V Blender Mixer:The Complete Buying Guide In 2025

Mixer is the irreplaceable machine for powder and granule mixing work. You may have find its applying in the common industry like pharmaceutical industry, chemical industry, food industry and so on. The deeper knowing about V blender mixer is so helpful and so intelligent for you and your business.

What are the advantages of V blender mixer? What are the main parts of V blender mixer? What is the working principle of V blender mixer? Are there other types of blender besides V blender mixer for pharmaceutical use? There is the comprehensive buying guide about V blender mixer for you to make the better manufacturing business.

1.What Is V Blender Mixer?

AIPAK V Blender Mixer

V blender mixer has the other name of twin shell blender. And you may find its name suits the shape greatly. The two cylinders make the “V” shape for the great mixing of various products in it. The angled design makes the fluent shaking of material from one side to another side.

V blender mixer is elegant in appearance and requires simple operation. You may make the easy cleaning and maintaining there. The high efficient work of this machine can handle the mixing of various dry powder or granule of various industries. There are also different size and type for you according to the different manufacturing scale.

2.Where Is The Application Field Of V Blender Mixer?

V blender mixer is flexible and versatile. And here are the application field for your V blender mixer.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:contractpharma

In pharmaceutical industry, there is the wide use of even and uniform powder and granules. For the manufacturing of tablets products, capsules and many other products. The V blender mixer can make the total mixing for your active ingredients and excipients. The high efficiency and stable feature make this machine welcomed in market.

Food industry

There are various food products which all need hygienic and even powder. The fine and even powders can be mixed comprehensively by V blender mixer. For flour, sugar, spices and other supplements, there is the great need of even mixing of V blender mixer.

Chemical industry

Chemical Industry-Sourced:donaldson

V blender mixer can make the great and precise work of mixing, homogenizing, blending and so on for your various chemical products. You may apply your V blender mixer for the mixing of pigments, fertilizer, resins, paints, explosive, lubricants oil and so on.

Cosmetic industry

V blender mixer can make the emulsification and particle size reduction which is needed for your cosmetic industry. The qualified emulsifying is the base for the great cosmetic products. Besides cosmetic industry, V blender mixer can also be used for personal care industry and so on.

3.What Are The Advantages Of V Blender Mixer?

V blender mixer is so beneficial. And here are the main advantages of it. Come on and have a check.

Precise and efficient mixing

Precise And Efficient Mixing-Sourced:silverson

V blender mixer can make the precise and efficient mixing. The regular mechanical work of this machine can deal with the different powder and granule with high efficiency. You may have your time saved greatly with this machine and have the great harvest of your high qualified powder products.

Versatile mixing work

V blender mixer is versatile and flexible enough for dealing with various types of products. You have known its applying in food industry, chemical industry, various industry and so on. The high versatile mixing work can save you great energy and time for the

Little waste

The hallow shape moving of your V blender mixer makes no waste of your products. It can also release material with little condition. The less waste means more profits maintaining. V blender mixer can make you great benefits for your business.

Easy cleaning

V blender mixer has simple structure for cleaning and maintaining. The easy cleaning and maintaining can also save you great energy and time in your products manufacturing. You may prove the hygiene and safety of your V blender mixer for its easy cleaning.

Stable and durable structure

Stable And Durable Structure-Sourced:okgemco

V blender mixer is stable and durable for its strong structure and high qualified material applying. The high durability makes it flexible for the consistent and batch manufacturing. The stable and durable structure is so helpful for your business.

4.What Are The Main Parts Of V Blender Mixer?

V blender mixer is not the complex machine. And here are the main parts of V blender mixer.

Main Parts Of V Blender Mixer-Sourced:freundglobal

Feeding inlet

Feeding inlet is the place where you send the processed material in blending machine. Here are two inlet for your V blender mixer which makes great convenience for the material sending and so on. It can prove the hygiene and also help clean your V blender mixer chamber.

Mixing chamber

Mixing chambers of V blender mixer are two hollow cylinders. The two cylinders have the main body inclined for 70° to 90°. This is the place where blending process happens. The symmetrical vessel rotates on its horizontal axis and makes the even and precise material mixing work.

Discharge valve

Discharge valve is the parts where you may have the mixture material exist here. You may design the control of discharge valve according to your manufacturing need. And here are manual, automatic and so on according to your different discharging need. This is the important part for the proving of your products hygiene.

Drive system

Drive system is the part where power comes into the operating machine. You may have the powder and mixing speed guaranteed there. You may also adjust your drive system according to your machine starting way, material type and processing method.

Control panel

Control panel is the connecting point for operator and your V blender mixer. You may adjust your rotating speed, time and so on from your control panel. You may have the rotating feature adjusted according to your material type and other parameter.

5.What Is The Working Principle Of V Blender Mixer?

The working of V blender mixer is here. Come on and have a reading for the smooth operation of your V blender mixer.

Working Principle of V Blender Mixer

Parameter setting

Parameter setting is the first step of your V blender mixer. For the great and qualified material mixing, you should first set parameter according to your material type, size, feature and so on. The right parameter helps a lot for your products mixing.

Material loading

There are two chambers of V blender mixer and you may load the material in any of the chamber. You may also load the two chamber with same amount of material for the even mixture products. After the loading of your material, then it comes the next step of material mixing.

Mixing

Mixing is one of the most important step of your V blender mixer work. For V blender mixer, there is the regular and intermittent mixing for the material in chamber. The contact of material with vessel interior helps make the even and uniform material mixing. The high efficient mixing of V blender mixer can help make the qualified mixing in short time.

Material discharging

For the well mixer material, it is time to make the discharging. There are different discharge valve and you may adjust the valve according to your material type and need. You may corporate with other container or equipment for the safe and hygienic collecting of your powder products.

6.What Are The Main TypesOf V Blender Mixer?

V blender mixer has different types. And here are the main types of V blender mixer and they are divided according to their different structure.

Standard V blender

Standard V Blender-Sourced:inoxpausa

Standard V blender has the typical appearance of V shape. It is suitable for the blending of various material of different industries. For dry powder and granule blending and mixing, it can always make the rapid mixing with the inclined cylinder.

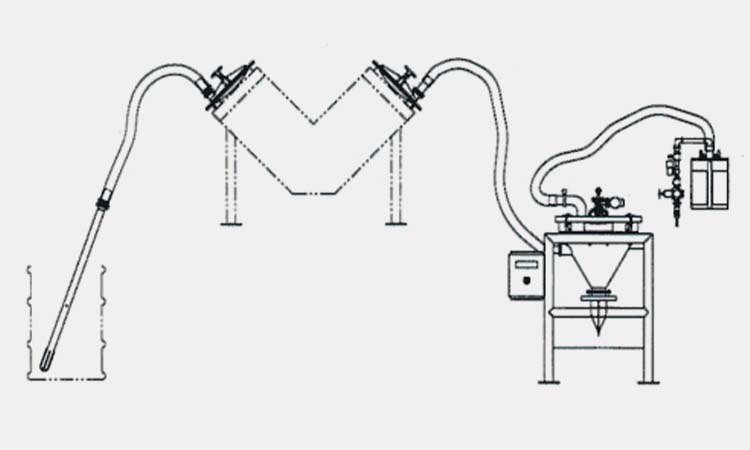

Vacuum blender

Vacuum Blender-Sourced:vac-u-max

Vacuum blender is the blender which is specially made for the sensitive material blending. In vacuum blender blending work, there is equipment for the removal of air of products. You may have the quality and hygiene of the material proved there.

Heated or cooled blender

Heated or cooled blender is equipped with cooling and heating part. For heat-sensitive or temperature-sensitive material, it can maintain the suitable temperature which is so good for your various sensitive material.

7.Are There Other TypesOf Blender Besides V Blender Mixer For Pharmaceutical Use?

There are various blender besides V blender mixer. And here are the typical blender for pharmaceutical use.

Ribbon blender

AIPAK Ribbon Blender

Ribbon blender is the machine which is made with “V” shape design. There is the blender with helical ribbons which can make the axial mixing for your products. For the abrasive material, ribbon blender is a good choice for you.

Bin blender

AIPAK Bin Blender

Bin blender is the type of blender which makes free fall. It can make the efficient mixing, storing and feeding. It may have different shape and size for your different need for manufacturing. You may find the square, rectangular, cone and different shape of it.

Double cone blender

Double Cone Blender-Sourced:chipandprocessor

Double cone blender is the type of blender which has the two sides with dual cones. And there is also equipped with multi shear deflector plates for the more smooth mixing and higher qualified mixing job.

Octagonal blender

Octagonal Blender-Sourced:anchormark

Octagonal blender is octagonal which is capable of containing large bunch of material. The two sides of it make the stable and strong supporting for the large scale blending work. It requires less space and less efficiency for the comprehensive and total blending work.

8.What Is The Difference Between V Blender Mixer And Other Blender Mixer?

There are so many different types of blender. What is the difference between V blender mixer and other blender mixer?

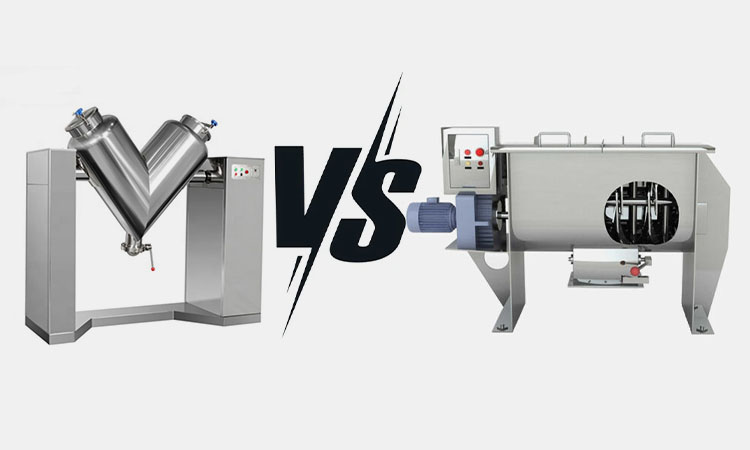

V Blender VS Ribbon Blender

AIPAK V Blender VS Ribbon Blender

| Points | V blender mixer | Ribbon blender |

| Shape | V blender mixer has the “V” shape of two inclined chamber. | Ribbon blender has the “U” shape with a place in it. |

| Material | V blender mixer can handle powder and fragile components. | Ribbon blender can deal with the abrasive solids. |

| Movement | V blender mixer makes the movement between the two chamber. | Ribbon blender has the axial and radial movement. |

| Efficiency | V blender mixer is efficient in dealing with the fragile parts. | Ribbon blender is efficient in dealing with abrasive parts. |

V Blender Mixer VS Double Cone Blender

AIPAK V Blender Mixer VS Double Cone Blender

| Points | V blender mixer | Double cone blender |

| Shape | Two inclined chambers make the “V” shape vessel. | Double cone blender combined two opposing chamber for the big chamber. |

| Discharging method | V blender mixer has the discharging at bottom or pneumatic. | Double cone blender makes the discharge with central outlet. |

| Blending stage | V blender mixer has a single blending stage. | Double cone blender has two blending stage. |

| Agitator design | V blender mixer has single shaft with arm or paddles. | Double cone blender has two separate arms. |

| Material flow | V blender mixer has the flipping flow along V side. | Double cone blender has the flow of two cones. |

| Mixture type | V blender mixer can mix only dry powder and granules. | Double cone blender can mix both dry and wet powder and granules. |

| Mixing ingredients | V blender mixer can mix more then ten types of powder and granules. | Double cone blender can mix only five types of powder and granules. |

| Blending method | V blender mixer mixes with the inclined V chamber. | The blending of double cone blender is in axial direction. |

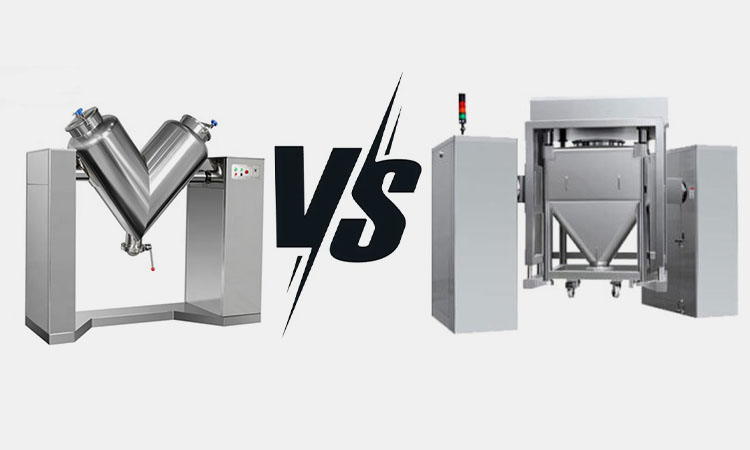

V Blender Mixer VS Bin Blender

AIPAK V Blender Mixer VS Bin Cone Blender

| Points | V blender mixer | Bin blender |

| Shape | V blender mixer restricted its type in “V” shape. | Bin blender is flexible in its shape. And you may find its different shape of square, rectangle and so on. |

| Blending manner | V blender mixer makes the flipping flow blending. | Bin blender makes the unique free fall type. |

| Function | V blender mixer has the more restricted function in blending. | Bin blender makes the function of mixing, storing and feeding. |

| Manufacturing scale | You may apply different V blender mixer type for different manufacturing scale. | Bin blender makes the predetermined manufacturing volume and capacity. |

V Blender Mixer VS Octagonal Blender

AIPAK V Blender Mixer VS Octagonal Blender

| Points | V blender mixer | Octagonal Blender |

| Shape | V blender mixer has the simpler shape compared with octagonal blender. | Octagonal blender has two octagonal cone combined together. |

| Blending speed | V blender mixer is faster and makes the efficient mixing. | Octagonal blender makes the slow and mild blending work. |

| Power consumption | The power consumption of V blender mixer is lower. | Octagonal blender consumes less power compared with V blender mixer. |

| Material feeding | V blender mixer applies labor loading and bin charging system. | Octagonal blender is equipped with big charging system and vacuum charging system. |

9.What You Should Pay Attention To For V Blender Mixer Operation?

What you should pay attention to for V blender mixer operation? Here are some tips for V blender mixer operation.

No-load test

You should make the no-load test before your use of your V blender mixer. In this process, you may have the the various parts like electricity part, connecting part, reducer part and so on checked in no-load test.

Stable operation

Stable Operation-Sourced:marekhavrila

You should make the stable installation of your V blender mixer. The stable installing, leveling and adjusting are the base for the smooth and efficient V blender mixer machine operation work.

Adequate feeding

You should make the adequate feeding of material in your V blender mixer. The feeding of your material should not exceed the volume. The excess material loading makes no benefits for your smooth and efficient blending process.

GMP standard applying

GMP Standard Applying-Sourced:oic

You should apply GMP standard strictly for your products safety and machine operation. It is restricted to mix medical particle of different batches and produce different medicines in the same production line.

Strict cleaning and disinfecting

You should make strict cleaning and disinfecting for your V blender checker. After the manufacturing, it is essential to make the total cleaning and disinfecting for the reliable products producing.

10.How To Improve EfficiencyOf Your V Blender Mixer?

The high efficiency of your V blender mixer is so important for your business. And here are the suggestions for you to improve the efficiency of your V blender mixer.

Loading volume

You should make the restricted loading volume. There are the recommending volume and you should avoid the exceed of 50% or 60% recommending volume. The exceed loading volume may lead the abrasion of machine.

Low mixing speed

Low Mixing Speed-Sourced:penglaichina

You should make sure the low mixing speed for the reduction of more shear. This can reduce the percentage of dust forming and you may have the quality and reliability of your products proved better.

11.How To Make The Great Mixing From Your V Blender Mixer?

How to make the great mixing from your V blender mixer? The great mixing is the most important thing for a reliable V blender mixer.

Avoid overfilling

Overfilling is the terrible issue of V blender mixer. Overfilling may reduce the quality of your powder and granule products. Inadequate blending may lead the machine problem and lead the products insufficient blending and mixing. You should avoid overfilling for your machine safety and products quality.

More space for blending

You should leave more space for your V blender mixer work. The size of your V blender mixer and the available space are two important factor you should consider. The rolling and blending space is important for your machine. When the filling volume exceed 70%, you should care more about your products blending condition.

Great discharging

Great Discharging-Sourced:grandpackmachine

Discharging system makes the reliable discharging of your various products. The electrical control system of it makes the smooth and efficient discharging of your powder and granules.

12.What Are The Useful And Standard V Blender Mixer Maintaining Method?

What are the useful and standard V blender mixer maintaining method. You should follow the below tips for your machine maintaining.

Regular checking and inspecting

Regular Checking And Inspecting-Sourced:abilityfab

You should make the regular checking of your V blender mixer. The cleaning and sanitization are the important factors for your V blender mixer maintaining. The regular checking is thus important for your machine maintaining. It is the most basic road for your machine’s life span.

Lubricants applying

Lubricants Applying-Sourced:imeche

Lubricants for the connecting parts, adhering parts and so on of your machine are important. Suitable lubrication can make your machine more stable and smooth. You should make the comprehensive routine for your machine lubricating work.

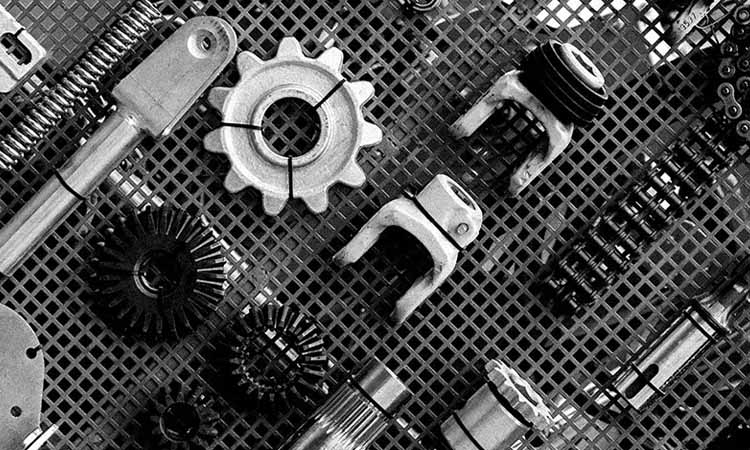

Worn parts replacing

Worn Parts Replacing-Sourced:lyonwaugh

The regular checking for the worn parts is also essential. You should make timely checking and replacing for your machine condition. Here you should also check the condition of various parts of your V blender mixer. The timely replacing of one parts make the wearing rate.

Machine calibration

You should also make sure the alignment and calibration of your V blender mixer of your V blender mixer. It can not only benefit the machine condition but also make the best effect of your machine.

13.How To SelectYour Reliable And Efficient V Blender Mixer?

The reliable an d efficient V blender mixer is the great helper for your business. How to select your reliable and efficient V blender mixer?

Budget

Budget-Sourced:er.educause

Your budget is the most important thing you should consider for your V blender mixer purchase. You should get the machine which suits your budget. There is always the machine with better performance. And the one suits you and your budget is the best.

Machine performance

Machine performance covers machine efficiency, machine manufacturing scale and so on. You should get the machine with the outstanding and adequate performance. The machine with advanced ability will help you a lot in your manufacturing.

Material type

Material Type-Sourced:epma

How about your material and manufacturing scale? There are various machine type for you to choose. And you may select your machine type according to your manufacturing need.

Machine configuration

Machine configuration makes the important affect for your later factory manufacturing work. You should get the adequate configuration according to your production line and material type.

14.How To Troubleshoot V Blender Mixer?

In the V blender mixer operating work, here may exist some problem. How to troubleshoot V blender mixer?

Troubleshooting-Sourced:habilelabs

| Problem | Solution |

| Powder and dust leak | This problem comes from the loose buckle of aging arts. You should fix or replace the relative position. |

| No movement | Sometimes, the powder didn’t make your machine work. You should then increase speed or replace fuse. For the further static condition, you should close protective cover or mount the iron absorption. |

| Abnormal vibration noise | You should make the tight screw of motor and other set of your machine for the reduction of vibration noise. And the adding of foot pad can also avoid the problem. |

| Cylinder falling | Cylinder may fall in operation process. And in this process, you should make the reposition and strict tightening of your screw. |

| Incomplete offloading | For the loading problem, you should make the deep cleaning of discharge vents, valve and other residues besides the discharge part. And you should also level V tank for the discharging angle. |

| Inadequate mixing | For the inadequate mixing, you should add the mixing time and try the different mixing speed to make the most suitable feature for your material. |

| Material buildup | The material buildup can be avoided with the applying of anti-caking agents in powder. You can also make the polishing or deep cleaning of your machine. |

Conclusion

V blender mixer makes so much help for you and your business. The deep knowing about V blender mixer can help you solve the many problem of your machine work. And for any problem and question in your blending business, you should feel no hesitate to contact AIPAK right now.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine