Types Of Tablet Compression Machine

As an important equipment in the pharmaceutical industry, the tablet compression machine can provide you with round, capsule-shaped, animal-shaped, bullet-shaped or any special shape tablet production. But among them, the tooling system of the tablet compression machine plays an important role.

Types Of Tablet Compression Machine-sourced: osdmachinery

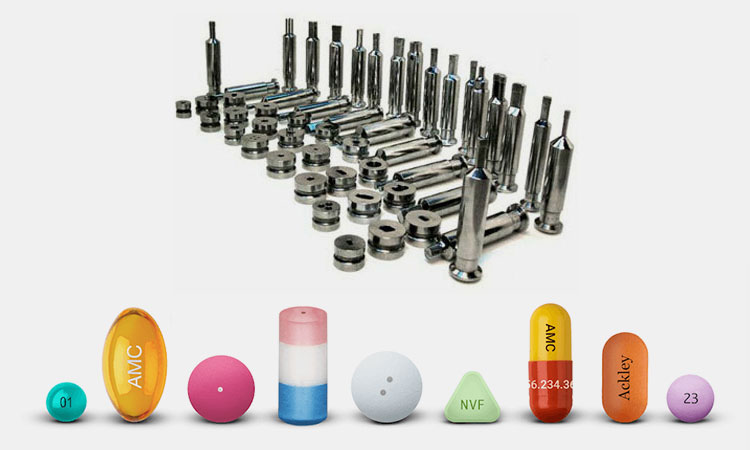

Tablet compression tools (i.e. punches and dies) are important tools for shaping any granules into a solid dosage form by applying compaction forces in a compressor. Before understanding the types of tablet compression machines, it is necessary to understand some basic tools of the tooling system. Let's start with some tool basics!

1.What Are The Various Types Of Tablet Compression Machine?

Tablet Compression Machine-sourced: yindamachinery

The tablet compression machine is a special device that designed for compressing your powder into tablets of uniform size and weight. It is used to manufacture tablets of a variety of materials and is widely used in tablet production in different industries such as pharmaceuticals, nutritional products, cleaning products, and cosmetics.

There comes in two main types of tablet compression machine: single-punch and rotary tablet compression machine:

Single Punch Tablet Compression Machine

AIPAK Single Punch Tablet Compression Machine

The single punch tablet compression machine is an electric continuous tablet press with a pair of punching dies installed on the machine. It can press various granular raw materials into round tablets, sugar tablets, calcium tablets, special-shaped tablets, etc. The machine is more suitable for your laboratory or small batch tablet production.

Rotary Tablet Compression Machine

AIPAK Rotary Tablet Compression Machine

Also known as rotary tablet press, taking the form of a rotating turret, the rotary tablet compression machine has multiple tooling systems for your tablet pressing and manufacturing.

With a stable structure and high-speed tableting speed, the rotary type is suitable for high-volume tablet production. Due to its excellent compatibility, highest level of speed and safety, the rotary tablet compression machine is widely used in pharmaceutical, food and other industries.

2.What Products Can Be Made By Types Tablet Compression Machine?

In addition to tablets and pills, through different types of tablet compression machines, there are more applications in different industries, including bath tablets, bouillon cubes, disinfectant tablets, and softener salt tablets.

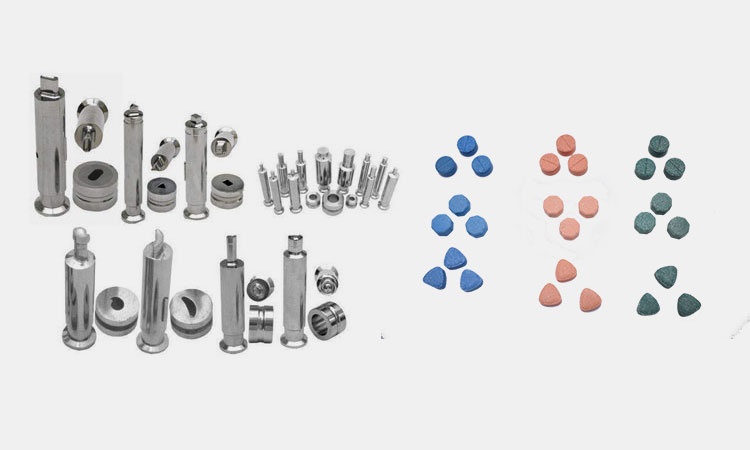

Tablets and Pills

Tablets and Pills-sourced: besttabletpress

The tablet compression machine is mainly applied in pharmaceutical industry for different types and shapes of your tablets manufacturing. It can compress tablets of various shapes of ordinary tablets, special-shaped tablets, ring-shaped tablets, etc. The products include oral pharmaceutical tablets, effervescent tablets, nutritional tablets, etc.

Bath Tablets

Bath Tablets-sourced: honeysticks

All types of tablet compression machines are widely used in bath tablets manufacturing in the daily chemical industry. By adjusting the punches and dies, the machine is able to produce bath tablets and bath bombs of various sizes, shapes and hardness for you.

Bouillon Cubes

Bouillon Cubes-sourced: mustakshif

Various seasoning tablets in the food industry, including bouillon cubes, can be processed and compressed using different types by tablet compression machines. Bouillon cubes processed by the tablet compression machine have a compact structure, are resistant to your storage and transportation, and have a longer shelf life.

Disinfectant Tablets

Disinfectant Tablets-sourced: berkshire

Different types of tablet compression machine also can offer you the safe and effective disinfectant in effervescent tablet form. They can be easily activated by dissolving in water. The disinfectant tablets are perfect replacement for all bleach liquid in all applications.

Softener Salt Tablets

Softener Salt Tablets-sourced: saltoftheearthltd

Hard water contains high levels of calcium and magnesium minerals, so there are softener salt tablets by delivering soft water for your use. The types of tablet compression machine can offer you softener salt tablets with good density and shape.

3.What Is Tooling System In Tablet Compression Machine?

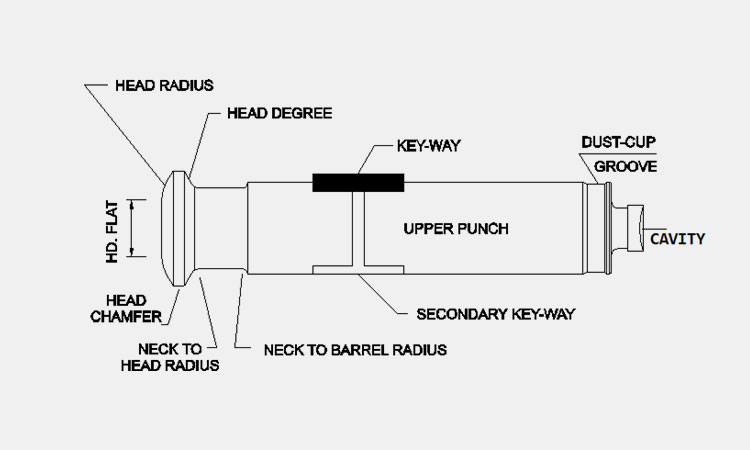

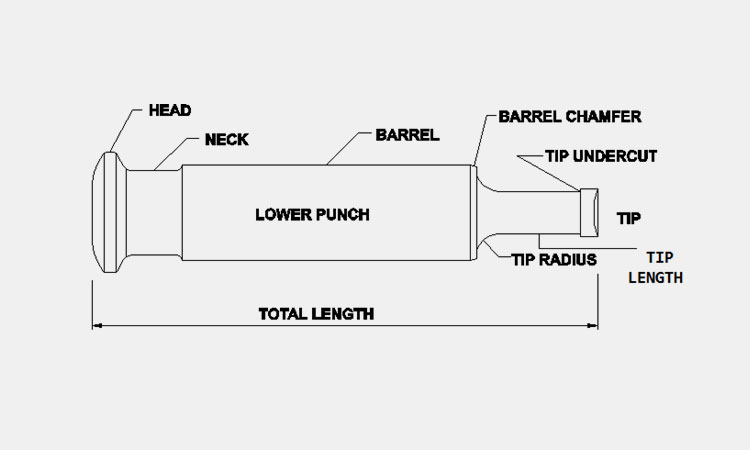

The tooling system of tablet compression machine generally consists of an upper punch, a lower punch and a mold. These punches are moved vertically by cams in the turret bore and compressed to form tablets. They mainly determine the shape, size and quality of tablets.

Upper Punch

Upper Punch-sourced: hvax

In all types of tablet compression machines, the upper punch is generally installed in the turret hole and moves vertically in the hole during the compression process. It generally forms the upper cavity of tablets and is used to align with the die hole in the case of a shape punch.

Lower Punch

Lower Punch-sourced: hvax

The lower punch is also installed in the turret hole and causes the tablet to form a lower cavity during the compression process. The tip of the lower punch always remains in the die hole, and its tip length is relatively long, generally 25-28mm. Because it has to cover the entire height of the mold and eject the tablets.

Molds

Molds-sourced: fuyimachinery

The mold is generally installed on the template of your tablet compression machine. The die holes in the mold are actually where the powder is filled. By means of the up and down vertical movement of the upper and lower punches, the powder in the die hole is compressed into tablets of the desired shape and size.

4.What Are The Different Tooling Systems For Types Of Tablet Compression Machine?

Different Tooling Systems For Types Of Tablet Compression Machine-sourced: hvax

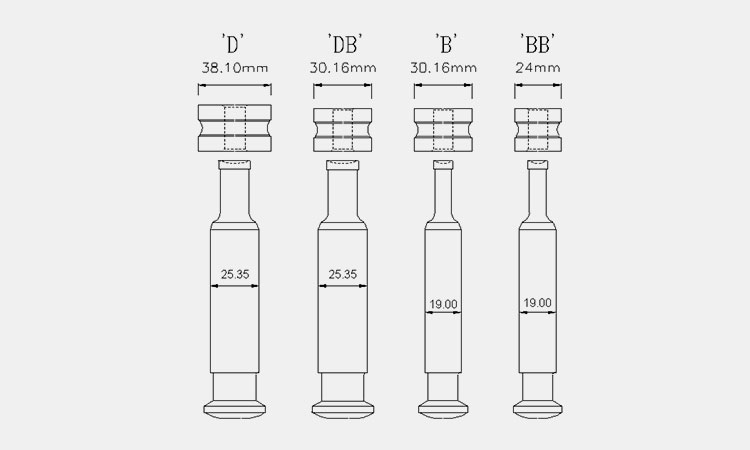

Currently, the tooling systems for all types of tablet compression machines used in tablet manufacturing in the world are mainly divided into type D, type B, type DB, and type BB.

D Tooling

The barrel diameter of the D tooling is 25.4 mm and the mold diameter is 38.10 mm. It is suitable for your tablets with a maximum length or diameter of 25.4 mm. Compared to the B tooling system, the punches and dies of the D usually have larger punch diameters. This makes D type more suitable for large size tablet compression.

DB Tooling

The DB tooling system has a barrel diameter of 0.75 inches, a length of 5.25 inches, a head diameter of 1 inch, and a mold outer diameter of 30.16 mm. When D tooling system is used on the tablet compression machine of class B tooling system, DB tooling system is formed.

B Tooling

The punch diameter of the B tooling system is 30.16 mm (1.1875 inches), suitable for all tablet sizes as well as the largest size of the B punch. Compared with D tooling system, the output of B tooling system will be 20% to 25% higher than D type.

BB Tooling

The smaller BB tooling system has a die diameter of 24 mm (0.945 in). This type of mold is suitable for tablets with a diameter of 9 mm or up to 11 mm.

Classification of tooling system on the basis of there sizes in the table below:

| Tooling Types | Punch Barrel Diameter(mm) | Punch Head Diameter(inch) | Outer Diameter of Die(mm) | Length(inch) |

| D | 25.4mm | 1.25 | 38.10mm | 5.25 |

| B | 19.0mm | 1 | 30.16mm | 5.25 |

| BB | 19.0mm | 1 | 24.00mm | 5.25 |

| DB | 25.4mm | 1 | 30.16mm | 5.25 |

The tooling system for different types of tablet compression machine:

| Single Punch Tablet Compression Machine | Rotary Tablet Compression Machine | |

| Tooling Type | TDP

TDP-sourced: besttabletpress |

RTP

RTP-sourced: tabletpress |

| Application | Only suitable for single-station tablet compression machines; | Suitable for rotary tablet compression machine; |

| Working Length | 42 mm | 115 ±0.02 mm |

| Barrel Diameter | 10 mm | 22 mm |

| Die Diameter | 37 mm | 26 mm |

| Die height | 22 mm | 22 mm |

5.What Are The Suitable Materials Of Tooling System For Types Of Tablet Compression Machine?

The tooling system materials of punches and molds for your tablet compression machine shall conform with CGMP. The most suitable materials for your tooling system is stainless steel. The reasons are:

Wear-resistant

Wear-resistant-sourced: bhagwatipharma

Because of the special way tablet compression machine works, it requires longer and more durable punches and dies. With strong wear resistance, the stainless steel is extremely compressible. This prevents your molds from deforming during continuous compression.

Strong Stability

Strong Stability-sourced: bhagwatipharma

Stainless steel helps maintain the stability of the tablet compression machine mold. Molds made of stainless steel will not wear out for a long time, thus avoiding a series of problems that occur during mass production.

Good Preservative

The raw materials used to produce the tablets are also important, so the tooling system materials used shall be away from contamination of your tablets. Stainless steel is not easily corroded, and punches and molds made with it will not cause material contamination of tablets.

6.Why It Is Important To Standardize The Tooling System For Types Of Tablet Compression Machine?

Calls for merging tooling systems for types of tablet compression machines have become increasingly widespread. To standardize the tooling system is important and can benefit you in the ways of:

Enhance Tooling Interchangeability

Enhance Tooling Interchangeability-sourced: bhagwatipharma

Using unified tablet tooling in different factories and locations can improve compatibility and interchangeability between different tablet compression machines. This standard can greatly improve your production efficiency.

Cost Cutting

Cost Cutting-sourced: omisoft

Using a single tablet tooling may greatly reduce your inventory pressure for different tooling. The requirements may help reduce production costs for manufacturers and customers.

Shortened Delivery Time

Shortened Delivery Time-sourced: justchinait

Rationalized and simplified tablet compression machine tooling can simplify your tooling production steps. This greatly shortens the delivery time of tooling suppliers.

Standardized the Tableting Process

Standardized the Tableting Process-sourced: usvalidation

When tooling is unified, the costs of your standardized tooling production, inspection, packaging, procurement, operation and maintenance will be greatly reduced, and the corresponding standardized inspection process will also be simplified.

Improve Global Cooperation

Improve Global Cooperation-sourced: eliz

When a globally unified tooling system is accepted by tablet press developers, the quality and grade of tooling will be consistent across all pharmaceutical products and plants. This will greatly enhance your technical exchanges, problem solving and development of global tablet compression machines.

7.What Are The Treating And Coating Tooling For Types Of Tablet Compression Machine?

During your tablet manufacturing process from all types of tablet compression machines, there may be some problems such as sticking and picking up. Polishing and coating tooling for the punches are the most common methods.

Diamond Coating

Diamond Coating-sourced:aimspharmaengineering

Applying diamond coatings into punch and die systems can greatly improve the durability of your punch and die systems. This method can greatly reduce the stickiness during your tablet compression. This is more suitable for tablet compression machines for effervescent tablets.

Chrome Electroplating

Chrome Electroplating-sourced:tincoat

Chrome electroplating is available on most standard tablet compression machine. This coating is typically 5 microns. Another technique almost similar to electroplating chrome processing is Physical Vapor Deposition (PVD). This treatment protects your tablet press tooling system from wear and ensures better stability.

Chromium Nitride Coating

Chromium Nitride Coating-sourced:pharmaceuticalmanufacturer

Chromium nitride coating is an extremely hard, inert thin film coating. It is superior to electroplating and has higher temperature resistance, making it ideal for high temperature environments. It is cost-effective and provides enhanced wear protection for your tooling systems.

Aluminum-titanium Nitride or Titanium Nitride Coating

Titanium Nitride Coating-sourced:jaiengineering

Aluminum-titanium nitride or titanium nitride coating is a thin film coating developed from titanium nitride and is known for its smooth surface and high surface hardness. It has higher temperature resistance and slightly higher hardness, especially higher thermal hardness. It is the best choice for most tablet compression machines.

8.What Are The Differences Between EU And TSM Tooling System Standards For Types Of Tablet Compression Machine?

The EU tooling system and TSM tooling system are two different tablet press punch and die specifications for different location application. There are two standard punch and die designs to consider when you plan to invest in new tablet press tooling for all types of tablet compression machine:

| EU Tooling System | TSM Tooling System | |

| Images |

EU-sourced: vortexsg |

TSM-sourced: eliz |

| Explain | l European standard known as the EU or EURONOM standard; | l American standard known as the TSM standard;

l TSM tooling specification is the sole reference on U.S. manufacturing standards for tablets and tablet manufacturing; |

| Establishment | l Established in the industry to provide a structure that protects companies' tooling investments while maintaining established processes and procedures;

l Have not published or governed by an organization or association; |

l Established by the American Pharmacists Association (APhA);

l It is the only published standards for the tablet compression industry; |

| Application Area | l The EU tooling standard is the most common tooling configuration in the Europe; | l The TSM tooling standard is widely applied in the U.S.; |

| Punch Length | l EU standard punch length is 0.01 inches longer than TSM standard; | l The TSM punch has a sloped top profile, whereas in the EU standard it has a domed profile; |

| Head Thickness | l In type "B" tooling system, EU punch internal angle is 30 degree, while TSM punch internal angle is 37 degree; | l In both tooling types "B" and "D", the head thickness in the TSM tooling system is greater than in the EU specification; |

The EU tooling system and TSM tooling system specification guide:

| Tooling Specification | Tooling Size | Working Length | Barrel Diameter | Die Diameter |

| EU | B | (133.6 - f) ±0.01 mm | 19 mm | 30.16 mm |

| D | (133.6 - f) ±0.01 mm | 25.35 mm | 38.1 mm | |

| BB | (133.6 - f) ±0.01 mm | 19 mm | 24 mm | |

| DB | (133.6 - f) ±0.01 mm | 25.35 mm | 30.16 mm | |

| TSM | B | (133.35 - f) ±0.05 mm | 19 mm | 30.16 mm |

| D | (133.35 - f) ±0.05 mm | 25.35 mm | 38.1 mm | |

| BB | (133.35 - f) ±0.05 mm | 19 mm | 24 mm | |

| DB | (133.35 - f) ±0.05 mm | 25.35 mm | 30.16 mm |

Conclusion:

All types of tablet compression machine come with similar or different parts and tooling. However, they all ensure you optimal tableting performance, minimal downtime, operational safety, and provide you the highest levels of tableting uniformity and accuracy. If there are more you want to know, come to us now!

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours