Wax Packaging: The FAQ Guide in 2025

Visual marketing is important aspect of business-design of packaging matters in fast selling. Millions of customers especially female buy packaged wax due to its look. Appearance of wax packaging is what which pulls the customers. Brand owners earn the loyalty of their patrons by rightly packaging their wax products. After all, first impression is all that matters. Life style industry is super crowded, therefore innovative and originality of wax packaging goes a long way in enchanting target customers.

Read this blog to customize your own wax packaging line.

1.What Is Wax Packaging?

It is the process by which wax is enclosed in a covering, wrapped, bottled or boxed for protection, logistics, transportation, handling, storage, advertising, and distribution. It is an act of presenting wax in the most advantageous way to customers.

Wax packaging encompasses different steps from designing to container manufacturing. Moreover, by packaging wax buyers can make informed decision regarding product purchase.

2.Why Do You Need Wax Packaging?

Wax packaging comes in handy due to its barrier protection and appeal. There are variety of reasons due to which wax packaging is important both for buyers and sellers, some of which are discussed below:

Mechanical Protection

Packaging acts as a shield and protects wax from mechanical damage such as scratching, collision, vibration and shock during transportation, handling, and distribution.

Environmental Protection

The most essential aspect of packaging is its barrier protection. Oxygen, heat, moisture, light, and other chemicals can harm and spoil wax if present in open.

Offers Hygienic Look

Packaging offers hygienic and clean look to wax as it prevents dust accumulation in packaged wax and inhibits microbial growth.

Marketability

Attractive and innovatively styled wax packaging draws the customers towards display shelf and positively impact buying appeal.

Shipment

Packaging has an integral role in logistics and shipment. Properly boxed wax items are stacked and shipment more easily than the ones who are unpacked. Box packaging also conserves space thus lowering fuel expenses.

3.What Are Top 5 Wax Packaging Ideas?

With advent of New Year, creatively thought wax packaging ideas are put into market that work their magic on customers. Some of these packaging ideas are:

Maximalist

After pandemic, explosion of energy and burst of colors are seen in packaging. Brand owners embrace maximalist approach for creating color chaos to bring joy and sense of liveliness to wax packaging.

Surrealism

Imaginative and fantastical designs are gaining popularity among customers to seek flee from depressing newsfeed. This creative and whimsical design conveys sense of wonder and blissful relish.

Minimalism

Some brands are leaning towards minimalist design consisting of soft pastel colors and simple designs to craft neat, elegant, and classy look.

Naturalism

In this fast-paced world, people want homey feel and peace. This drives brand owners to use earthy tones and rich colors in wax packaging for bringing coziness and serenity to their buyers.

Topographical

Streamline lettering and simple topography led design is yet another trend for wax packaging that has been on rise. Austere writing inscribed in clear-cut fonts usually inspire modest buyers.

4.What Are Different Wax Packaging Formats?

Wax can be available in different packaging styles in the market. It can be packaged in a variety of styles such as:

- Sachets

- Stick pack

- Doypack

- Pillow pack

- Cans/Jars

- Pouches

Sachets

Wax packaging in sachets are used to pack small amount of wax using small plastic and foil packets. This type of packaging is convenient for customers as it is economical.

Stick Packaging

Wax is also available in stick packaging form which is use to seal the things like envelopes etc. It is also use to remove unwanted hair of a big patch like chin, upper lips and fore head. In this packaging three or more solid wax sticks are packed together in plastic packaging and cardboard paper.

Doy Packaging

Wax is commonly dispensed in Doypack packaging. It is the style of flexible packaging, also known as a stand up pouch. It can contain both granular solids and liquid or viscous products. For this packaging aluminium foil and polyethylene are used.

Pillow Packaging

This type of wax packaging is used to pack melted wax. It is easy to handle and secure melted wax, just pull out the side flaps then insert and close it again. It is also essential for gifts.

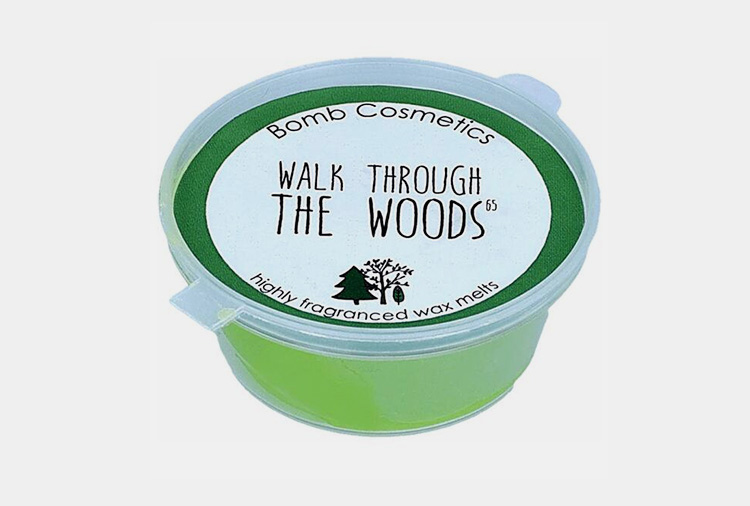

Cans And Jar Wax Packaging

This is also called concentrate packaging. The metal jars and cans protect wax from outer temperature and environmental effects. Wax is available in Dab jars in Bulk.

Pouch Wax Packaging

Wax is also packed in zip lock bags or pouches. This style is great for melted wax packaging; heat sealed bags are perfect for one time use sample packs. It is also used for selling bulk amount of wax in wholesale rates.

5.What Are Different Materials Used for Wax Packaging?

Look, feel, protection, aesthetics, and designing of wax packaging is determined by the packaging materials. Therefore, it is essential that you must carefully choose packaging materials for your wax products.

Some packaging materials for wax are penned below:

Paper

This is manufactured from wood pulp and is suitable packaging material that can be easily recycled, decomposed, and biodegraded.

PET

This plastic type is routinely used for wax packaging, Inertness, impermeability, lightweight, cost-effective and formability are characteristics the makes PET plastics popular preference of manufacturers.

Cellophane

It is reasonably price when bought in huge quantity. Cellophane is generally derived from wood, hemp, or plant starch. Clear cellophane is best for showcasing packaged wax.

Glass

Wax product packaged inside glass bottles and jars retain their potency and fragrance due to chemical inert nature of glass. It gives top-notch and luxurious look to the products. Moreover, it has 100% recycling ratio.

Aluminum

It has superior barrier protection packaging material and is preferred choice for premium quality brand for wax packaging due to its ductility and weight saving ability.

6.Which Devices Are Used In Wax Packaging?

Wax product packaging line consists of several machines, each of which has their specific role in packaging of wax. These equipments are connected in sequence for rapid and time-saving packaging.

Some of these machines are discussed below:

| Wax Filling Machine

These equipments consist of pumps and pistons for melting and filling wax into molds or containers. These devices have heating units for increasing the fluidity of viscous liquid wax. |

|

| Capping Machine

The caps or lids are placed or secured on the bottles or jars top after wax filling by capping machines. These equipments can place metal or plastic snap on or twist off caps on containers for sealing the contents inside packaging as well as to prevent their leakage. |

|

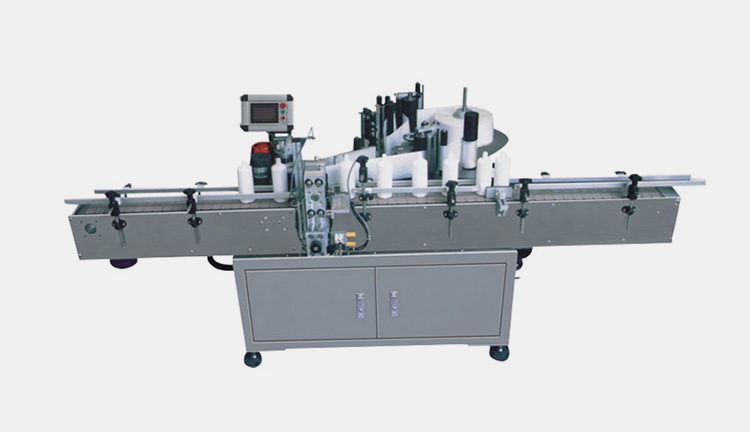

| Labeling Machine

Labels are dispensed and applied to the principal display panel of container via labeling machines. They can glue or affix stickers, laminated papers or add-on tapes to sides of containers or can wrapped labels around containers. |

|

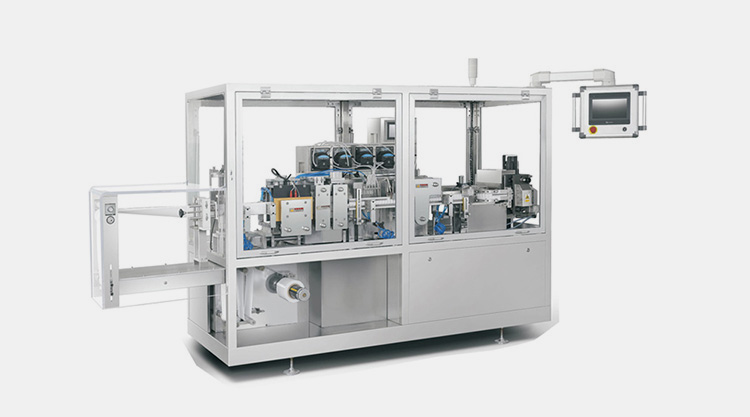

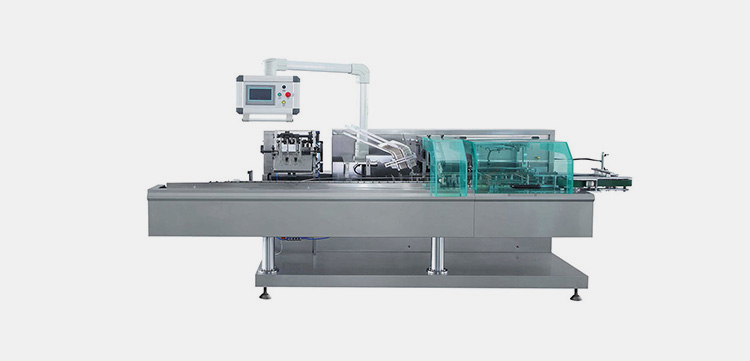

| Cartoning Machine

These machines are involved in tertiary packaging of wax. They usually place primary packaging containers of wax into cardboard or fiberboard cartons for easy storage and transportation of products. |

|

7.What Are Common Wax Packaging Machines?

Mentioned below is the list of commonly used wax packaging machines:

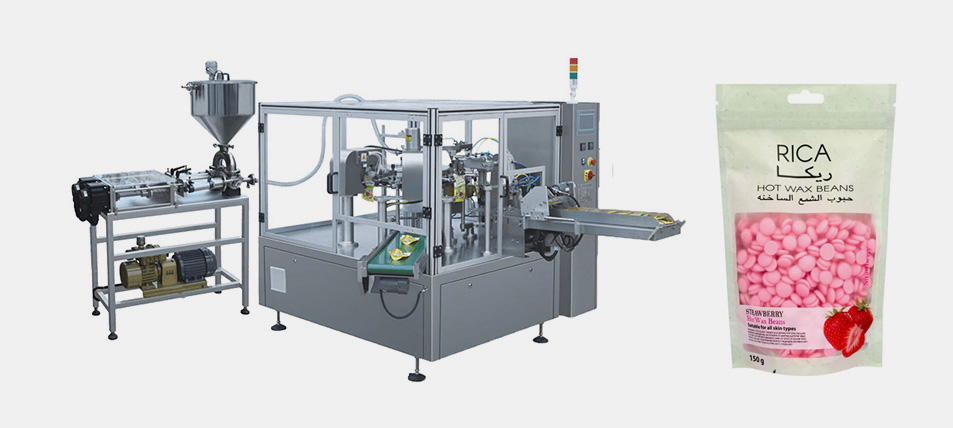

WAX PACKAGING MACHINE

This machine is commonly used for packaging wax in granular or beans depilatory wax in bottles, bags, or pouches.

| The working principle of machine is followed as:

A stored wax in hopper is introduced into filling nozzles via mechanical feeding system. An accurate quantity of wax is delivered into bottles and containers. With the help of conveyor, it is transferred to capping machine and labeling machine. |

The components of machine are:

Hopper: helps to store the material for packaging. Feeding Heads: supporting packaging material to enter filling nozzles smoothly. Filling Nozzle: helps in transferring material directly into containers, bags, or jars. |

VFFS FILLING MACHINE

A VFFS machines are the series that allows filling of different bag sizes and shapes, as well as different volume in a vertical fashion. This machine can form, fill and seal entire packs; where a heat-sealing process used in the forming and sealing units is typically temperature-controlled to ensure proper sealing and avoid product contamination.

| The working principle of a VFFS filling machine is as follows:

Film is unwound from the roll and fed into the forming unit. The film is heat-sealed and shaped into a tube, with the bottom of the bag being sealed in the process. The product is dispensed into the bag by the filling unit, which can use various methods such as volumetric, gravimetric, or auger fillers. The top of the bag is sealed by the seal unit, and the filled bag is separated from the flat film by the cutoff unit. |

A VFFS (vertical form fill seal) filling machine typically consists of the following major components:

Film unwinder: provides the packaging material (usually a roll of heat-sealable film) for the machine. Film transport: conveys the packaging material to the forming area. Forming unit: creates the bag from the flat film and seals the bottom of the bag. Filling unit: dispenses the product into the bag. Seal unit: seals the top of the bag, trapping the product inside. Cutoff unit: separates the filled bag from the flat film. |

HFFS FILLING MACHINE

HFFS (Horizontal Form Fill Seal) filling machine is a type of packaging machine used for wax packaging. This process is repeated continuously, producing a continuous stream of packaged wax products.

| The working principle of HFFS filling machine is as follows:

The film is fed from the roll into the machine and is formed into a bag shape by the forming unit. The filling unit dispenses the desired amount of wax into the bag. The sealing unit then seals the bag, ensuring that the contents are kept inside. The cut-off unit cuts the bag to the desired length, completing the packaging process.

|

The major components of the machine are:

Film Transport System: transports the packaging film to the forming and sealing station. Forming Unit: forms the film into the desired shape and size to create the packaging bag. Filling Unit: fills the bag with the desired amount of wax. Sealing Unit: seals the bag to keep the contents inside. Cut-off Unit: cuts the bag to the desired length. |

CAN FILLING MACHINE

A can filling machine is a machine used to fill containers with liquids or other products. By doing so, it increases the efficiency and accuracy of the filling process while reducing the risk of contamination and spillage.

| The working principle of a can filling machine is based on the following steps:

The containers are loaded onto the feeding system. The filling nozzle dispenses the product into the container. The filling head regulates the flow of product into the container. The capping station places a cap on the top of the container. The control system manages the entire operation of the filling machine.

|

The major components of a can filling machine are:

Feeding system: The feeding system is responsible for loading the containers into the filling machine. This is typically done using a conveyor belt or a rotary table. Filling nozzle: The filling nozzle is the component that dispenses the product into the container. The nozzle is usually designed to prevent product from splashing and spilling. Filling head: The filling head holds the filling nozzle and is responsible for controlling the flow of product into the container. Capping station: The capping station is responsible for placing a cap on the top of the container after it has been filled. This can be done using a screwing mechanism or a press-on cap. Control system: The control system manages the operation of the filling machine and is responsible for controlling the speed of the feeding system, the amount of product dispensed, and the capping process. |

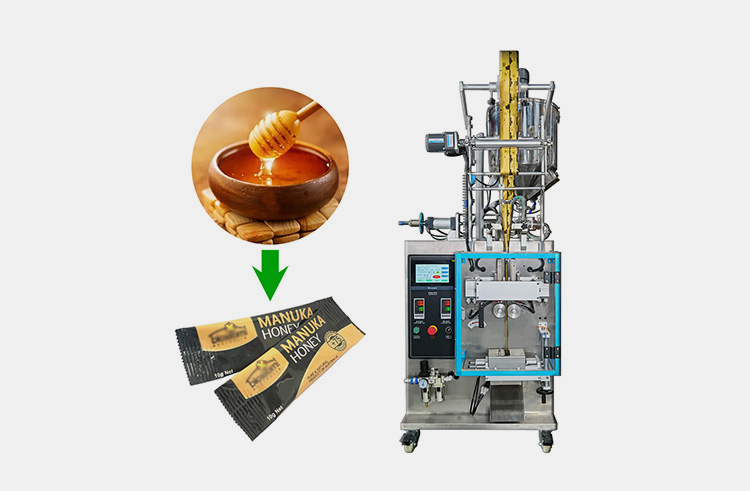

SACHET PACK MACHINE

This machine produces a continuous flow of sachet packs ensuring precise and cost-economical solution for single serving sachets. The major components of a sachet filling machine for wax packaging are:

| The working principles of a sachet filling machine for wax packaging are:

The wax is first melted in the hopper using the heating element. The melted wax is then transferred to the filling nozzle. The filling nozzle dispenses the wax into the sachet. The sachet is then sealed using the sealing mechanism. The control panel controls the entire process, ensuring that the correct amount of wax is dispensed and the sachet is properly sealed. |

Hopper: It is used to store the wax before filling.

Filling Nozzle: It is used to fill the wax into the sachet. Heating Element: It is used to melt the wax and make it easier to fill into the sachet. Sealing Mechanism: It is used to seal the sachet after it is filled with the wax. Control Panel: It is used to control the entire operation of the machine. |

POUCH PACK MACHINE

| The working principle of a Pouch Wax packaging machine is as follows:

The raw material is fed into the feeding hopper. The filling and measuring device measures and fills the raw material into the pouch. The heating system heats the pouch and melts the wax, which coats the material inside. The sealing unit seals the pouch to trap the melted wax inside. The cutting device cuts the sealed pouch to desired length. The conveying system transports the finished pouches to the next process or storage.

|

The major components of a pouch Wax packaging machine are:

Feeding hopper: This is where the raw material is fed into the machine. It is usually a hopper or a container with a feeding mechanism to transport the material into the measuring and filling device. Filling and measuring device: This component measures and fills the raw material into the pouch. It can be a volumetric or gravimetric filler, or a combination of both. The device dispenses the correct amount of material into each pouch. Heating system: The heating system melts the wax and coats the material inside the pouch. It usually consists of heating elements, such as heating plates or hot air blowers, that are used to heat the pouch and melt the wax. Sealing unit: The sealing unit seals the pouch to trap the melted wax inside. It typically includes a pair of sealing jaws that press together to make a heat-sealed edge. The heat-sealing temperature is regulated to ensure proper sealing of the pouch. Cutting device: This component cuts the sealed pouch to desired length. It can be a rotary cutter, a linear cutter or a guillotine-style cutter. Conveying system: This component transports the finished pouches to the next process or storage. It can be a conveyor belt or a transfer mechanism, such as a roller or pneumatic system. The conveying system helps to keep the production line moving smoothly and efficiently. |

STICKPACK MACHINE

The stick pack wax filling machine is designed to efficiently and accurately dispense, seal, and cut stick pack bags of wax. The entire process is monitored and controlled by the PLC control panel, which adjusts the filling volume, sealing temperature, and cutting length as needed.

| The working principle of the stick pack wax filling machine is as follows:

The wax is loaded into the hopper and fed into the filling nozzles. The nozzles dispense the precise amount of wax into the stick pack bags. The bags then pass through the heat sealing unit, where the top of the bags is sealed. The sealed bags are then cut into individual portions by the cutting unit. |

A Stickpack wax filling machine typically consists of the following components:

Hopper: for storing and feeding the wax into the machine. Filling nozzles: to dispense the wax into the stickpack bags. Heat sealing unit: to seal the stickpack bags after filling. Cutting unit: to cut the filled and sealed bags into individual portions. PLC control panel: to control and monitor the machine operations. |

8.What Are Parts Of Wax Packaging Machines?

A wax packaging machine typically consists of the following parts:

- Barrel – stores and feeds the wax into the machine. A storage container that holds the raw wax and feeds it into the machine.

- Measuring Cup- allows accurate quantity material for packing.

- Heating system – heats the wax to a pourable temperature. A system that heats the wax to a temperature that makes it pourable for extrusion.

- Extruder – melts and pushes the wax through a die to form the desired shape. A machine that melts and pushes the wax through a die to form the desired shape.

- Cooling system – cools the extruded wax to a solid state. A system that cools the extruded wax to a solid state.

- Film Former – This is narrow tube helps in creating bag or pouch of recommended shape and size.

- Label– Helps in supporting film stack that revolves during process and allows formation of film material.

- Product Conveyor – transports the packaged wax to the next stage of the production process. A mechanism that moves the packaged wax to the next stage of the production process.

- Control panel – manages the operation and settings of the machine. The center of control and operation for the machine, including settings and control buttons.

These parts work together to turn raw wax into packaged wax products for use in a variety of industries. The specifics of each part may vary depending on the size, capacity, and application of the wax packaging machine.

9.What Are Printing Options For Wax Packaging?

There are numerous printing options by which small businesses give their products a deluxe look and catch the eye of all and sundry. Some of these options are:

Silk Screen Printing

It is the type of printing in which logos and information directions are imprinted onto exterior of containers. These use silk screen consisting of wooden frame and woven mesh to print design on wax packaging.

Pad Printing

It involves transfer of 2 D design from silicon pad to the packaging container. It is quick, easy, and reasonably priced.

Offset Printing

It is a common approach for printing detailed and colored design to wax packaging containers. In this technique inked design is moved to blanket or roller from design plate then former is used for transferring design to container.

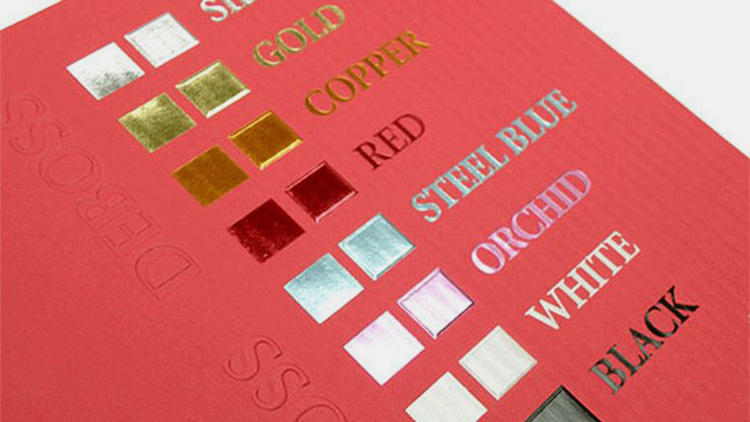

Hot Stamping

It is the process in which heated stamp die or foil is used for printing design to surface of the containers. Hot stamping can label variety of materials such as plastics, papers, and metals. It is often used for embossing luxurious design to packaging.

10.What Are FDA Guidelines For Labeling Wax Packaging?

Labeling wax packaging is deemed important by FDA for protecting buyers from unsafe or fake labeled packaged goods. FDA guidelines for proper labeling ensure correct information about amount of product contents to customers. These guidelines for correctly labeling wax packaging are:

Identity or Logo

This section includes common name of the product, its nature and illustration. It should be mentioned in bold large sized font as compared to other sections. Moreover, it should be aligned to base of packaging.

Business Information

It entails general information about business-its brand name, address, country of origin and website.

Weight of Contents

For retail distribution, the total amount of wax content in metric systems with units should be displayed within lower 30% of display panel. It must be conspicuous and printed with bold lettering.

Warning Statements

As per law, wax packaging must include warning when required to prevent health risk linked with product use. It should be prominent and written in bold lettering. Warnings statements include avoiding direct contact with eyes etc.

Ingredients Labeling

Every other ingredient except flavor, perfume, and trade secret used in wax manufacture should be declared on product labeling. The order of ingredients should be in descending form with highest proportion ingredient coming first.

Direction for Use

This section gives information as to how, when and where customers should apply wax.

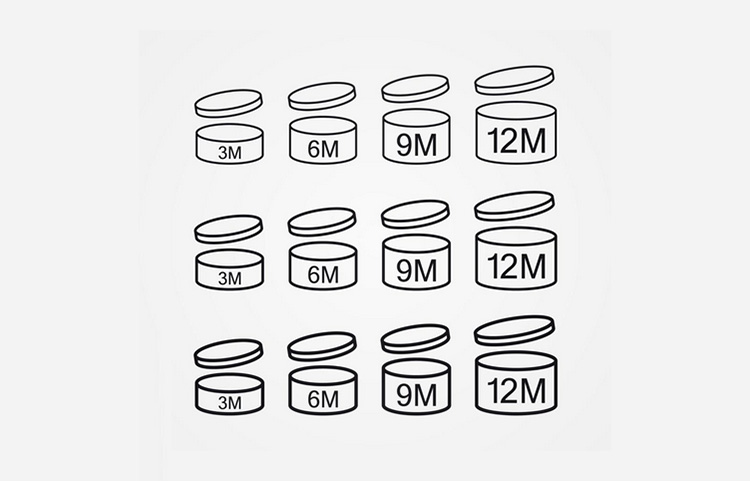

Expiry Date

It is the best before date and usually informs consumers about safe usage time period of wax.

11.What Is Difference Between Rigid and Flexible Wax Packaging?

Both rigid packaging and flexible packaging are routinely applied for packaging of wax. Differences in terms of advantages and disadvantages of these packaging types are detailed below:

| Characteristics | Rigid Packaging | Flexible Packaging |

| Definition | It is strong and has a good tensile strength but does not bend into different shapes. | This is easily bended or molded into different innovative shapes and is malleable and formable. |

| Packaging Styles | Cans, Jars, Bottles, Cartons | Pouch, shrink film, clamshell, blister |

| Materials | Plastic, paper, foil, cellophane | Metals, glass, hard plastic, cardboard |

| Price | It is more expensive than flexible packaging. | Since materials are easily available hence flexible packaging is relatively cheap. |

| Protection | It offers superior protection against heat, oxygen, water vapors, and UV light | This packaging has less barrier protection and impermeability against environments agents and chemicals. |

| Recyclability | It is high recycling ratio. | It is quite difficult to recycle flexible packaging due to unavailability of infrastructure. |

| Transportation Space | These are heavier and bulky taking much space thus need more fuel for shipment. | Flexible packaging is light in weight and is easily piled up thus need less fuel for transportation. |

| Branding | It is quite difficult to print on rigid packaging. | These are easily printed complete with striking graphics for branding. |

12.What Is Difference Between Women And Men Wax Packaging?

Previously wax products are only associated with females. But now these products are also catered towards men as well. Although both women and men wax packaging are essentially the same yet there are few minor differences between these two. Few of these differences are:

Color

For women wax packaging, generally bold, vibrant, muted, soft and light colors are used. When designing men wax packaging usually monochrome colors and backgrounds are employed.

Shape

Women wax containers comes in all shapes and styles. Men wax containers are mostly bottles and jars.

Details

Intricate detailing, lines, and patterning is involved in women wax packaging. Men wax packaging is simpler and minimalist.

Labels

Labels for women wax packaging are vibrant, pastel, floral, and bold. Dark, cold, and vintage is the theme of men wax packaging.

13.What Are The Wax Packaging Problem And Solution?

Defects in wax packaging can result in product recall, damage to reputation of business and loss of customers trust. However, these issues are easily resolved by adhering to following tips.

| Problems | Cause | Solution |

| Incomplete Or Jagged Seals | Temperature of sealing jaws is low | Adjust or increase the temperature of sealing jaws |

| Sticking Together Or Bunching Of Film | Excessive temperature while sealing | Lower the sealing temperature |

| Non-Uniformity In Pouch Length | Inadequate webbing of polymer film

Insufficient tension in film unwind belts Dust accumulation on film belts |

Adjust the alignment of unwind rollers

Properly secure the belts for right amount of tension in unwind belts Clean the belts before operation |

| Improper Alignment Of Caps On Bottles | Inaccurate elevation of cap drop station | Adjust the elevation of cap drop station |

| Misplaced Or Curved Caps | Lower number of caps in bowl

Obstruction in path of caps Inaccurate level of belts and stabilizers |

Add more caps in bowl

Clear the hindrance in path of caps Properly level belts and stabilizers |

| Loose Caps | Space between spindle wheels is wide

Decrease torque for cap tightening Improper positioning of gripper belts |

Reduce the space between spindle wheels

Increase amount of torque for tightening of caps Properly position gripper belts |

| Scars Or Scratching On Caps | High speed of spindle wheels | Properly adjust moving speed of spindle wheels |

| Missing Label | Incorrect calibration of photoelectric sensor

Small separation distance between two consecutive bottles |

Adjust the calibration of photoelectric sensor

Increase the separation between two bottles. |

14.How To Make Wax Packaging Sustainable?

With increasing environmental awareness buyers prefer products that come in green environment-friendly packaging. Here are some tips for making your wax packaging more sustainable.

Decrease Amount of Plastic in Bottles

Bottles or jars used in wax packaging ends in landfill. By lowering the amount of plastic in your packaging you can decrease plastic waste.

Use Biodegradable Packaging

Packaging made from seaweed, corn, and rice is gaining popularity in recent years. Using these materials for your wax packaging not only craft biodegradable and recyclable packaging but also offer product an elegant fashionable look.

Switch to Recyclable Metals

Tin and aluminum are more easily recycled and reused. Therefore, selecting them as your packaging materials proves more sustainable while offering best possible protection to your packaged wax.

Refilling

It is another way to decrease packaging waste and to make your brand more sustainable. Many brands have launched initiatives of refilling solution which will decrease carbon emissions.

15.How Does Wax Packaging Extend Products Shelf Life?

Like all other products, packed wax also has an expiry date which is generally about 3 years if container remained unopened. If wax does not work properly, it smells off, lost its color and consistency this means wax has gone bad.

For good results and longer shelf life, wax must be stored in airtight packaging like pouch or jar. Properly cap or reseal wax containers if not in use. Opaque, un-translucent and airtight packaging protects wax from sunlight and oxygen that can increase chemical oxidation.

Keep wax packaging in cool, dry, and dark place. It should be stored at room temperature or below but not less than 5°C for effective performance.

Conclusion

Packaging not only contains and protects wax but is integral aspect of branding and marketing. Sustainable and recyclability in wax packaging has become new modern. Up-to-date trends and artistic flares in wax packaging tempt and charm buyers. Moreover, carefully crafted packaging triggers emotional responses in passerby that cause impulse buying. If you are interested in increasing your knowledge related to wax packaging you are more than welcome to contact our customer support.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine