What Are The Challenge For Bilayer Tablets?

Do you know bilayer tablets? The bilayer tablets looked like the combination of two different types of tablets. Have you ever wondered the manufacturing process of the tablet with different color or the reason of its combination. Bilayer tablets are now taking more market share and will be more known in future.

What is bilayer tablets? What medicines are frequently applied bilayer tablets? What are the features of high qualified bilayer tablets? What are the challenge of bilayer tablets? How to optimize the manufacturing process of bilayer tablets? Come on and have a reading for the all questions!

1.What IsBilayer Tablets?

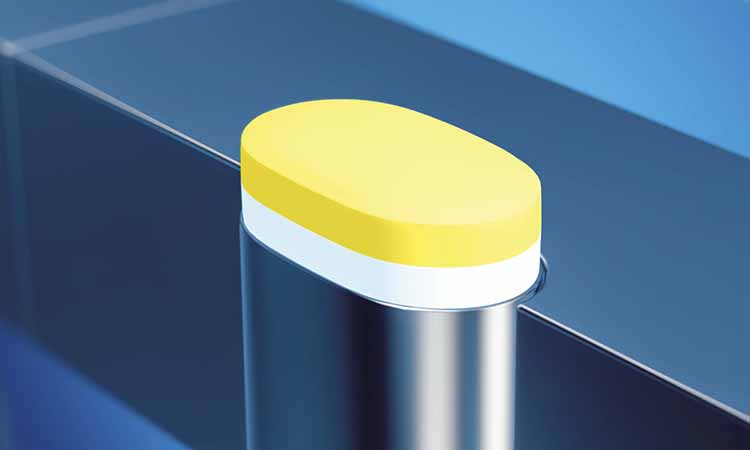

Bilayer Tablets-Sourced:acg-world

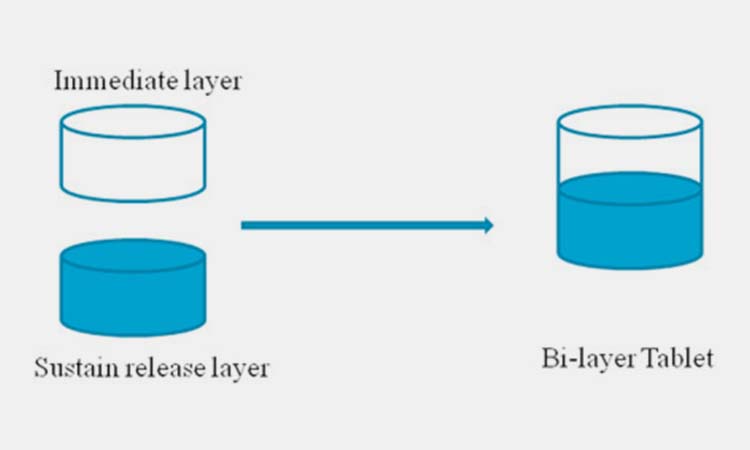

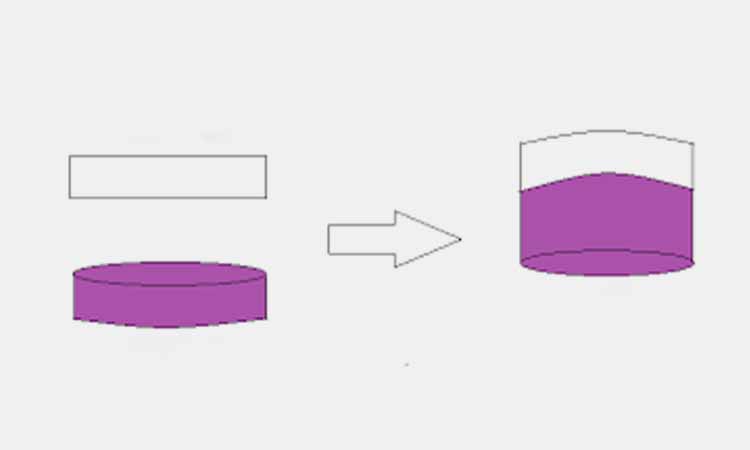

Bilayer tablets are a fixed-dose combination dosage form for oral administration, usually including an immediate-release layer and a sustained-release layer. This medicine type is able to produce more than one type of active ingredients. This is able to make the more precise and targeted curing for chronic patients.

The immediate-release layer is responsible for releasing the initial dose (loading dose) and contains a superdisintegrant to accelerate the release rate of the drug and quickly initiate the drug effect, while the sustained-release layer (maintenance dose) uses different polymers as release delayers to continuously release the drug, and hydrophilic polymers are usually used to achieve this sustained-release effect.

2.What Medicines Are Frequently Applied Bilayer Tablets?

Bilayer tablets are frequently applied for chronic medicines. You may find diabetes, high blood pressure, antihistamines, pain relievers, fever reducers, and allergy medications as the great example. And here are some of its common application.

Diabetes

Diabetes-Sourced:clinicablasi

The bilayer tablets for diabetes has the great combining of metformin and acarbose. The one layer of bilayer tablets is able to defeat diabetes and the second layer of bilayer tablets is made for the maintaining of blood concentration in plasma for a long period.

Pain relievers

Pain Relievers-Sourced:lubrizol

There is also the creation in pain relievers of bilayer tablets. The two layer of medicine make the great combining work and can work for pain relieving and preventing at the same time. For acute pain, it is the great helper.

Fever reducers

The bilayer tablets for fever reducers can make the medicine with better effect and releasing rate. The bilayer tablets of fever reducers are usually made with paracetamol and ibuprofen which make the nice work in reducing fever.

3.What Are The Features Of High Qualified Bilayer Tablets?

Bilayer tablets is the welcomed medicines. And here are its common features.

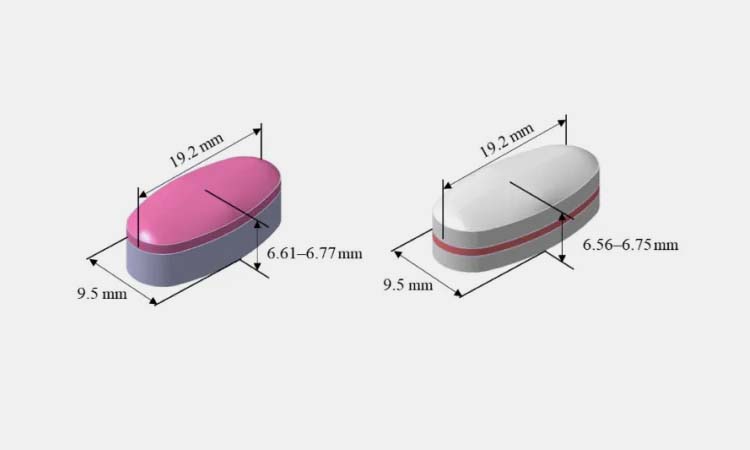

Elegant appearance

Elegant Appearance-Sourced:medicalexpo

The basic feature of bilayer tablets is its elegant appearance. You may find its even and symmetrical look of tablets of two different color. The two color has no discoloration and contamination. The qualified bilayer tablets are always well proportioned and beautiful.

Sufficient strength

Sufficient Strength-Sourced:jmpas

Bilayer tablets are the medicine with strength which means it can stand the shock or collision in transporting, packaging or distributing. It looked like the combining of two layer is fragile and breakable. The bilayer tablet, in reverse, is strong.

Chemical and physical stability

Bilayer tablets are also stable in their chemical or physical feature. Its physical properties won’t change quickly with time went on. Bilayer tablets are also stable in their shelf life which is just like the other oral medicine.

4.Are There Any Requests For Bilayer Tablets Raw Material And Composition?

For the high qualified bilater tablets, there are request on its raw material and its composition. Here are its key ingredients.

API

API-Sourcd:goodrx

For bilayer tablets, there are two types of active ingredients for the composing of the whole bilayer tablets. You may choose the different API according to your different medical or treating need.

Binders

There are various binders and you may find microcrystalline cellulose as the common one. It is applied to combine powder for the forming of bilayer tablets. The adequate binders can make the strong and resistant bilayer tablets.

Disintegrants

Disintegrants are the ingredients which is applied for the better breaking down of bilayer tablets into small particles. This ingredients help decide the spreading speed of particles in your body for more targeted cure.

Lubricants

Lubricants are the great ingredients which are used for the friction reducing of bilayer tablets forming. The common lubricants are magnesium stearate, sodium lauryl sulfate and so on. You may get the dreamed lubricants according to your bilayer tablets need.

Colorant and flavoring agents

Colorant And Flavoring Agents-Sourcd:news-medical

Without colorants and flavoring agents, you should add the according colorants and flavoring agents for the better appearance and smell of your biyaler tablets. The great colors combining and smell of your bilayer tablets products can attract more people.

5.What Are The Advantages Of Bilayer Tablets?

Bilayer tablets are the welcomed medical type in market. And here you may find the advantages of bilayer tablets.

Improve medicine efficacy

Improve Medicine Efficacy-Sourced:sciencedirect

Bilayer tablets have the efficacy of curing and caring improved greatly. The corporation of two different kind of medicine make the great work of making the best and targeted effect for your disease.

Benefit patient

The bilayer tablets can benefit patients as it takes great convenience for medicine taking. It saves the daily dosage of medicine and improves the living standard of patients of many disease.

Stable product quality

Stable Product Quality-Sourced:gea

Bilayer tablets have the outstanding stability in chemical and physical aspects. The proved stability in shelf life and product quality can make the better effect and care for patients.

Less package waste

Less Package Waste-Sourced:fette-compacting

Bilayer tablets combined several types of active ingredients in one medicine which saved the packaging waste in products manufacturing. And this is the great saving for earth resource and packaging material.

6.What Are The Challenge For Bilayer TabletsManufacturing?

In bilayer tablet manufacturing, there are various challenges. And the neglecting on the challenges may lead the problem of bilayer tablets.

Material characteristics

Material Characteristics-Sourced:bruker

The physicochemical properties of active pharmaceutical ingredients (APIs) and excipients are crucial for the successful manufacturing of bilayer tablets. The characteristics of the materials play a significant role in the strength and rupture behavior of multilayer tablets. For example, the plasticity, brittleness and viscoelasticity of materials can have a notable impact on the tablet compression process.

Plastic deformation and the brittleness of materials are especially important during tablet compression. Additionally, particle damage in the middle region of the mold is more severe than in the outer layer particles. Therefore, special attention should be paid to the material properties before using any substance to manufacture bilayer tablets.

Compression force

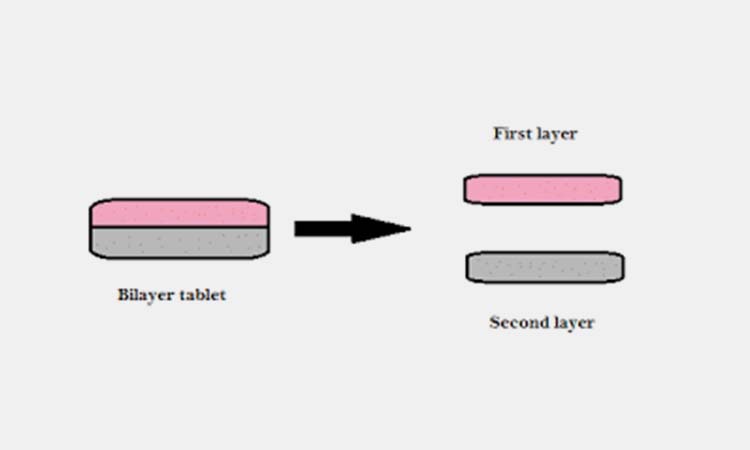

Research shows that one of the most important parameters in bilayer tablet production is the compression force of the first layer, which affects the interlayer strength and adhesion, thereby influencing the mechanical cohesion of the bilayer tablet.

The compression of the first layer primarily reduces the volume of the powder/particle material, smooths the surface, and creates space for the deposition of the second layer. In general, higher compression forces help enhance the tensile strength of the tablet and reduce surface roughness, but they may also increase the risk of delamination between layers.

Lubricants

Lubricants-Sourced:pharmaexcipients

Substances with higher lubricity cause less friction when in contact with the particles and mold, as they allow for an even distribution of materials. On the other hand, in bilayer tablets, lower levels of lubricant are needed to enhance the interaction and strength between the two layers.

Lubricants have a significant effect on brittle materials, so special attention must be given to the lubricating properties of the materials during the development of bilayer tablets.

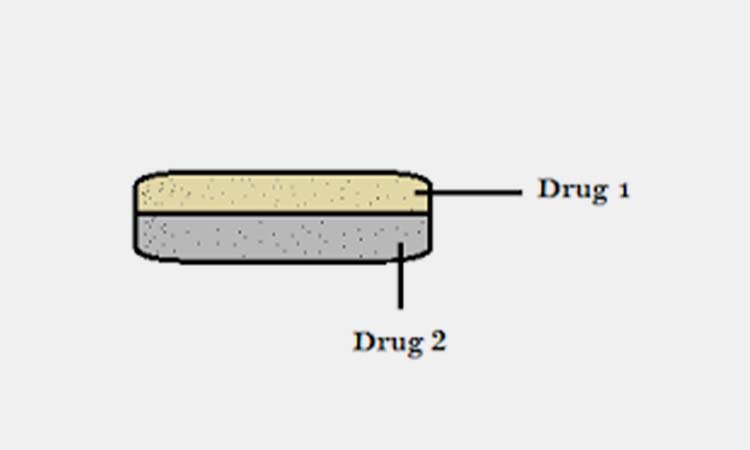

Layer Ratio and layer sequence

Layer Ratio and Layer Sequence-Sourced:mmbiz

In the design of bilayer tablets, the weight ratio of the two layers is often unequal, and there is usually a significant weight difference. Although in most cases, the weight ratio of the first and second layers is 1:1, 1:2, or even 1:3 in rare instances, keeping the weight of the second layer consistent with the first layer is a challenge.

Environmental factors

During the preparation of bilayer tablets, humidity and moisture can significantly affect the compactness of the tablets. Excess moisture can cause the tablets to absorb moisture or release water, leading to expansion of the tablet layers, which impacts interlayer contact and can result in delamination over time. Therefore, it is recommended to pre-treat materials during the manufacturing process to ensure they are in equilibrium with the humidity in the air and to seal the tablets in moisture-proof packaging.

Layer weight control

Layer Weight Control-Sourced:encrypted

To ensure uniform distribution of active pharmaceutical ingredients in bilayer tablets, certain prerequisites such as material flowability, particle size distribution, and the compactibility of the bilayer tablets must be controlled. However, currently available bilayer tablet presses are unable to independently monitor the weight of the second layer, which presents a significant challenge in bilayer tablet manufacturing.

7.How About The Compression Force Of Bilayer Tablet Manufacturing?

The compression force of biyaler tablets can make great difference to biyaler tablets quality.

Hardness

Hardness-Sourced:tabletscapsules

The excessing compression force may lead the hardness of bilayer tablets. The bilayer tablets which are too hard may have trouble in disintegrate. And the leaking of compression force may lead the easy breaking of bilayer tablets.

Fragility

The uneven compression force may also affect the stability of biyaler tables and the disintegrating of bilayer tablets. The lack compression force may lead the forming of the fragile biyaler tablets.

Disintegration time

Disintegration Time-Sourced:merlin-pc

The compression fore can also affect the disintegration time of bilayer tablets. The hard compression may affect the disintegration of active ingredients and lead the longer disintegration time. You should make clear the disintegration time and make the compression force balance.

8.How About The Quality Control Of Bilayer Tablet Manufacturing?

Quality control is the important factor of bilayer tablet manufacturing. Here is the factors which may affect product quality and the essential quality control of bilayer tablet manufacturing.

Quality-affecting factor of bilayer tablets

Pre-compression force

Pre-compression Force-Sourced:huadapharma

Pre-compression force is the force which is made at the first stage of bilayer tablets work. It makes the direct affect to tablet quality. You should adjust the pre-compression force for the high qualified bilayer tablets.

Punch penetration depth

The depth of penetrating from bilayer tablet pressing machine will affect the thickness and weight of tablets. You should make the precise adjust of punch of bilayer tablets pressing machine for the great quality of bilayer tablets.

Feed frame adjustment

Feed Frame Adjustment-Sourced:ima

You should make the careful and accurate adjustment of feed frame to ensure the even distribution of granulates in die. This is helpful for ensuring the even and proper distribution of granules which is the great help for the bilayer tablets manufacturing.

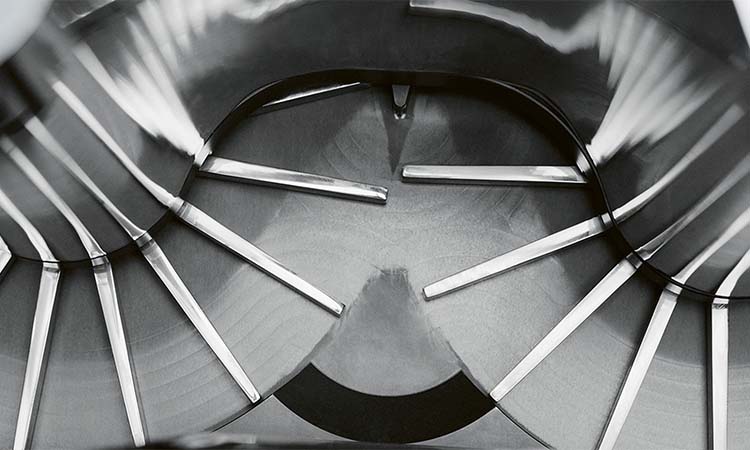

Turret speed control

The turret rotation speed affects the dwell speed which controls the compression time of granules. The precise controlling of turret speed makes the essential affect for the even bilayer tablets hardness.

Tablet taking

Tablet Taking-Sourced:istockphoto

Tablet taking is the last step of the whole bitaler tablet pressing process. You should get out the bilayer tablets with the right methods. You may avoid the breaking and flow of bilayer tablets. The careful tablet taking can also reduce the flaws of bilayer tablets.

Quality control of bilayer tablet manufacturing

Rawmaterial inspection

Raw Material Inspection-Sourced:gmptrends

Raw material inspection is the first stage for your quality control of bilayer tablet manufacturing. You should first make sure the high quality of your raw material for the later manufacturing of the high qualified bilayer tablets.

In-process checks

ln-process Checks-Sourced:karkhana

In bilayer tablet pressing process, you should also make the careful inspecting in the bilayer tablet pressing. The weight change, hardness change, dissolution rate and so on an all be checked well in the process of bilater tablet manufacturing.

Finaltesting

Final Testing-Sourced:isspllab

The final testing for bilayer tablet products is the most comprehensive test compared with the above two test. You should make the deep test about its appearance, effect, dissolution rate and so on. The passing of the final test means its distribution in market.

9.What Are The Disadvantages Of Bilayer Tablets?

Bilayer tablets benefit pharmaceutical industry in a comprehensive way. And there also exist disadvantage of bilayer tablets.

Complex manufacturing

Complex Manufacturing-Sourced:tabletingtechnology

Bilayer tablet manufacturing is complex compared with the normal tablet manufacturing. It takes more complex manufacturing process and also cost longer manufacturing time. The complex manufacturing increases its cost of bilater tablets sales.

Product quality control

It is hard to make control for bilayer tablets quality. The insufficient hardness of bilayer tablet may lead the layer separation. And the bilayer tablet manufacturing may also make the cross contamination which may affect medicine effect greatly.

Inaccurate dosage

Inaccurate Dosage-Sourced:semanticscholar

The bilater tablets have different combination and sometimes different dosage of medicines. For bilayer tablets manufacturing, it may be hard to make the accurate dosage. And the precise medicine dosage is the secret of the medicine effect.

10.What Are The Machines Applied For Bilayer Tablets?

Qualified bilayer tablets product involves the precise and excellent machine manufacturing. What are the machines applied for bilayer tablets? Here you may check.

Single sided tablet press machine

AIPAK Single Sided Tablet Press Machine

Single sided tablet press machine is the common tablet press machine which can make the tablet pressing according to your production need. The corporation of punch and a die will make the relative tablet products. This machine is high efficient and can make the compressing for the difficult formulation.

Double sided tablet press machine

AIPAK Double Sided Tablet Press Machine

Double sided tablet press machine is the kind of machine which makes the excellent work in making tablets of two different sides. The bilayer tablets can be made by this machine. Double sided tablet press machine is the rotary type which can make the efficient manufacturing work and even and qualified bilayer tablets.

11.Comparison Between SingleSided And Double Sided Tablet Press

Single-sided tablet pressing machine and double sided tablet pressing machine, which one you should choose? Here is the comparison between single sided and double sided table pressing machine.

Comparison Between Single Sided And Double Sided Tablet Press

| Factor | Single sided tablet pressing machine | double sided tablet pressing machine |

| Production scale | Single sided tablet pressing machine is suitable for the production of small production scale. | Double sided tablet pressing machine is the ideal choice for the large production scale tablet products. |

| Production efficiency | Single sided tablet pressing machine is highly efficient and you may apply it for the many tablet production in a short time. | Double sided tablet pressing machine is more efficient compared with single sided tablet pressing machine as the former has two side for the tablet manufacturing. |

| Machine cost | Single sided tablet pressing machine is compact in its structure and more economical for the various use. | Double sided tablet pressing machine costs more as it is equipped with the larger turret, more die and more punches. The larger production scale and large structure make the higher price. |

| Maintaining cost | Single sided tablet pressing machine is less complex and can be maintained much easier. | Double sided tablet pressing machine costs more for its complex structure and larger size. |

| Tablet complexity | Single sided tablet pressing machine is able to manufacture the simple tablets. The tablet complexity is low. | Double sided tablet pressing machine can handle the tablet with high complexity. It is used particularly for the production of bilayer tablets. |

| Machine size | Single sided tablet pressing machine is compact and has the small size compared with the double sided tablet pressing machine. | Double sided tablet pressing machine is bigger and more complex as it is more flexible and is composed of more complex parts. |

12.How About The Testing And Evaluation Of Bilayer Tablet Manufacturing?

Testing and evaluation of bilayer tablet manufacturing is essential for the products manufacturing. Here are the tests you cannot ignore in the bilayer tablet manufacturing.

Visual inspections

Visual inspection is the basic test for bilayer tablet manufacturing. From visual inspection, you may have the rough judgement of bilayer tablets size, completeness, color and so on. From visual inspections, you may get to your basic judge about biyaler tablets’ quality.

Functional test

Function Test-Sourced:verywellmind

Function test is the test which applied to test the effect of your biyaler tablets. It compares the function and effects of bilayer tablets. The conforming of bilayer tablets’ effect with the actual effect can help the meeting of patients’ expectations.

Weight variation test

Weight variation test is applied to test the even and uniformity of bilayer tablets. As bilayer tablet is formed by granules, there may exist the weight lacking or layer uneven. And this may lead the problem for products safety, products quality and so on.

Layer uniformity test

Layer Uniformity Test-Sourced:humanjournals

Bilayer tablets are made with two or more different layers. And the precise dosage of different layer decides in some way the great effect and quality of your bilayer tablets. Layer uniformity test can make the precise test about the tablets layer and make sure the great conforming of your biyaler tablets.

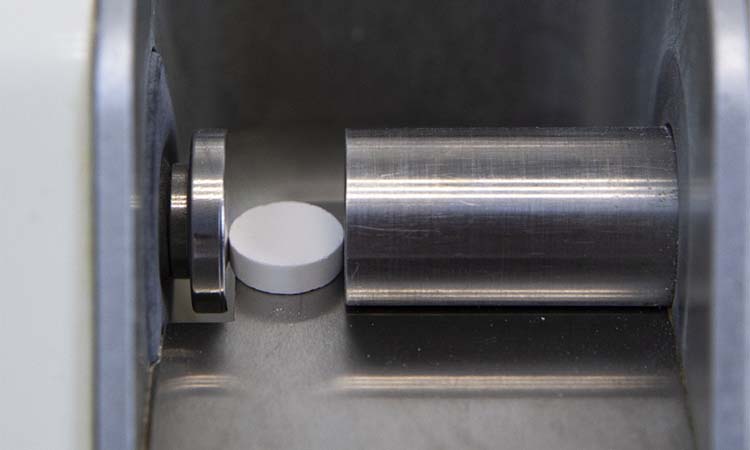

Hardness test

Hardness Test-Sourced:merlin-pc

Hardness of bilayer tablets is also the important factor of quality testing. It can show the pressing quality of tablet pressing machine and its hardness in some way affects the dissolution rate of biyaler tablets. You should make clear the hardness of your tablets and make the relative hardness test.

Fragility test

Fragility test is the test which is made to test the fragility of bilayer tablets. The fragile bilayer tablets may be easy to break down or separate. The strong tablet can prove the safety and completeness of bilayer tablets in the transportation or storing. The tablets which pass the fragility test is the products which manufacturer expect.

13.What You Should Consider For The Storing Of Bilayer Tablets?

Bilayer tablets have different manufacturing process, and its storing should also be different. Here is the tips you should pay attention to in its storing.

Moisture affect

Moisture Affect-Sourced:sedpharma

Moisture makes the outstanding affect for your bilayer tablets products. The absorbing of moisture will make the loose pore structure for the connecting place of bilayer tablets. You should make sure its conserving in the airtight pack.

Light affect

Light Affect-Sourced:nowpsych

Light may affect the stability of chemical effect of medicines. You should have your bilayer tablets avoid the long and direct contact with light. And for some medical element, the exposing to light may lead the damage for patients.

Stable environment

Stable Environment-Sourced:krka

You should make the stable environment for your bilayer tablets. The unstable environment and collision may make the breaking of bilayer tablets or the separation of two layers. You should make sure the stable environment of your bilayer tablets.

14.How To Optimize The Manufacturing Process Of Bilayer Tablets?

The manufacturing process of bilayer tablets is precise and efficient. And here is the way for you to optimize the manufacturing process of bilayer tablets.

Optimize material

Optimize Material-Sourced:syntegon

You should choose the material which has the great compatible property. The similar compaction profile can help reduce the stress matching problem. You should thus optimize your material for your bilayer tablets manufacturing for the nice tablets products.

Optimize technique

Optimize Technique-Sourced:promoboz

The rotary tablet press machine with advanced control system can make sure the high qualified bilayer tablets products. The mechanical work of tablet press machine makes the great effect on the products quality.

Optimize lubrication and pressing

You should optimize lubrication and pressing for your manufacturing process of bilayer tablets. The smooth and high qualified lubrication and pressing improve the completeness of your tablets and also the efficiency of your manufacturing process.

15.What Qualification Standard Bilayer Tablets Manufacturing Should Conform?

Bilayer tablets enjoys the different manufacturing process. And here are the qualification standard bilayer tablets manufacturing process should conform.

GMP

GMP-Sourced:angstromtechnology

GMP is one of the most important standard for bilayer tablets manufacturing process. It represents the good manufacturing process. It makes the precise request for the manufacturing of medical products for people and animal use. For bilayer tablets manufacturing, you should apply GMP standard for the high qualified and efficient bilayer tablets manufacturing.

FDA

FDA-Sourced:pharmaoffer

FDA has the full name of food and drug administration. To make the great distribution of your products in the United States, you should conform to FDA which makes the great request on the manufacturing process and equipment applying for drug, medical devices, food and so on. Your bilayer tablets will be more reliable when conforming this.

ISO

ISO-Sourced:nutreebio

ISO is the international organization for standardization. Its manufacturing standard cover products manufacturing and managing which makes the full prove of safety, quality and effect of your bilayer tablets products. You should conform to this qualification standard for more reliable products producing.

16.How To Troubleshoot Common Problems During Bilayer Tablet Manufacturing?

There is no perfect and smooth bilayer tablets manufacturing process. And here are the common problems you may meet in the process and the relative solutions.

Common problem

Delamination problems

Delamination Problem-Sourced:easy-peasy

Delamination problem happened for your formulation problem and the pressing technique. The separation of two layers may lead the weak of medicine effect and its appearance. The delamination problem can be solved with the outstanding formulation and pressing mechanism.

Individual layer weight

Individual Layer Weight-Sourced:jmpas

You should make the accurate control of the dosage of different layer. The layers dosage change may lead the great wavering of medicine effect. The uneven or wavering layer weight may lead the medicine problem for patients and affect the curing experience.

First and second layer compression

There are several layers of bilayer tablets and the different layers are made of different components. The unqualified compressing may make the problem in compressing. The condition is frequently seen in first and second layer connecting part.

Relative solutions

Adjust formulation and machine configuration

Formulation and machine configuration are the parts which make the essential effect for bilayer tablet quality. You should adjust bilayer tablets formulation for the more tight connection and better compressing work. Formulation and machine configuration is the important factor you should consider for the high qualified products.

Enhancing bilayer tablet technology

Enhance Of Bilayer Tablet Technology-Sourced:korsch

The enhance of bilayer tablet technology can improve the bilater tablet manufacturing quality. The great bilayer tablet technology makes the more safe, efficient and precise bilayer tablet manufacturing work. The manufacturing of bilayer tablets will be more precise and accurate.

Arrange turret and tablet

Arrange Turret And Tablet-Sourced:fette-compacting

The arrangement of turret and tablets can also make the great affect for your bilayer tablets manufacturing. The adequate turret speed, press force and the relative work of turret and tablets can be shown on your biyaler tablets quality. You should make the regular maintaining of the parts for the high qualified products manufacturing.

Case study for bilayer tablet manufacturing

There may be various coincidence or problem in bilayer tablet manufacturing. You should make the study of various cases and the different success and failed stories for the smooth manufacturing and dealing of the various problems.

Conclusion

What are the challenge for bilayer tablets? What medicines are frequently applied bilayer tablets? Bilater tablets are the welcomed medical form on market, here you may find all secrets about it. If you want to know more or have any questions about the bilayer tablets, you may have no hesitate to contact AIPAK now.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine