V Type Powder Mixer: The Complete Buying Guide In 2025

Ready to enhance your mixing process? Are you still using a manual mixer to slow down your process? In order to save labor, improve efficiency and reduce waste, the new v type powder mixer is being widely promoted and researched.

This guide has done extensive research on the v type powder mixer. It can provide you with detailed information and guidance for understanding and selecting this equipment. By reading this article in depth, you will get a lot of relevant information.

1.What Is V Type Powder Mixer?

AIPAK V Type Powder Mixer

V type powder mixer is a professional equipment that can be used to process common powder and granular materials in industries such as food, cosmetics, medicines, chemicals, fertilizers and plastics. It can evenly, efficiently process and mix various powders and granular materials. This equipment is the most basic mixing equipment in various industries.

2.What Are The Applications Of V Type Powder Mixer?

V type powder mixer is suitable for the processing of various mixtures of granules and powders with small fluidity and material differences. It is mainly used in the following industries:

Pharmaceutical industry

Pharmaceutical industry-sourced: lifeextension

Without damaging the appearance of the material, V type powder mixer can help mix and stir various pharmaceutical powders and granular products. The processed powder can be used for capsule filling and tablet pressing.

Chemical industry

Chemical industry-sourced: mppinnovation

This equipment is also suitable for mixing and stirring various chemical powders, including metal powders, mineral powders and other materials.

Food industry

Food industry-sourced: dwarakaorganic

Various grain powders, coffee powders, dairy powders, food seasoning powders, etc. can be processed and mixed using V type powder mixer.

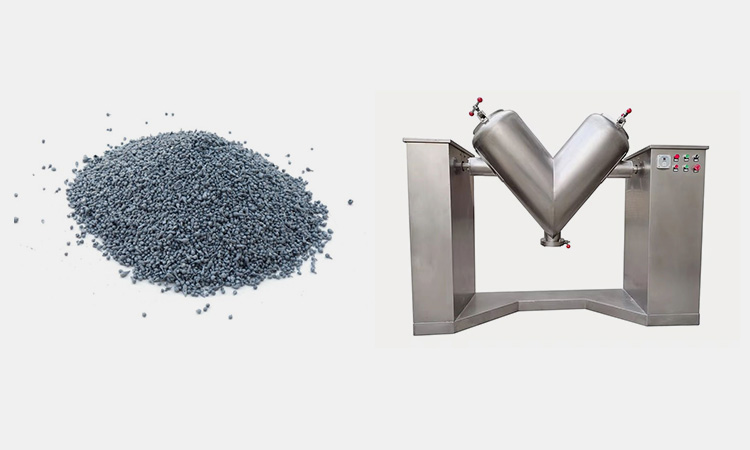

Plastic industry

Plastic industry-sourced: storker

Various plastic granules, powders, etc. can be pre-processed using V type powder mixer. The processed plastic granules and powders can be used by the textile industry.

Agricultural industry

Agricultural industry-sourced: trendhunterstatic

V type powder mixer can be used to process various pesticides, herbicides and other materials.

Cosmetic industry

Cosmetic industry-sourced: opvbeauty

Various powders in the cosmetics industry, such as loose powder, eye shadow, blush, or talcum powder, can be processed using V type powder mixer.

3.How Many Ingredients Can V Type Powder Mixers Mix and Blend At One Time?

Ingredients V Type Powder Mixers Can Mix and Blend At One Time-sourced: lanphanrotovap

Depending on the actual application, the V type powder mixer can process up to 10 different powder material components at the same time. This result also depends on the size and capacity of the V type powder mixer you choose. Generally, the larger the capacity, the more types of powders it can process.

4.What Are The Main Benefits Of V Type Powder Mixer?

The advantages that V type powder mixer can bring to you are:

Efficient mixing

Efficient mixing-sourced: lanphanrotovap

Using a special V-shaped structural design, it can fully stir, tumble, rotate and fuse the materials during mixing and movement, providing you with a fast and uniform mixing effect.

Uniform mixing

Uniform mixing-sourced: sanyuantangcn

The inner wall of the V type powder mixer is smooth without any dead corners. This design allows the materials to be fully and evenly mixed. Since there are no obstacles, the materials are mixed more evenly.

Easy to operate

Easy to operate-sourced: tianhe

Adopting fully automatic advanced control technology, you can set the mixing time and speed and other related parameters in advance on the operating panel.

Energy saving and environmental protection

Energy saving and environmental protection-sourced: insyde

Using efficient and energy-saving motors and transmission devices, V type powder mixer can provide you with efficient powder mixing operation, improve production efficiency, and meet environmental protection requirements.

Multi-function

This equipment can be customized according to the characteristics of different materials and the size of powder or particles.

No cross contamination

There are no dead corners inside the V type powder mixer, and it is tightly sealed during operation. There will be no cross infection during the material processing process, providing you with higher quality powder mixing.

Long service life

Long service life-sourced: freundglobal

Made of stainless steel, it is anti-corrosion, anti-rot and anti-rust, stable and durable.

Customized mixing

It can provide personalized customized mixing services and functions according to your material type and particle size requirements.

5.What Are The Types Of V Type Powder Mixer?

According to the application, V type powder mixer includes:

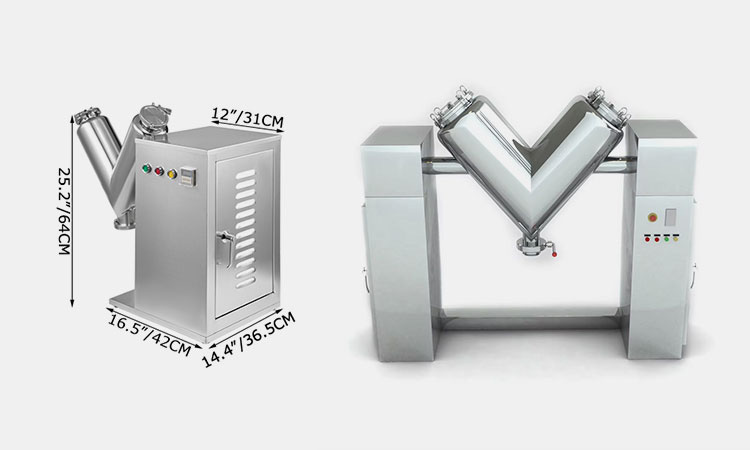

Lab-scale V type powder mixer

ALLPACK lab-scale V type powder mixer

Lab-scale V type powder mixer has a smaller capacity and is more suitable for laboratory-scale dry powder processing and mixing in pharmaceutical, health care, chemical, food and other related industries. Its sturdy shell can provide back-and-forth mixing, cross-mixing and 360°rotation for uniform mixing of materials. Due to its small capacity, its mixing efficiency may not be high.

Commercial or industrial-scale V type powder mixer

ALLPACK commercial or industrial-scale V type powder mixer

Commercial or industrial-scale V type powder mixer is specially used in large-scale industrial and pharmaceutical applications. They have large capacity and size, and can process 20-30L of product at a time. It provides a versatile and efficient mixing solution with high efficiency and low cost. The V-shaped design of this equipment ensures uniform mixing of powders and granules.

6.How Does The V Type Powder Mixer Work?

The working principle of V type powder mixer is as follows:

- Prepare the materials and open the feed port of the mixer. Load the materials you need to process into the feed port manually or automatically;

- Control the capacity you need to process. Make sure there is no leakage of powder, lock the feed port, and confirm that the discharge port is closed;

- Start the switch button. The equipment will perform a rotary mixing movement from top to bottom. Depending on the type of material, the equipment will run according to the set mixing time;

- After the mixing time expires, the equipment will automatically stop operating. The discharge port of the mixer will face the ground;

- Cut off the power. Place the container loaded with materials under the discharge port. Open the discharge port and unload the material.

7.What Are The Main Components Of V Type Powder Mixer?

The V type powder mixer main consist of:

Main Components Of AIPAK V Type Powder Mixer |

|

| Two v-shaped cylinders | It is made up of two cylinders that are put together at an angle. The angle between them is generally between 75 and 90 degrees. The size and length can be different. The space formed by the cylinders is the space for handling materials. |

| Inlet doors | It generally has two entrances to facilitate the input of your materials. |

| Digital panel | Equipped with a high-quality digital panel, you can control the material mixing speed and time at any time. |

| Shaft axis | The shaft axis allows the V-shaped cylinders to rotate freely to achieve the correct homogeneity. |

| High-speed intensifier | It is an optional reinforcement component. If you want higher processing efficiency and a large amount of powder material processing at one time, you can choose this component. |

| Discharge valve | This valve can control the unloading of materials. |

| PLC control system | PLC control system is equipped with fully automatic loading and unloading functions, with a "touch screen" operator interface display to facilitate your fully automated operation. |

8.What Are The Special Design Of V Type Powder Mixer Work?

The special design of the micro mixer includes:

Asymmetric design

Asymmetric design-sourced: lanphanrotovap

You can use two cylindrical shells of different lengths for welding. This makes the mixer asymmetric. The materials can be well separated and mixed when they pass from one shell to another, and the mixing time is reduced. This design can improve the uniformity of mixing.

Intensifier bar

Intensifier bar-sourced: topspack

You can install a reinforced intensifier bar along the axis of the V type powder mixer. This can ensure high-speed rotation of the materials and provide stronger shearing and mixing forces.

9.What Are The Usual Capacities Of V Type Powder Mixer?

Different types of V type powder mixers have different capacities. However, on the market, the capacity of this equipment is generally designed from three liters to about 20 liters.

3L

3L-sourced: caneov

This small capacity V type powder mixer can meet your various small capacity material processing. This design can help you with various movements.

10-20L

10-20L-sourced: freundglobal

10-20L V type powder mixers are suitable for industrial fields such as food, animal feed, cosmetics, chemicals and pharmaceuticals.

10.Is V Type Powder Mixer A Dry Powder Mixer?

V Type Powder Mixer A Dry Powder Mixer-sourced: tianhe

V type powder mixer can also be called V type dry powder mixer. It can be used to mix and stir dry powder or granules, and even some viscous liquids. Its application range and field are very wide, suitable for mixing and stirring different materials, and can provide you with uniform and efficient material mixing.

11.How Long Does It Take A V Type Powder Mixer To Mix With An Intensifier Bar?

V Type Powder Mixer With Intensifier Bar-sourced: rotarydrumflaker

The V type powder mixer equipped with a reinforcing rod can mix two or more powdered or granular materials at the same time. It usually takes about 5 to 15 minutes. If the volume of the material increases to 50% of the total volume, you need to add the material to the mixing tank in batches so that the materials can be evenly mixed.

12.Can You Use The V Type Powder Mixer For Solids?

AIPAK V Type Powder Mixer For Solids

In addition to powder, V type powder mixer can also be used to mix solid materials. Although its granular material mixing and processing process is relatively rough, it is also applicable.

13.What Are The Precautions For V Type Powder Mixer?

Before using V type powder mixer, you need to pay attention to:

No-load test run

AIPAK V Type Powder Mixer Test Run

Before using V type powder mixer, you should test it in advance. For example, no-load test run. This can test the firmness and practicality of the connection of each part of the equipment. At the same time, avoid damage or defects to the equipment during the formal use of the material in the later stage.

Pre-inspection

Pre-inspection-sourced: distincthomeinspections

You need to check whether the various parts of the equipment are loose. If there is looseness, you need to tighten these parts and add some lubricating oil during the test run. If any abnormality is found, repair and adjust it immediately.

Material addition

Your material capacity should not exceed the volume range specified by the equipment. If your equipment has too much material, it will cause abnormal operation of the machine equipment or low material handling efficiency.

Comply with GMP standards

Comply with GMP standards-sourced: arenasolutions

During use, it is strictly forbidden to mix different batches or multiple batches of powder granular drugs together for processing. You should strictly comply with GMP standards.

14.How Do You Clean The V Type Powder Mixer?

The V type powder mixer has a very simple structure and is very easy to clean:

Cleaning agent preparation

Cleaning agent preparation-sourced: cleaningcrew

Prepare the cleaning agents needed for cleaning, including alkaline cleaning agents containing sodium silicate, potassium hydroxide and other ingredients.

Warm water rinse

Use running warm water to thoroughly rinse the internal and external structures of the V type powder mixer. Use the cleaning agent to thoroughly clean the equipment.

Residue cleaning

Use warm water to clean the residue and dirt in the equipment.

Equipment disinfection

Equipment disinfection-sourced: aimsindustrial

Throughly disinfect and dry the inside and outside of the equipment. After completing all steps, place the equipment in a dry and tidy place.

15.How To Maintain V Type Powder Mixer?

V type powder mixer also needs regular maintenance. These include:

Storage

The applicable ambient temperature of this equipment is about -5 degrees to 40 degrees, and the relative humidity should be less than 90%. Therefore, when not in use, this equipment should also be placed in a well-ventilated, dry and clean place.

Lubrication

Lubrication-sourced: stoneclinic

The parts that need to be lubricated in the equipment should be thoroughly lubricated and cleaned every three months.

Fault repair

Always check the cleaning and sensitivity of the electrical control components. If any fault is found, it should be repaired in time.

Cleaning residues

Cleaning residues-sourced: cleanroomtechnology

After stopping the use of the equipment, the remaining material in the equipment should be completely emptied, and the residual powder on the equipment should be removed with a brush. If it is not used for a long time, it should be thoroughly cleaned and covered with a dustproof cloth to prevent dust from sticking.

Parts inspection

At least once or twice a month, various parts should be checked for wear and temporary conditions, including power shafts, transmissions, gearboxes, etc. If any defects are found, they should be repaired and replaced in time.

16.What Are The Certificates That V Type Powder Mixer Have?

V type powder mixer strictly complies with various safety requirements during design and manufacturing. Its product certificates include CE certificate, CSA certificate and UL certificate. This not only makes the product meet various safety and performance standards, but also meets the safety and regulatory requirements in the future.

CE certificate

CE certificate-sourced: tebadul

If the product wants to enter the EU market, it is very necessary for V type powder mixer to obtain CE certificate. It can ensure that the equipment fully complies with the EU's safety use requirements, environmental protection requirements and quality management requirements.

CSA certificate

CSA certificate-sourced: keyence

Various electronic equipment and industrial equipment sold in the North American market need to obtain CSA safety certification. It is a safety certification issued by Canada to ensure that electrical and electronic products meet safety standards.

UL certificate

UL certificate-sourced: ledmyplace

The UL certificate is a certificate issued by the United States that the equipment meets safety standards. It is widely used in the US market. V type powder mixer gets UL certificate, which is convenient for its promotion and marketing in the US market.

17.What Should Be Paid Attention When You Are Selecting A V Type Powder Mixer?

When choosing this type of equipment, you should consider the following points:

Material types

Material types-sourced: cdsentec

Although V type powder mixer is suitable for mixing and stirring most powders, granules and viscous materials on the market, its best application should be to handle various dry powders.

Equipment capacity

Equipment capacity-sourced: toolots

Different equipment capacities correspond to different customer material handling needs. If it is a simple personal and laboratory application, you can choose a small capacity. If it is a large-capacity industrial or pharmaceutical industry application, it is recommended to choose a large-capacity type.

18.What Are The Future Trends And Development For V Type Powder Mixer?

After continuous research and progress, the future trends and development of V type powder mixer include:

Automation

Automation-sourced: spiceworks

Future technology is moving towards full automation and incorporating more advanced AI technology, so that the equipment can handle various materials for you in severe situations.

The development of integrated technology

The development of integrated technology-sourced: aqugen

The ability to integrate V type powder mixer into the entire line is the development of integrated technology.

Conclusion:

With its superior design, the V type powder mixer can provide you with consistent and uniform mixing of materials. Complying with strict hygiene standards, it can provide you with high-quality material handling and mixing. This equipment is an excellent choice for its wide range of uses and low cost. If there are more you want to know, start your partnership with AIPAK now!

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine