What Are The Different Pharmaceutical Packaging Machines ?

Packing of multiple items in different fields is a necessary thing that can assure your product validity, safety and security during on and off the road movement.

Pharmaceutical packaging machines are there to help multiple industrial packings and business packing of different products such as tablets, pills, capsules, dosages and multiple more.

This useful blog about multiple Pharmaceutical packaging machines will cover their working, uses and benefits in packing with multiple working abilities that includes wrapping, packing, sealing, and counting.

Table of Contents

I.What are the different types of Pharmaceutical packaging machines?

There are many Pharmaceutical packaging machines and all of these packing machines work in a different way as compared to each other.

Following are the different Pharmaceutical packaging machines.

- Blister Packing Machine

- Cartoning Machine

- Strip Packing Machine

- Effervescent tube packing machine

Let me explain these Pharmaceutical packaging machines including there working, uses in medical industry and their advantages.

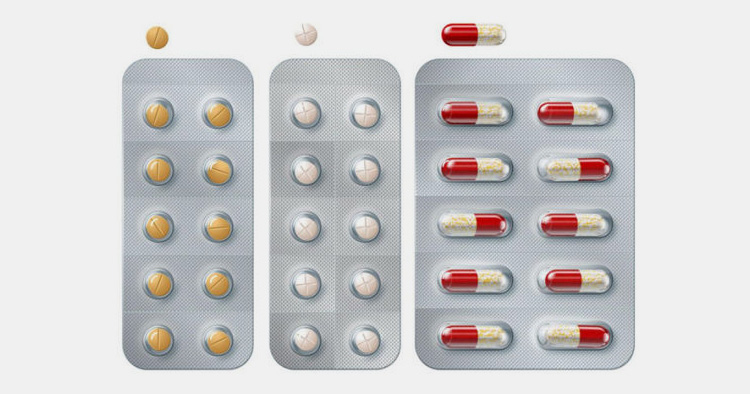

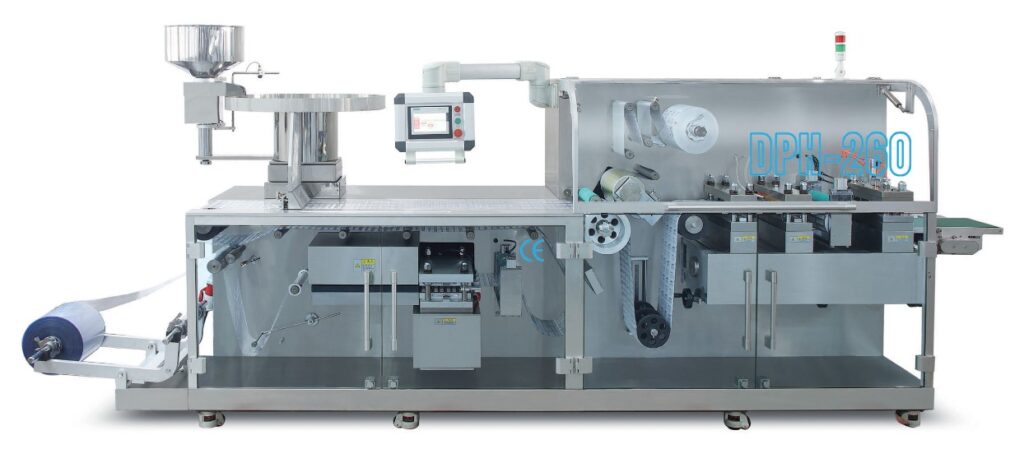

Blister Packing Machine

AIPAK DPP 80 PVC aluminum blister packing machine

Blister packing machine is an electro mechanical device used for packing different sorts of products such as medicine, food items, chemical, and other items in a blister.

Blister is a kind of plastic film in which different things can be packed to secure the products activity life run and nutrition level.

Blister machine works through a cavity pocket which can adjust the shape of a blister according to your products packing. Most of the capsules and tablets that we often use when we are sick they are also packed in a blister.

Sealing can be done with an aluminum foil or plastic film depending upon the kind of product that you are packing and shape of blister.

Uses

Blister packing machine has wide variety of applications to pack different products in different shape blisters and sizes. Here are some of blister packing machine uses.

- Protection from external particles interaction.

- Multiple pharma products packing option.

- Useful to store & pack food items in a blister.

- Packing of different chemicals vials and dry items in a blister box.

- Beauty and cosmetic products packing is also done with the use of blister packing machine.

Benefits

Blister packing machine holds different kinds of benefits in almost every industry with its quick packing features.

- Transparent packing for customer satisfaction.

- Free advertising along with authentic packing.

- Blister packing machine is easy to customize according to the type of product.

- Maintain the complete freshness & healthy organs of the packed product.

Cartoning machine

AIPAK BZX-120B automatic Cartoning machine

Carton packager or Cartoning machine is uniquely designed tech equipment that is used for secondary packing of the product in a carton.

Cartoning machine basically pack the product inside a carton for example in pharmaceutical industry we see injection vials, syrup vials etc packed inside a paper box called carton.

In this machine you can carton pack different type of already packed and unpacked products like trays, bottles, vials, capsules in a blister, and many more.

This machine is not only limited for pharmaceutical packing but also very common in other industries like food etc. Cartoning machine also put a batch number on every carton.

Cartoning machine is basically a type of packing machine but it is quite different as it made cartons of hard paper to pack bulk amount of products in it.

Uses

Cartooning machine uses and applications are as follows:

- Very reliable to pack almost every kind of medical equipment and soft dosages.

- Packing of liquid vials and injections in a carton.

- Packing stationary items in cartons.

- Helpful in automobile industry to pack parts & other things in carton.

- Food delivery items and many more can be packed with this machine.

Benefits

Cartoning machine is a beneficial technique to secure your product inside a large hard paper box for safety purpose.

- Complete secure and automatic packing.

- Ultimate packing solution for almost every type of product.

- Save your labor expense.

- Sealed packing with batch information printing.

Strip Packing Machine

APK-SP300 Strip packing machine

Strip packing in a newly introduced modern packing practice used in pharmaceutical industry as well as in other industries for packing small items in a double strip film.

In strip packing a strip sheet is used to enclose a tablet or capsule with the help of heat sealing.

Strip packages are very flexible just like blister packages but blister packing is quite hard as compared to strip packing.

Laminated rolls carries the strip to a desired location where packing product packed inside the strips and then sealing is performed on strips.

A cutter in a strip packing machine cuts the sealed strips into desired sizing and then these strips came into the collection container.

Uses

Strip packing machine holds variety of applications and uses in different industries that are as followed.

- Strip packing of capsules, small pills and tablets in a strip.

- Chemical items or pesticide substances packing in a plastic strip.

- Useful in food packaging with aluminum foil.

Benefits

Strip packing machine has many advantages that are as follows:

- Air proof packing.

- Strip packed products are easy to carry.

- Strip packing looks beautiful and simple.

- Error free working & user friendly working experience.

Effervescent tube packing machine

Effervescent tube packing machine is a pharmaceutical packing line used to pack effervescent tablets in a tube.

This packing machine is perfectly designed to work with effervescent tablets and capsules packing inside a tube in the form of layers.

Effervescent tablets packing takes place in a rotational principle.

To make the packing of effervescent medicine secure it also puts a stopper or cap head on the top of a tube.

Different calcium tablets that we use to take by dissolving them in water they are packed in a tube with effervescent tube packing machine.

Uses

Here are some applications and uses of effervescent tube packing machine.

- Cost-effective to pack effervescent tablets in a tube by forming a layer.

- It can improve the packing quality of your effervescent tablets.

- Secure the packing by putting cap or stopper on the top of a tube.

- It is also used for inspecting the packed product before ejection.

- Effervescent tube packing machine can also label the tube.

Benefits

Effervescent tube packing machine can give you some following benefits.

- Automatic working of effervescent tablet packing machine will save the cost that you will spend on manual packing.

- Accurate packing with modern design and structure.

- Easy to install with an inform production unit to pack effervescent tablets.

- Works through modules which make it easy for you to maintain the machine.

Ⅱ.Why packing is so important in Pharmaceutical industry?

When you are dealing in pharmaceutical products you can not compensate on packaging that is why different pharmaceutical packaging machines are introduced to overcome medical & pharmaceutical packaging problems.

Safety & Security of Product

Well, if you have a pharmaceutical production unit but you do not have a packing unit then your most of your production get wasted because of damage done during transfer.

Hygiene Products

To maintain the good quality of tablets, capsules and other medications then packing is vital. Packed products remain bacteria and germ free do not get any contamination.

Easy travel

In pharmaceutical industry when you made your production in bulk amount it needs to be packed well for transportation purpose because packing will not let any damage come to your product.

In pharmaceutical industry packing is important in several other ways as well because it is a major part of your production.

III.How to select best Pharmaceutical packaging machine?

In pharmaceutical packaging machine you need to be careful while purchasing or investing large amount of money on a machine.

Type

Type in pharmaceutical industry means what are the products that your business line is producing or what is they product type you are dealing with.

If you have the answer for this question then you become more specific and selection become easy and appropriate.

Money/Cost

Always set your budget value at a moderate rate to get a pharmaceutical machine in a mid-range price. If you see a machine that fulfils your required features then select that one do not go for extra features it will cost you double.

Market Searching

Purchasing a pharmaceutical machine in these days has become an easy work for most of the people all you have to do is just contact an appropriate supplier.

Question rises how to get appropriate supplier?

The solution is that just take your time and do some research on google, reach different suppliers tell them or ask them any information then come with an appropriate one who holds the best product according to your needs.

Why AIPAK?

AIPAK always contact its supplier first and you will be asked different questions related to your pharmaceutical machine told them your needs, features and other necessary points.

You will get best modern designed, innovative feature pharmaceutical machine within best price range along with high speed working.

IV.What is meant by quality packing?

Quality packing means that the inner product is safe, secure and there is not any chance of outer particles to go inside and cause any trouble to the product.

Packed product look better, remain better as compared to unpacked product and packing enhance the products longevity.

Here are some quality packing points that you will get.

- Quality product

- No damage during travel

- Air sealed packing

- Safe & secure for shipment

- Reliable and steady

- Free advertisement

- Informative labels

Conclusion

Packing of different pharmaceutical products is done through different packing machines all of these machines that I have explained earlier have unique and specific packing ability.

I hope you get your answer for what are the pharmaceutical packaging machines because I have covered many things about pharmaceutical packaging machines.

AIPAK is a globally growing pharmaceutical company with quality, innovation and reliable working machines for multiple production lines.

If you want any idea, clue or information in regards to the pharmaceutical packaging machines just reach us from here ! Customer care & help is our basic priority.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours