V Cone Mixer: The Complete Buying Guide In 2025

Do you have any idea who is behind the uniform mixing of protein powder, you just bought yesterday? Or spices which you use, to create finger licking food dishes? It’s no one other than v cone mixer.

V cone mixer has remarkable influence on different industries like medicine, food, cosmetics and chemical. When you look for an advantageous investment, you cannot overlook v cone mixer benefits. The reason behind that is the role of this mixer in mixing such important daily products. This topic contains all the key information, essential for buying a v cone mixer.

1.How do you describe v cone mixer?

Dry Powder And Granules-Picture Courtesy: The Spice House

A v cone mixer, commonly known as V- blender or twin shell blender is an important equipment, used to blend dry powders and granules with uniformity to attain a quality product. It is considered as an integral part of different industries like pharmaceutical, food, cosmetic and chemical.

Each industry utilizes this equipment for powdered products to attain conformity in their products. As a purchaser, you must be aware of the initial information about this mixer to make a well-informed decision.

2.Why v cone mixer is called as twin shell blender?

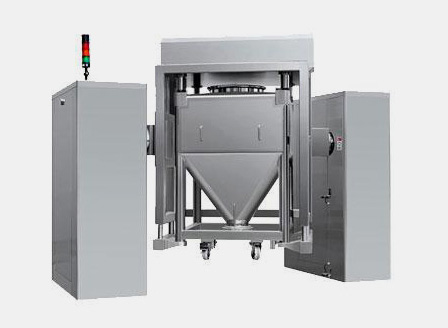

Twin-Blender Mixer-Picture Courtesy: Powderprocess.Net

V cone mixer is also called as twin shell blender. The reason for highlighting this information is to prevent you from getting confused. As a buyer, you must know the alternate name of your concerned equipment.

The logic behind naming it “twin-shell blender” is the design of its mixing chamber, which is comprises of two aligned cylindrical shells combined at an angle to form shape V.

These two cylinders are at one end, and powder is introduced from both inlets. When shells start rotating together, they allow homogenous mixing of powder by the tumbling action. As the mixer continues to rotate, the powder in each shell lifts, splits and then recombines in mid of chamber. This consistent movement of powder permits mixing without dead zones by diffusion mixing principle.

3.What favors v cone mixer can give to industry?

V cone mixer is widely used to mix dry powders and granule in different industries. The reason behind this preference is highlighted qualities of mixer, to perform established blending process, soft handling and consistent mixing.

This mixer proves to be a great source of investment as it covers prime products of daily life. In order to obtain complete comfort from this mixer, you need to know about its benefits to industrial sector.

Even mixing of powder:

Evenly Mixed Dry Shampoo Powder-Picture Courtesy: Corinne Taylor

V cone mixer allows even mixing of dry powders and granules with great efficiency. The mechanisms behind this homogenous blending are tumbling motion and diffusion mixing. These two mechanisms divide the powder then recombine it to attain uniformity.

Tender mixing for fragile powders:

Thermochromic Powders Are Heat Sensitive Powders Used In Paints, Resins, Nail Polish -Picture Courtesy: SFXC

V cone mixer offers minimal material breakage, proving it perfect for fragile powders. This mixer avoids generation of heat, which is essential for heat-sensitive substances.

Appropriate for free flowing powders and granules:

Free Flowing Powder-Picture Courtesy: Astra Chemicals

V cone mixer proves to be the best choice for free flowing powders and granules. It promotes homogeneous mixing and avoids material partitioning, which helps in maintaining quality of product.

Minimal energy expenditure:

High Quality In Low Price-Picture Courtesy: Next Generation Equity

V cone mixer commonly operates at minimum RPM (rate per min) i.e. 5-10 RPM. This results in less energy utilization. As low energy consumption is there so you do not witness high friction or heat production during processing. High quality is attained in low price.

Simple design:

Easy Design Of V Cone Mixer-Picture Courtesy: Arnold Equipment Company

V cone mixer possesses simple design, which has benefits. Powder is discharged from V chamber by the help of gravitational force leads to less material retention. This mixer is easy to clean and maintain that’s why you can consider it best for frequent batch change processes in industries.

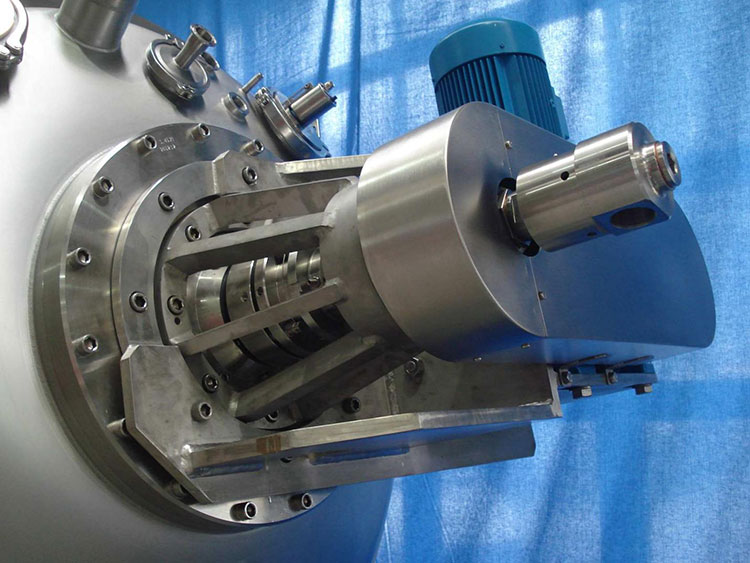

Enhanced blending:

Cohesive Powder-Picture Courtesy: Micromeritics

Addition of intensifier bar in to v cone mixer provides enhanced blending for cohesive powders. This intensifier bar breaks clumps present in fine powders and v cone mixer helps to mix them homogenously.

4.What are the drawbacks of v cone mixer?

While securing prime position in different industries, v cone mixers do have some disadvantages, which put a question mark about its utilization at some places. This topic has all knowledge about limitations of v cone mixer, which you require as a buyer to save you from any trouble.

Limited mixing mechanism:

Grueling Blend Of Powder-Picture Courtesy: Linkedin

V cone mixer works on primary principles of mixing powders, sometimes which are not helpful. When the powder gets stuck in dead zones then you need extra agitation for such grueling blends, which require flow aids for good flowing property.

Effective but not for all:

Heat Sensitive Powder-Picture Courtesy: Gosupps.Com

V cone mixer is used effectively for blending so much important products. But it is not appropriate for some materials like sticky or very fragile powders that need binders to flow well. Fibrous powders get tangled in rotating bar and coarse powders can cause equipment wear.

Demands downtime between batches:

Demands Downtime Between Batches-Picture Courtesy: Garvey Corporation

Complete emptying of batch is needed before loading of every next batch, this demands downtime between batches filling or discharging and it affects the speed of operation. Sometimes it is also difficult to empty chamber from small outlet when you have fine powders for mixing.

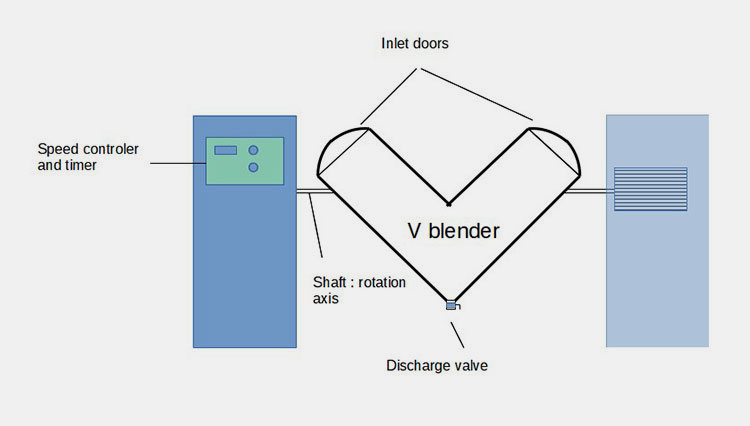

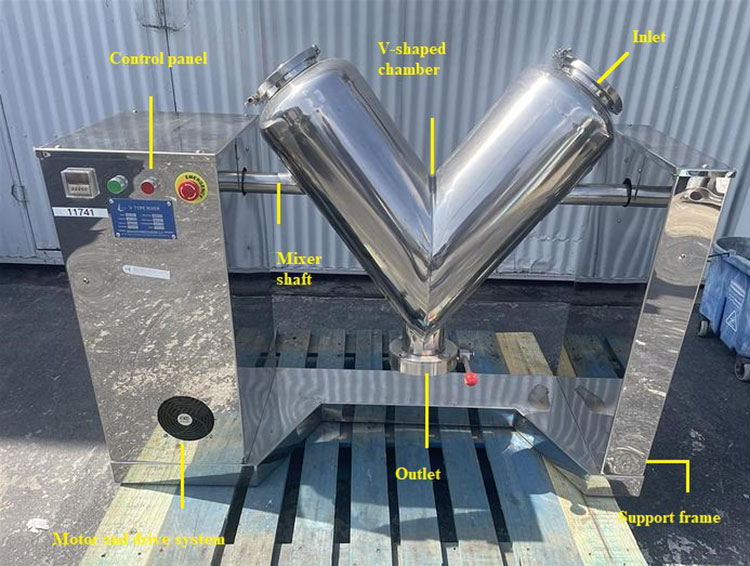

5.What are the basic parts of v cone mixer?

Basic Parts Of v Cone Mixer

As a buyer, it is crucial to have right information about basic parts of v cone mixer to avoid any problem in future. This mixer secures great importance in different industries and to work efficiently, presence of all fundamental parts has to be made sure.

Basic parts of v cone mixer are listed below:

| Basic parts | Their function |

| v-shaped chamber: | The most important part of v cone mixer. It is shaped like a “V”, which permits homogenous mixing of dry powders and granules through different principles. |

| Mixer shaft: | Chamber is attached to a shaft which helps it to rotate and this result in absolute blending. |

| Inlet: | Material is introduced through this inlet in to chamber for mixing uniformly |

| Outlet: | Material is discharged through outlet after being completely mixed. |

| Support frame: | A rigid structure that holds the v cone mixer in place and takes up vibrations |

| Motor and drive system | This system helps mixer to revolve at its central axis at a controlled rate |

| Control panel | It oversees the speed, rotation time and further settings during operation. |

6.How many types of v cone mixer are available in the market?

V cone mixer secures great importance in different industries like medicine, food, agriculture, chemical etc. the utilization of v cone mixer depends upon the scalability of industry or characteristics of material. Types of v cone mixer are distinguished on the basis of design and scalability.

On the basis of design:

V Cone Mixer-Picture Courtesy: Adinath International

| Designs of v cone mixer | Function |

| Standard v cone mixer: | It is a basic v shaped chamber containing mixer, which ensures the uniform blending of dry powder and granule. Ideally used for free flowing powders. |

| V cone mixer with intensifier bar | This mixer comes with an addition of intensifier bar inside it, in order to perform even mixing of cohesive powders. The purpose of intensifier bar is to break clumps, formed in fine powders and provide homogenous blend. |

| V cone mixer with liquid spray | It is designed by adding liquid sprays inside the mixing chamber to facilitate the liquid ingredient inclusion during mixing process. It is used for coating, flavoring or granulation applications |

| Jacketed v cone mixer | This mixer is specially designed for temperature sensitive powders. A heating or cooling jacket is installed inside the mixing chamber to provide uniform blending of delicate powders. |

| Vacuum v cone mixer | This mixer works under vacuum conditions.

It avoids oxidation and makes mixing more efficient. Preferably, used in pharmaceutical and chemical industries for fragile powders that are moisture or heat sensitive. |

On the basis of scalability:

High-Capacity Industrial V Cone Mixer For Large Scale Production-Picture Courtesy: India Briefing

| Scalability | Function |

| Lab-scale v cone mixer | V cone mixer with small capacity for research and experimental trials. |

| High-capacity industrial v cone mixer | V cone mixer with huge capacity for vast amount of material. It is ideal for operations carried out on large scale like in industries. |

7.How to elaborate about steps of operation of v cone mixer?

Protein Powder Is Uniformly Mixed By V Cone Mixer And Packaged In Pouch To Get Into Your Hands Safely-Picture Courtesy: Healthline

Do you have any idea how protein powder is uniformly mixed by v cone mixer and packaged in pouch to get in to your hands safely?

This topic tells you about all the steps, involved in processing of v cone mixer. In order to make any investment about this mixer, it is necessarily important to get knowledge about its operation’s steps.

Step by step processing of v cone mixer is discussed below:

| Steps of operation | How it is carried out |

| Handling of material: | Measurement of material, which will be subjected to v cone for blending is carried out using load cells and weighing stations.

Materials are passed through a sieve if needed to prevent presence of lumps and foreign particles. |

| Loading in v cone mixer: | Material is loaded in to v shaped chamber of v cone mixer by inlet. |

| Process of powder mixing: | Processing of powder mixing is carried out at calculated speed of 5-25 rpm.

Intensifier bar is present to enhance the efficiency of mixing. Mixing process continues for 5-30 minutes depending upon the nature of powder. |

| Discharging the uniform blend: | The blended powder is discharged from outlet, by removing a valve present at bottom of mixer. |

8.What are the differences between v cone mixer and double cone mixer?

Double Cone Mixer And V Cone Mixer-Picture Courtesy: Saintyco

There are many factors in which v cone mixer is different from double cone mixer. As being a purchaser, it is adequate to know the distinction between these two mixers in order to choose the right one as per your needs.

| Factors | v Cone mixer | Double cone mixer |

| Application : | It is widely used for free flowing and fine both type powders on large scale setup of different important industries including medicine, chemical, food etc. | It is commonly used in pharmaceutical or chemical industries for delicate powders. |

| Design | It consists of v-shaped chamber with an intensifier bar. | It consists of two opposing cone-shaped halves fused together at the mid. In this way two separate blending chambers are there, provided with a combining section in between. |

| Mixing principle: | Tumbling motion, diffusion mixing and enhancement of shear force are the principles on which v cone mixer based. | It is based on tumbling motion and diffusion mixing principles. |

| Intensifier bar: | Commonly included in mixer, depends upon the powder characteristic. Cohesive powders require it. | Usually not seen to add intensifier bar in this mixer. |

| Capacity: | It is available in huge capacities, so usually use in large scale production. | It has smaller capacity as it has two divided chambers. |

| Mixing process: | Whole mixing process is completed at once. | Mixing process is divided in to two stages. In first chamber, material is supplied and premixed there. After that it is shifted to other chamber for final mixing. |

| Discharging process: | Mixed powder is discharged from outlet present at bottom of v cone mixer. | Some double cone mixer has their outlet at the mid of two cones and some has at the bottom of mixer for discharging the blended powder. |

9.What are the uses of v cone mixer?

Importance of v cone mixer is undeniable. It counts as an integral part of so many production lines of different valuable industries. As a purchaser, you must have an idea about the use of this mixer to get most of its benefits. This topic enlightens the value of v cone mixer in different industries like pharmaceutical, food or chemical etc.

Medicine industry:

APIs Filled In Capsules Or Compressed To Form A Tablet-Picture Courtesy:TA Instruments

How many medicines you take often and get rid of your ailment, have you ever thought who has its part in delivering such useful thing to you? It’s v cone mixer. This mixer has crucial role in blending active pharmaceutical ingredients (APIs) with excipients.

This evenly mixed powder is further subjected for tablet compression or capsule filling or sometimes used to form granules.

The purpose of choosing this mixer is to get uniform mixing of APIs with excipients, avoid overheating or powder deformation and attain a quality product that meets mandatory standards.

Food industry:

Spice Blends Are Made By Mixing Different Spices-Picture Courtesy: NY Spice Shop

You cook different food dishes for your loved ones and put magic in it after adding spice blends. It is v cone mixer behind providing you uniformly mixed spices.

This mixer is necessarily used in food industry to mix spices, flavors, seasonings and nutritional supplements like protein powder. It is also utilized in flour and baking ingredients blending.

The purpose of selecting v cone mixer is to maintain the originality of powder by gentle mixing of ingredients. In this way, taste, texture and aroma are preserved. This mixer avoids separation of ingredients in spice blends, protein powders, baking blends etc. you achieve a top quality product that is competent to food safety regulations.

Chemical industry:

Washing Powder-Picture Courtesy: Fluff And Fold Laundary

Washing powder which cleans your clothes as neat as a new pin is uniformly mixed by aid of this amazing v cone mixer. This mixer is vastly used in chemical industry for even mixing of dry chemical powders like pigments, polymers, fertilizers etc. It is also utilized for preparation of detergents and for inclusion of additives in certain chemicals.

The purpose of this mixer application in chemical industry is to obtain uniform dispersion of chemical components, avoid reactions to sensitive powders.

Cosmetic industry:

Perfumed Powder Evenly Mixed By V Cone Mixer-Picture Courtesy: Yardly London

A bottle of perfumed powder, which is a constant part of your grocery during summers as it refreshes you every time you use it, have you wondered that it is mixed by the help of v cone mixer and then filled in bottles to get delivered to you…!

This mixer is used in cosmetic industry for several ways, either it’s blending of powdered ingredients for makeup products like eye shadow, face powder etc. and talcum powder. Toothpastes, shaving cream etc. ingredients are homogenously mixed in this mixer before subjecting to wet mixing.

Purpose of utilizing this mixer is to secure color and texture of powder ingredients used in makeup products or perfumed powder. Clumping of fine powders is also prevented by intensifier bar containing v cone mixer and we obtain a product possesses precise ratio of ingredients in it.

Agriculture industry:

Fertilizers For Your Plants-Picture Courtesy: Unicorp Biochem

For optimum growth of your plants, you need fertilizers, which are prepared by mixing in v cone mixer. This mixer plays a prime role in agriculture industry by providing even blending of many powdered or granular ingredients to form a furnished product of your need.

Different kinds of fertilizers like nitrogen, phosphorous etc. are available in market; these are uniformly mixed with the help of this mixer.

Animal feed is prepared by mixing certain nutritional ingredients like vitamins, minerals, protein with other feed material for livestock and poultry. This homogenous mixing offer balanced feed for animal.

Various soil conditioners are made by mixing different chemical ingredients like lime, gypsum or organic matter to facilitate good quality of soil. This mixer ensures consistent mixing of all ingredients in order to deliver a useful product. All above discussed applications in agriculture industry reflects the importance of v cone mixer to attain a gentle blending while preventing material degradation.

10.What are the factors that can influence mixing efficiency of v cone mixers?

Powder Characteristics Is One Of The Factors That Affect Mixing Efficiency-Picture Courtesy: Asian Mixer Machine

There are certain factors that have their influence upon the mixing efficiency of v cone mixer. If you have intention to buy this mixer, then you must be known to these factors to operate this equipment efficiently. These factors are listed below

| Factors | How they affect |

| Level of filling: | V Cone mixer works by tumbling motion and diffusion mixing. So it requires optimal space for uniform mixing of powder. Chamber must be filled around 40-60% of total space for good mixing. |

| Speed of rotation: | Controlled speed of mixer is demanded to attain homogenous mixing. Too slow rotation will cause improper mixing and rapid rotations will cause deformation to powders. Usually 5-25 rpm speed is considered suitable for v cone mixer operations. |

| Duration of mixing: | To obtain a perfectly homogenous blend, you need to decide duration of mixing for respective powder according to its nature. Suggested time for mixing is 10-30 mins. |

| Powder characteristics: | Powder characteristics include particle size, ability to flow and how dense it is, all these things collectively have their influence on mixing ability of equipment. |

11.What are the practices to maximize the performance and shelf life of v cone mixer?

Every equipment demands care and maintenance to yield good outcome. This topic tells you about practices that can robust the performance and shelf life of your v cone mixer and save you from setbacks.

Inspection of mixing chamber:

Improper mixing of powder-Picture Courtesy: Always Eat Dessert

The most important function of blending is carried out in mixing chamber. So it’s the utmost priority of operator to maintain mixing chamber according to mandatory standards otherwise you will face improper mixing of powder.

- Check mixing chamber for corrosion and abrasion and repair where needed.

- Get rid of material accumulation in mixing chamber to prevent cross-contamination and variation in force.

- Ensure complete emptying of powder from chamber after execution of each batch.

- Check the rotating bar present inside the chamber for wear and tear. Correct it immediately.

- Perform mixing test regularly to beware of any issues causing irregular mixing.

Inspection of sealed areas of mixer:

Inspect Sealed Parts Of Mixer-Picture Courtesy: K A S A G Swiss AG

Check mixer shaft seals on daily basis for cracks and replace the cracked parts at the moment.

Inspect inlets and outlets door for air leakages or erosion and repair it without any delay to get trouble-free mixing.

Monitoring electrical and drive system:

Electrical System-Picture Courtesy: Apollo Electric

Monitor electrical and drive system by checking the alignment and intactness of electrical and drive components.

Lubrication of moving parts:

Lubrication Of Moving Parts-Picture Courtesy: Micro-Lube

In order to get good outcome, lubrication of moving parts of mixer is essential. Lubricate drive motor bearings and other movable parts in accordance to manufacturer’s guide.

Make maintenance schedule during downtime:

Scheduled Maintenance-Picture Courtesy: CleanLink

In processing of v cone mixer, equipment goes for downtime to get prepared for next batch. During this downtime period, scheduled maintenance must be followed for deep cleaning, inspecting and replacing worn parts to prevent jamming of mixer.

Conclusion:

V cone mixer marks a paramount place in different industries because of its versatility and increased capacity. It assures the established uniform mixing of dry powders and granules in low expenditure. Due to its vast applications and user-friendly design, it proves to be a profitable investment despite of having some limitations. For any query, you can contact AIPAK anytime.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine