What Are The Pharmaceutical Tablet Forming Solutions For Special Materials?

Are you an expert in tablet manufacturing? Do you know what are the solutions for different tablet forming? How to solve the forming of special tablets? Tablets in life are rich in variety and full of functions. But not all tablets use the same forming solution.

Different tablets need to consider the ingredients and dosage of raw materials, the auxiliary properties added, and the stability of active ingredients. Tablets with different ingredients use different forming methods. Through this special tablets post, you may understand the forming methods of different tablets and what solutions should be adopted when encountering special materials. Take action now!

1.What Are Special Pharmaceutical Tablets?

What Are Special Pharmaceutical Tablets-sourced: lubrizol

Unlike ordinary oral tablets, special pharmaceutical tablets are specially made to treat various rare or difficult products. They are usually made of special materials and also require special handling. For example, Chinese herbal extracts, poorly soluble drugs, highly elastic materials and heat-sensitive materials. Different from the handling of ordinary tablets, the production method and material handling of special pharmaceutical tablets are different and require special attention.

2.How Many Types of Special Pharmaceutical Tablets Are There?

There are four main special pharmaceutical tablets in the market now. They are:

Chinese medicine tablets

Chinese medicine tablets-sourced: accessibleacupuncture

Chinese medicine tablets, also called as Chinese herbal medicine tablets, are made from raw materials extracted from various Chinese herbal ingredients. There are of various types and have different characteristics, such as ginseng, astragalus, angelica, musk, bezoar, cinnabar, ganoderma, etc. Due to their different characteristics, they need to be distinguished from ordinary tablet ingredients during the extraction, production and compression process.

Poorly soluble drug tablets

Poorly soluble tablets-sourced: Healthy AF

Poorly soluble drug tablets refer to a special type of tablet with low solubility. The drug cannot be absorbed by the human body without special treatment. The special nature of the ingredients leads to low bioavailability in the tablets. In addition, they may also cause problems such as difficult metabolism or low permeability. This type of tablet requires a longer drug release time. This type of tablet includes phenobarbital, etc.

Highly elastic tablets

Highly elastic tablets-sourced: mdpi

Highly elastic materials refer to materials that have great resilience during tablet compression, are not easy to be made into tablets, and are prone to fission and loose tablets during the production process. Such tablets are difficult to maintain their initial stability, and their shape and size will be affected. Whether through physical or chemical solutions, it is difficult to change their physical state.

Thermo-sensitive material tablets

Thermo-sensitive tablets-sourced: alcimed

Thermo-sensitive materials refer to the fact that the drug ingredients are prone to physical or chemical reactions when heated, such as degradation, discoloration or deterioration. In addition to affecting the quality of the tablets or the efficacy of the drug, it is necessary to strictly control the relevant temperature, humidity or pressure during the production process, and special methods need to be taken to keep it from being affected by heat, so as to fully exert its efficacy.

3.Where Are Special Pharmaceutical Tablets Used For?

Special pharmaceutical tablets are used in a wide range of complex applications and are generally used to treat rare or complex health problems. The characteristics of these special tablets include:

More complex manufacturing process

More complex manufacturing process-sourced: spm

The complexity of special tablets increases the complexity of the manufacturing process. They need to be processed and manufactured by more specialized pharmaceutical equipment and tableting equipment. It involves various issues related to materials and material handling.

High R&D cost

High R&D cost-sourced: hystax

The complexity of special tablets increases its R&D cost, making the production cost of this special tablet higher.

Specialized treatment of difficult and complicated diseases

Specialized treatment of difficult and complicated diseases-sourced: healthline

Special pharmaceutical tablets are generally used to treat difficult and complicated diseases or relatively rare health problems. And these drugs are not used by most people, so local pharmacies generally have less inventory. The input rate for production use may be lower.

Requires special follow-up or care

Requires special follow-up or care-sourced: ccchclinic

When patients take special tablet drugs, they need professional healthcare teams or personnel to follow up or provide special care.

4.What Are The Pharmaceutical Tablet Forming Solutions For Special Materials?

There are several ideas for the production method or solution in the production process of this special types of tablet:

Traditional Chinese medicine extract

Traditional Chinese medicine extract-sourced: elgalabwater

The composition of traditional Chinese medicine extract is relatively complex, and is generally accompanied by a large amount of viscous or polysaccharide components. This makes the composition of traditional Chinese medicine extract extremely poor in fluidity and easy to absorb moisture. In the later tablet production process, it is easy to cause tablets to be difficult to form and the quality is unstable in the later stage.

Solutions:

- Granulation process

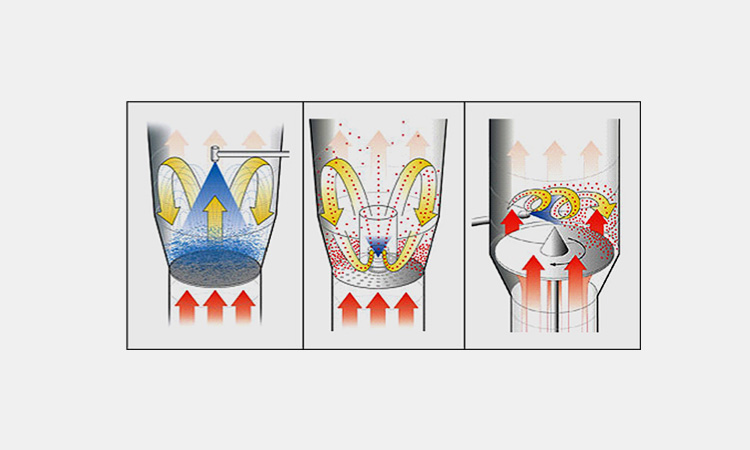

Granulation process-sourced: genemamakine

By using spray drying granulation or fluidized bed granulation and other technologies, the components in the traditional Chinese medicine extract are evenly dried and granulated. The more viscous components are quickly dried into fine particles to reduce the fluidity of the viscous components, thereby increasing the hardness and dryness of the later tablets and maintaining stability.

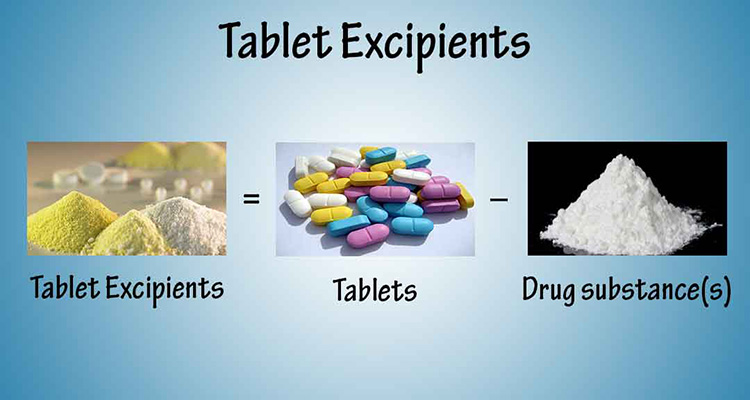

- Selection of excipients

Selection of excipients-sourced: pharmapproach

By adding some excipients that can improve the composition and texture of traditional Chinese medicine extracts, such as fillers such as microcrystalline cellulose and lactose, the texture of the material is increased, its fluidity is reduced, and its hardness is increased. Lubricants such as talcum powder can also be added to reduce the friction between particles, prevent stickiness, and increase its hardness.

- Strictly moisture control

Strictly moisture control-sourced: genemamakine

The ingredients in Chinese herbal extracts are relatively viscous and easy to absorb moisture, so during the tableting process, the ambient humidity and temperature need to be strictly controlled. Try to use moisture-proof packaging materials and tablet and package the Chinese herbal extract materials in a dry environment.

Poorly soluble drugs

Poorly soluble tablets-sourced: vitaquest

Poorly soluble drugs have very low solubility in water and dissolve very slowly. This property greatly affects the bioavailability of the drug and the absorption of the patient. Therefore, the combination of drug particles and excipients will be very weak, and it is easy to have problems with cracking or loose tablets during the subsequent tableting process.

Solutions:

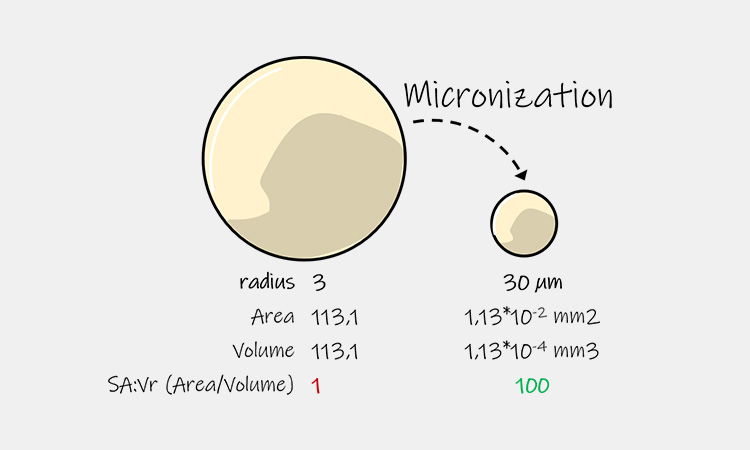

- Micronization technology

Micronization technology-sourced: technologyscientific

Use airflow to crush or micro-damage the drug. By reducing the diameter of the drug particles, the surface area of the drug is increased, thereby increasing the dissolution rate of the drug. You can also increase the technical difficulty of tablet production and upgrade the powder of the poorly soluble drug to the micron or nanometer level to improve its solubility.

- Solid dispersion technology

Solid dispersion technology-sourced: digimsolution

Mix the drug with a water-soluble carrier material, such as polyethylene glycol, to improve the solubility and dissolution rate of the drug.

- Highly elastic materials

Highly elastic materials-sourced: globalsources

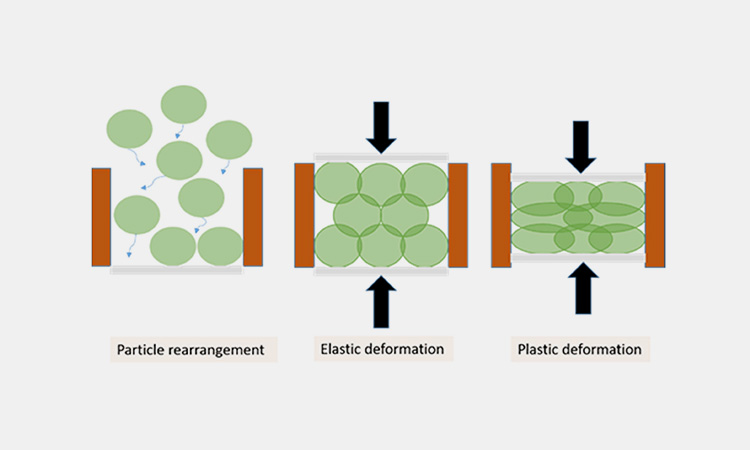

During the tableting process, due to the characteristics of the material itself, the resilience of highly elastic materials will be very large. Therefore, deformation problems are prone to occur in the later tableting process. And it is difficult for the finished product to maintain a stable shape or size.

Solutions:

- Pre-treatment

Pre-treatment-sourced: fabtechnologies

For highly elastic materials, you can perform a pre-treatment. Heat or cool it. By changing the physical state of the material, its elasticity can be reduced. And for some materials with strong elasticity, their brittleness can be increased by low-temperature crushing, thereby reducing their elasticity.

- Add auxiliary materials

Add auxiliary materials-sourced: mcepharma

You can improve the compressibility of the material and reduce its resilience by adding auxiliary materials with plastic properties, such as starch, dextrin, etc., and mixing them with highly elastic materials.

- Optimize tableting process

Optimize tableting process-sourced: sigmaaldrich

You can also use a lower tableting speed or a larger pre-pressure to allow the material to have a longer pressing time or withstand greater pressure in the mold. This can reduce the impact of material elasticity and improve the molding quality of the tablet.

Heat-sensitive materials

Heat-sensitive materials-sourced: dessica

During the tablet manufacturing process, heat-sensitive materials are easily affected by themselves or the environment, causing degradation, discoloration or deterioration. This problem will affect the quality and efficacy of the later drugs. Therefore, in the tablet preparation process, whether it is drying or granulation, the temperature needs to be strictly controlled.

Solutions:

- Low-temperature granulation

Low-temperature granulation-sourced: shpilotech

Unlike high-temperature granulation, low-temperature granulation mainly uses cold water or low-temperature ethanol as a binder and solvent. Granulation and tableting of materials are performed at a lower temperature. This method can prevent the materials from being affected by the heat of the external or internal environment, thereby affecting the quality of the product itself.

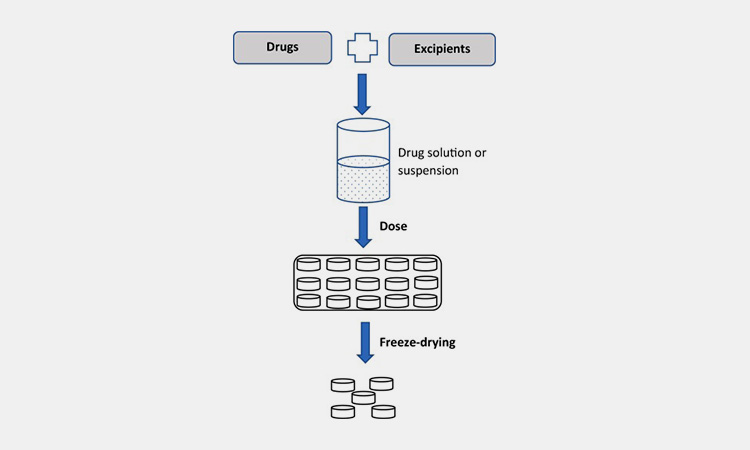

- Freeze drying

Freeze drying-sourced: sciencedirect

For some materials that are extremely sensitive to temperature, freeze drying technology can be used to freeze the materials at low temperatures. Then, it is sublimated by water under vacuum conditions, which can maximize the retention of the active ingredients of the materials.

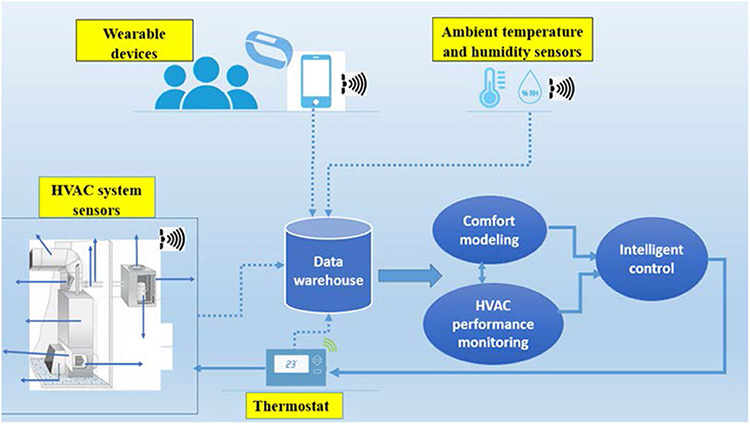

- Controlling ambient temperature

Controlling ambient temperature-sourced: frontiersin

During the tableting process, the ambient temperature needs to be kept at a low level and maintained stable. By using air conditioning systems or cooling equipment to cool the tablet press and the surrounding environment, heat-sensitive materials can be prevented from being affected by heat during the tableting process, thereby changing stability.

5.Which Machines Are Used For Special Pharmaceutical Tablets Manufacturing?

Different materials can be prepared in different equipment for special pharmaceutical tablets. Here are two types of equipment for you to choose from:

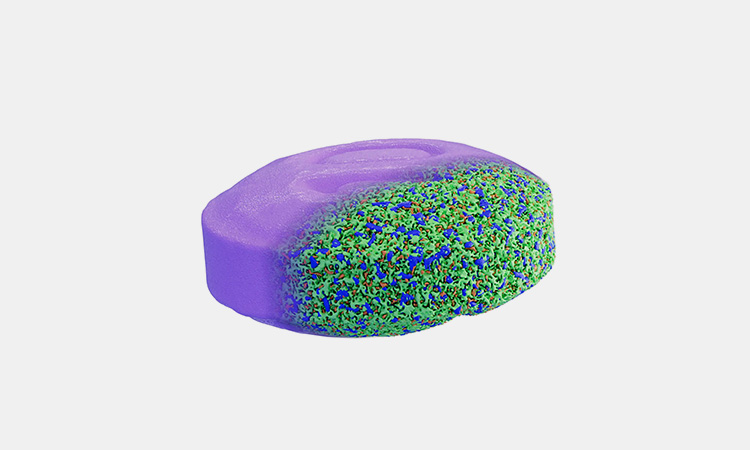

Tablet press machine

AIPAK tablet press machine

Tablet press machine is a machine that can directly compress different drug powders or granules into tablets without changing the physical properties of the material. For special tablets manufacturing, this method is direct and economical. During the compression process, appropriate excipients, disintegrants and lubricants are added, which can provide you with the highest quality tablet form.

Working principle of tablet press machine

Working principle of AIPAK tablet press machine

- Filling. When the processed special drug powder is loaded into the tablet press machine, it is accurately dosed by the filling hopper and distributed into the membrane holes of the rotating disk of the machine. You can set the amount of powder you need for each tablet.

- Compression. After being filled into the membrane hole, the two punches and the die of the machine impact and act on each other. Under the interaction of the upper and lower punches, the powder in the membrane hole is subjected to compression force. Thus, it is slowly compressed to the set tablet size, thickness and hardness.

- Ejection. After being compressed, the upper and lower punches will move out of the membrane hole and push the tablet out of the die. When the finished tablet is ejected and carried away by the discharge chute, a new tablet compression phase begins again.

Main parts of tablet press machine

Main parts of AIPAK tablet press machine |

|

| Punches and dies | This is the most basic and important parts of tablet press machine. It mainly includes the top, bottom and sides of punches and dies. Punches and dies can help you press tablets of various shapes, sizes, thickness and hardness. |

| Filling system | The filling system of tablet press machine is responsible for delivering the drug powder or granules you need to process to the tablet pressing area. It mainly ensures the continuous and smooth supply of drug powder. |

| Pressure regulation system | Specially used for pressure regulation of punches. It is responsible for controlling the pressure of punching to ensure that the tablets have consistent thickness, size and shape. |

| Tablet ejection system | The tablet ejection system is responsible for ejecting and recycling the pressed tablets to facilitate the subsequent secondary processing and packaging. |

| Turntable | The turntable is mainly used to support and release the punches and dies used for tableting. During the rotation of the turntable, the punches will repeatedly and cyclically complete the compression of the powder, which is efficient and stable. |

| Motor | The motor is the power source of the entire equipment. It can provide a continuous source of power for the tablet press machine, driving the operation of the entire equipment. |

6.What Are The Future Trends For Special Pharmaceutical Tablets?

The pharmaceutical industry is constantly innovating and has begun to move towards digital pharmaceutical manufacturing. More and more investors and businessmen are very concerned about the trend of special tablet manufacturing. The following are the relevant survey results.

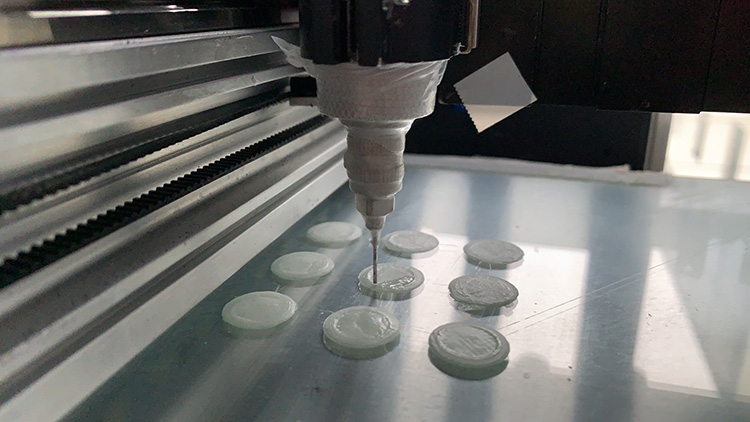

3D Special Tablets Printing

3D Special Tablets Printing-sourced: estonianworld

According to the condition of each patient, a special tablet is customized to suit the symptoms. Then the tablets are made through 3D printing technology. There is no specific solution for this technology now, and it has not been actually applied in clinical environments. Everything is still experimental.

Special Tablets Manufacturing with artificial intelligence

Special Tablets Manufacturing with artificial intelligence-sourced: thefloridavillager

Artificial intelligence has been changing the world and is constantly changing the healthcare industry. It can mine medical records, design treatment plans, speed up medical imaging, and even help drug development and production. Especially in the manufacturing of special tablets, it can provide excellent processing solutions.

Conclusion:

Special tablets are developed and manufactured for special diseases. Their production process, technology and forming options are more complicated than the production and development of ordinary drugs. Therefore, if there are more you do not understand through this whole post of What Are The Forming Options For Special Tablets, do not hesitate to contact AIPAK now!

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine