V-powder mixer: A Complete Buying Guide in 2025

Are you looking for a machine that can mix your powder and granule ingredients well? In the pharmaceutical, food, chemical, or cosmetics industries, it is way more difficult to mix dry powder manually. Then, a machine named V-powder mixer is here to solve your problems of mixing.

V-powder mixer is of V-shaped machine that is designed to mix dry powder and granules. This is powerhouse mixture that ensures the precision and consistency you need in operation. V-powder mixer is perfect for both small-scale and large-scale industries because it provides efficient and maintains product quality.

There are many options available in the market. But choosing the right one might be challenging. This buying guide is all about V-powder mixer. Let’s ready and explore it.

1.What do you know about V-powder mixer?

ALLPACK VH-8 V-powder mixer

V-powder mixer is blending or mixing machine designed to mix dry powders and granules. It is V-shaped drum that efficiently and flexibly mixes ingredients. Because of its design, clumps are not made as materials move freely which guarantees consistency in finished products. Its tumbling motion ensures no breakdowns of materials.

They can be used at different production scales because they come in various sizes and combinations. Additionally, due to its simple to clean process, they are used in sectors where high hygiene is required. Different sized particles can be powdered using this versatile machine.

2.What are the benefits of V-powder mixer?

Due to its fine mixing, V-powder mixer provides numerous benefits. Here are the following benefits.

Uniform mixing

One of the advantages of this machine that offer you uniform mixing of material by tumbling and rotating inside mixing chamber. Compared to traditional mixing, it guarantees uniform powder dispersion and avoids clumping.

Versatility in materials

Versatility of powder-Picture Courtesy: naturealle.com

Another amazing benefit is it can handle different materials you are using. It can powdered fine particles and granules with different sizes and properties.

Easy to use

Easy to use-Picture Courtesy: intellect.com

This machine is easy to operate even a non-technological expert can set machine. V-powder mixer is user-friendly as one can set speed and time.

Reduced mixing time

V-powder mixer can mix your materials in less time when you need them in a hurry hour. This time -saving advantage increases overall production capacity, assisting companies in meeting deadlines, and cutting expenses.

Easy to clean

Easy to clean

To maintain the hygiene of products, it is necessary to clean machine parts. This machine is simple to clean with no complex parts, cleaning after each batch is quick, which also ensures little downtime between mixing cycles.

Safety features

V-powder mixer provides you with safety features of automated shutdown system and emergency stop button to avoid unintentional restart. These safety features are productive at workplace to avoid incidents.

3.What industries use V-powder mixer?

V-powder mixer showers you with lots of benefits. That’s why most of the industries grasp hands over the use of V-powder mixer. What are you waiting for? Let’s get into it.

Pharmaceutical industry

Pharmaceutical industry

Now, you will think in the pharmaceutical industry, what is the use of a V-powder mixer? To make tablets or capsules, granules, active pharmaceutical ingredients (API), and excipients are mixed by using V-powder mixer to efficiently mix these. There are drugs with heat and pressure sensitivity, these are mixed with V-powder mixer.

Cosmetic industry

Cosmetic industry-Picture courtesy: aranca.com

Cosmetic industry uses V-powder mixer to blend dry materials and pigments used in many products such as facewash, foundations, scrubs etc. To prevent color discrepancies, pigments for cosmetics must be mixed precisely. V-powder mixer uniformly mixes all the ingredients of cosmetics, though protecting their characteristic.

Food industry

Food industry

Another industry that uses this machine is the food industry. To mix spices used in ready-to-eat meals, baking powder, coffee powder etc. To protect these delicate materials from any damage, low-sheer mixing is done.

Agriculture industry

Agriculture industry-Picture courtesy: flipkart.com

V -powder mixer is used to mix fertilizers, pesticides, herbicides, and animal feeds. For effective use, these are blended evenly. When working with bulk of granular and solid materials, this machine is beneficial.

Paint industry

Paint industry

To mix large quantities of paint materials, v powder mixer is easier-hand pick up than traditional way of mixing. This machine mixes pigment color, fillers, dry components and resins for paint making, which evenly distributes hues and ensures vibrant colors.

4.Do you know the components of V-powder mixer?

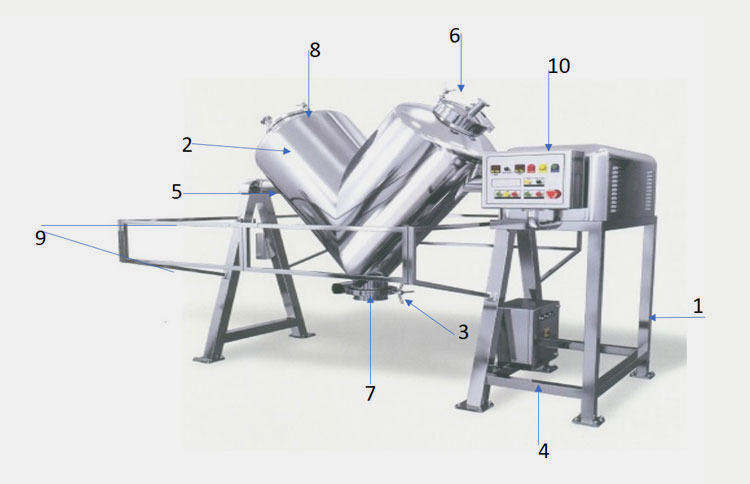

Components of V-powder mixer

Usually, a V-powder mixer consists of various parts. These parts work together to ensure that each mix is produced accurately and precisely.

Here are the components of a V-powder mixer.

Frame

The frame provides support to the machine. This part is made from stainless steel which helps to maintain the operation of V-powder mixer. To provide a sturdy base, the frame ensures maximum machine stability and minimal vibration.

Mixing vessel

This component is of heart shapes which allows well mixing of powder materials. V-shaped mixing vessel has two chamber that allows free motion of material. Chamber guarantees effectively transport of powders without their clumps. Baffles are the mixing blades that are located and rotates in the vessel. These helps in grinding of hard materials to form powders. As you might have seen that powders are well grinded which is all due to baffles

Rotating shaft

Rotating shaft positioned horizontally and is connected to V-shaped mixing vessel. This ensures that vessel is rotating on its axis, which moves and mixes the particles inside. There is a gearbox which regulate the rotation of the shaft.

Drive motor and gear box

Drive motor is an electric motor while gearbox works is a speed control. Various kinds of powders require different speed to blend them effectively. Motor and gearbox cooperate to provide a steady and tunable rotation speeds. For sensitive particles, slow speed is necessary.

Bearings

The smooth and continuous movement of machine is all due to bearings., reducing friction. They guard against shaft and housing wearing. By lowering friction, bearings also play an important role in lowering the noise created by machine.

Feed inlet

Inlet and discharge ports are connected on the top and bottom or side of the vessel. Its purpose is to load materials in mixing chamber. to prevent spill, seals may be installed in the port.

Discharge port

Discharge port facilitates the easy discharge of mixed materials. Seal is frequently included with outlet to prevent the control and prevent contamination.

Inlet inspection

It is placed in the opening of V-chamber. By visual inspection and ingredients monitoring, it ensures quality control without power off the machine.

Guard rail

Guard rail is the protective barrier around mixer. Due to these, operators cannot access to the running machine.

Control panel

Control panels include emergency button, timers, and speed control. If you want to increase or decrease speed, change time and power off or on the mixer, control panel allows you to do these changes.

5.How does a V-powder mixer work?

V-powder mixer is known for its amazing blending of powder quality. By this lots of industries use this. Now, you will wonder that if there may be a process or steps involved in high quality final blend. Here are the crucial steps involved in blending.

Loading

Loading-Picture Courtesy: proliderconsultores.com

The first step is loading of appropriate number of materials in V-shaped mixing chamber. Here, materials must be ready before loading. This entails making certain that powder is accurately weighted, dry, and have no lumps. For better mixing and quality, moisture of powder must be checked.

Materials are loaded in the chamber. To avoid overfilling, it must be noted that you should fill chamber at roughly 50% of its capacity, as overfilling leads to ineffective mixing. Sometimes, materials are loaded manually from hopper.

Blending

Blended powder-Picture courtesy: deltaformulation.com

The primary function of this machine is blending. The V-shaped chamber is rotated to mix powders using tumbling action. Here, when materials are loaded, blenders start rotating along its horizontal axis. Tumbling action starts inside chamber which causes movement of materials.

Powders undergo several flows. This promotes even dispersion by enabling the particles to mingle in all directions. Materials are equally distributed to ensure no clumps, and evenly mixing. The time taken in blending depends on the density and kinds of powder.

Unloading

Unloading

After mixing, the next step is unloading out of the chamber. To guaranteed that powder is retrieved without contamination and wasting, this procedure entails releasing the mixed materials from V-powder mixer. There is a discharge valve at the bottom that can be operated manually or by a pneumatic system.

As the valves open, blended power comes out of machine into the collection container.

6.What types of V-powder mixer are available in market?

Depends on material types, in market various types of V-powder mixer come. Each has their own specialty. Here are the types.

Based on design/shape

Standard V-powder mixer

ALLPACK VH-50 Standard V-powder mixer

As the name suggest, its shape is V shaped. By its rotation, granules and dry materials tumble. They are mixed evenly by tumbling action results in powder lifting. As the materials are gentle, there is low force applied on them to protect them from any damage.

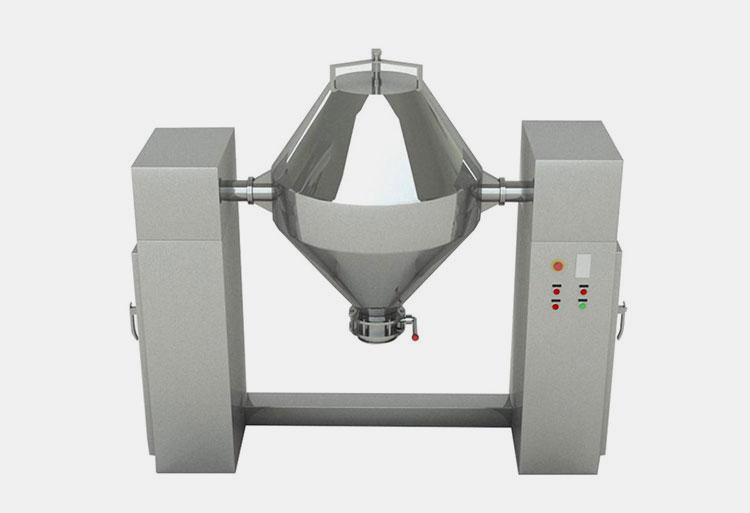

Double cone V-powder mixer

ALLPACK- Model W Series Double tapper V-powder blender

Double cone V-powder mixer consists of two cones creating double cone structure.

Powder flows from one cone to another ensures efficiently mixing. There is large internal volume. So, there can be large powder store for mixing and can freely move between the two cones.

It is commonly used in industries that require large space for large quantity mixing material such as chemicals, pharmaceutical and food industry.

Based on speed

V-powder mixer is classified in following.

Higher speed V-speed powder mixer

ALLPACK-VH-8 High Speed V-powder mixer

High speed V-shape power mixer with high speed is used for materials that need pressure to be blend. It is made for heavy duty mixing. When powders have tendency to lump or disperse quickly, high rotational speed choppers guarantee homogeneity in mixture and fast blending.

Low speed V-shape powder mixer

ALLPACK-VH-12 Low Speed V-powder mixer

For delicate materials to blend, low speed V-powder mixer is efficient. It is perfect for use in nutraceutical, chemical, and pharmaceutical because of its gradual mixing action which prevents breakdown of fine particles. By tumbling action, materials freely flow inside the V-shaped chamber vessel by lifting and dividing powder.

Based on size and capacity

Followings are the classification on the basis of size and capacity.

Laboratory V-powder mixers

Laboratory V-powder mixer

For small scale industries, and in settings related to research and development, this type of mixer uses. If you are looking for machine that can blend powder to few kilograms, then this machine does the same, small storage.

They are used to produce samples for additional examination or combine to smaller amount of granular or powder components for testing, or experiments. This type of mixer also works on the same way as other large models, V-shaped chamber allows powder to mix and shift from one end of chamber to other.

Industrial V-powder mixer

ALLPACK-VH-20 30 Highly efficient V-powder mixer

Industrial V-powder mixer is designed for large scale production. It can handle large quantity of materials to be blend in powder. Having big motor, it rotates chamber and by tumbling action, powders are mixed.

Industrial V-power mixer also blend powder with heavy density of 900 Ibs/cu. ft or more.

7.Can you use V-power mixer for wet blinding?

First of all, you will wonder what is actually wet blinding? Wet blinding involves mixing of liquids with any dry powder to form semi-wet mixture. Generally, if you look at the design of this machine, it is for dry powders. But wet materials can also be blind with some modifications in machine. Let’s have a look onto those modifications.

Chopper blades

Chopper blades

Chopper blades are fixed in V-powder mixer. These blades rotate at high speed which break wet lumps and mix liquid with this mixture evenly.

Spray nozzles

Spray nozzle-Picture courtesy: spraydryingnozzels.com

Nozzles are installed in internal machine, the V-chamber vessel. Small drops of liquid are spray into dry powder in order to moist them. This helps to break wet lumps.

Drying vacuum

Purpose of vacuum is to remove or extract extra moisture from blinding. This helps in to avoid over-witting, and helps to ensure that you do not need to buy a separate equipment for drying. This will save your time and energy.

Advantages

To look at the advantages of above, it is helpful for moisture sensitive drugs, chemicals, and in food industry, it is used to make liquid coating on dry powder.

Challenges of using wet blinding

There are few problems we can face while using wet blinding. Following blow are the challenges.

- Clogging inside chamber may form which reduces flow of liquid materials effectively and efficiently.

- Liquid sticks to the inner chamber walls.

- Processing time of liquid is bet longer than dry powder.

8.How much time does it take to complete mixing cycle?

Speed indication

Time taken to complete mixing cycle may be vary. Followings are the factors that affect the mixing cycle are:

Mixing speed

Mixing speed is one of the important factors that affects the mixing cycle. As materials are different, so time taken by is also different. If machine is in high speed, there will be low mixing cycle time. But sometimes, it leads to uneven mixing.

While if mixing speed is low, it will reduce mixing time, but mixing will be gentle and thorough.

Mixing chamber design

Mixing chamber size is large and not enough full, then it will take less time for mixing. For easy material discharge, there is inlet and outlet valves, helps in easy material flow and no blockage of material.

Batch size

Batch size also affects the mixing speed. If batch size is large, it will take more mixing time. This may lead uneven mixing. If your batch size is small, mixing time will be less and will be quickly mix.

Unloading and unloading

When materials are manually loaded, it will take more time and has no goo quality.

Automatically filling or loading are very efficient and it does not consume your time. It completes cycle time that takes hours while doing in manual way.

Motor capacity

Another factor that has an impact on mixing cycle is motor power. Incase, your motor power is insufficient, it will have extended mixing cycle. But a good condition motor is ideal for large batch for their well mixing.

9.How to maintain V-powder mixer?

To maintain mixer, it increases productivity, hygiene of mixer, and safety of operators. Here are the tips to maintain V-powder mixer.

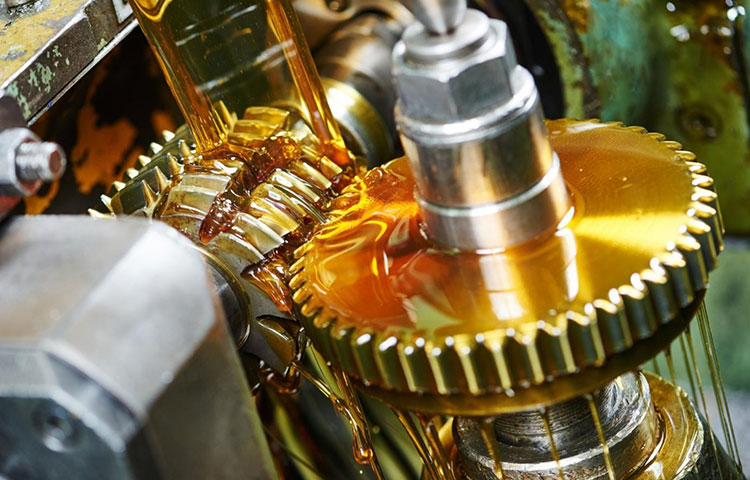

Lubrication

Lubrication-Picture Courtesy: electricalapparatus.com

Lubrication of machine is a must thing to do. Make sure to lubricate and oil moving parts in order to check there is no rusting and wear tear kind of things. Lubrication must be done in a month.

Cleaning

Cleaning-Picture courtesy: criticalcleaningadvice.com

One of the important aspects is to maintain mixer. As you know that materials left from previous batch can contaminate the present or upcoming batch. Cleaning this mess is necessary as it can deteriorate the product quality, will make them cheap and crap. The first thing to do is clean the chamber using cloth, soft brush or vacuum. If parts are removable, detach them for thorough cleaning.

Parts inspection

Inspection ensures each part is in good condition and does not affect mixing. Check wear and tear situation of blades and ribbons. As cracks and leaks in chamber vessel could affect the quality of powders. So, their checking and maintenance is important.

Maintenance of discharge system

Powders get stick with discharge valves when moving out of the chamber vessel. This buildup the materials which clog and block the discharge. In order to ensure no obstruction and smooth flowing, clean discharge system after every batch. Also, check powders are flowing out at correct speed or not.

Check fasteners

Fastening nuts-Picture courtesy: constructionfasteners.com

Nuts and screws hold components of mixer together. Tighten loose screw and nuts is necessary. If any fasteners are corroded or rusted, change it immediately. They can affect overall performance.

10.What are the quality certifications for V-powder mixer?

Followings are the quality certifications that V-powder mixer must be abide by to ensure the safety and performance standard.

FDA

FDA-picture courtesy: southeastcomputers.com

FDA (food and drug administration) compliance ensures that industries do not use non-toxic and food grade materials. These industries must meet the quality standard and hygiene.

ATEX certification

ATEX certification-picture courtesy: aager.com

This certification is required where inflammable powders are used. It is intended to use when V-powder mixer blended explosive substance. It ensures anti-explosion design and anti-static materials.

GMP

GMP- picture courtesy: complianceease.in.com

GMP (Good manufacturing practice) is must in food and pharmaceutical industry. It ensures that V-powder mixer must have stainless-steel mixer with easy cleaning and no dead zone.

11.What are the factors to look for when buying V-powder mixer?

There are various factors to consider when buying V-powder mixer. Followings are those factors.

Budget

Budget

Whenever you think of buying something, must consider your budget first. Whether your budget comply with buying machine or not. Costs of different types of V-powder mixer must be considered. As all models of machines give you various benefits, whether the machine is less expensive and higher price.

Mixing efficiency

Important thing in mixer machine is blending power. Mixing efficiency is one of the important factors to consider. Efficient mixer will provide you with better blending of powder.

Capacity

One should look for the capacity of mixer. A mixer should not be small that could not meet your production demand, and should not be large enough to be unable to handle and costly. Always choose mixer with varying capacity, from small-scale to large-scale and fits your current need.

Compatibility

Compatibility-Picture courtesy: alpapowder.com

You blend various materials. It must be noted that chamber vessel must be compatible with material you want to blend. To use the powder for mix, it should be sure that chamber and other components are made from material that can handle these.

Consider that mixer machine also blends wet materials.

Easy to clean

Easy to clean

Cleaning is important to reduce the downtime. Look for V-powder mixer that has removable parts and self-cleaning machines. Select a discharge valve that release quick blended powder.

Conclusion

To conclude this file, it is necessary to look for factors before buying V-powder machine. Ensure compliance with GMP, ATEX, and FDA for proper hygiene and other standards. In market, variety of models come in market, but selecting a right mixer is very important. If you are looking for machine, then AIPAK is available for you help.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine