.What Is Wet Granulation In Pharmaceutical Industry?

Wet Granulation-Sourced:foodfeedfinechemicals

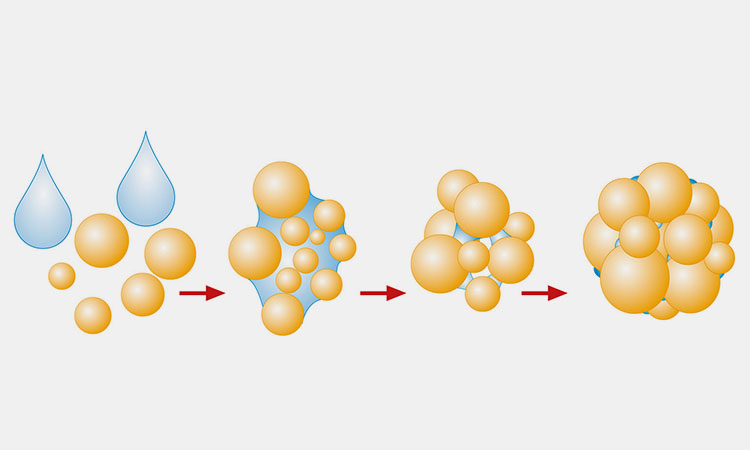

Wet granulation refers to the mixing of various powder particles with fluid to make the wet granules. It can make granules with powder mixing products. The later sieving process can make your powder mixing into the even and uniform particles. Wet granulation is widely applied for the manufacturing of various products in different industries.

You may see the applying of wet granulation in pharmaceutical industry for various medical products manufacturing. For tablets, pills and various medical products, the even and uniform particles are essential in the manufacturing. The material preparing is the first step of your whole medical products manufacturing.

2.Why You Need Wet Granulation In Pharmaceutical Industry?

Wet granulation is widely applied in pharmaceutical industry. Have you ever wondered the reasons?

Qualified particles

Qualified Particles-Sourced:vecteezy

Wet granulation in pharmaceutical industry can make the qualified particles. For the medical products with great quality, you should prepare your particle with even uniform and size. The qualified particles which made in wet granulation is the base of medical products manufacturing.

Stable feature

Stable Feature-Sourced:robinsonpharma

Wet granulation in pharmaceutical industry can make products with stable feature. From wet granulation, your particles can be strong enough for the various handling and processing. With stable feature and great flow, your particle material will be flexible enough for dealing with various medicine manufacturing process.

Compatible formulation

From wet granulation, you can make particles which are compatible with other components in formulation. This saves your steps in material preparing and also prove the smooth manufacturing process and qualified medical products.

3.What Are The Advantages Of Wet Granulation?

Wet granulation can help you in a comprehensive way. And here are the advantages of your wet granulation.

Large scale manufacturing

Wet granulation is suitable for the large scale manufacturing. The technique applied for wet granulation is so helpful and so efficient that it can handle large scale manufacturing for your various business. The great work can save you energy and time in product manufacturing.

High qualified products

High Qualified Products-Sourced:liberty-bd

Wet granulation can help make the high qualified products. The quality of your products are decided by various factor. And the great powder material is the base for your high qualified products. Wet granulation can make your powder and particle products with great flow and uniformity.

Better Compressing

You may have better compressing products from wet granulation. As wet granulation searches for better compressing in the process, you may have your energy and time in compressing ability of your products improved. The better compressing ability of your powder products can also have the wear and tear reduced.

Mask tablet deficiency

Mask Tablet Deficiency-Sourced:fabtechnologies

Wet granulation can help make the spherical granules which have better flow ability and better appearance. Your tablet deficiency can be easily shielded there. Your wet granulation can also mask the defects of your powder material in the production of tablets products.

Better tablet coating

Better Tablet Coating-Sourced:vikramthermo

Coating is also essential for some tablets products. Wet granulation can make tablet coating easier. Your tablets can be easily shaped after the wet granulation. It can save your energy and time in your further tablet coating process.

Reduce dust pollution

You may also reduce dust pollution with your wet granulation. In medicine manufacturing process, there may be medicine pollution and so on. Wet granulation has the chance of medicine contacting powder reduced. And you can have your medicine hygiene proved there.

4.What Factors May Affect Your Wet Granulation?

Wet granulation is so important. So do you know what factors may affect your wet granulation?

Properties of active ingredients and excipients

Properties Of Active Ingredients And Excipients-Sourced:behchinchemi

Particle size and distribution of drug powders

Too much fine powder can lead to poor flowability and may cause clumping during granulation, affecting the uniformity of the particles. On the other hand, excessive coarse particles may result in insufficient binding force between the particles, leading to lower particle strength.

Shape and surface properties of drug powders

Drug powders with irregular shapes and rough surfaces have a larger specific surface area. During granulation, they have a larger contact area with the binder, which facilitates the formation of uniform particles and results in higher particle strength.

Ratio of drug to excipients

The ratio of drug to excipients affects the properties of the granules. If the excipient ratio is too high, it may cause the granules to be too hard and dense, affecting drug dissolution. If the drug ratio is too high, it may result in poor granule formation and insufficient strength.

Binders and wetting agents

Binders And Wetting Agents-Sourced:tabletbindertdp

Type and amount of binder

Different binders have different binding properties. Common binders like starch paste and polyvinylpyrrolidone (pvp) solution have concentrations and amounts that directly influence the hardness, particle size distribution, and compressibility of the granules. If the amount is too low, the binding force between particles is insufficient, leading to problems like loose or cracked tablets. If the amount is too high, the granules become too hard, affecting disintegration and dissolution.

Choice and amount of wetting agent

Wetting agents help to wet the surface of the drug powder, reducing its surface energy, and aiding in the uniform distribution and penetration of the binder. Common wetting agents include ethanol and water. The wetting effect varies with the ethanol concentration. If the concentration is too high, the wetting effect is weaker, making it harder to form granules. If the concentration is too low, the granules may become too wet, sticky, or even soft.

Granulation equipment and process parameters

AIPAK High Shear Mixer Granulator

Stirring speed and time

The stirring speed and time have an important impact on wet granulation. If the stirring speed is too fast or the time is too long, the granules may be excessively sheared, reducing particle size and even destroying their structure. If the stirring speed is too slow or time too short, the particles may not mix evenly, leading to uneven distribution of the binder and affecting granule quality.

Shear speed and time

In wet granulation, shear force helps to cut the material into uniform granules. The choice of shear speed and time should depend on the material's properties and the required particle size. If the shear speed is too fast or the time too long, the granules may break or the particle size distribution may narrow. If the shear speed is too slow or the time too short, the particle size may be uneven.

Drying temperature and time

If the drying temperature is too high or the time is too long, the surface moisture of the granules may evaporate too quickly, forming a hard shell that traps moisture inside, thus affecting the granules’ disintegration and dissolution. If the drying temperature is too low or the time too short, the granules may contain excessive moisture, leading to sticking, mold growth, and other issues that affect the quality and stability of the granules.

Environmental factors

Environmental Factors-Sourced:hanningfield

Temperature

High environmental temperatures can speed up the evaporation rate of binders or wetting agents, causing the soft material to dry too quickly and affecting the granulation process. Low temperatures can reduce the flow of materials, also hindering the granulation process.

Humidity

High environmental humidity can cause drug powders to absorb moisture from the air, increasing the moisture content of the granules and affecting their quality and stability. Low humidity can cause moisture to evaporate from the granules, making them brittle and affecting subsequent processing and storage.

5.What Is The Wet Granulation Process?

Wet granulation process isn’t complex. And here are the basic wet granulation process for you.

Screening and delumping

Screening And Delumping-Sourced:quadro-mpt

The first step of wet granulation is screening. This step can make sure the uniformity of your natural powder products. According to different powder feature and your product request, there is different need in your particle size and distribution. Screening of wet granulation can improve uniformity and make great job. There may exist large mass or bulk of powder or granules. Delumping makes the important job of removing or destroying the large bulk of powder or granule size.

Wet mass producing

The adding of powder or other solvent may make the forming of wet mass. The wet mass is composed of various powder or particle material. The former look of it is irregular and sticky. And you may control the particle size according to the different material request.

Milling

Milling-Sourced:hockmeyer

Dry milling is the last step of your wet granulating process. After the drying, the mass is still irregular. For the later smooth and beneficial medicine products manufacturing, you should apply the careful milling for your wet granules. The milling can help the forming of your irregular mass into the even and uniform particles.

6.How To Control The Size And Particle In Wet Granulating Process?

Size and particle of your powder are the two things which are important for your wet granulation work quality. So how to control the size and particle in wet granulating process.

Selection and processing of raw materials and excipients

Selection And Processing Of Raw Materials And Excipients-Sourced:chemlinked

Raw material particle size

Choose drug powders with a narrow particle size distribution and an appropriate particle size as raw materials. If the raw material powder is too fine, it can be pretreated, such as by spray drying or agglomeration, to increase the particle size and reduce the amount of fine powder. This can prevent the formation of overly small particles or uneven agglomeration of fine powders during granulation.

Properties of excipients

Select suitable excipients based on the required particle size and shape. For example, microcrystalline cellulose can increase the hardness and compressibility of granules, making the particle shape more regular. Excipients with lubricating effects, such as magnesium stearate, if used in excess, may affect the binding between particles, causing them to become loose and irregular in shape. Therefore, the amount of excipient must be controlled.

Use of binders and wetting agents

Use Of Binders And Wetting Agents-Sourced:freepik

Types and concentrations

Different binders have varying effects on the formation, size, and shape of granules. The higher the binder concentration, the larger and more regular the granules will generally be. However, if the concentration is too high, the granules may become too hard, affecting disintegration and dissolution.

The appropriate binder type and concentration should be selected through experiments. For cases where smaller granules are needed, binders like hydroxypropyl methylcellulose (hpmc) with relatively weak binding properties can be chosen, and the concentration should be kept at a lower level.

Addition method and speed

The key to controlling the uniformity of granules is to add the binder or wetting agent evenly to the drug powder. A spray addition method can be used to distribute the binder as small droplets on the powder surface, helping form uniform and regular granules. It is also important to control the addition speed to avoid the formation of excessively large particles in local areas due to an over-concentration of the binder.

Granulation equipment and process parameter adjustments

Granulation Equipment And Process Parameter Adjustments-Sourced:medicalexpo

Stirring paddle and cutting knife speed

Increasing the stirring paddle speed will make the material mix more evenly and enhance the shearing effect, helping form smaller, more uniform granules. Lowering the stirring paddle speed may result in larger particle sizes. The cutting knife speed primarily affects the shape and particle size distribution of the granules.

The faster the cutting knife speed, the stronger the cutting effect, making the granules more regular in shape and size. Both speeds need to be matched. For example, when preparing spherical granules, the cutting knife speed can be appropriately increased, along with a moderate stirring paddle speed, so that the granules gradually take on a spherical shape due to the combined effect of stirring and cutting.

Granulation time

If the granulation time is too short, the material may not mix evenly, and the binder may not fully interact with the powder, leading to incomplete granule formation with significant size and shape differences.

If the granulation time is too long, the granules may break due to excessive stirring and shearing, or become too hard and large due to prolonged binder interaction. The ideal granulation time range should be determined through experiments. For some drugs, a granulation time of 10-15 minutes may yield ideal particle size and shape.

Material fill volume

If the material fill volume in the equipment is too high, the pressure on the material during granulation will be uneven, leading to inconsistent particle sizes and shapes. If the fill volume is too low, the equipment’s utilization will be inefficient, and there will be insufficient collision and friction between the granules, making it harder to form well-shaped granules. The appropriate fill volume should be determined based on the equipment model and material properties, typically between 30% and 70% of the equipment's volume.

Drying process control

Drying Process Control-Sourced:ichimaru

Drying temperature

If the drying temperature is too high, the surface moisture of the granules will evaporate too quickly, and the internal moisture will migrate outward faster, potentially causing a hard shell to form on the surface while trapping moisture inside. This can lead to particle expansion and deformation, affecting shape and size.

Conversely, if the temperature is too low or the drying time is too long, the granules may remain damp for an extended period, leading to sticking, increased particle size, and irregular shapes. The drying temperature should be chosen based on the material properties and granule requirements. For temperature-sensitive drugs, the drying temperature can be controlled between 40°c and 60°c.

Drying method

Different drying methods also affect the size and shape of the granules. For example, fluidized bed drying allows the material to be in a fluidized state, minimizing particle collisions and friction. The dried granules have a more regular shape and a more uniform size.

In contrast, oven drying may have uneven temperature distribution, so the granules need to be turned frequently to ensure even drying and prevent uneven drying, which can affect the size and shape.

7.What Are The Common Equipment Applied For Wet Granulation?

The equipment applied for your wet granulation is varied. And here are the common equipment which is applied for your wet granulation.

Mixing granulator

AIPAK High Shear Mixer Granulator

High shear mixer granulator is designed for the mixing and granulating of various powder or granules material. It can make the mixing and granulating with high productivity and the work it produced can also benefit the later manufacturing process. This machine can make mixing and granulating at the same time.

Fluid bed dryer

AIPAK Fluid Bed Dryer

Fluid bed dryer is the kind of machine which is widely used in pharmaceutical industry. This machine apply the hot air to make the smooth and even powder. Heat transfer from fluid bed dryer is so efficient and helpful and you may get the great powder and particle work there.

Vibratory sifter

AIPAK Sifter Machine

Sifter machine is the equipment applied for the the sieving work of powder and granule products. You may have the uneven powder and particle size be uniform and regular. There are different mold size for you to choose. The sieving and vibrating work of your vibratory sifter can make the high qualified powder products.

Multi mill

Multi Mill-Sourced:bombaypharma

You may see multi mill for wet granulation work frequently. The high efficient and uniform milling job can benefit your products of different industries. This machine combines the work of vibrating, sifting, milling and so on. It may also be customized for the different request of different customers.

8.Where Can Wet Grabulation Be Applied In Tablet Manufacturing Process?

In tablet manufacturing process, there is the wide applying of wet granulation. Here are the places you may find the applying of wet granulation in tablet manufacturing process.

Mixing

Mixing-Sourced:amixon

For tablet products manufacturing, it is important to make the total mixing of raw powder material for your next step work. The total mixing of active pharmaceutical ingredients with blender and other excipients can prove the great quality of your later tablet products.

Granulating

Granulating-Sourced:genemamakine

Granulating refers to the forming of granules with powder and other liquid. Powder can then become wet mass. Granulating is the important step in wet granulation and tablet manufacturing process. The granules can make the more even, regular and uniform tablet products.

Screening

Screening-Sourced:RoopUltrasonixLtd

Screening can help make the precise sieving of the large particle size. The particle or powder with same size or type can make the better tablet products producing. In tablet products producing, screening takes the important place in making the preparation for your qualified tablets material manufacturing.

Drying

You may apply fluid bed dryer in the drying step. After the drying process from your fluid bed dryer, you can then apply the dried powder for the later pressing work. The dried powder and granules can be better applied for the next blending and compressing work.

Milling

Milling Work-Sourced:hanningfield

Milling refers to the pruning of your medical powder or granules of various size and type. The uniform size can make the better work in tablet products pressing. Wet granulation can help you make your tablets products with little defects.

9.Are There Other Granulation Technique?

Granulation is essential for many medicine products type. And here are other granulation technique which can be applied according to different request.

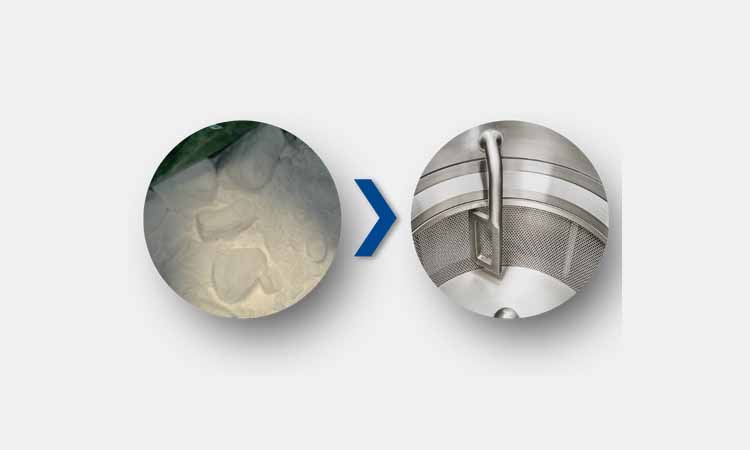

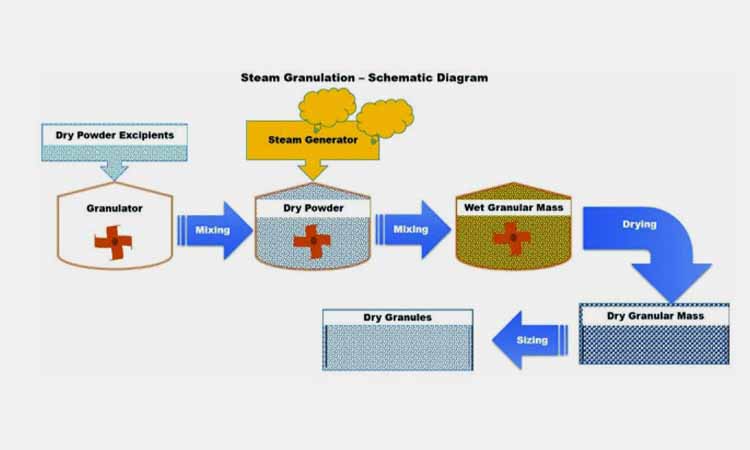

Steam granulation

Steam Granulation-Sourced:pmc.ncbi

Steam granulation is the creative granulating methods which apply steam as water for the blending of your powder and particles. It makes series of job like granulating, drying and so on. Steam granulation can help make the powder with better distribution, more uniformity and balance.

Melt granulation

Melt Granulation-Sourced:newcrownmachinery

Melt granulation applies heat as technique for the blending of powder. It applies the meltable binder which may melt in certain temperature. The various powder and granules can get together for the heat and make melt granulation.

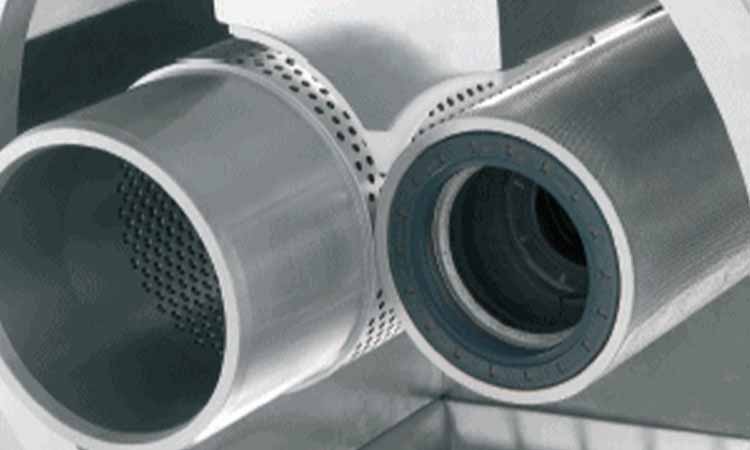

Moist granulation

Moist Granulation-Sourced:alexanderwerkinc

The adding of granulating fluid in dry powder and granules and forcing the compacted powder products are the typical moist granulation work. In this technique, wet agglomeration of powder and moisture distribution are two important factors you should consider.

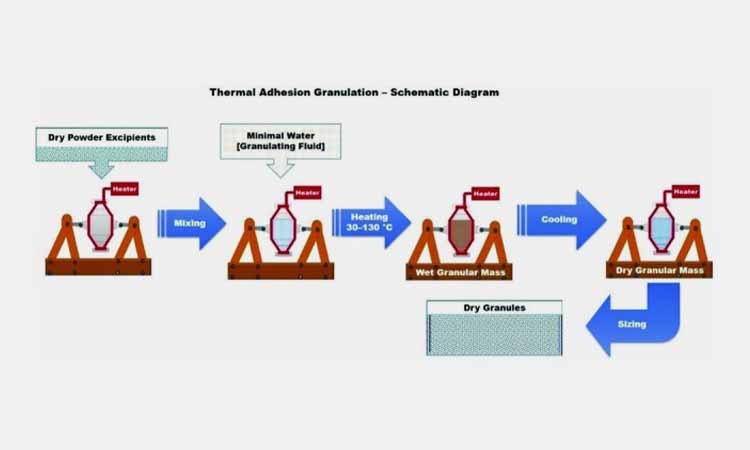

Thermal adhesion granulation

Thermal Adhesion Granulation-Sourced:pmc.ncbi

Thermal adhesion granulation applies low moisture solvent or minimal water with heated moisture component. This granulation technique applied less water and solvent. This type pf granulation is also common and welcomed.

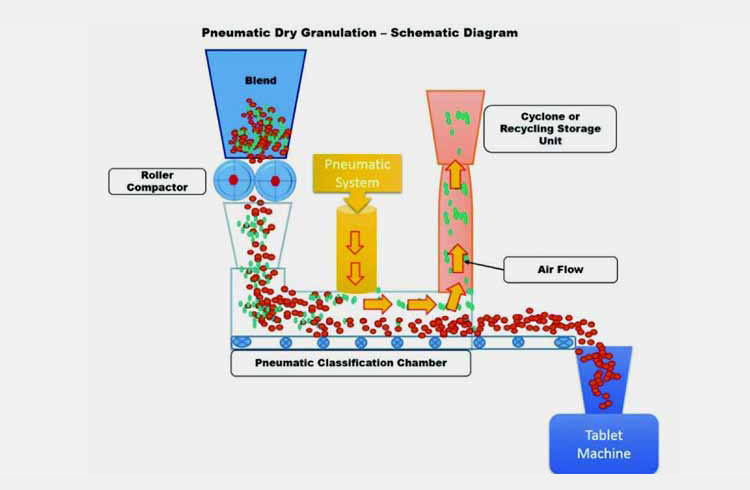

Pneumatic dry granulation

Pneumatic Dry Granulation-Sourced:pmc.ncbi

In pneumatic dry granulation, there is roller compactor for the compressing of powder and granules. This granulation technique comes compacted mass with high efficient. Without applying solvent or other binder, this granulation technique is unique.

Conclusion

How to make the great wet granulation in pharmaceutical industry? Do you have your answers? Here , besides the solution, you may also get the comprehensive knowledge about wet granulation process. If you have any question or problem about wet granulation, you may have no hesitate to contact AIPAK now.

Granulator Machine Related Products

Granulator Machine Related Posts

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box? Sign up for AIPAK’s monthly newsletter, we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machin