What Are the Checkpoints Before Running Softgel Encapsulation Machine?

Do you think working on a softgel encapsulation machine is easy? The answer is puzzling as ‘Yes’ and ‘No’. The machine itself was constructed to make the complicated task of forming softgel, filling, and sealing, in an easier way.

However, for operating the machine, you need to have proper knowledge of checkpoints to attain a successful procedure. In this blog post on ‘What Are the Checkpoints Before Running Softgel Encapsulation Machine’ you’re going to learn particularly about those factors that must be up to date before running a softgel encapsulation machine.

Do read the blog to find out more about the great results of softgel encapsulation making.

1.Monitor Calibration

Monitor Calibration- Picture courtesy: UNIPHARMA

Every instrument need calibration. This is not only a one-time task but with time softgel encapsulation machine loses its effectiveness. It simply indicates that you need to calibrate the machine for sharp and quality results. Therefore, before starting the manufacturing of softgel encapsulation, be assured that the machine is precisely calibrated and re-tested. Once you ensure that the machine is giving the desirable shape, weight, filling, sealing, etc elements in the softgel encapsulation process; so, begin with the final run.

Moreover, it is routinely required to avoid hectic troubles during or after work. Regular calibration simply saves your time and energy by skipping the amendments. Also, you can perform calibration of the softgel encapsulation machine by resetting the option and checking the weight of materials to be dispensed in each capsule, by tamper pin compression forces, or by calibrating the production speed of the equipment.

2.Observe Temperature Regulation

Temperature regulation- Picture courtesy: CPHI Online

The first thing you should understand either you are making a softgel capsule based on gelatin or vegetables.

Animal-Based Softgel Encapsulation

Animal-based softgel encapsulation- Picture courtesy: Lifevision manufacturing

If the capsules are gelatin-based, you must have a surrounding temperature of 23-25℃. If the room temperature is below, then the softgel encapsulation machine ribbon cutting of the gelatin strip would be very difficult and not the finest one. Moreover, the humidity level should be controlled around 30-40% for animal-based gelatin. This is because the low bloom powder works better around 30%.

Plant-Based Softgel Encapsulation

Plant-based softgel encapsulation- Picture courtesy: PB liener

To begin the process with a softgel encapsulation machine, vegetable or plant-based encapsulation requires temperatures around 20-21℃. This is suitable particularly when you’re working with starch gel or tapioca softgel encapsulation.

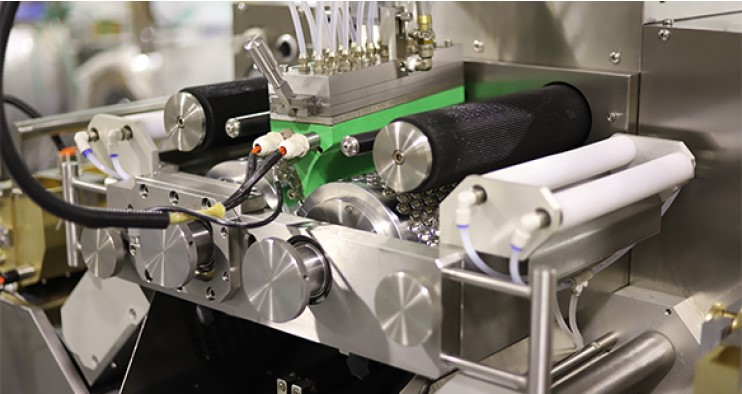

Aipak softgel encapsulation machine part

A good point to note is that the modern softgel encapsulation machine offers you a feature for monitoring the surrounding temperature. By this, you can maintain and adjust the temperature requirement to form a consistent encapsulation process. If the machine operation is carried out in high heat, they will make thin gelatin ribbon, and the capsule will leak or break after some time. Or the below-range temperature would directly lead to abrupt texture and poor quality.

3.Monitor Humidity Regulation

Humidity Regulation

For humidity, the vegetable-based capsules require longer drying time, and, in this case, you need to check the balance control over the installation of dehumidifiers. The humidity level must be less than 30% and it is in between around 25-30%. You must know that if the concentration of humidity is higher it will pose a greater time for drying.

4.Check the Die Roll

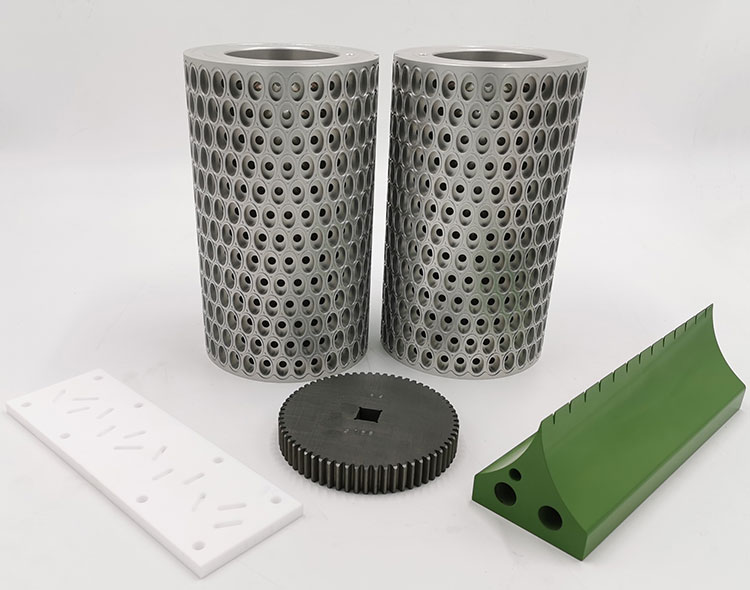

AIPAK softgel encapsulation machine die roll

There are various shapes of softgel capsules such as oblong, star, heart, circular, etc, the die roll is an object responsible for capsule size and shape. You need to check if either the install or integrated die roll is right for the process. Side by side, you can attain smooth and regular-shaped capsules if it is properly checked and used without any wear and tear. Also, it should be cleaned and fully stand by for the operation of the next process.

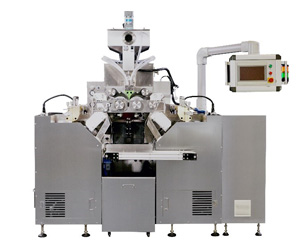

5.Check Pressure Regulation

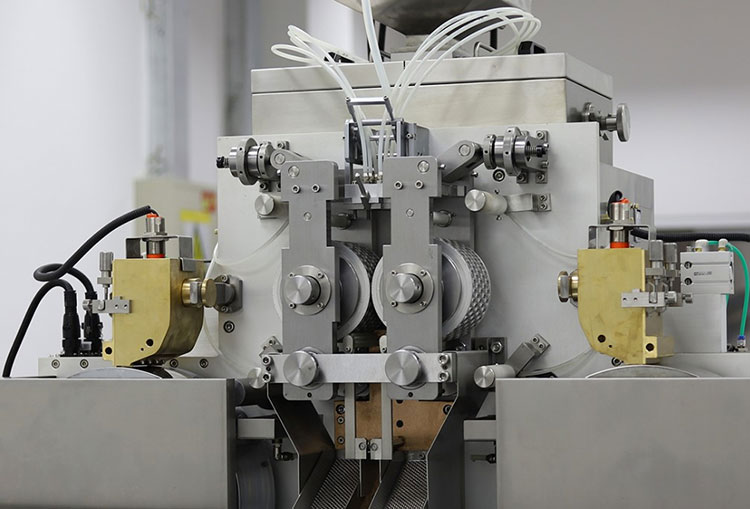

AIPAK softgel encapsulation machine

Along with temperature, pressure is another entity you must monitor when running a softgel encapsulation machine. What exactly pressure is? It is actually the force that is applied over the gelatin ribbon once it is encapsulated with material.

The reason for pressure application is to properly seal the edges of a capsule. The normal pressure limit of a softgel encapsulation machine is 50-300 bar. In case of less pressure, it will affect the sealing properties.

The pressure is too high would weaken the sealing bond of the softgel capsules and vice versa for low pressure. Therefore, before running the softgel encapsulation machine the pressure limit must be checked and calibrated.

6.Maintenance & Operating Properties

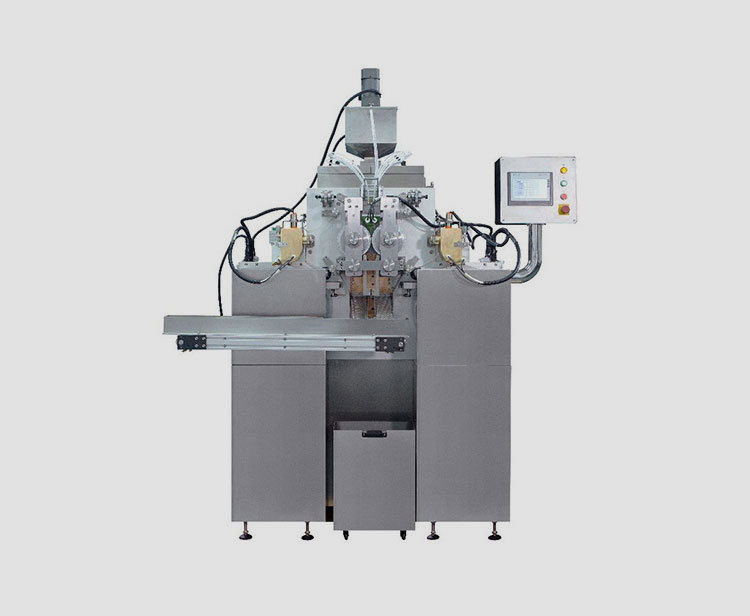

AIPAK Softgel Encapsulation Machine Maintenance & Operating Properties

For standard processing, you must check the maintenance and proper inspection protocol of the softgel encapsulation machine. This is way more essential component of the workflow as it will help in the flexible process. You must identify the main issue prior procedure so you can enjoy quality work without affecting the procedure.

In this matter, the main problems that have arisen during work are machine clogging, improper or failure to detector response, etc. Therefore, the maintenance and its updated status knowledge must be known to you.

7.Check Lubrication or Oiling of The Movable Parts

Lubrication or Oiling of The Movable Parts- Picture courtesy: Schaefer Technologies

The softgel encapsulation machine is not only confined to the manufacturing of softgel capsules, but it is a series of processes where the gelatin is passed through various movable components of the unit. For example, die roll, ribbon stripper, the filling nozzle, etc.

Therefore, if you are ignoring its proper maintenance by applying lubrication or oiling, it will increase the chances of downtime. Then it is highly recommended to check whether the movable parts are smooth and working properly. Remember if the mobility of the machine is compromised the formation as well as encapsulation process also go down.

Bear in mind to lubricate the component in an optimum concentration, if the lubrication concentration is too high, it also impacts the negatively. Similarly, if the level of lubrication is low it also induces rigidity in movement with noises. That is why weekly inspection and lubrication of the machine are recommended to get an ideal output.

8.Check Sensors Response

AIPAK Advance softgel encapsulation machine with sharp sensors

Today the whole world's types of machinery mainly rely on advanced response of the sensors. Nevertheless, the traditional formation of softgel encapsulation is based on the greater involvement of technicians as well as machines. But, the practices have changed with time.

The modern softgel encapsulation machine works based on high automation. However, there are still some checkpoints that you must have to look into before running the softgel encapsulation machine.

That is to check whether the sensor is connected with the software of the machine is operating properly or not. Simply if you are using your mobile phone you also have to check and update the software. Similarly in this way, when you are using a softgel encapsulation machine, their sensors also need timely updates.

Recheck and re-update the protocol that you have been using for a long time. Certain parameters that mainly rely on the sensors, for example, temperature, pressure, humidity, cutting, etc processing always based on sensors and are calibrated appropriately.

9.Check the Nature of Gelatin

Nature of Gelatin- Picture courtesy: Pharmaceutics International

Before running the softgel encapsulation machine, you must know the nature of the material that you are planning to subject to the unit. You cannot deny the importance of the raw material, because it is directly involved in the formation of a consistent, and a quality of gel capsule.

Of course, the main raw material that has to be intended for the machine is gelatin slurry. It must be properly formed when you subject the solution to the hopper of the softgel encapsulation machine. So, the gelatin that you are incorporating into the machine should have an optimized thickness or viscosity as well as the right bloom strength to get a standard gelatin ribbon.

10.Check The Quality of Encapsulation Material

Quality of Encapsulation Material- Picture courtesy: Pharmaceutical manufacturer

The next thing is what you are going to fill inside the softgel capsule. Because whatever material you are planning to encapsulate must be compatible with the gelatin ribbon. Before running the softgel encapsulation machine, you must assess that the material is free from any sediment, or undissolved particles, and it must be in a pure state.

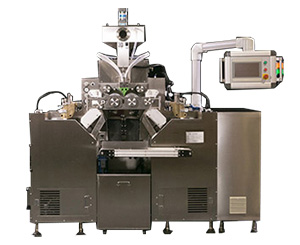

11.Assess Trained Technicians and Operators

AIPAK Softgel Encapsulation Machine

Nevertheless, a softgel encapsulation machine is an automatic and innovative apparatus that gives you a professional and high production of soft gel capsules. But, you cannot ignore the role of an operator or a technician who is mainly an expert in running the machine. You must know all of the essential components and how to troubleshoot the issues you are facing.

Therefore, whoever the running the process must be properly trained and this is mainly offered by the manufacturing companies. Whenever you are purchasing the softgel encapsulation machine, the expert team is mostly sent from the company that suggests the training program based on some days' trials.

Additionally, it is the responsibility of the manufacturing company to provide brochures and booklets with discussed FAQs to minimize the chances of troubles during or after the procedure.

12.Check Safety Protocols

Safety protocols- Picture courtesy: Pharma land

Usually consider the safety parameters when we’re running the softgel encapsulation machine. It mainly involves the management of emergencies. This is important to check the mandatory risky points that are under control before running the process to keep the work environment and process very safe.

13.Check Units of Production Line

Units of Production Line- Picture courtesy: Pharmamachinerys.com

Manufacturing the softgel capsule is not a ‘One Machine Show’ rather there are various sets of types of machinery involved in its production. When you are running the process, you must keep an eye on all required units of the production line. For example, a gelatin melting tank, an insulator or storage tank, a tumbler dryer, perforated trays, etc. You must know that if any of the units is non-functional or unavailable can disturb the whole process. Therefore, timely availability is prime important to bring sufficient production capacity without wasting your time and materials.

Conclusion

In a nutshell, a softgel encapsulation machine is an integral component of pharmaceutical, nutraceutical, herbal, cosmetic, etc fields. It gives you tremendous benefits with quality production of softgel encapsulation in no time. Thus, the unit is ideal to make your brand more valuable through excellent manufacturing properties. The blog ‘What are the checkpoints before running softgel encapsulation machine’ has described the relevant points and we hope it will be very informative for you. In case of confusion, AIPAK warmly welcomes their readers and customers to contact their experts. We are here to grow your business with innovative and affordable machines to produce better future products. Let's open the horizon of better services with the AIPAK team now.

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine