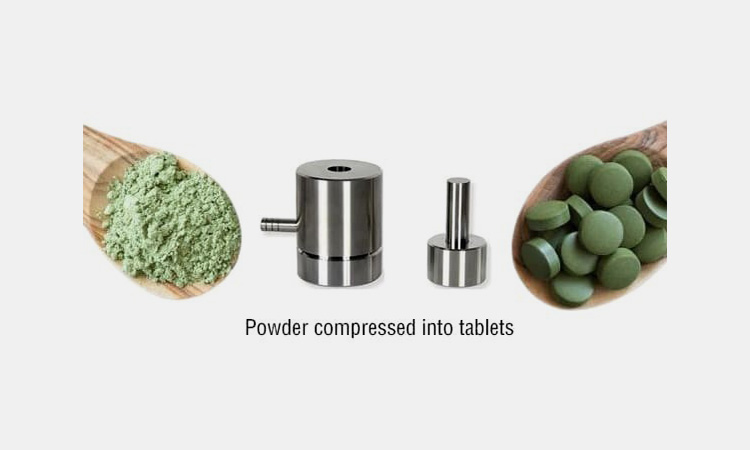

What Are The Effects Of Drug Crystal Form On Tablet Press?

With the development of the pharmaceutical industry, the development of drug crystal form in the tablet pressing process has also been included as an important indicator of the pharmaceutical industry. Crystals of different raw materials and ingredients will affect the final compression and pharmaceutical results of the drug.

After studying the synthesis process of the raw materials, the following effects of drug crystal form on tablet press were obtained. This post has performed a deep study of drug crystal form for tablet press. Take a look now!

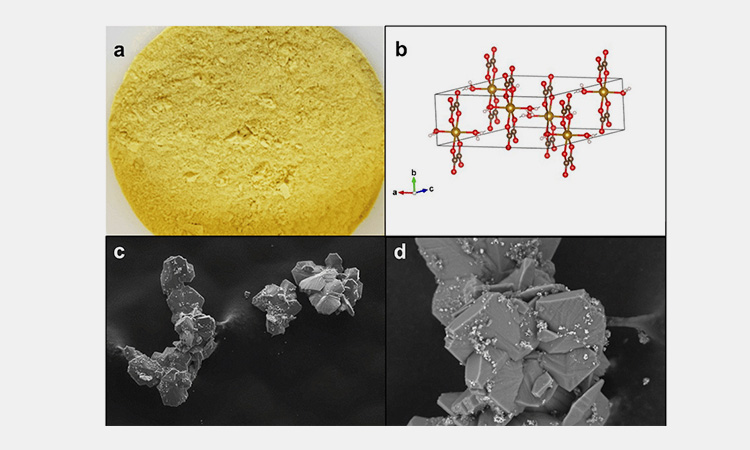

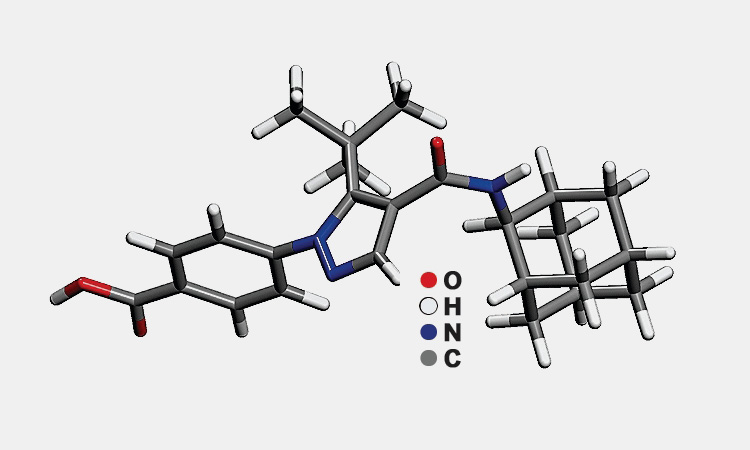

1.What Is Drug Crystal Form?

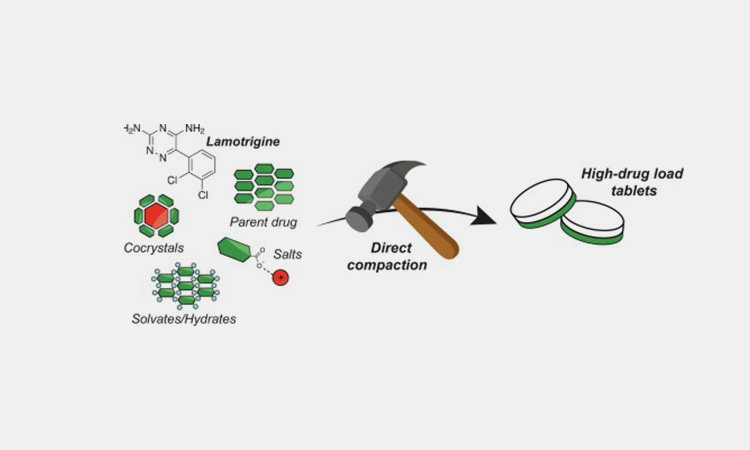

What Is Tablet Crystal Form-sourced: sciencedirect

The crystalline state of a drug refers to a state in which a solid drug exists. Its appearance is crystalline. This is a way of describing the state of a substance. The crystalline state of a drug includes salts, polycrystals, cocrystals, amorphous hydrates and solvates.

The tablet press process is crucial for solid dosage forms. It mainly provides the main way for tablet formation and can maintain the stability and effectiveness of tablets. Among them, its key roles are:

Give tablets a complete and stable shape and structure

Tablet complete and stable shape and structure-sourced: wikimedia

The tableting process can give tablets a complete and stable structure. Thanks to the fine structure and sophisticated design of the tablet press, it can compress materials with different crystals into slow-release solid tablets. And it can provide you with accurate dosage and content of active ingredients. Tablet press can provide you with solid dosage forms with more uniform drug content and easier to store and carry.

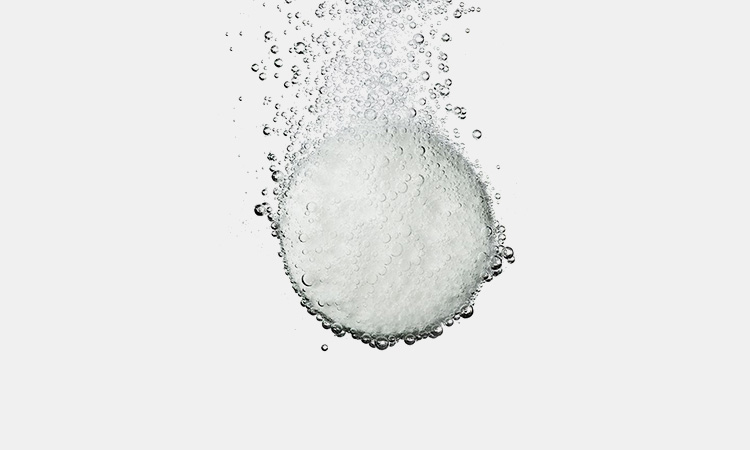

Ensure the disintegration and solubility of tablets

Ensure the disintegration and solubility of tablets-sourced: pharmaexcipients

Excellent tablets can provide stable disintegration and solubility. In addition to the use of excipients and lubricants, which will affect the disintegration and solubility of the drug. The pressure during tableting and the choice of subsequent coatings will also affect the disintegration and dissolution behavior of tablets. Adhesives can enhance the dissolution between particles inside the material and improve the pressure resistance of the material.

Provide high mechanical strength and reduce breakage rate

Provide high mechanical strength and reduce breakage rate-sourced: theonpharma

When processing high-particle materials, the tablet press can provide you with high-strength compression capacity and wear resistance. In the tableting process, in order to avoid excessive and low pressure, tableting will not only ensure that the tablets do not break, but also prevent the tablets from sticking.

Ensure the uniformity and stability of drug ingredients

Ensure the uniformity and stability of drug ingredients-sourced: theguardian

Tablet press can give tablets high-quality uniformity and stability of drug ingredients. Before tableting, the materials and excipients will be evenly mixed, the in-homogeneity of drug ingredients during the filling process will be optimized, and the drug crystal form will not change or degrade.

Suitable for the production of different types of solid preparations

Tablet press is used in the production of various solid preparations, including ordinary single-layer tablets, coated tablets, effervescent tablets and sustained-release tablets. Whether it is to change the taste and flavor of the coating film, control the release, disintegration and solubility of the tablet, or adjust the speed of tablet release, tablet press is a good choice.

2.What Are The Effects Of Drug Crystal Form On Tablet Press?

The influence of the state of drug crystals on tableting is mainly reflected in the following aspects:

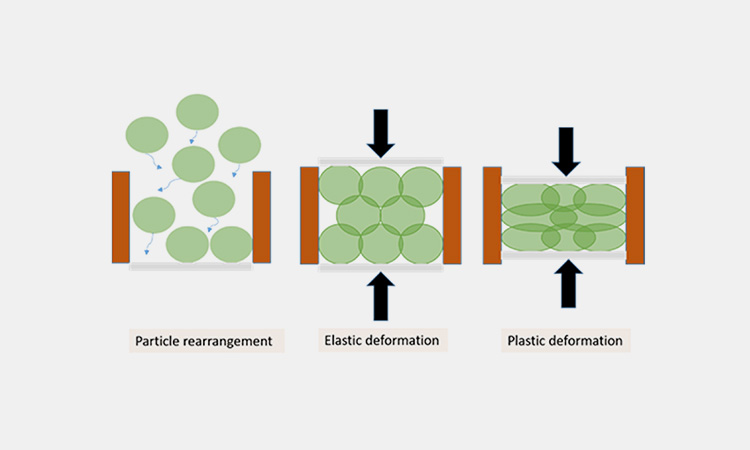

Plasticity

Plasticity-sourced: mdpi

The crystal structure molecules in different crystalline drugs are different, and the forces between them are also different, which leads to different plasticity of crystalline drugs. If the molecular forces between some drug crystals are relatively weak, they can show good plasticity during tableting.

If the molecular forces of some crystals are strong and form a close connection, the crystals will show very poor plasticity. It takes a longer tableting time or greater pressure to form tablets during tableting.

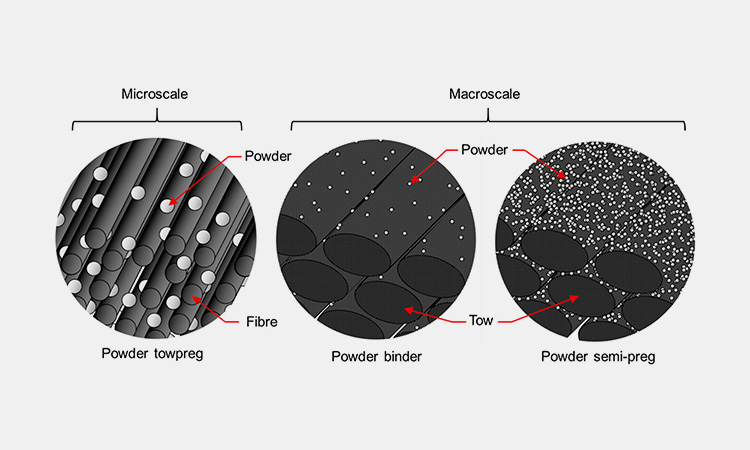

Flowability

Flowability-sourced: azom

Crystal form and particle shape

Crystal form and particle shape-sourced: tbzmed

The type and shape of drug crystals determine the type and shape of particles. Spherical crystal drug particles have less friction and better fluidity. They can be evenly filled into the mold during tableting, and the weight difference of the final product is small. However, the friction between flake or needle-shaped crystal types is greater and the viscosity is less. Therefore, poor fluidity will cause uneven filling of materials in the mold, which will eventually affect the quality and uniformity of the finished product.

Crystal form and surface properties

Crystal form and surface properties-sourced: researchgate

Different crystal types of drugs have different surface roughness and electrostatic properties. If the surface is smooth and the electrostatic effect is small, then the crystal has good fluidity. On the contrary, the rougher the surface and the stronger the static electricity, the easier it is to adsorb the surrounding particles, making the fluidity of the material worse and less suitable for tableting.

Compressibility

Crystal form and pressure transmission

Crystal form and pressure transmission-sourced: cen

Different drug crystal types will affect their pressure transmission. If the drug crystal type is regular and tightly arranged, the pressure in the crystal can be evenly transmitted to each other during tableting, so that the internal drug density of the final product is evenly distributed.

If the crystal type is more irregular and there are many spaces or defects, the pressure transmission inside the crystal will be uneven during the subsequent tableting process, which may cause problems inside.

Crystal form and compression ratio

Crystal form and compression ratio-sourced: huadapharma

Different drug crystal types have different compression ratios. Some crystal forms can withstand strong compression forces, so they are more suitable as materials for tableting. Some drug crystals cannot withstand greater pressure, so longer tableting time is required to achieve the same effect.

Tablet stability

Crystal form and hygroscopic properties

Crystal form and hygroscopic properties-sourced: mdpi

The hygroscopicity of different drug crystal types is also different. Some crystals have strong hygroscopicity and easily absorb moisture from the air during tableting, causing crystal transformation.

The particles also swell, thereby destroying the tablet structure and reducing tablet stability. The crystals of these crystal structure drugs will change in a high humidity environment, resulting in a decrease in tablet hardness. Disintegration delays and other problems may occur during later use.

Crystal form and long-term storage

During long-term storage of drugs, crystals may change. Unstable crystal types will gradually transform into stable crystal types. With the transformation, the volume and hardness of the crystals will change, affecting the appearance and quality of the finished tablets in the later stages. When some crystals transform, the tablet color becomes darker and the efficacy decreases.

3.What Are The Factors May Affect Drug Crystal Transformation?

The transformation of drug crystals will affect the quality of the final tablet. The following factors will affect the formation or transformation of crystals:

Solvent type

Solvent types-sourced: solvents

The crystal transformation of drugs is affected by many factors such as solvent temperature and water content. In the process of drug crystallization, different solvents at the same temperature and the same water content will lead to differences in drug crystallization.

Temperature

Temperature-sourced: cielowigle

When the crystallization environment temperature is too high, it will accelerate the change of drug crystals. When the crystallization environment temperature is too low, the crystals will remain in a more stable state. Therefore, if you want to change the crystal form of the drug, you need to increase the temperature.

Grinding

Grinding-sourced: capsulcn

In the physical state, grinding drug particles will also change the shape of the crystals. Evenly grinding the crystals will also change the crystals.

Preparation process

Preparation process-sourced: kindle

During the tableting process, the pressure generated by the equipment will generate heat, which will cause the drug crystals to transform. When the tablet press presses the crystal form a, the drug crystals will eventually transform into the crystal form c and amorphous.

4.What Should You Do For Drug Crystal Form On Tablet Press?

During the tableting process, if you need to deal with the crystal form changes of the tablets, you need to pay attention to the following points:

Control temperature and humidity

Control temperature and humidity-sourced: cielowigle

Especially under high humidity and temperature conditions, the crystal form of the drug is most likely to change. Therefore, during the tableting process, in order to prevent the crystal form of the drug from changing, you need to accurately control the temperature and humidity of the tableting. Try to complete the tablet pressing in a mild and dry environment, and avoid high humidity and high temperature environments.

Adjust pressure

Adjust pressure-sourced: cielowigle

Excessive pressure will also affect the change of the drug crystal form. You need to reasonably control the tableting pressure, avoid excessive and excessive pressure, and reduce the risk of crystal form changes.

Use stabilizers

Use stabilizers-sourced: intheswim

If it is really impossible to avoid the change of the drug crystal form, you can add some stabilizers to reduce the interaction between drug molecules and maintain the stability of drug crystals.

Optimize process conditions

In the process of drug tableting, in order to prevent the drug crystal from changing, you can use wet granulation to pre-treat the drug powder before tableting, and then dry it thoroughly. Control the air temperature, humidity, etc. of the environment.

Monitor and control environmental factors

Monitor and control environmental factors-sourced: iebmedia

Whether in the process of tableting, packaging or storage, you can effectively control the temperature, humidity and light of the environment. Effectively reduce the risk of crystal changes and adjust the optimal environment for pharmaceutical production.

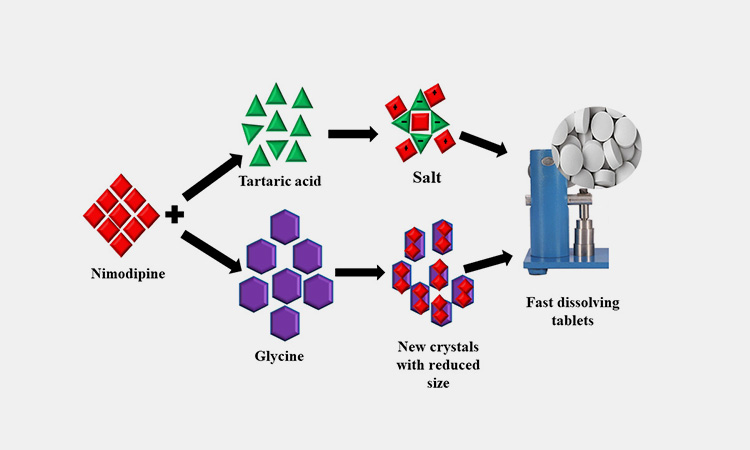

5.How To Improve The Particle Size Of Crystals During Tablet Press?

In order to improve the particle strength of the crystals and obtain high-quality tableting products to the greatest extent, you can improve and control the particle size of the crystals during the drug powder processing and tableting process. The specific methods are:

Control API over-saturation

Control API over-saturation-sourced: access-pharma

If the API saturation in the drug is too high, the molecular forces between them will be stronger, and it is very easy to generate needle-shaped crystals. The more crystals there are, the more difficult it is to control the particle size of the crystals. Therefore, the lower the API saturation in the drug, the more uniform the particle size control of the crystals.

Control evaporation rate

Controlling the temperature in the tableting environment can well control the evaporation rate of the water in the drug. If the ambient temperature drops too quickly, it is easy to destroy the crystal structure of the drug, thereby reducing the quality of the finished product.

Stirring speed

Stirring speed-sourced: anton-paar

When handling the powder material in the early stage of tableting, it is necessary to control the crushing or stirring speed of the powder well. If the crushing and stirring speeds are too fast and the force is too strong, it is easy to cause the particle size of the crystals to become smaller, which is not suitable for later tableting.

Impurity treatment

Generally, if the drug material is not handled finely enough, it will lead to the presence of impurities or additives. Additives and impurities will affect the growth and structure of crystals. In order to control the crystal structure and particle size of the material, you need to screen and process the impurities of the material appropriately.

Conclusion:

The crystal form of different drug raw materials will affect the effect and quality of the tablets and pills after final processing and tableting. Different crystal forms of the same drug may have different appearance, solubility or bioavailability. Through this post, you may understand the impact of crystal form on drug tableting. If you have more needs later, please contact AIPAK now.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine