Vial Cartoning Machine:The Complete Buying Guide In 2025

Vial is more and more popular in our market. So how much do you know about vial packaging? Have you ever wondered the way of protecting vial and transporting vials? If you have little know about vial and vial cartoning. You should have a reading of this post.

What is vial and vial cartoning machine? What industry can vial cartoning machine benefit? What are the main parts of vial cartoning machine? How to maintain your vial cartoning machine? How about the vial cartoning machine market and its future trend? Here are the answers! Let’s have a reading!

1.What Is Vial And Vial Cartoning Machine?

Vial-Sourced:adelphi-hp

Vial is the welcomed pharmaceutical type which is widely applied in many medicine type. It is usually a small bottle kind container which can help conserve powder, liquid or other medicine type. For injection and the medicine which need the high hygienic standard, vial is the essential medical type.

Vial cartoning machine is the machine applied particularly for vial packaging. The fragile and breakable vial needs the special careful care for its stable conserving, storing and transporting. Vial cartoning machine can make the great handle for vials of various size and type. It can make a series of work for the efficient and safe settling of vials in cartons. It can also make the various carton type and size according to your panel setting.

2.What Are The Common Vial Carton Packaging?

You may find the various vial packaging type. Vial carton packaging has various types and here are the common vial carton packaging.

Multiple vial carton packaging

Multiple Vial Carton Packaging-Sourced:keyboxco

The vial cartoning machine can make the multiple vials packaging. For some vial products, there is the need of making the multiple packaging. The multiple packaging can save your material and budget. The application of this type of packaging is more acceptable. You may also have the security and safety proved from this packaging.

Plastic tray vial carton packaging

Plastic Tray Vial Carton Packaging-Sourced:romaco

Plastic tray vial carton packaging applied a plastic tray for the better and more safe conserving of vials. The adding of plastic tray in vial carton packaging is also widely used in pharmaceutical industry. It can stand the stronger bumping and swinging in transportation. Plastic tray vial carton packaging is applied usually for vial injection for its high safety.

Single vial carton packaging

Single Vial Carton Packaging-Sourced:asahi-pp

Single vial carton packaging makes the packaging for vial with the single room. The special care for precious and breakable vial can be achieved from the single vial carton packaging work. It can be operated fast and makes the great conserving for vial products. In pharmaceutical industry, this type of vial carton packaging is widely welcomed.

Eye drops carton packaging

Eye Drops Carton Packaging-Sourced:pinterest

There are eye drops with different shapes. There are rectangular, cubical and irregular eye drops. For the packaging, vial cartoning machine can make the great job. You may also have your energy saved in printing the necessary information on cartons.

E-liquid carton packaging

E-liquid Carton Packaging-Sourced:boxproof

E-liquid requires high sanitary and careful settling. The great performance of vial cartoning machine can make the outstanding packaging for E-liquid. You can also have the choice of different box shape and so on.

CBD hemp oil carton packaging

CBD Hemp Oil Carton Packaging-Sourced:cannavie

CBD hemp oil has the special need in packaging sanitary and packaging technique for the real qualified and outstanding performance. Vial cartoning machine can make the great handling of CBD hemp oil carton packaging.

3.What Types Of Cartons Can Vial Cartoning Machine Produce?

Vial cartoning machine can produce cartons of various types. And here are the common cartons it produce for vial production.

Auto bottom cartons

Auto Bottom Cartons-Sourced:cclhealthcare

Auto bottom cartons is the welcomed carton applied for vial products packaging. It has the bottom formed automatically which saved the energy of worker in forming cartons. The features of simple and easy forming make it welcomed in pharmaceutical industry. It is stable and durable and can make the great job in protecting the vial products.

Reverse tuck cartons

Reverse Tuck Cartons-Sourced:staticecp

Reverse tuck cartons have the sealing parts at the panel part. There are tucks at the two sides of cartons. The panels of two parts are folded in the opposite sides. The special design can prove the safety and stability of vial products in its storing and transporting. Reverse tuck cartons are thus welcomed for vial products packaging.

Seal end cartons

Seal end cartons make the comprehensive consideration for vial products protection. In the seal end carton manufacturing, there are flaps, inner closure panels and outer closure panels tuck in for the great protection. The flexible vial cartoning machine can help make the packaging of this type of cartons.

5th panel carton

5th Panel Carton-Sourced:cclhealthcare

5th panel folding carton which is also named as book cover folding carton adds two more panels on the basic carton. There are more space for the protection and instruction of your vial products. It makes better display of products for customers and helps improve sales of vial products.

Tuck with partitions

Tuck With Partitions-Sourced:cclhealthcare

Tuck with partitions are the cartons with special look. With the partition inside it, you may have the double vial products stored inside it. And your vial products can also be preserved well with the great and strong protection. The partition can be applied for printing the instruction or informing the important information.

4.What Are The Advantages Of Vial Cartoning Machine?

Vial cartoning machine is widely applied in vial products packaging. It benefits manufactures greatly. Here are the basic advantages of vial cartoning machine.

Cost effective

Cost Effective-Sourced:shutterstock

Vial cartoning machine can save you great cost. Obviously, the cost in labor can be reduced greatly. And you may also have the products of high quality which is the great saving of your vial products industry. The high efficient and reliable vial cartoning work save your time and your cost.

High efficiency

High Efficiency-Sourced:aihr

Vial cartoning machine is high efficient. Its automatic work can make the high speed cartoning job for your vial products. The high efficient work can save your precious time for your production.

High productivity

Vial cartoning machine is high productive. It can handle the large production of vial products in a short time. For the large production, you may have the simple and quick handling. It saves the trouble of dealing with the large production.

Great quality

Great Quality-Sourced:locaria

The packaging work from vial cartoning machine makes the high qualified products. The settled panel and programme can help make the high qualified work and inspect the unqualified or low qualified products.

Safe and easy to operate

Safe And Easy To Operate-Sourced:fekrait

Vial cartoning machine is easy and safe to operate. The panel setting is clear and has the organized process. The operator avoids the hard and dangerous work. Its safe and easy operation benefits many manufacturer.

Strong ability

The intelligent and strong vial cartoning machine makes the powerful job. You may apply the flexible and versatile vial cartoning machine for various products type manufacturing. It is easy to operate and has the ability to handle various products type.

Corrosion resistant

Corrosion Resistant-Sourced:da-yi

Vial cartoning machine is made from the high qualified 304 stainless steel. Besides, it also apply the various strong and resistant parts for smooth operation. The material applied for vial cartoning machine can take handle of the various types of products.

Sanitary prove

You may have the sanitary proved with the application of vial cartoning machines. The adoption of food grade or drug grade material prove the sanitary of your products. Besides, the less joining of labor in manufacturing process can also prove the sanitary of your products.

5.What Industry Can Vial Cartoning Machine Benefit?

Vial cartoning machine can be applied to various products packaging. And here are the industries vial cartoning machine be applied.

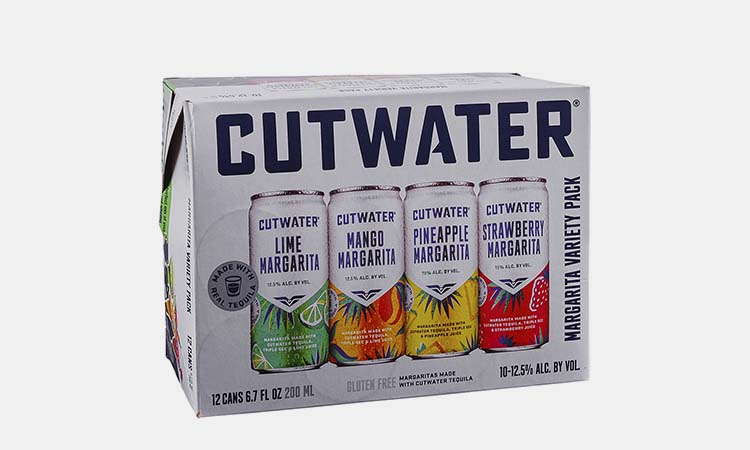

Food industry

Food Industry-Sourced:applejack

Food industry makes the high standard on hygiene and safety of products. Vial cartoning machine can help pack vials for pharmaceutical use and also the various drink in food industry. You may find the application of vial cartoning machine in packing the various drinks.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:westpharma

Pharmaceutical industry makes the frequent use of vial cartoning machine. There are various ampoule, vials, drips, eye drops and many other fragile and breakable products which need the careful treating of vial cartoning machines. Vial cartoning machine can always make the reliable and high qualified packing work.

Cosmetic industry

There are also the various cosmetic products which need the packaging help of vial cartoning machines. You may find the essence, emulsion, lotion, shampoo and so many cosmetic products are packed by glass or plastic bottle. For the great conserving and safe transporting of these products, you should apply vial cartoning machine for help.

Supplementary industry

Supplementary Industry-Sourced:liquidhealth

Supplementary industry needs the careful packaging to protect the precious supplementary pills. For the liquid supplementary products, it is essential to make the careful cartoning for the safety and effect of supplementary products. You should make the careful cartoning with vial cartoning machine for your supplementary products.

6.What Are The Main Parts Of Vial Cartoning Machine?

Vial cartoning machine is not the complex machines. And here are the main parts of vial cartoning machine.

Control segment

AIPAK Control Segment

Control segment makes the control of the whole cartoning process. It is like the brain of vial cartoning machine which makes the essential instruction for vial cartoning operation. You cannot operate your vial cartoning machine without the help of control segment.

Electric panel

AIPAK Electric Panel

Electric panel is the heart of vial cartoning machine. It provides power for the smooth manufacturing of vial cartoning machine. Without it, you cannot prove the reliable work and smooth function of the vial cartoning machines. Electric panel is essential part of vial cartoning machine.

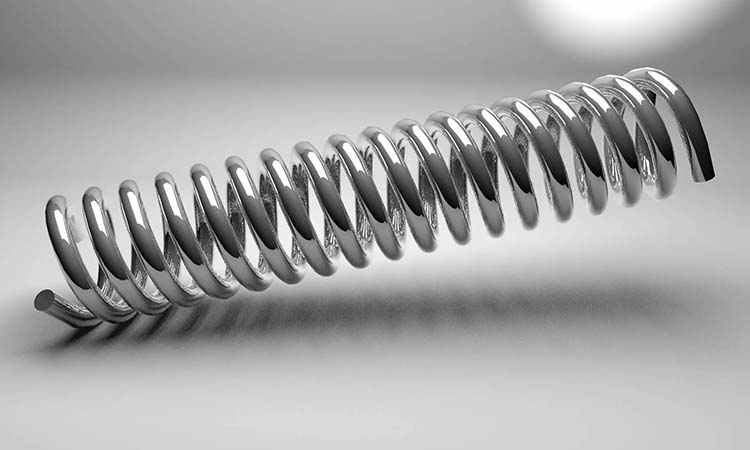

Lubrication system

AIPAK Lubrication System

Lubrication system exists in the bearing and gearing parts. It ensures the smooth running of vial cartoning machine. For the long working life of machine and smooth vial cartoning manufacturing, lubrication system is irreplaceable for vial cartoning machines.

Ink-jet printer

For any qualified vial products, you cannot miss the information and instruction on packaging. Ink-jet printer prints the essential information like date, instruction and many important information on the cartons. It saved the energy in making the separate printing.

Carton pick-up

AIPAK Carton Pick-up

Carton pick-up seeks the help of mechanical hand for the picking of carton sheet for folding and further work. The flexible and alert work of carton pick-up can always make the precise and efficient work.

Leaflet pick-up

There are instruction and leaflets for information the reliable vial products. The leaflet pick-up makes the continuous work of filling leaflet or instructions in the cartons. It saves your further time and energy in making the work.

Product insert

AIPAK Product Insert

The vial products should always prove the safety of its products. Products insert makes the quick and reliable inserting of products in carton. It can make the accurate placing for your vial products. The great inserting of products show the high quality of your products and also prove the products safety.

Carton closure

AIPAK Carton Closure

After the filling of the products and instruments of your vial products, carton closure then makes the great work of close cartons. Carton closure makes the precise and airtight sealing for your vial products. For the last step of carton closure, carton closure can prove the safety of your vial products.

Carton discharge

For the well packed vial carton, vial cartoning machine will lead them to the last step of discharging. Carton discharge makes the important work of avoiding the products accumulating. It is the last step of vial cartoning manufacturing and makes the important work for the products.

7.How About The Working Process Of Vial Cartoning Machine?

For the smooth manufacturing of vial cartoning machine, you should have the comprehension of the working process of vial cartoning machines.

The Working Process Of Vial Cartoning Machine

Material prepare

For the smooth work of your vial cartoning machine, you should make sure the preparing of your products. The carton piece, instruction and vial products should be prepared for the later operation of your vial cartoning manufacturing.

Material enter

After the preparing of your material, you should then put them well and lead them into the vial cartoning process. There are the settled position for bottle, carton leaflet and instructions. You should put them in the right place for the smooth operation.

Carton folding

After the loading of all types of products, vial cartoning machine then begins the folding of carton piece. The mechanical hand can perform the great work and fold the carton according to panel and setting. Carton folding from vial cartoning machine can make the great and reliable work.

Products inserting

The formed carton box is open for the filling of its products. And then, according to panel setting, bottle and instruction will fill in the carton in order. The automatic and mechanical work made by vial cartoning machine can save you great time and strength.

Carton closing

After the filling of all products, you may notice that your carton box is open. The last step of your vial cartoning work is to close the cartons. And here you may need the glue or adhesive tape for the airtight and stable closing for your vial carton.

Products discharging

The well closed carton then should get out of the vial cartoning machine and its whole process. Discharging is the last process of vial cartoning machine. It leads the safe exiting of vial products.

8.What Machines Can Corporate With Vial Cartoning Machine For Vial Products Manufacturing?

Have you ever wondered the machines which can corporate with vial cartoning machines for the consistent and high efficient vial products manufacturing? Here are the machines you may consider for the vial production line.

Extraction machine

AIPAK Extraction Machine

Extraction machine helps extract essence from various types of products. For both solid and liquid, it can make the great extraction which fulfill your request of fine separation and great sanitary. Extraction machine is widely used in food, pharmaceutical, biological and the relative industries.

Bin blender

AIPAK Bin Blender

Bin blender is the blending machine which can make the comprehensive and efficient blending for various types of material. For pharmaceutical industry, there is the need of blending liquid and solid. The applying of bin blender can make the even blend and perform the serious of work like mixing, filling and so on.

Bottle washing machine

AIPAK Bottle Washing Machine

For the vial products sanitary and safety, you should first make the careful washing for the bottles. The ultrasonic bottle washing machine can make the series of work like bottle holding, turning, disinfecting and washing. The automatic work and inspecting from bottle washing machine can prove the sanitary and quality of your bottles.

Vial filling machine

AIPAK Vial Filling Machine

Vial filling machine is the most important part for vial production line. It is applied for the filling of powder and liquid. It has more than one nozzles which can be applied for the filling of small bottles. You can adjust the size of vial products for the precise filling. The high efficient and precise work of vial filling machine assures the high quality of your vial products.

Automatic labeling machine

AIPAK Automatic Labeling Machine

Automatic labeling machine makes the accurate stick for various kinds of bottles. The versatile and flexible labeling machine can handle the label sticking of food, medical products, supplementary products, plastic products and so on. Automatic labeling machine helps to show the essential information on bottles.

9.How To Maintain Your Vial Cartoning Machine?

Vial cartoning machine is the efficient but complex machine. You should know its basic maintaining methods for the better performance and longer lifespan.

Regular cleaning

Regular Cleaning-Sourced:thepackman

You should make the regular cleaning for your vial cartoning machines. Regular cleaning can prove the sanitary and quality of your vial products and can also prove the nice condition of your machine. In the cleaning process, you should adopt the mild detergents and towel for the cleaning.

Checking and replacing

Checking And Replacing-Sourced:sidem

You should make the regular checking of the function of your vial cartoning machines and get out its worn parts or unqualified parts. The daily check can help you find the degradation of your products. It proves the nice condition of your vial cartoning machines and the great performance of it.

Professional operating

The operating for your vial cartoning machine should be professional. The wrong operating may lead the malfunction of your vial cartoning machines. You should thus adopt the professional work for the smooth operating of your vial cartoning machine and the great maintaining of the machines.

Preventive planing

Preventive Planing-Sourced:maintenanceinnovators

You should make the preventive plan or preparation for the operating and emergency of your vial cartoning machine work. The plan should be comprehensive and covers the various process of your machines. It can prevent the problem and reduce the risk of machine malfunction.

10.How About The Vial Cartoning Machine Market And Its Future Trend?

With the development and creation of machinery and more and more concern on human health, there is the fast growing in cartoning machine market for pharmaceutical industry. It is predicted that vial cartoning machine market will have a blooming in future. The high efficiency and great sanitary of it prove the high products quality.

Future trend of vial cartoning machine

Intelligent cartoning work

Intelligent Cartoning Work-Sourced:blueprintautomation

In future, the work of vial cartoning machine will be more intelligent. The corporation with vial cartoning machine and artificial intelligence can save you great energy and time in operating vial cartoning machines. Intelligent cartoning work is the future trend of vial cartoning machines.

Recyclable and biodegradable cartoning

Recyclable And Biodegradable Cartoning-Sourced:thepackagingcompany

The future trend of protecting world and reducing carbon emissions promote the adopting of recyclable and biodegradable material for vial cartoning machine work. Besides the recyclable material, there will also the design for energy saving and world protecting for vial carton machines.

Compact and modular design

Flexibility and versatility is also the great trend of vial cartoning machine work. The design for compact and modular vial cartoning machine is the trend in future which can benefit manufacturing, factory setting and production line.

11.What You Should Consider For The Vial Cartoning Machine Purchase?

Here are so many different brand and machine type of vial cartoning machine in market. To get the reliable and suitable one, here are the tips you should conform.

Production need

Production Need-Sourced:rssinc

Your production need decides the size and type of your vial cartoning machine. You should choose your vial cartoning machine according to your business size and production scale. For the large production scale, the purchase of the machine with large production is essential for your business operating.

Product type

You should also consider your product type for the selection of your vial cartoning machine. How about your bottle size or vial shape? Are there any special design of product? The choose of suitable vial cartoning machine is essential for the later dealing of your vial cartoning machines.

Automation level

There are different automation level for different types of vial cartoning machines. The high automatic vial cartoning machine is of course more intelligent and efficient. But the automation also means higher price. You should consider your need of automation level for the vial cartoning machine choose.

Budget

Budget-Sourced:universalfunding

Budget is the most important factor for your machine purchase. The vial cartoning machine in your budge range can take you the most benefits. There are always the machine with higher price and better performance. But the one excess your budget may hinder your business.

Brand

Brand-Sourced:marketingdonut

The reliable vial cartoning machine brand can offer you reliable after sale service and professional inquiry. You should search big brand for the reliable service. And here AIPAK is greatly recommended for its high profession and great reliability. The great service and high qualified machines keep benefiting manufacturers of many industries.

12.What Are The Common Problems And Solution Of Vial Cartoning Machine?

In the operating of vial cartoning machines, there may exist some problem or trouble. And here are the common problems and the relative solutions of vial cartoning machine.

Problems And Solution-Sourced:copyengineer

| Problem | Solution |

| Stack packaging material | The stack packaging material comes from the wrong size and material of cartons. You should find the suitable carton according to your product type and machine size. The unsuitable packaging material will make the worn or damage for your machines. You should also make the lubricating for the stack of packaging materials. |

| Adhesive problem | Adhesive makes great impact for the sealing of your vial products. The wavering adhesive temperature, cheep adhesives and jammed spray system are the reasons of the adhesive problem. For the solutions, you should make the stable adhesive temperature and adopt the qualified adhesives. For the smooth adhering, you should make the regular cleaning of your spray nozzles. |

| Stuck processing | Processing stuck may lead a series of mistakes and jams for vial cartoning operation. The problem comes from the belt trouble, carton size and sensor trouble. For the relative solution, you should make the regular check and calibration for the smooth operating of the products. |

| Damaged carton box | Damaged carton box reduce the protection for your vial products and also affect the appearance of your products. For the damaged carton box, you should check the carton piece size and height first. Besides, you should also match rails in the right place and condition. |

| Sudden stop | Sudden stop of vial cartoning machine comes from system malfunction. For the smooth operating of vial cartoning machine and avoid of sudden stop, you should make the regular calibrate for sensors and upgrading for software. For the machine with longtime use, you should upgrade its system and make the regular checking for the smooth operating and high efficiency. |

Conclusion

Vial cartoning machine makes so many benefits for pharmaceutical industry. You can also find its use in food industry, cosmetic industry and so on. After reading, you may have the deeper understanding of the vial cartoning machines. If you have any questions about this machine, you may have no hesitate to contact AIPAK now.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours