Vacuum Emulsifying Mixer: the Ultimate Buying Guide in 2025

When it comes to topical applications, everyone wants to feel and look better by their applications.

We are seeing so many skincare products like creams, foundations, and lotions in the market but knowing which one best is somewhat tricky and not easy to reveal.

This is due to fact that so many ingredients are employed in the manufacturing of these products. Most consumers have little knowledge about the effectiveness of active ingredients as well as the preparation.

This is true, elegant packaging and popularity of brand sometimes easily trap the consumers without knowing the background of the product.

In this blog, we will discuss mandatory actions required for the manufacturing of those products which require an emulsification process as a necessity. We will give a clear picture of how modern equipment, accurate dosing, and high mixing technologies will boost the potency of your product.

We will discuss an important manufacturing parameter such as emulsification and the type of mixers involved in this process such as vacuum emulsifying mixer that helps in mixing highly viscous materials efficiently.

So, if you’re looking for a vacuum emulsifying mixer for manufacturing the best skincare creams, lotions, eye creams, ointments, hair dye, conditioners, and so on.

Then you’re at the right place!

This blog will get you to know the major classifications, working principles, advantages, troubleshooting, etc related to vacuum emulsifying mixers. Thus, you can easily decide the most suitable equipment that will skyrocket your business.

Let’s start it!

1.What is a vacuum emulsifying mixer machine?

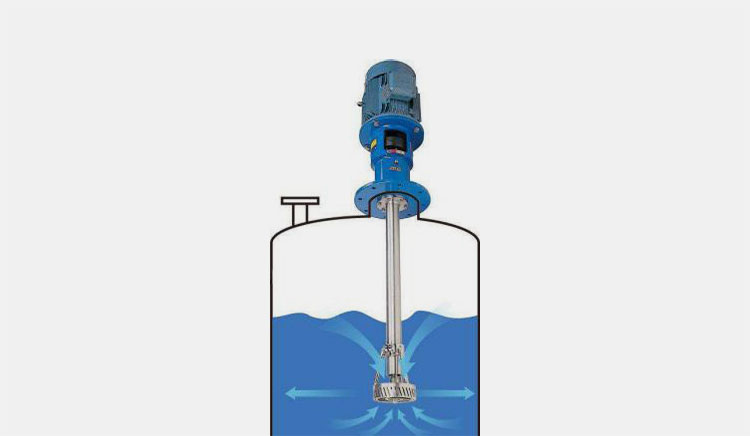

A vacuum emulsifying mixer is a multi-functional equipment that uses a reduced atmospheric pressure. In a simpler term, it lowers the number of gas molecules/units in comparison to the room temperature. This mechanism of vacuum emulsifying mixer facilitates a perfect performance and improved handling of mixing ingredients.

The vacuum emulsifying mixer keeps on experiencing evolution in technologies and becoming more robust, reliable, and efficient in the mixing process.

Vacuum emulsifying mixer is a well-acknowledged machine that is employed for manufacturing cosmetics (skin, eye, hair conditioners, hair dyes, shampoo), pharmaceutical preparations (syrups, ointment, emulsions), chemicals, food, and beverages (mayonnaise, creams, etc).

A vacuum emulsifying mixer is a customizable equipment that can be configured corresponding to a customer’s particular requirements. A vacuum emulsifying mixer is appropriate for manufacturing goods that need to be properly emulsified and stirred under a vacuum state. This machine is equipped with a low-velocity wall scraper and a mixer for emulsifying products that come up with a high degree of viscosity.

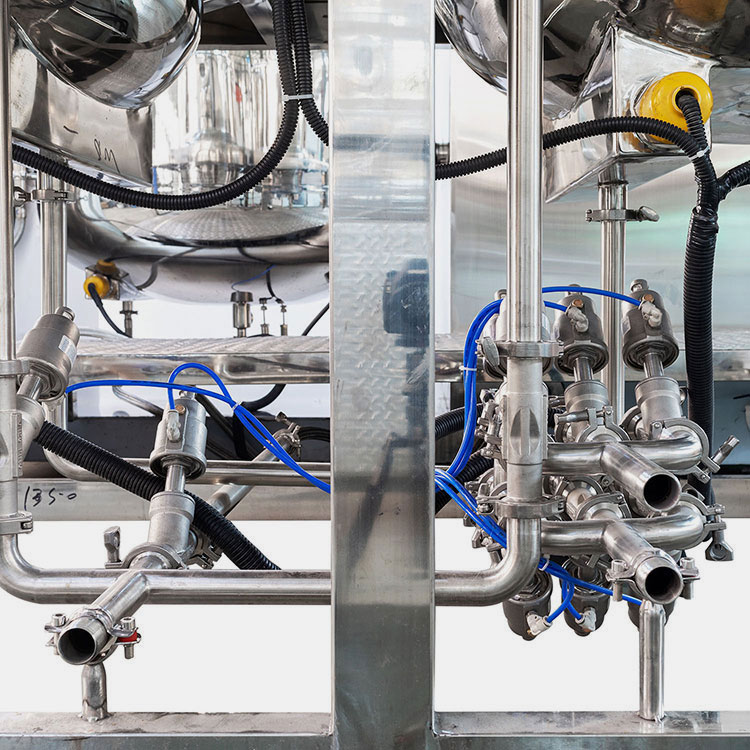

Vacuum Emulsifying Mixers

Vacuum emulsifying mixers are also equipped with a high-shear emulsifier to facilitates an efficient dispersion, homogenization, and emulsification process.

Generally, a vacuum emulsifying mixer is a highly controlled machine that has a unique composition with specified characteristics.

All-in-one versatility

It is of prime importance that your equipment perfectly can perform all in one procedure. Such as

Mixing

Emulsifying

Temperature modulation

Dispersion

Heating

Cooling

Washing. Etc.

Probes and Devices for Electrical Heating.

The main device of vacuum emulsifying mixers has probes and controllers adjusted for electrical heating that preferably have a double temperature.

Cooling system

As you know, a vacuum emulsifying mixer works by a heating system. This is a long process that depends upon the type of manufacturing, that it will need a longer mixing time. As long as this equipment works it emanates heat energy.

So, a cooling system ensures to address this concern efficiently.

A Transfer pump/ Discharge Valve

To make an efficient transferring of the finished product is an easier and quicker task for vacuum emulsifying mixers. With the help of transferring pump, good assistance is achieved for a smooth discharge.

Emulsifier and Agitator Adaptable Velocity

Effective emulsification is basically relying on the speed and power of homogenization. The greater the power and speed of it, the more it will produce ideal work on much larger particles in bulk yields.

A High-Shear inline Mixer

A horizontally supporting high-shear inline mixer along with pipes is an ideal feature of a vacuum emulsifying mixer that does an external homogenizing emulsifying task.

A Separate Jackets for Heating & Cooling

The availability of heating and cooling jackets in vacuum emulsifying mixers allows easy temperature modulation as per requirements.

2.What is the working principle of vacuum emulsifying mixers?

The working principle of vacuum emulsifying mixer is as follow:

The working principle of a vacuum homogenizer is almost similar to a high-shear emulsifying mixer.

- Making of a stable, emulsifying mixture followed by series of steps such as cutting, strong dispersing, emulsifying, and homogenizing with a help of rotor and stator. A precise and accurate technology of vacuum emulsifying mixer is accompanied by strong coordination between rotor and stator.

- Firstly, a vacuum vessel creates an air-free environment where no oxidation takes place that ensures a high-quality mixing procedure to meet manufacturing requirements.The transferring of ingredients from the oil and water phase is allowed to the main working chamber.

- A motor facilitates strong speed rotation that ultimately results in the formation of a vacuum between rotor and stator.

- Mixing ingredients are introduced from the upper and lower part of the rotor and stator. A rotor is directly connected to a homogenizing motor with flanges. The average speed of the rotor is estimated as 3000rpm that generates a powerful suction force.

- All material is mixed by heating and continuous stirring side by side. With the help of attached Teflon blades. Adhesive ingredients are scraped off from the wall of emulsifying tank and flares upward to avoid further sticking and burning.

High Shearing Emulsification process of Vacuum Emulsifying Mixer

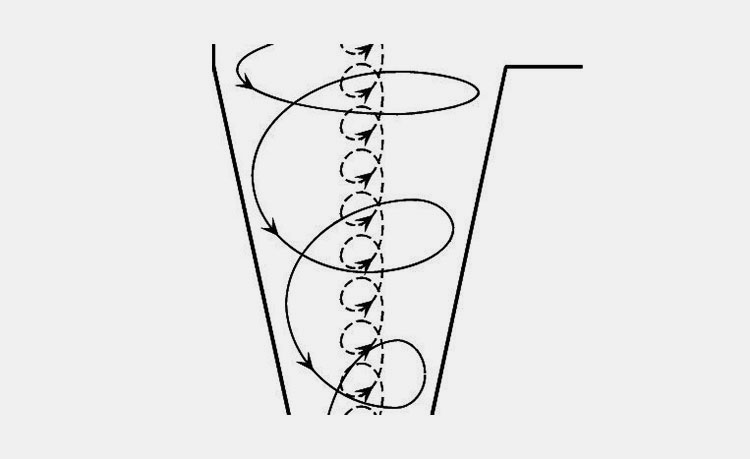

- By the action of several forces from multiple directions leads to generate strong turbulence that triggers the crushing, dispersing, centrifugation, and high shearing between rotor and stator.

- The cutting of material in the shearing seam takes place that quickly breaks the mixing particles into 200nm-2um in an emulsifying pot.

- In a vacuum state, air bubbles are produced during the stirring process which is removed at the time of the vacuum homogenizer mixer.A piece of auxiliary equipment, such as a water ring vacuum pump which pulls out the air bubbles and helps in generating strong mixing and homogenizing process.

- Because of strong forces by impeller and wall scraper, the mixing ingredients moves to top from bottom and this process repeatedly occurs. When the mixing has completed the heat from the jacket is rapidly transfer to inside the wall.

- The auxiliary equipment is connected for all-around targets. Such as an oil hydraulic pump is employed to boost the main body of the mixer. The purpose of safety equipment ensures the mixing of the product would not initiate till the cover is lifted.

3.What are the basic applications of vacuum emulsifying mixers at the industrial scale?

A vacuum emulsifying mixer is a kind of multifunctional homogenizing and stirring equipment. This is customizable equipment that is based on individual own needs. Every industry has different production needs, so customized high shearing emulsifying mixers are becoming a necessary tool behind their success.

Various Uses of Vacuum Emulsify Mixer

A vacuum emulsifying mixer is widely used in the various fields of industrial regions that demonstrates the high importance of this machine.

Discussed below are the following applications of vacuum emulsifying mixers on an industrial scale.

1)- Laboratory Vacuum Emulsifying Mixer

A laboratory vacuum emulsifying mixer is specially designed to implement the laboratory-based methodology.

Laboratory Vacuum Emulsifying Mixer

This machine is composed of a small emulsifying tank, water and oil pot, a vacuum pump, wall scraper, electric and controlled system.

This machine is suitable to hold material ranges from 15 to 20L. They are capable to homogenize ingredients with high viscosity up to 10,000~50,000cps. They are perfect for production on a smaller scale for foods, pharmaceutical products, and other routine chemicals.

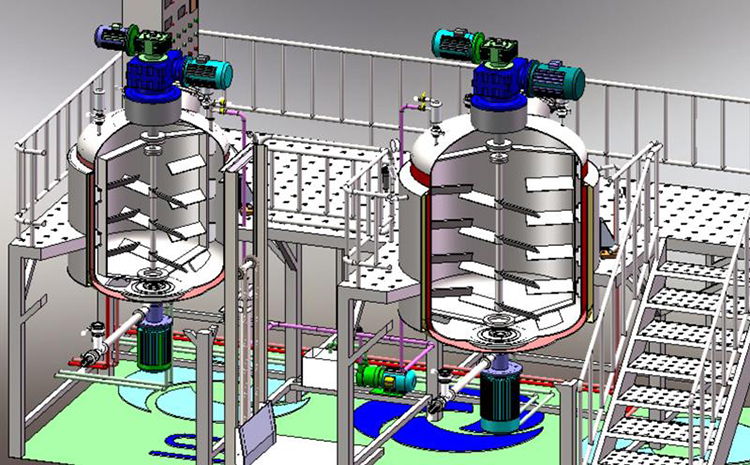

2)- Cosmetics and Pharmaceutical Industry

Vacuum Emulsifying Mixer

The vacuum emulsifying mixer is extensively used in pharmaceutical and cosmetic industries to mix immeasurable products such as body creams, lotions, shampoos, shaving gel, sunscreen, emulsion, lip glows, syrups, injections, etc.

A vacuum emulsifying mixer is advanced equipment that is designed according to protect the active constituents via suitable mixing procedures.

3-D graphical Presentation of a large -scale Vacuum Emulsifying Mixer- Picture Courtesy- Sinaekato

Vacuum emulsifying mixer is facilitating easy operating functions, quality production performance, high-level speed, stable homogenizing efficiency with a high degree of automation that ultimately improves the uniformity and regulating viscosity.

3)- Food & Beverages Industry

The role of vacuum emulsifying mixers in the food industry is complicated.

In the food industry, you always required extensive hygiene, liquid, and dry powder mixing, an accurate blending of fluid with various viscosities, dispersing and solubilizing sugars, hydration of gum, treatment of foods after addition of thickeners and stabilizers.

Therefore, vacuum emulsifying mixers are ideal in this case. For instance,

Dressing, Mayonnaise, and Sauces

The evolution of modern equipment helps you to provide variation in food formulations, and cost reduction. Vacuum emulsifying mixer is highly demanding equipment used in the production of mayonnaise, creams, and sauces.

Applications of Vacuum emulsifying mixer for food formulations

Dairy

Growing challenges and improvisation in product quality offering day-by-day variations in dairy manufacturing. For instance, fortification of dairy products, flavored milk, or availability of dairy products with nutritional supplements. Therefore, vacuum emulsifying mixers are highly demanding equipment used for blending and solubilizing mix for dairy products.

Applications of Vacuum emulsifying mixer in the dairy industry

Beverages

The proliferation of health and fitness, nutraceutical, and other healthy beverages creating a high demand for high shearing vacuum emulsifying mixers that produces a high-quality beverage.

Applications of Vacuum emulsifying mixer for Beverages

4)- Meat & Poultry

Generally, meat & poultry products require vacuum emulsifying mixers for spices, brine, binders, and food emulsifications.

Applications of Vacuum emulsifying mixer for poultry and meat

5)- Chemical Industries

The chemical industries are not being left behind if it comes to utilize the vacuum emulsifying mixers. Vacuum emulsifying mixers are efficiently used in the manufacturing of polyesters and synthetic fibers. They are highly recommended in the production unit of latex, detergents, and saponification goods. In the paints industry vacuum, emulsifying mixers are utilized for mixing different ingredients required to form a homogenized paint solution. Not only this, in Petrochemicals industries, pesticides or fertilizers, rubber as well as power electronic industries found vacuum emulsifying mixers worthy. They are required to mix colors, wax, coating fluids, and creams.

Applications of Vacuum emulsifying mixer in chemical industries

4.What are the major components of vacuum emulsifying mixers?

A vacuum emulsifying mixer is a highly organized device that possesses efficient and versatile emulsifying properties.

The major components of vacuum emulsifying mixers are as follow:

Vacuum Emulsifying Mixer

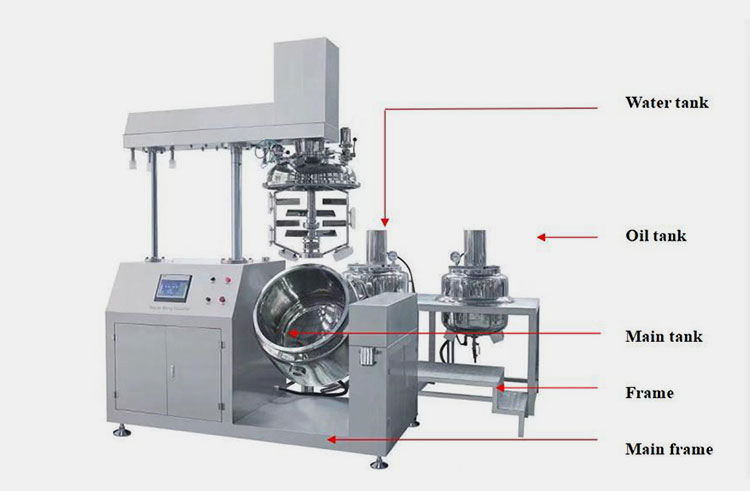

1)- Oil Pot

The oil pot is used to dissolve solid particles in an oil phase. After dissolving particles solvent is sucked into an emulsifying pot via dedicated pipes.

2)- Water Pot

The function of the water pot is similar to an oil pot. The water pot is suitable to dissolve solid particles in the water phase only. After mixing particles solvent is merged into an emulsifying pot.

3)- Emulsifying Pot

A stainless-steel emulsifying pot is compatible with both the oil and water phase to bring a rigorous mix. Each emulsifying mix requires an emulsifying pot, stirring paddle, motor, feeding device (automatic suction), discharge pipe and vacuum device, a temperature sensor with a heat regulator.

The pipes material sucks oil and water pot into an emulsifying pot that is taken in the manner of auto-move up and down. Emulsifying pot blends material with a help of strong kinetic energy to make ingredients narrow down in a rotor and stator.

A net effect of centrifugation, dispersion, tearing, and emulsification instantly produced a uniform emulsified, a high-quality product without air bubbles.

An emulsifying pot is heated with the help of electricity. The heat transfer also takes place from the hot water which is filled up into jackets. Application of electrical heating of water depends upon the user’s requirement.

Furthermore, emulsifying pot is also heated with help of steam. By connecting a steaming generator, you can easily heat an emulsifying tank.

A vertical motor rotates at the range of 0—3500 RPM/min.

4)- The Main Frame

A mainframe of vacuum emulsifying mixer occupies with a lifting system, an emulsifying tank, a discharger, vacuum system, electric control system while PLC is an optional, rotating, mixing system, etc.

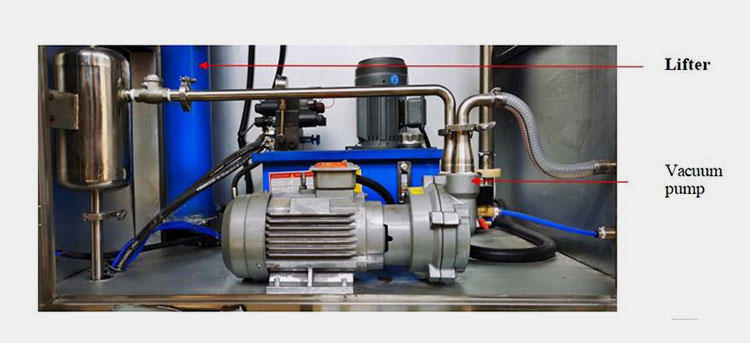

5)- Vacuum Pump

A vacuum pump connects two pots, one is connected to the water tank while the other to the main emulsifying pot.

It is a mechanical device that enables the ejection of air and gas particles from a sealed area to make emulsion reaction restricted of these molecules. The separation takes place by sucking steam into a vacuum pump while some of the steam flows out from the bottom of the separator. The purpose to integrate a vacuum pump is to achieve cleaned and sealed pumping material.

Thus, a vacuum pump facilitates to draw out the presence of air from material to ensure the emulsified product is fine, smooth, and stable.

A Vacuum Pump

This machine is heated by electricity, you just fill water into the jacket, then turn on the heating system, the water is heated by electricity according to your requirement.

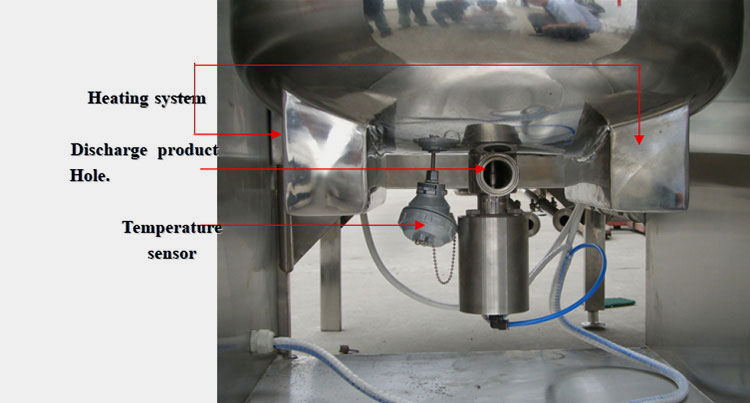

6)-Discharging Valve

When material is mixed completely in an emulsifying pot then you require to discharge them safely by using a discharging valve. The discharging valve works when an emulsification process is turned off. You can open the discharge valve present at the bottom of the emulsifying pot. Now you can transfer material into a storage tank with the help of a pump.

Additionally, there is another way to discharge material. For that you need to stop the homogenizer and stirring process. you can open the covering of emulsifying tank and push the button of toppling available on emulsifying pot to pour the emulsified ingredient directly into a storage tank. After discharging the entire material, you can make emulsifying pot return to it localize position.

A discharge valve, Temperature Sensor and Heating system connected to Emulsifying pot.

7)-Temperature Sensor

Good quality mixers are installed with a temperature sensor that reliably facilitates a temperature-controlled environment to mixing products present inside the pot. This is a smart solution for that material which are sensitive to harsh temperature and requires a firm and uniform mixing.

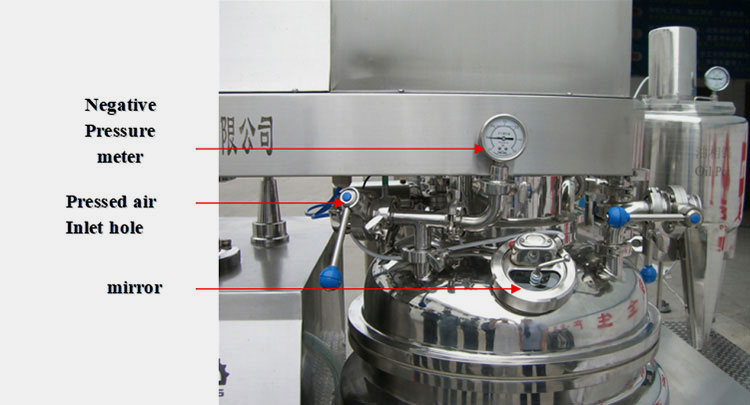

8)- Negative Pressure Meter

A negative pressure meter is used to assess the pressure inside an emulsifying pot. You cannot open the pot lid of the emulsifying tank when the pressure inside is negative. Using negative pressure techniques is beneficial to avoid the contamination of the product during manufacturing.

Negative pressure meter

9)- Pressed Air Inlet Hole

A pressed air inlet is connected to an air compressor available at the emulsifying tank; it is of great importance as it enhances the mixing and flow of ingredients and accelerates dispersion, centrifugation, and diffusion process to homogenize the molecules greatly.

10)- Mirror

Vacuum emulsifying mixer is also adopted a polished mirror, that fully corresponds to GMP requirements. The purpose of mirror is to observe/monitor inside the homogenizing tank by turning ON the light.

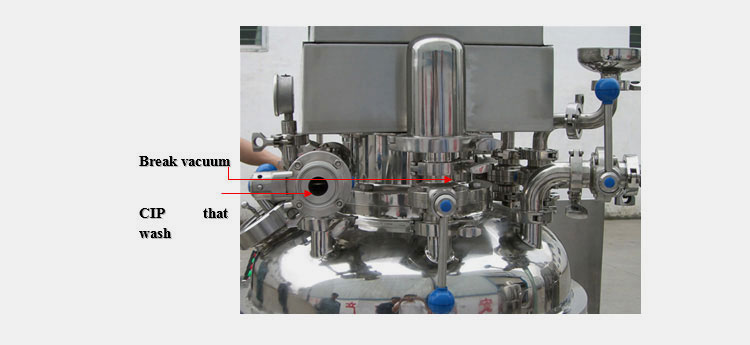

11)- Break Vacuum Hole

As its name shows it is used to terminate the vacuum created inside the pot by opening the valve. Because you cannot discharge the material present inside the homogenizing tank until the vacuum is a break. Therefore, it is mandatory to cease the vacuum.

A Vacuum Breaking hole and CIP cleaning system

12)- CIP system

A vacuum emulsifying mixer is cleaned by a CIP cleaning system. It is integrated with water pipes which is useful for cleaning and washing of an emulsifying tank, Blenders, vessel tanks, etc.

The CIP inlet is allowed pneumatic functions for water (hot/cold), detergent, deionized water with a pressure pump supplies to the washing area. It is operated by using a PLC control system and touch screen as per requirement.

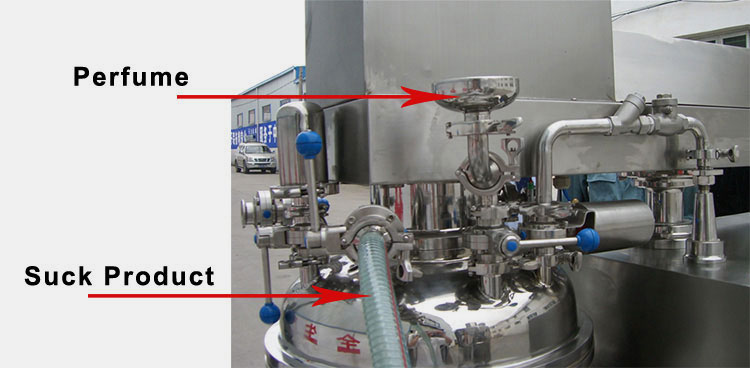

13)- Perfume Inlet

Perfume inlet is used to release the fragrance into the emulsifying pot.

14)- Suck Product Inlet Pipe

A suck product inlet pipe is used to draw the mixing material from the oil and water pot with the help of a vacuum.

Perfume Inlet & Suck Product Inlet Pipe

15)- Vacuum Protection Switch

The vacuum protection switch is constructed to avoid the opening of the pot lid when a vacuum is present inside. This is beneficial to run a smooth emulsification process.

16)- Safety System

A vacuum emulsifying mixer is accompanied by a safety valve which is also known as a pressure-relief valve. It automatically works when parameters inside the system exceed their assigned limits such as temperature, or pressure and restore the normal conditions.

A Safety Valve

17)- Water Inlet ‘OR’ Cooling system

The water inlet or cooling system facilitates the cooling of equipment and eliminates the heat transferring from one medium to another.

Water inlet or Cooling system

5.What are the major benefits of vacuum emulsifying mixers?

A vacuum emulsifying mixer is the finest machine under specific conditions and applications than any other machine. This is very common that manufacturer invests time, finance, and lots of energy in selecting the right option for vacuum emulsifying mixers.

Their primary goal is to achieve mixing properties that will give maximum output for several years. As long as it runs at the optimal level the greater it will return your investment efficiently. With time you will find new modern innovations in technologies. The industrial vacuum emulsifying mixers are now proficiently arising. The type of addition and alternations to bring updated equipment has several advantages mentioned below:

1.Reduced the Production Time

Apart from the cost of production, your time is also of great importance as money. It is a significant aspect that no one can replace. So, the operational levels of the new vacuum emulsifying mixer give you maximum benefits. This technology gives you maximum production in a lesser time with improved performance.

2.Homogenization of Immiscible Liquid Phases

There is a certain kind of fluid that requires some additional effort to get a uniform mix. For instance, mixing of water and oil phase.

The mixing of oil and water phase is a primary and mandatory method involved in the manufacturing of creams and ointments. Thus, their mixing requires a high shearing homogenization which is achieved by a vacuum emulsifying mixer efficiently.

When you combine these two phases (oil & water), the viscosity and texture of the sample are the targeted factors of the mixing game. So, always opt for those mixers that can efficiently handle these factors.

3.Lesser Waste Production

Using a vacuum emulsifying mixer has a better reduction in the wastage of materials. The presence of a scraper agitator has net-centrifugal effects throughout the operation and making perfect scraping around the wall of the emulsifying tank that collectively solves the complications of the sticky material around the pot with no adhesive particles so fewer chances of product deterioration.

Furthermore, the concentration of raw material wastage during each production process is now controlled than before. This is very commonly observed that at the end of the production cycle you get a large cost due to wastage of raw material, so vacuum emulsifying mixer has intricately surmounted this problem ultimately saves you extra cost.

4.High Production Capacity

If you have understood the above-mentioned benefits, you will get an idea that how the following factors of vacuum emulsifying mixers are directly proportional to an increase in the production capacity of the manufacturing unit.

In simpler words, timesaving, and reduction of wastage can increase your productivity. So, this is improving the production capacity. Similarly, here you are not requiring spending more time and investment of large costs on arranging raw materials. An enhanced turnaround and excellent production volume will give you more market to sell your products. An accelerated rate of production and high- quality directly benefits the consumer as well as the manufacturer.

5.Lowered Operational Costs

A vacuum emulsifying mixer is more energy-efficient equipment than conventional mixers. So you will spend less to run the operation and get leverage to have substantial savings.

6.Safety and Efficiency

The structure of vacuum emulsifying mixers has improved the safety and efficiency of the equipment. The safety valve of this machine secures the operator while it is operational. Furthermore, there are fewer chances of damage during the process. The vacuum protection inlet, CIP cleaning system, break vacuum hole, pressure air inlet hole, etc are constructed for security purposes to avoid mishap during the procedure ultimately reducing the risk of injury. So, the manufacturer always considers these important points to maintain their investment revenue and product quality.

7.PLC Touch Screen

With innovation, a high degree of automation in vacuum emulsifying mixers is also getting higher. And PLC touch screen is one of prime importance that makes the operation flexible and reduces the work intensity via integrated procedures. You can now record the data as per your requirements. Furthermore it is suitable for those production batches that have single-variety products that require continuous working.

6.What are the disadvantages of vacuum emulsifying mixers?

Despite having so many advantages, vacuum emulsifying mixers also connects some disadvantages such as:

- The cost of a vacuum emulsifying machine is relatively higher than conventional mixers. You’ll require a considerable amount of money to get an efficient vacuum emulsifying mixer.

- Rarely, there are chances of clogging minutes pores of the mesh.

- Vacuum emulsifying mixer machines are not very suitable for sensitive tissues samples, lysols (disinfectant sprays), and foams.

- Some heat-dependent ingredients require an excessive amount of heat, although high shear mixing does not generate an extreme amount of heat. Furthermore, temperature-sensitive samples require a cooling system for a homogenizing method which extends the time and cost of the process.

- Not all samples are well-suited to process a specific homogenizing task. As probes at all means are not suitable to process multiple samples. Every piece of the sample must fit within a particular probe and its accompanied rotor and stator to get significant homogenization. So the time-effective process would be negated.

Different Types of homogenizing Probes

7.What are the major classifications of vacuum emulsifying mixers?

We come in contact with a lot of mixers in our routine life. For example, blenders, beaters, grinders, etc.

In the same way, there are uncountable applications of mixers on an industrial scale. For efficient mixing, we require a vacuum emulsifying mixer which is a mixing device that emulsifies your product under vacuum. Every industry requires vacuum mixer depend upon their necessity. There is a certain classification of vacuum emulsifying mixer such as:

#1- Upper Homogenization Vacuum Emulsifying Mixer

A vacuum emulsifying mixers are commonly employed for the pharmaceutical, food, chemicals, and cosmetic sector. This multi-functional equipment performs certain tasks such as defoaming, stirring, homogenization, PLC controlled functions and also provides heat to the mix.

Upper Homogenization- Vacuum Emulsifying Mixer

#2- Vacuum Planetary Mixer

A vacuum planetary mixer works specifically for high field viscous material. During a rotation of planet carrier, a stirring shaft inside the box rotates in such a way around the drum that facilitates a high-speed shaft rotation.

A vacuum Planetary Mixer- Picture Courtesy- MTI

Therefore, the material used for mixing in vacuum planetary mixers is those that need to subject to strong shearing and kneading to attain complete emulsification, distribution, and mixing. This machine has a knife scrapper which rotates continuously with the planet carrier and hangs with the walls of the container. So, the barrel wall does not have any stationery material with brilliant mixing effects. This machine has a degassing kettle that avoids the accumulation of gases inside the container. This machine works under a vacuum and continuously discharges the unwanted water and volatile molecules. This equipment is integrated with a rack, covering lid, and a hydraulic lift with a double column at the bottom. The entire design and input of equipment are reasonable and convenient.

#3-Vacuum Stainless-Steel Mixing Pot

This is a simplified form of vacuum emulsifying mixer. The composition of a machine is a simplified version of a vacuum emulsifying mixer which is indeed a cost-effective mixer suitable for those consumers who require a simple mixing procedure. In this machine, some structures and designs are omitted which are not that necessary. This machine is widely used to perform smaller tasks such as washing of chemicals, preparation of chemicals, mixing fluids and so on. This machine is used in daily routine for chemical cleansing and is also known as a liquid washing pot.

Vacuum Stainless-Steel Mixing Pot- Picture Courtesy-HUND

#4- Laboratory Vacuum Emulsifying Mixer

A laboratory vacuum emulsifying mixer is a smaller scale emulsifying machine which is suitable for laboratory uses. This machine is very helpful when you are required to mix a small concentration of chemicals in specified mixing values.

A laboratory-Vacuum Emulsifying Mixer

#5- Lower Homogenization Vacuum Emulsifying Mixer

This is a precise equipment that provides you uniformly mixing materials achieved by a continuous mixing process. In this machine, bottom base emulsification is performed using kinetic energy with the help of integrated motor. The vacuum defoaming ensures the manufacturing of material meets the general necessity of being aseptic environment. The mode of heat is either steaming or electric heat. This is very stable equipment that adopts all international standards required for a machine.

Bottom Homogenization-Vacuum Emulsifying Mixer

#6- Fixed Type Vacuum Mixer

A fixed type of vacuum mixer is suitable for manufacturing large volume productions. The fixed means, the covering lid of this machine is integrated into the pot body which cannot be separated.

This type of emulsifying mixer is employed for mixing lubricating oils that require high shear emulsification to distribute several phases in a continuous phase uniformly.

The fixed type of vacuum mixer is mainly applied in such industries that deals with biopharmaceuticals, food, pesticides, rubbers, plastics, electronics, and fine chemicals.

The emulsifying effects of this machine are very strong therefore, it is suitable for high base viscosity materials as well as solid content.

A Fixed Type Vacuum Mixer – Picture Courtesy-Ailusi

#7- A Nanometre-Vacuum Emulsifying Mixer

A nanometre vacuum emulsifying mixer is commonly used for manufacturing sensitive and intricate mixing of solutions as their mixing requires extreme supervision to get a uniform mixing. This machine has a high-shearing speed which makes it more versatile and adaptable.

A nanometer- Vacuum Emulsifying mixer

#8- Suppository- Vacuum Emulsifying Mixer

A suppository vacuum emulsifying mixer is composed of a dissolving tank, boiler, a heat preservation tank with a water circulation system, automatic feed, electric control, etc. This equipment is majorly used for making medicines, suppositories, pectic substances, or emulsification of lubricant stroma. This machine provides a steady operation with strong efficiency and high automation.

A suppository Vacuum Emulsifying Mixer

8.How to troubleshoot the problems associated with vacuum emulsifying mixers?

A vacuum emulsifying mixer is a multi-functional device that can warm and cool the ingredients as well as mix and emulsify them.

But this process, sometimes an emulsified tank heats abnormally that transfers the unnecessary heat to mixing ingredients which greatly influences the production and processing of ingredients.

This problem occurs due to an increase in the absorption rate of heat in stainless steel. The reaction of the steel kettle is much greater than the heat supply that ultimately increases the temperature inside. For this purpose do not disassemble the parts of the machine by yourself to avoid unwanted damage to a mixer, rather contact the manufacturer to carry the maintenance.

Moreover, sometimes, machines generate heat due to high control on reducing the pressure and overflow valve. For this, you need to assess whether the vacuum valve is open or refueled properly. Also, you need to check if a sealing ring is leaked, a water tank is filled with water and the potation path is correct or not.

- Sometimes, the heating temperature of the vacuum emulsifying mixer cannot go up. For this, you need to examine certain points.

- There might be a problem with the heating power supply and heating motor configuration.

- A stainless-steel reactor which is an important part of a vacuum emulsifying mixer is appeared to be disconnected with heat resistance wire or simply damaged that results in a stoppage of temperature rising.

- A computed configuration might be damaged so the user cannot observe the disturbance in temperature visually.

- Occasionally you encountered failure in the hydraulic lifting system. To troubleshoot failure of the hydraulic lifting system of the vacuum emulsifying mixer, you need to properly check the surface cleaning, appearance, and viscosity of hydraulic transmission oil. You can also assess the smell of transmission oil to get an idea if it is present in the right state. Check the temperature of the oil can also help to prevent serious damage or failure of the system.

- Always check if the delivery of energy is smooth without any leaking into the electrical cord.

- Always check if the blades of the motor are functioning correctly.

- When there is difficulty in mixing two- different phases, then always pay attention to the type of mixing, proper quantity of mixing ingredients, time, speed, and heating during the process. By considering these factors you mayachieve a homogenous mix.

- To avoid sedimentation, use a rapid high shear mixing with increased mixing time, as well as reduce the air incorporation with mixture.

- To avoid lumping and clogging is very important to manage the mixing correctly. This is a common problem that occurs when you deal with highly viscous material. To avoid this problem, you need to choose the right temperature and mixing speed. So, it can dissolve efficiently high viscosity ingredients in a larger concentration.

9.How do you operate a vacuum emulsifying mixer?

To operate the vacuum emulsifying mixer, you need to follow certain assigned steps.

- Switch ON the power and heating button to pre-heat the oil and water pot.

- Monitor the emulsification equipment if valves are closed.

- When equipment is heated, add ingredients, and close the valves.

- When the temperature of the process reached a required protocol, then stir the pots to attain a uniform temperature throughout the ingredients.

- After assuring the water and oil pot have estimated temperature up to 60 ° C or above, then open the heating valve of the vacuum emulsifying mixer.

- Adjust the speed of homogenization and homogenize the emulsification pot.

- Open the vacuum emulsifying tank when you observe a required temperature is achieved. By pressing the vacuum button on the touch screen panel, the upper valve of the vacuum emulsifying tank opens. The vacuum pumping is carried out when pressure is up to 0.2Mpa or more. After completing pumping, close the pumping valve. The vacuum is halted/ closed when the pressure is taken to 0.4Mpa.

- By using a hydraulic lifting system discharge the material and pour it over-discharging containers.

- Clean the equipment with the de-greasing solution and tap water (cooled and hot).

10.What do you know about the high shear homogenizing mixer?

A high shear homogenizing mixer is well-structured equipment used to mix, stir, emulsify, disperse as well as homogenize the immiscible material to form a uniform phase. The presence of the rotor and stator inside the homogenizing pot allows the material to pass through and create a shear.

This high shear ultimately results in the formation of a smooth emulsion, micro aeration, and perfect suspension in liquids. The high shear homogenizer is suitable to reduce the particles and stir the adhesive substances, chemicals, medicines, food and cosmetics, etc. The speed of fluid around the diameter of rotor is much higher than the mid of the rotor. The larger the velocity variation, the higher would be the shear. This machine is ideal for larger batches of high viscous ingredients such as gels, deodorant, and other sticky materials.

11.What do you know about the low-shear homogenizing mixer?

A low shear homogenizing mixers are characterized by mixing the ingredient without dispersing or reducing the particles' size.

This type of mixing machines is suitable for blending highly delicate and sensitive materials such as foods products, certain adhesives, or bio-pharmaceutically active compounds.

Pharmaceutical components such as protein, biological serums, cells are very sensitive to shear stress. Whenever you mix, always confirm the balance between homogeneity and protection of sensitive mixture. Because when protein or other biological components meet high shear forces, they will break and agglomerate which indicates the failure of product quality.

12.What are the major difference between high and low shear emulsifying mixers?

1) A high shear mix requires a lot of energy to shear the mixing particles. The impact of mixing disperses the particles and mix them freely. Whereas the low shear mixer allows the mixing procedures which are relatively ordered. The process of mixing occurs in a low speed and the material’s particles movements occur in an orderly manner throughout the mixer.

2)- The high shear mixing is ideal for those particles that use great energy to mix the cohesive material. Whereas the low shear mixing significantly ideal for free flowing and heat sensitive ingredients.

13.Does the vacuum emulsifying mixer comply with quality standards?

Vacuum emulsifying mixer is specially designed to meet high cGMP and FDA requirement necessary for pharmaceutical, food and beverages and biological laboratories. Adherence to the cGMP regulations, conforms the identity, potency, as well as quality of manufacturing operations.

cGMP also determines a strong quality management systems with robust operating procedures also offers product quality deviations.

Additionally, vacuum emulsifying mixer has to comply with CIP and SIP system. The CIP or cleaning in place and SIP or Sterilization in place, are designed to bring automatic cleaning and sterilization of equipment without causing major disassembling or equipment or a workplace.

14.What is the optimum operational and temperature range provided by a vacuum emulsifying mixer?

The optimum temperature ranges this machine can produce is between 50-80 ⁰C. Depending on the procedure this temperature can exceed up to 100 ⁰C. However, mixing that leads to a temperature rise to 105 ⁰C is not usually conducted in vacuum emulsifying mixer. As previously mentioned for longer procedures that can increase the temperature exceeding 105 ⁰C, machines with integrated cooling systems are preferred that can control temperatures up to 150 ⁰C.

15.What safety measures need to be considered and are built in a vacuum emulsifying mixer?

To avoid occupational hazards several steps, need to be checked before operating the mixer.

- All the electrical wirings should be grounded.

- Functionality of valves and pressure gauge should be monitored.

- A number of built-in safety features are available to avoid mishaps during the manufacturing process such as coloured push buttons that reduce accidental activation and alarm system that indicates loosely held vacuum valves.

- The platform should be dry at all times to reduce chances of injury by falling.

16.How can you enhance the life of the vacuum emulsifying mixer?

All Accessories are made of high-quality stainless steel that makes it durable and functional for a number of years if properly maintained and taken care of. Following are the points that can further improve functional years of any equipment.

- Proper lubrication of gears and parts that runs over each other.

- Inspection on a regular basis of vacuum valves and pressure gauges.

- To improve mixing quality the distance between agitator and bowl should be checked every half a year.

- Keep a record of the maintenance log to assist in troubleshooting.

- Always remember to cleanse the emulsified tank before and after usage to ensure proper cleansing.

- Never allow the mixer to work in an over-loaded state such as over-weight or overtime that ultimately exacerbates the life of mixer.

- If the mixer is not utilized for a longer time then always switch it ON for a trial operation, so it can be pre-heated and adjusted as computed feasibly.

- Maintain cleaning records every day. Use soap and water for cleaning pots and unit base. Keep unit base as dry as possible to avoid corrosion. Avoid using water hose on the vacuum emulsifying mixer as water can damage internal hardware. For further instructions refer to the operating manual.

A cleaning schedule of vacuum emulsifying mixer

17.What are the essential options that you need to consider when selecting a vacuum emulsifying mixer?

When select a best industrial scale vacuum emulsifying mixer, you must consider various technical and financial factors. Yet, this can be a daunting job, but their ultimate results would be rewarding for your business.

The best advice to not rely on your instinct, also you cannot solely dependent on recommendations from industrial suppliers no matter how honest the motive is.

Mentioned below points are essential you need to consider when buying a vacuum emulsifying mixer:

- Speed of rotor tip

- The processing time

- Volume and capacity of the material

- Position and type of rotor and stator

- Viscosity of ingredients

- Size of sample

- Investigating optimum rheological features

- Size of rotor and horsepower

Always ask supplier to provide:

- Freight cost

- Installation and commissioning fees

- The expense of annual maintenance and providing integrated parts.

Don't forget to share this post!

Vacuum Emulsifying Mixer Related Products

Vacuum Emulsifying Mixer Related Posts

Vacuum Emulsifying Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine