Vibrating Fluid Bed Dryer: The Complete Buying Guide In 2025

Production facilities struggle with the herculean task of drying the difficult-to-process feed. It is often because these materials are comprised of fine powders, large proportions of moisture, and, major variability in particle sizes.

But no worries. There is an ultimate solution called a vibrating fluid bed dryer, well-received by every processing unit, due to its excellent and swift drying rates. Now there should be a question in your mind. How does it work? This handy instrument follows the principle of vibrating movement to aid in breaking molecular forces between particles. Thus, promoting faster moisture evaporation.

If your main objective is to figure out about intricacies of a vibrating fluid bed dryer. Then you’ve come to the right place. As in this buying guide, we’ll delve into wide-ranging aspects of a vibrating fluid bed dryer.

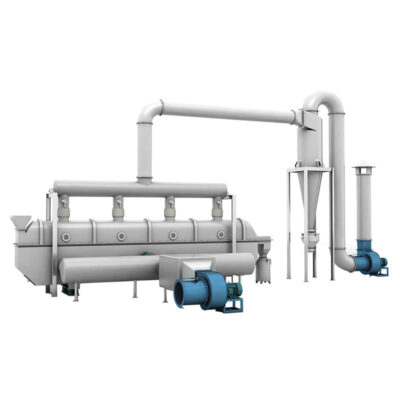

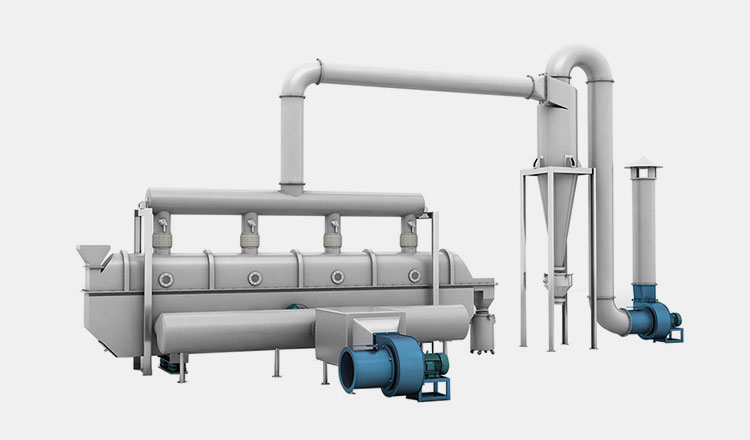

1.What is meant by a vibrating fluid bed dryer?

AIPAK Vibrating Fluid Bed Dryer

A vibrating fluid bed dryer is the newest series of industrial dryers, undertaking the complex task of drying stubborn and hygroscopic substances that couldn’t be dehydrated with other industrial dryers. How does it execute the drying task? It exercises an optimal pairing of vibration and gas flow to impeccably vaporize solvents and other fluids from a wide variety of feed. It has tailored conformation with numerous air inlets at the bottom to increase airflow.

The upward motion of gases through the machine initiates the fluidity of substances. While vibrations of this device facilitate in movement of the fluidized bed by which you can increase the efficiency of the heating process.

This equipment is not only concerned with drying but is also well-regarded for its cooling capabilities. Using this device, you’ll get two functions at the price of one. Which in turn boosts your process flow and saves you from needless expenditures.

2.What advantages does a vibrating fluid bed dryer offer industries?

A vibrating fluid bed dryer is at the top of the dryer list of every manufacturer. Do you know why? Well, the truth is it boosts a wide set of benefits that generate a mountain load of profits for businesses. At this moment, you’ll be contemplating the advantages of a vibratory fluid bed dryer. So without delay, let’s start detailing them:

Optimized and Efficient Drying

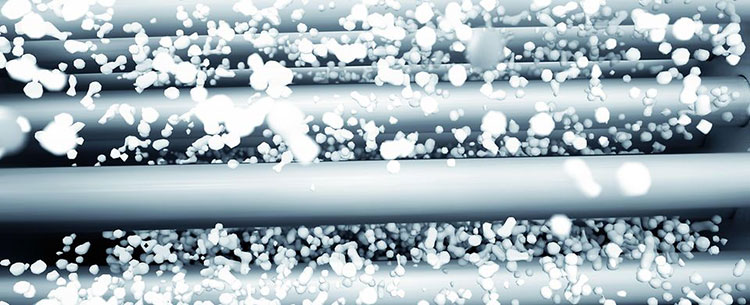

Optimized and Efficient Drying- Picture Courtesy: ADRITZ GROUP

One of the many reasons, producers always want to install a vibratory fluid bed dryer in their facilities is its optimized drying potential. The utilization of material flow and vibration at the same time translates into effective heat transfer. And that leaves no zone without heating. This machine principally cuts down your drying time and increases your output estimates.

Reliability in Drying Quality Over Time

Reliability in Drying Quality Over Time- Picture Courtesy: Bulk Solid Portal

Yes, constancy in moisture level in each batch after drying is attributed to augmented quality control approaches. But drying consistency is attained? Simply, by the use of a vibratory fluid bed dryer. Unlike other static dryers, it operates through vibrational motion. You can minimize agglomeration and massing of materials with it. This will lead to uniform exposure of heat and gas to feed and transmute into consistent drying rates in all product batches.

Processing a Wide Assortment of Feed

Processing a Wide Assortment of Feed

Are you manufacturing materials having diverse density profiles and size ranges? Then, you should procure a vibrating fluid bed dryer. The reason? It easily processes and treats feed, differing in its texture, dimensions, and weights. This device dehydrates powders, granules, flakes, and crystals. You do not need to install other solutions when you’ve got this equipment in your units. This saves you from the hassle of procuring, installing, and, running several instruments.

Trouble-free Maintaining and Cleaning

Trouble-free Maintaining and Cleaning- Picture Courtesy: ANDRITZ

The vibrating fluid bed dryer is fabricated from simple controls and a minimal number of components, making this machine quite convenient to operate and maintain. Does it allow product buildup? Absolutely not. It is a straightforward assembly- unlike other typical dryers- that decreases the frequency of residual particle accumulation. It simplifies the cleaning operations after each batch.

Increased Operational Safety

Increased Operational Safety- Picture Courtesy: ANDRITZ

Manufacturers always look for ways to guarantee the safety of their workforce during operations. And vibrating fluid bed dryer is a foolproof means of upholding safety in facilities. Do you ever wonder why? To cut a long story short, it has a closed-loop design, due to which it doesn’t emit dust outside. These features lessen the hazards of explosion.

3.Where do you find a vibrating fluid bed dryer?

Due to its vast capabilities, every manufacturing unit is hard-pressed to acquire a vibrating fluid bed dryer. It is an absolute marvel due to which industries increase their chances of advancing success horizons. Let’s learn about handy applications of a vibrating fluid bed dryer:

Pharmaceutical Industry

Pharmaceutical Pills- Picture Courtesy: Evergreen Healthfoods

You don’t need to guess, as a vibrating fluid bed dryer is obviously found in the pharmaceutical industry. Indeed! It has the competent potential to vaporize every drop of moisture from pharmaceutical materials, for instance, granules, herbal powders, and active ingredient mixtures. It is used after granulation and is notorious in the fabrication of drugs, nutraceuticals, and, other excipients.

Food and Beverage Industry

Spices

Similar to other industries, a vibrating fluid bed dryer has craved its spot in the food and beverage industry as well. Food consumables, for example, grains, coffee powders, spices, berries, spinach, carrots, etc expire quickly due to moisture content in them. Hence, this instrument lengths their perishable period by uniformly drying them. You can safely use this device in your food facilities. Because it doesn’t impact the taste, color, aroma, and nutrition of food products in any way.

Chemical and Polymer Industry

Plastic Polymers- Picture Courtesy: Sinoxe

It is one of the biggest users of a vibrating fluid bed dryer. Chemical powders, cleaning agents, catalysts, rubber, and plastic pellets are every so often ruined because of moisture particles in them. It is the reason for unneeded reactions in chemical compounds. That’s why, a vibrating fluid bed dryer has a pivotal prominence in chemical and petrochemical facilities. It removes watery content from all and sundry chemical powders and flakes without causing operators and production units harm at all.

Chemical and Polymer Industry

Agricultural Grains

In this sector, various types of seed, grains, crops, millet, animal feed, fertilizers, insecticides, wood chips, and organic manures are processed on a routine basis. However, these components have a major proportion of moisture. Hence, the significance of a vibrating fluid bed dryer can’t be overlooked in this area. It dehydrates agriculture feed to store and prepare it for the next operational procedures.

Metal and Mining Industry

Clay and Sand

It is a known fact that metals experience corrosion if there is even a little moisture matter in them. Therefore, to clear out these watery constituents, metal and mining industries always go for a vibrating fluid bed dryer. How does it support the metal and mining industry? It facilitates these fields by removing water from metallic ores, coal, sand, clay, limestone, bauxite, and others.

Energy Sector

Wood Flakes

Can you imagine the application of a vibrating fluid bed dryer in the energy sector? Sure, it has forged its path in the renewable energy industry. Because it offers reliable outcomes by effectively eliminating watery solvents from biofuels, biomass, wood flakes, agricultural waste, and algae. It is a valuable way to enhance the combustion efficiency of biological fuel resources.

4.Enlist the working steps of a vibrating fluid bed dryer.

The working principle of a vibrating fluid bed dryer is grounded on two significant pillars- vibrations and heated air. The solid materials are fluidized by the lifting motion of air as it passes through the product bed. The bed is shaken via a motorized source to improve the exposure of particles to each other and also air.

Thus, the solid particles are continuously moving and colliding with each other in bed. And that’s how this machine improves the drying rate. Now let’s shift our focus towards working steps occurring in the operation of a vibrating fluid bed dryer:

Entry of Feed and Air

Entry of Feed-Picture Courtesy: Bepex

At the initial stage, natural air from the surroundings is filtered using air filters and blowers. After that, it is heated to a preprogrammed temperature by means of a steam exchanger or the electric burner through pipelines found at the lower end of the machine. This air then becomes the drying medium.

The moist feed is introduced into a machine from the feed inlet using an automatic feeding system or manually by the workforce.

Fluidization of Product

Fluidization of Product-Picture Courtesy: Feeco

Now the question is how are the wet substances fluidized. As the air goes upward, it causes the suspension of particles. At the same time, this suspended bed is shaken using a vibration motion- present on both sides of the device.

With the vibration, the fluidized feed travels horizontally curved in inside and outside directions. This vibration motion is integral in promoting the flow of feed and its interaction with hot air.

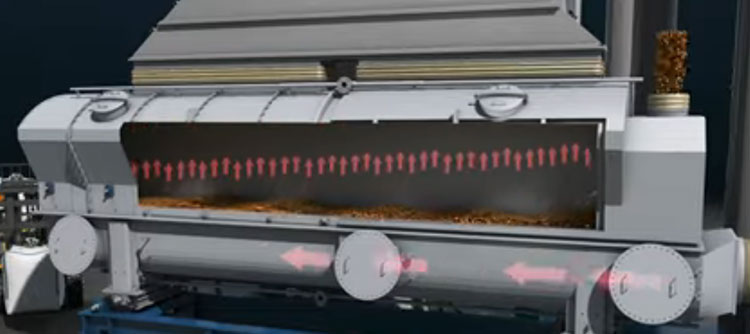

Drying

Drying-Picture Courtesy: Tempa Process

Have you thought about the mechanism behind moisture drying? It is relatively simple. Due to the contact of hot air with feed particles, heat exchange occurs. And causes an increase in the temperature of feed materials that results in the vaporization of solvent from the surface of the feed.

Moisture Removal and Product Offloading

Moisture Removal and Product Offloading- Picture Courtesy: ATEX.CENTER

The moisture-concentrated air goes out of the instrument via the exhaust system. What happens to this air after discharge? Various types of accessories, for example, condensers, scrubbers, and filters are attached to exhaust pipelines that aid manufacturers in catching fine dust particles, averting their emissions, and, solvent recovering.

The products after complete drying are offloaded from the discharge port of the machine. It is now ready for the subsequent processing or packaging phases.

5.What are the fundamental components of a vibrating fluid bed dryer?

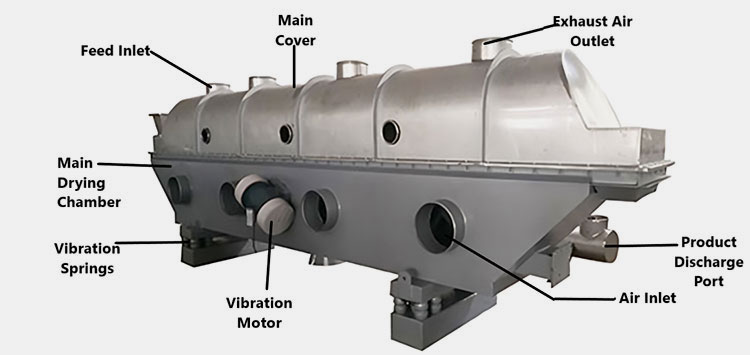

You can operate your vibrating fluid bed dryer by learning about its various fundamental components and their functionalities. This knowledge will indeed help you in the swift troubleshooting and maintenance of the device. We are penning a thorough description and illustration of the basic components of a vibrating fluid bed dryer:

Parts of a Vibrating Fluid Bed Dryer

| Main Drying Chamber | It is the core part of a fluid bed dryer. It typically constitutes the fluidized bed and perforated screen. The purpose of this component is to provide a space for the suspension and drying of feed. Also, it is the zone through which hot air is moved to dehydrate materials. It performs the task of evenly distributing hot air through the fluidized bed. The manufacturers have devised this chamber to stop products from leaking and to regulate the airflow. |

| Feed Inlet | The aim function of the feed inlet is to offer an opening through which feed is deposited in the chamber using a feeder instrument. You’ll often find this feed port at one corner of the main drying vessel. By this port, you can control the loading of material inside the machine. |

| Main Cover | Generally, it is considered a main covering or enclosure that seals the drying vessel. It acts as a shield that doesn’t allow dust or product particles to escape outside. With the use of the main cover, you can keep the temperature, pressure, and, humidity under the desired range. Likewise, this safety component reduces contamination hazards. |

| Exhaust Air Outlet | This is the vent found at one end of the drying chamber and is responsible for the removal of moisture-concentrated gases from the drying chamber. You can also equip the exhaust air outlet with a pulse filter, cyclone separator, and condenser to trap any feed matter and recover expensive solvents. These devices facilitate purifying air and reducing product wastage. |

| Product Discharge Port | You’ll obtain completely dried products from the vibrating fluid bed dryer through the product discharge port. It is usually present on the front end of the machine and at the opposite end of the feeding port. You’ve continuous and smooth product removal with this port. |

| Air Inlet | You can use this air inlet port to introduce air inside the drying bed. It is also connected to a supply blower and heating source to feed heated gases for a uniform dryer. |

| Vibration Motor | It is the driver of the whole system. Because it provides power to the vibration unit for agitating the bed. It rotates in a counter-clockwise direction using eccentric weights. You can adjust its frequency, amplitude, and stroke to improve its speed. It has a central role in homogenous drying and counter-acting clumping possibilities. |

| Vibration Springs | It is a structural support component of a drying chamber. It is designed with durable rubber and steel coil isolation springs. They are useful in regulating and minimizing transmitted vibrations. And doesn’t allow any damage to the core parts of a vibrating fluid bed dryer. |

6.What is the difference between a vibrating fluid bed dryer and a conventional dryer?

Vibrating Fluid Bed Dryer and Conventional Dryer

In industrial settings, both a vibrating fluid bed dryer and a conventional dryer are utilized to de-moisturize the feed. However, they are drastically dissimilar to each other based on their operational principle and design. Here we’re accounting short comparison between both these drying devices.

| Feature | Vibrating Fluid Bed Dryer | Conventional Dryer |

| Drying Mechanism | It runs on the principle of vibration and hot gases to fluidize and dehydrate the material. The vibrations are for the suspension of particles. This enhances the exposure of feed to hot air. | The conventional dryer generally operates using static air or direct heating sources to boil the moisture solvents. |

| Drying Speed | It has a shorter residence time. Because of the higher fluidity of feed and the continuous exposure to heated air. | It has a longer drying cycle because the raw materials remain stagnant in this dryer or are rotated occasionally. This decreases heat distribution. So the drying process is slow. |

| Drying Quality | Absolutely, due to its precise control settings, it’ll yield products of high quality with minimal variations in their moisture content. | You’ll obtain end-products of inadequate quality because there is uneven heat transfer, generating overdried or highly moisturized spots. |

| Suitable Materials | Used for de-moisturizing powder, granules, and, flaky feed. | Utilized for heavier and bulker feed. |

| Energy Consumption | It is considered more energy-efficient because less energy is consumed for heating. Due to fluidization and vibrations. Also, it comes with heat recovery systems. | Conventional dryers need a lot of energy as they have increased drying times, sometimes, taking hours. |

| Maintenance | Difficult to maintain and requires continuous maintenance because of its intricate design and frequency drives. | Has a simpler construction. So, it is easy to maintain and doesn’t need exhaustive maintenance protocols. |

7.Does a vibrating fluid bed dryer process sensitive and delicate material?

Sensitive Materials- Picture Courtesy: JOST Gmbh

This question would be coming to your mind while reading this guide. In short, certainly, this machine can process sensitive and delicate materials. Due to its precise control, you can use a vibrating fluid bed dryer to maintain low temperatures while drying heat-sensitive feed.

Besides this, it gently and homogenously distributes heated air to maximize drying proficiency without overheating even a single section of feed. Particle attrition is also lowered owing to gentle vibrational fluidization. You can also adjust the vibration level to decrease the stress on the delicate feed. Temperature-sensitive products can be gradually cooled in this equipment to avert post-drying heat degradation.

8.What is the minimum and maximum temperature achieved by a vibrating fluid bed dryer?

Temperature Range of a Vibrating Fluid Bed Dryer- Picture Courtesy: Changzhou Doing Machine

The vibrating fluid bed dryer temperature range must match the thermal characteristics of the raw feed as well as the moisture content required in it. Hence, experts advised novice manufacturers to ask about the minimum and maximum temperature range of the machine before signing the bill. So, for your ease, the minimum and maximum temperatures of this equipment are mentioned below:

The minimum temperature is around 30°C (86°F). You could set a lower temperature in a vibrating fluid bed dryer to dry thermo-sensitive powders. Whereas, the maximum temperature can reach as high as 300°C (572°F). You can adjust this temperature range to dehydrate hard-to-dry materials, for example, minerals, ores, chemicals, and, biofuels.

However, you should keep in mind that temperature profiles are mostly dependent upon the design construction and intended drying uses. Furthermore, you can contact manufacturers to customize your instrument to include a multi-zone heating range in order to attain optimized results.

9.What are the challenges in a vibrating fluid bed dryer? How to solve them?

A vibrating fluid bed dryer is one of the highly advanced versions of an industrial dryer and is widespread in manufacturing fields because of its controlled vibrations for precise drying. Indeed, it has a flexible design for varied applications, still, some operational challenges in this instrument can’t be ignored.

Hence, we are penning some frequent challenges and their solutions in a vibrating fluid bed dryer:

Challenge: Uneven Fluidization

Uneven Fluidization- Picture Courtesy: Visval

Have you ever noticed uneven fluidization in the vibrating fluid bed dryer? Well, it is a quite regular issue occurring owing to lumping and massing of feed. This means they bind together to form small balls, leading to insufficient flowability and drying.

Solution

You can solve this problem without any difficulty by just following these suggestions. For instance, you can alter the vibration frequency and gas speed to keep particles from massing. Also, even air distribution is increased by adding a distributor plate with a suitable aperture size to your machine. In addition to this, pre-drying or mixing anti-caking agents with materials (prone to clump) can decrease the rate of even fluidization.

Challenge: Overheating of Thermo-Sensitive Materials

Overheating of Thermo-Sensitive Materials

Sometimes, you’ll notice burnt surfaces after drying. Why is that? It’s because some materials are inclined to lose their structural integrity to high temperatures. Which could cause quality control issues.

Solution

There is no need for excessive worrying. Because this challenge has an easy solution. It is rectified by paying attention to details, such as the regulation of temperature and gas movement. These points are achieved by setting up a multi-temperature zone in your device, or you can establish a cooling area in your machine. This will help you to make gradual temperature alterations. Likewise, a closed-loop drying device can aid in keeping a uniform temperature.

Challenge: Increased Dust Generation

Increased Dust Generation- Picture Courtesy: GEA

Sometimes, the vibrating fluid bed dryer tends to produce a high amount of dust. This is attributed to the wastage of valuable end-products, inhalation risks, as well as air pollution in the facilities.

Solution

A few easy solutions to this challenge are: first, it is advised to connect the machine’s exhaust system with dust collection units or cyclone separator device to purify the exhaust air. Secondly, you can also procure a closed-loop vibrating fluid bed dryer if you’re dealing with materials that are prone to form excessive dust particles. Last but not least, routine maintenance and changes in gas flow rates can go way beyond minimizing dust generation.

Challenge: Jamming of Feed or Discharge Ports

Jamming of Feed or Discharge Ports

Some hygroscopic, soggy, or sticky feed can block or jam the feed or discharge port. This significantly lowers the drying yield and interpret productivity.

Solution

To prevent jamming in the product ports you should take these measures. Apply anti-caking agents to product ports. Using an appropriately designed machine also remedies this problem. You should alter the frequency and amplitude of the vibratory motor to cut down product accumulation.

Conclusion

You’ve likely realized the transformative power of a vibrating fluid bed dryer. It is preferred for drying a diverse range of materials due to its effective use of fluidization techniques with vibration and heated gases. Its multi-drying zone enables you to control drying procedures, thus drastically reducing damage to sensitive feed. Not only this it also comes with heat recovery and feed cooling options. It’s hard to resist the temptation to install a vibrating fluid bed dryer in your facilities. So, don’t wait anymore and check our machine catalog today. Because, we, AIPAK are here to provide you astounding machine that’ll exceed your expectations.

Don't forget to share this post!

Drier Machine Related Products

Drier Machine Related Posts

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine