What Factors May Affect The High Disintegration Of Hard Capsules?

You may often found that when you are making hard capsule disintegration, the capsule always sticks to the pressing block and moves up and down with the pressing block, resulting in disintegration for more than 30 minutes, which is the case with hollow capsules of different manufacturers and batch numbers.

However,the contents of the capsule are extracted extract, mixed with raw powder after drying, dry granulation, drying, total mixing, filling, without adding other excipients.So you may wonder what factors may lead to the high disintegration of these hard capsules?

Regarding this problems,many people has various thoughts,some people in the industry believe

that the disintegration of hard capsules may be caused by too much extract and too strong hygroscopicity. Some traditional Chinese medicine can be used to powder, or coated after granulation.

Some other people also believed in the industry that there should be components in the extract that become sticky when encountering water (similar to glue components). It is suggested that you should boil the extract more when the concentration is almost over, that is, to concentrate the density of the extract a little, which may solve the problem of disintegration.

It is understood that the disintegration time limit is an important control index for tablets, capsules and dropping pills. Disintegration time limit inspection is generally carried out by disintegrating instrument, which is specified in detail in the new pharmacopoeia, in which it is specified that the disintegration time limit of hard capsule is 30 minutes.

However,some people who make traditional Chinese medicine capsules that result in disintegration thought this is because the traditional Chinese medicine extract is too sticky,and their solution is to use 50% or higher concentration of ethanol during granulation, and add 1% magnesium stearate when making soft wood.

While other people the stickiness of traditional Chinese medicine extract is caused by the expansion of water-soluble polymer in it when it meets with water, so that the traditional Chinese medicine extract powder can contact water as little as possible. Magnesium stearate is a hydrophobic substance, which can form a hydrophobic film on the surface of particles to prevent adhesion.

In this way the hard capsules can be disintegrated within 20 minutes, which has met the requirements of the Pharmacopoeia; If you still can't, you may have to regard it as quality problem.

Not only in capsule manufacturers, tablet manufacturers also face the problem of over disintegration time limit.

For example, some manufacturers of traditional Chinese medicine dispersible tablets also said that many methods have been tried, but the disintegration time limit can not meet the requirements. There are more disintegrating agents added, and mixing with particles is a problem, which leads to poor reproducibility of disintegration results.

However,some hard capsules manufacturers said,they replaced the sodium carboxymethyl starch with low substituted hydroxypropyl methyl, and the disintegration time was miraculously reduced to 3 minutes. The disintegrating agents in our prescription are all added, and the proportion is about 20%.

While, compared with the disintegration of tablet manufacturers, capsule disintegration has attracted more attention in the industry and is more difficult to solve.

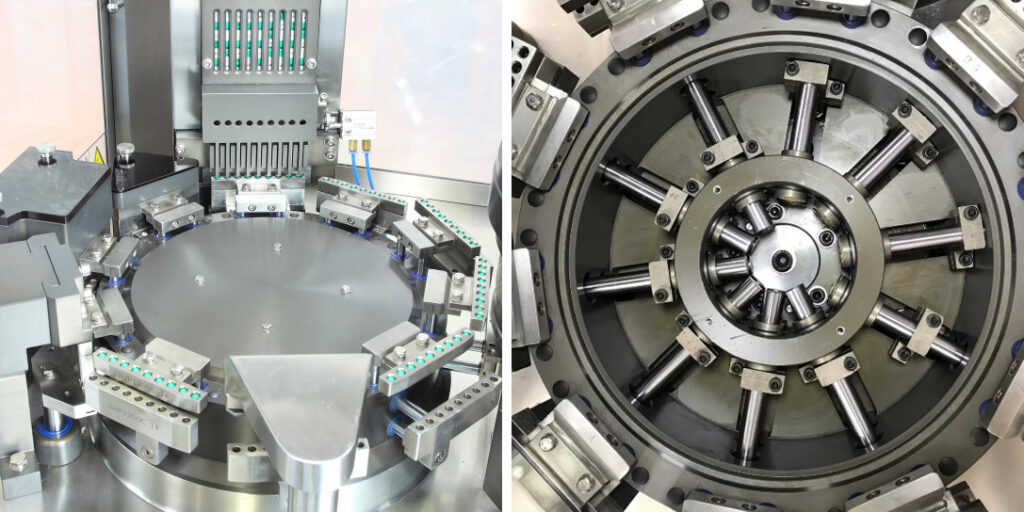

In fact, with the continuous application of hard capsule production lines and hard capsule filling and sealing machines in recent years, there has been a great increase in the variety and output of hard capsule in China.

However, the problem of disintegration time limit often puzzles producers, and has been paid more and more attention.

Some experts pointed out that the disintegration of hard capsules is related to packaging materials, preparation technology, pharmaceutical excipients and other factors.

The disintegration time limit of hard capsule during storage is related to packaging materials, and different packaging materials have different disintegration differences.

At the same time, the disintegration time limit is also related to the preparation process. The disintegration of the same capsule prepared by different processes is also different.

In addition, capsules filled with different pharmaceutical excipients also have a certain impact on disintegration during storage.

Ordinary hollow hard capsules for medicine, mostly stomach soluble capsules, are filled with therapeutic drugs. After taking, the hard capsules will be disintegrated in the stomach of the human body and release drugs.

Due to the different causes and lesions, and the different effects of some drugs, if released in the stomach, may cause irritation to the stomach and produce adverse reactions, reducing the efficacy.

In other words, the current common medicinal hard capsules have the defect that they cannot be disintegrated and administered.

The purpose of the utility model is to provide a medicinal hard capsule that can realize the positioning administration, overcome the defect that the ordinary medicinal hard capsule can only be disintegrated and administered in the stomach, but can not be disintegrated and administered in the positioning, and increase the type and use of the medicinal hard capsule.

In order to achieve the above purpose, the utility model adopts the structural form of the capsule body and the capsule cap of the ordinary medical capsule. A coating layer of materials different from the disintegration point of the original capsule is adhered to the outer surface of the capsule cap and the capsule body.

After the capsule is filled with drugs, the capsule cap is sleeved on the capsule body to form a pharmaceutical capsule preparation that can be administered in a targeted manner. The working principle of the utility model is: the pH value of the gastric juice of the human stomach is 1.2, the pH value of the intestinal juice of the small intestine is 6.8, and the pH value of the intestinal juice of the large intestine is 7.8. A coating layer of material dissolved only in a medium with a pH value of 6.8 is pasted on the outer surface of the medicinal hard capsule to obtain a hard capsule that can be positioned in the small intestine to disintegrate.

A coating layer of material dissolved only in a medium with a pH value of 7.8 is pasted on the outer surface of the medicinal hard capsule to obtain a hard capsule that can be positioned in the disintegration of the large intestine.

By using the utility model, a medicinal hollow hard capsule which can be disintegrated and administered in a fixed position can be obtained, and the variety and use of the medicinal capsule can be increased; The drug contained in the capsule can be administered in a targeted manner in the human body, which can reduce the stimulation of the drug to the stomach and the resulting adverse reactions, and ensure the efficacy.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine