Vertical Cartoner VS Horizontal Cartoner

Are you wondering how to package your products well and show its nice looking? Have you selected the suitable carton packaging? Don’t forget to match your packaging a good cartoner! When you are doing this purchase, you can find the different types for products packaging.

What do you know about vertical cartoner and horizontal cartoner? Both of them can provide you the nice cartoning work, but do you know their difference, do you know how to choose the real suitable one?

This post will give you the most detailed information about the two types of machine. You can get your wanted knowledge and get the one suits your manufacturing best. Go for reading!

1.What Is Vertical Cartoner VS Horizontal Cartoner?

No products can get on shelf without package and no one can refuse the cartoner which can make good package. Cartoner can make cartons, fill products, print necessary information, sealing the cartons. In a word, it provide the one-stand service for package making. It improves your efficiency and products quality greatly.

Vertical cartoner

Vertical Cartoner-Sourced:pmikyoto

Cartoner can be divided as vertical cartoner and horizontal cartoner mainly according to the different way products gets into cartoning process. Vertical cartoner, as it names, gets in vertically, can reduce the damage on products and thus gets great favors for bottles, cans and fragile products packaging.

Horizontal cartoner

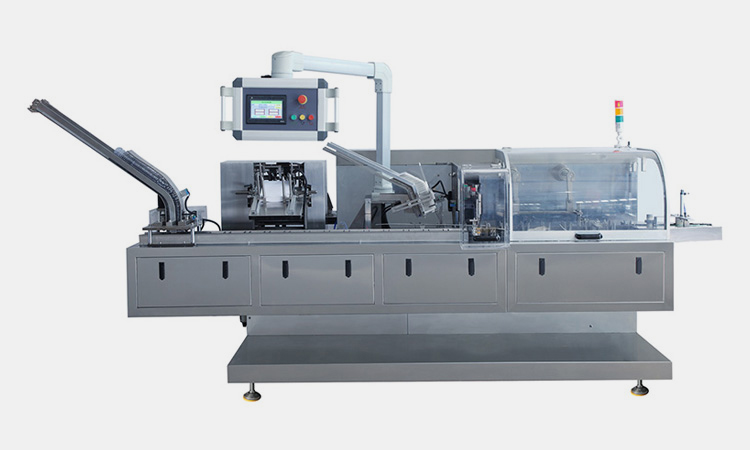

Horizontal Cartoner-Sourced:zhpackagingmachine

Horizontal cartoner is reverse with vertical one. As gets in horizontally, it suits for most products and can get products fill the cartons tightly. But for the fragile products, it may not handle these as good as vertical one. And for bare products, it loses the advantages like vertical one by using gravity to fill products into cartons.

2.In Which Industry Can Vertical Cartoner VS Horizontal Cartoner Be Applied?

Vertical cartoner and horizontal cartoner can suits all industries need packaging.

Food and beverage industry

Food And Beverage Products-Sourced:packagingcorp

Vertical cartoner and horizontal cartoner plays an essential role in food and beverage industry. The special multi-packaging vertical cartoner provides is rather suitable for drink, spirit and soda beverage. Besides, the special design of getting things vertically can greatly protect the fragile fresh food and save a lot in bare products packaging.

Pharmaceutical industry

Pharmaceutical Products-Sourced:medium

Pharmaceutical industry produces medicines filled in bottles and products requires extra care in protection and settling. Vertical cartoner and horizontal cartoner can fulfill the need of pharmaceutical industry in many aspects.

Cosmetic industry

Cosmetic Products-Sourced:halfpricepackaging

You must find the new trend in cosmetic industry. Customers are now more care about the natural gender and timeliness of products which has a higher standard on packaging. Vertical cartoner and horizontal cartoner can package vial which is just the new trend need and make least damage to the delicate natural parts.

Health supplement industry

Health-Care Products-Sourced:boxprintingcompany

Health industry makes health-care products. The most common types care tablets or capsules which contains the benefiting nutrient. It’s just like bare products. The vertical cartoner and horizontal cartoner packaging can use the strength of gravity and reduce the damage on medicines.

Electronic industry

Electronic Products-Sourced:thedieline

Vertical cartoner and horizontal cartoner can be applied to various electronic devices, components and accessories. Batteries, watch, phone or CD, you can use electronic industry to package small one as well as big one.

Cloth industry

Cloth Products-sourced:pixartprinting

Cloth products are usually light and well-folded. Vertical cartoner and horizontal cartoner can put textile products like socks, shirts, ties, and other apparel in cartons perfectly.

Sports industries

Sports Products-Sourced:halfpricepackaging

Sports industry has various products ranging from balls, sports equipment and sports clothing. These products are usually packaged by vertical cartoner and horizontal cartoner.

Toy industries

Toy Products-Sourced:salenzv

You can package the dolls, bears, cars or even robots from toy industry by vertical cartoner and horizontal cartoner. Its high efficiency can show you the expected and well packaged products.

3.Vertical Cartoner VS Horizontal Cartoner

| Points | Vertical cartoner | Horizontal cartoner |

| Loading way | Vertical cartoner is top loaded and gets the products loaded from above. | Horizontal cartoner is side loaded and get products get pushed into from side. |

| Appearance |

Vertical Cartoner Appearance-Sourced:cariba Vertical cartoner has a vacuum powered rotary feeder in its one side and cartoning process on other side. |

Aipak Horizontal Cartoner Appearance Horizontal cartoner has inline horizontal carton magazine feeder rather than rotary feeder, and the left is normal cartoning process. |

| Applying field | Vertical cartoner are ideal packaging device for vials, bottles and cans packaging, besides the normal packaging. For fragile and bare products packaging like cereal of vegetable, it’s the best choice. | Horizontal cartoner are widely used for products packaging and has the advantage in tight packaging and multiple items packaging, for small parts which need to stuck tightly and snacks which can has multiple package in sale need. |

| Versatility | Vertical cartoner endows you a versatile cartoning experience and does various packaging for various products. | Horizontal cartoner may have some restriction in products kinds as its loading way may not as gentle as vertical one and can cause damage to bottles, vials or some fragile products. |

| Multiple packaging | Vertical cartoner can make multiple packaging which packaged products into a single items like drink, can, bottles and so on. | Horizontal cartoner can also make multiple packaging which has the priority in packaging products like snack packs, pens or toys in tight condition. |

| Tight packaging | Vertical cartoner can make safe and delicate packaging for almost all products, but not so good at tight packaging. | Horizontal cartoner can make a tight packaging. It gets the products pushed to cartons and can make it fill carton tightly. |

| Fragile products packaging | Your fragile products can get packaged by vertical cartoner as it can make the least damage and good delicate handling. | Horizontal cartoner can handle all kinds of packaging, but comparing with vertical one, its horizontal loading way may not that delicate. |

| Footprint | Vertical cartoner takes smaller footprint as it has the feeder system stand vertically. | Horizontal cartoner takes larger space for its horizontal feeder layout. |

4.What Package Material And Carton Types Do Vertical Cartoner VS Horizontal Cartoner Adopt?

Vertical cartoner and horizontal cartoner as all used for products packaging, share much similarities in products material and carton type.

Packaging material

Different packaging material shows different products feature and plays different packaging roles.

- Paperboard

Paperboard-Sourced:spartanpaper

Paperboard is usually the first choice for carton packaging as it is the most easily get and cheapest one. It is made by several layers of paperboard and can hold products steadily.

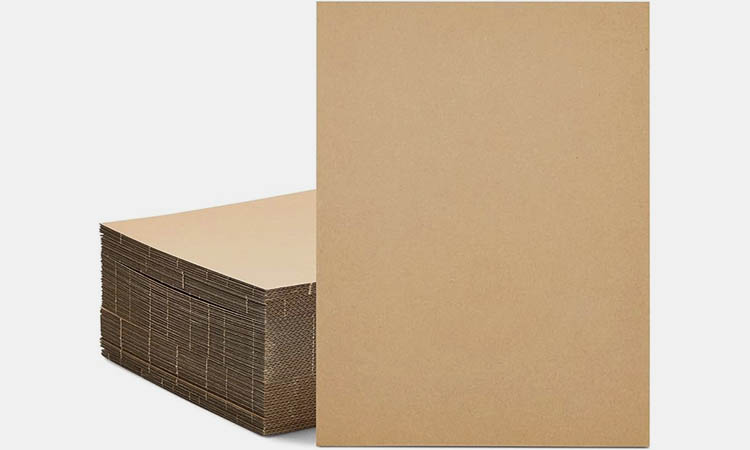

- Corrugated paperboard

Corrugated paperboard-Sourced:Juvale

Corrugated paper is made of a fluted corrugated sheet and flat liner boars on its two side. This structure makes it stabler for product holding.

- Kraft paperboard

Kraft Paperboard-Sourced:Swastik Packaging

Kraft paperboard can be further divided as unbleached kraft paperboard and bleached kraft paperboard. Besides the basic ability to hold a product, kraft paperboard can stand resistance, compressive strength and tearing.

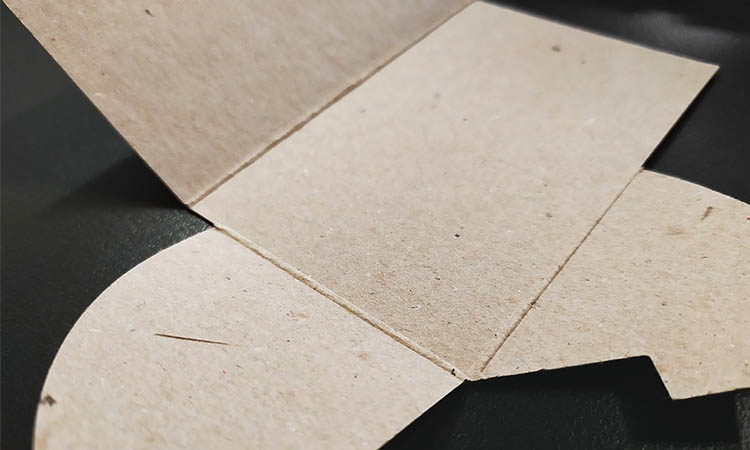

- Recycled paperboard

Recycled Paperboard-Sourced:offsetcards

Recycled paperboard is mainly made from paper but adds some extra recyclable material. It can make great cartons and at the same time, make the contribution to serve the earth protection.

- Micro-flute corrugated paperboard

Micro Flute Liners-Sourced:albertpaperproducts

Micro-flute corrugated paperboard is thin and light for it is composed by thin pieces of corrugated cardboard and out layers. The lightness, great protection and flimsy make it great popular for some products.

Carton types

Carton has various types according to different features or need of a products.

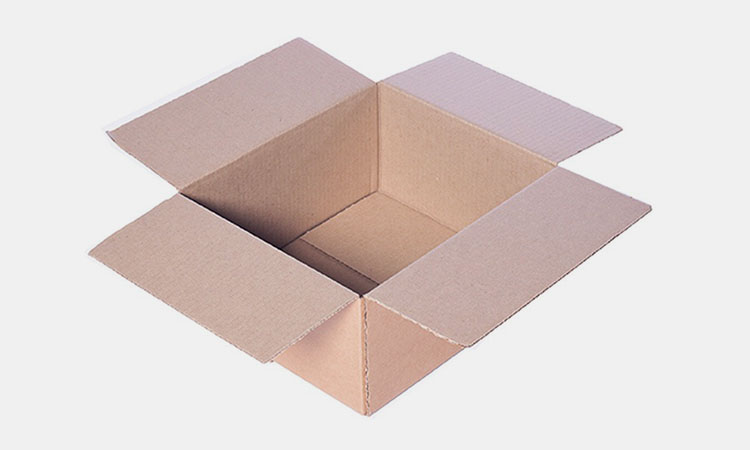

- Slotted box

Slotted Box-Sourced:westlineschool

Slotted box is the most common and conventional one. It has various size but always keeps four out flappers on two sides and keeps the flappers in half length of container for closing.

- Half-slotted box

Half-Slotted Box-Sourced:coltpaper

Half-sized box has the similar main features as slotted box, but it’s has only one side open. It suits special products and benefits products handling.

- Lock bottom box

Lock Bottom Box-Sourced:printingcircle

Lock bottom box has its bottom flaps pushed into each other and is thus more stable. It can benefit you in products holding but its assembly may take your more time.

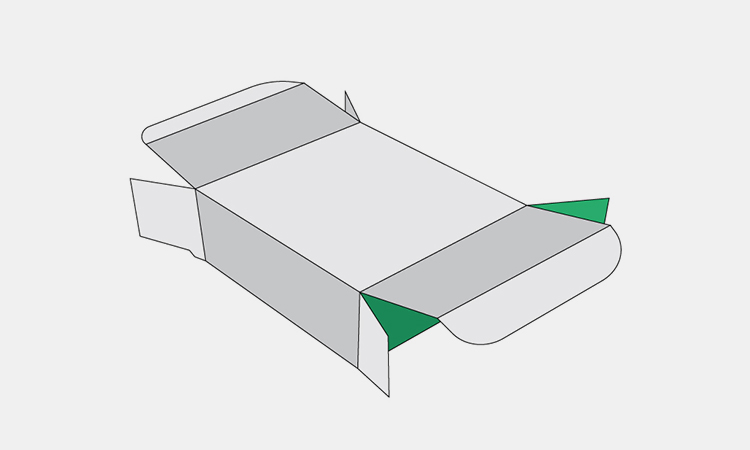

- Seal end box

Seal End Box-Sourced:qinprinting

Seal end box is specially designed for high-speed products set up and bare products. It has a side panels sealed out and can thus seal products well.

- Hanger box

Hanger Box-Sourced:packaging-warehouse

Hanger box has a small hook on its one side and other side being closed normally. It fulfill the displaying need of some products, but only for the light products.

- Grable top box

Gable Top Box-Sourced:pactivevergreen

Gable top box has a plastic cap on the top of carton which is specially designed for beverage like juice, milk and such. It seals products well and makes pouring more easy.

- Tuck top box

Tuck Top Box-Sourced:customboxusa.

Tuck top box is made by two flaps of paperboard. They are stuck to each other and are thus formed a tight and sturdy cartons for heavier products packaging.

- Straight tuck end box

Straight Tuck End Box-Sourced:ibexpackaging

Straight tuck end box has its top and bottom panels attached to same direction. It makes products handling more easy and convenient.

- Reverse tuck box

Reverse Tuck Box-Sourced:liquidprinter

Reverse tuck box is just like straight tuck end box, but has its two panels attached to reverse direction. This design improves the strength of cartons.

5.What Can Vertical Cartoner VS Horizontal Cartoner Benefit You?

Vertical cartoner and horizontal cartoner is the great help for your manufacturing work. They combine the process like making cartons, sending products, filling products and so on. They can benefit you in a all-round way.

High efficiency

High Efficiency-Sourced:sirosilo

As working is all performed by the professional and precise mechanical cartoning process, you can get your expected products in a short time. This proves your high efficiency and productivity of your manufacturing.

Great products protection

Great Products Protection-Sourced:greatnorthernpackaging

The labor-leaded cartoning way can of course make your the packaged cartons, but you can’t assure the cartons condition. Machines have a stable working process and can make the reliable cartons which conform to your setting. And only good cartons can play its protection role for products in shelf and transportation.

Stable and high quality

Quality-Sourced:bsstainless

Cartoner, both vertical and horizontal one, make a high level of precision in cartoning process. You can get your well-packaged and qualified cartons consistently.

Great flexibility

Flexibility-Sourced:shinebenmach

Vertical cartoner and horizontal cartoning didn’t restrict themselves in one size carton or one kind of products. The machines can handle different packages and suits different products by little adjusting.

Low labor cost

Labor Cost-Sourced:.mbaknol

The cartoner’s use can cut your labors greatly and the improved efficiency and quality of products can make you more profits.

6.How Do Vertical Cartoner VS Horizontal Cartoner Work?

Though all make the work as cartoning and packaging, vertical cartoner and horizontal cartoner work differently.

Vertical cartoner

AIPAK Vertical Cartoner

- Products are gets into cartoning process from rotary feeder and then leaded to the beside conveyors.

- Cartons has its bottom side being folded and closed to make the preparation for products.

- The brochures or instruments are waiting between cartons and products. While products gets into carton, they also gets into by the same force.

- Filled with products, cartons get to the next process to have information printed and sealed.

- Well packaged cartons get out from carton chute.

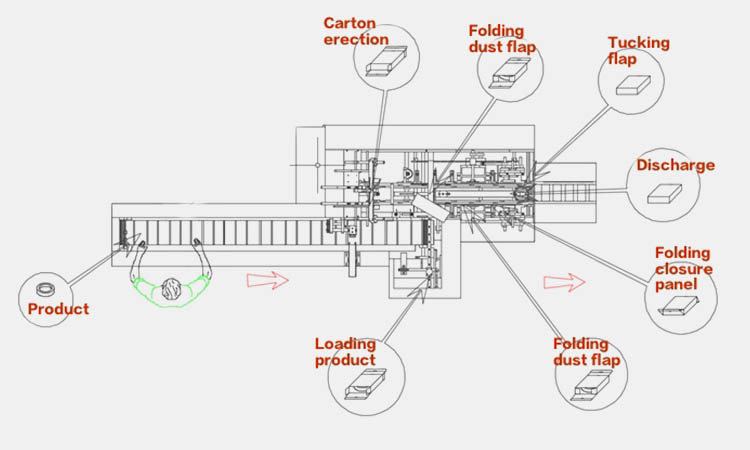

Horizontal cartoner

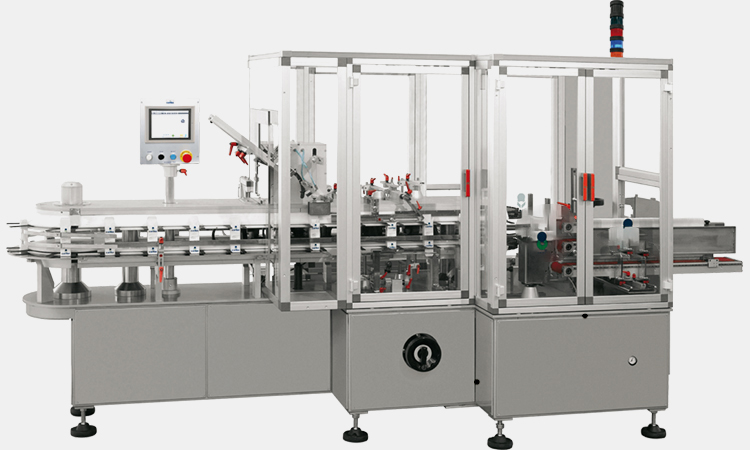

AIPAK Horizontal Cartoner

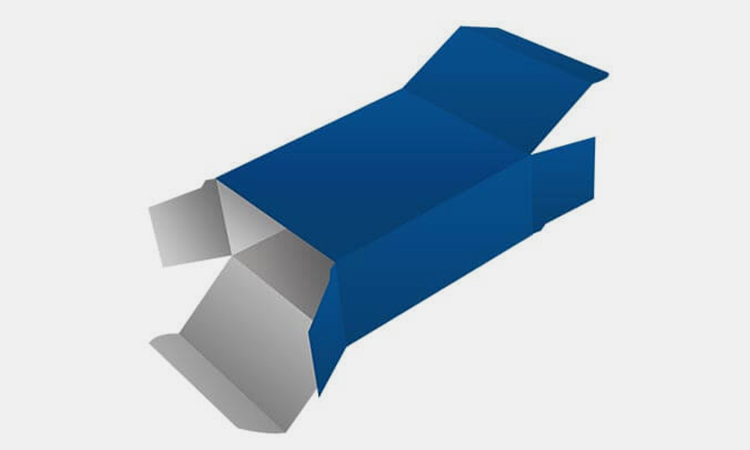

- The flat paperboard on carousel conveyors is erected and folded by a mechanical hand. Its bottom is folded and sealed.

- Products at the product tray are pushed to the waiting carton one by one.

- The brochures or instruments are at the middle and sent by the force products get into cartons.

- Filled with products and printed well, cartons have its top flaps closed and sealed.

- The packaged products then get out the manufacturing process.

7.What Is The Main Component Of Vertical Cartoner VS Horizontal Cartoner?

As playing the same role, vertical cartoner and horizontal cartoner share the similar main components. They all have control panel, electric system and conveyors to operate the whole machine. But as make different loading way, there exists difference in many parts.

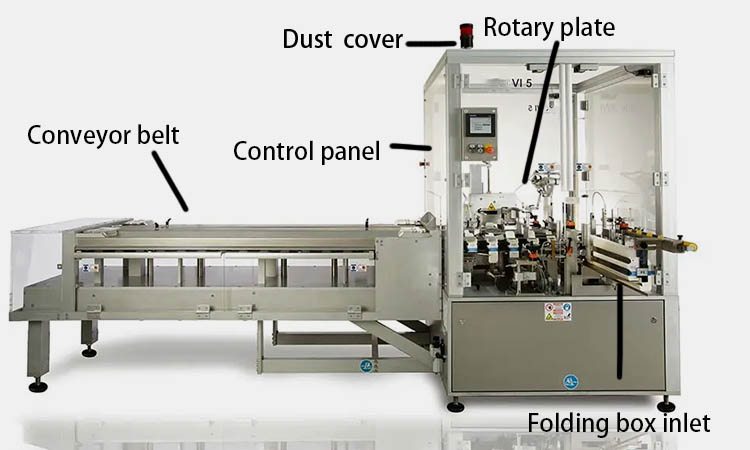

Vertical cartoner

Vertical Cartoner Component-Sourced:iwk

- Control panel

The panel is like the control center of the machine which decides the operation of carton and relative working process or working parameter.

- Conveyor belt

Conveyor belt plays the transporting and linking role. It links all parts and proves the smooth operation of the machine.

- Rotary plate

Products filling in vertical cartoner get into the cartoning process from rotary plate. The revolving and vertical loading way helps reduce the damage to products mostly.

- Folding box inlet

Folding box inlet gets in the flat carton board and sends them to conveyor belt for folding and products filling.

- Dust cover

As the works of vertical cartoner is performed in a box, to prevent the dust from spreading and affecting your working space, a dust cover is settled on the box.

Horizontal cartoner

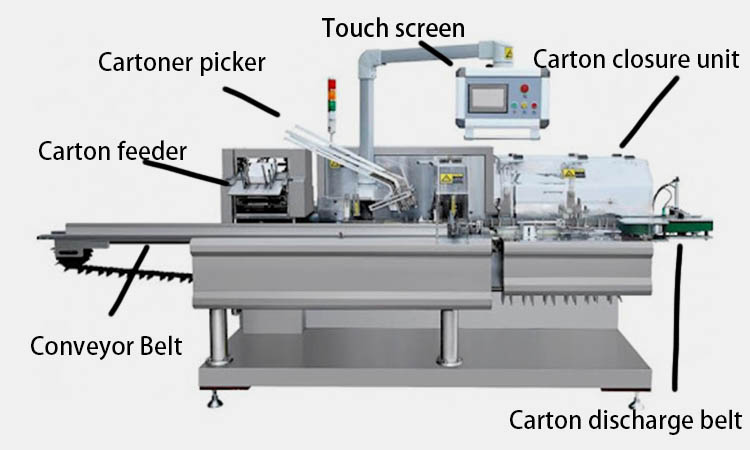

Horizontal Cartoner Component-Sourced:zhpackagingmachine

- Touch screen

Touch screen is a kind of control panel. As get upgraded and merged its function in touch screen, it makes your operation of the machine more convenient.

- Carton feeder

Carton feeder sends the piles of flat carton board into the whole cartoning process. Its the first step cartons get into the machine.

- Carton picker

Carton picker gets a piece of carton board and takes them to next process of carton making or filling.

- Carton closure unit

While gets the carton filled with package and has a opening part, carton closure unit makes the work to seal it and produce the well-packaged carton.

- Carton discharge belt

Carton discharge belt is the last step of the whole working process, it gets the cartons out instead of letting them piling up and affecting packaging process.

8.Which One Suits You Best, Vertical Cartoner VS Horizontal Cartoner?

Wanna choose the suitable cartoner? You should have a clear planing of your budget and factory development, and then a combination of the two machine’s relative features for a nice choosing.

Product type

Product Type-Sourced:behance

Vertical cartoner provides more delicate packaging and suits for fragile products, like drink, fresh food or bread. Horizontal cartoner can handle solid or irregular-shaped products more easily. And for bare products, vertical cartoner has the advantages to give it precise weight.

Footprint

Footprint-Sourced:uxwing

Vertical cartoner has smaller footprint as it is vertical and has no horizontal layout.

Price

Price-Sourced:ownr

Horizontal cartoner, as efficient as vertical cartoner, but has a cheaper price compared with the vertical one.

Speed

Speed-Sourced:vecteezy

Two machine can give you efficient work, but horizontal cartoner machine has the advantages in its production speed.

Conclusion

Vertical cartoner and horizontal cartoner can give you a big convenience in product manufacturing, you can quickly find their shining points once you use it. Believe me, their outstanding performance can improve your products greatly. If you have any questions on this two machine, just contact us.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine