Types Of Powder Mixing Machines In Pharmacy

Powder is an essential element in processing and making of different pharmaceutical products. And granulation or mixing of powder can increase the processing rate as well as dosage effect.

You may have been facing problems during the selection of pharmaceutical powder mixing machine for your business or personal usage.

Do not lose hope! In this post I will explain about different types of powder mixing machines for pharmacy along with their uses, features and working ability etc.

Table of Contents

Ⅰ.Explain different types of powder mixing machines for pharmaceutical industry?

Many sorts of powder mixing machines are there for pharmaceutical industry which can give you great working ability and capacity depending upon their type.

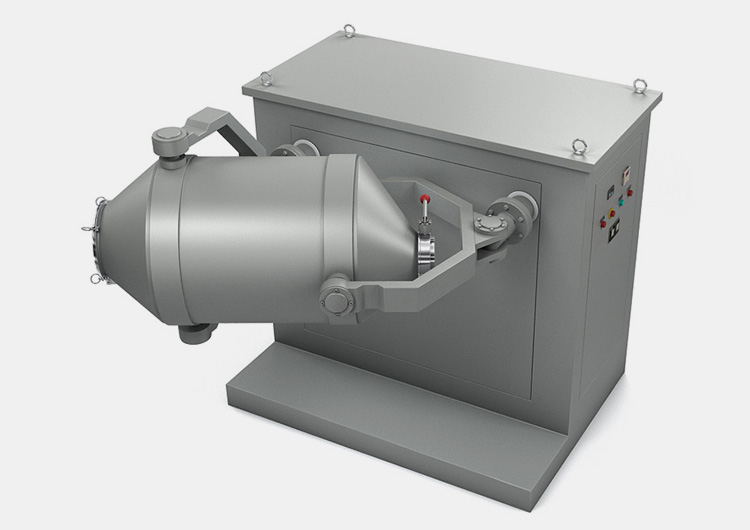

Cone type Powder Mixing Machine

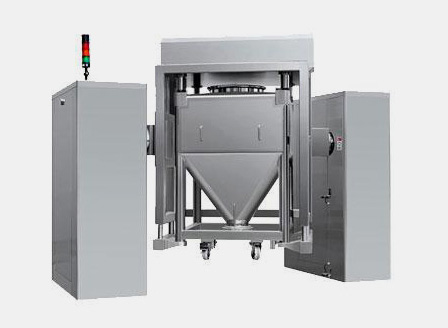

Aipak Powder Mixing Machine

Cone type powder mixing machine is a versatile equipment used for homogenous mixing of powder or granule elements in pharmaceutical industry with great efficiency.

Usually, V-type & other cone shape powder mixing machines come in this category.

Working Operation

Basically, a cone machine may have a single or double mixing cones on it that contain mixing material but there working is somehow same.

Cone powder mixing machine mix the material by making rotation in one way or two-ways depending upon his feature.

It can make a single rotation cycle in less than 5 minutes which contain multiple rotations to intermix the different materials.

Benefits

Cone powder mixing machine can give you some following benefits during mixing.

- Optimum working ability for homogenous mixing

- 70% to 80% homogeneity in mixing material

- SLANT design to overcome dead mixing spots

- Easy discharging capability without sticking

Horizontal Powder Mixing Machine

AIPAK WLDH Horizontal Powder Mixing Machine

Horizontal powder mixing machine is used for even mixing of dry or wet powder in pharmacy by making its movement in horizontal way.

Working Operation

This mixing machine uses an agitator or handle for mixing two or more powdery items inside a mixing tank.

On a horizontal shaft there are mixing arcs inside the mixing tank which agitates the material to make it homogenous & even in every manner.

Agitator or handler outside on the bowl is used for tilting the bowl for discharging purpose when the content is mixed in fine quality.

Benefits

Horizontal powder mixing machine can give you some following mixing benefits.

- Comfortable for dry & wet mixing of powder

- Great volume & sheer sizing for large quantity mixing

- Time saving with great capability

3D Powder Mixing Machine

AIPAK 3D SWH powder mixing machine

3D powder mixing machine is a uniquely designed machine used for uniform mixing of dry powder and granules.

Its continuous and even mixing ability make it more appropriate and demanding as compared to other mixing machines.

Working Operation

3D mixing machine contains a large size bowl for mixing which moves in three different dimensions for high quality mixing.

A spindle having metal jaws on it holds the mixing bowl and controls the movement of the mixing bowl.

It can make the movement in three different dimensions so every single particle is mixed well and gives you the fine quality mixed powder without facing any flaws.

Benefits

3D powder mixing machine can facilitate you with some of the following mixing abilities.

- More precise & uniform mixing with ease

- It is quick & more automatic in mixing different raw elements

- Easy cleaning of mixing bowl with removable ability

- Gentle & efficient mixing without any contamination risk

Ⅱ.Explain which industries use powder mixing machine?

As the main purpose and usage of a powder mixing machine takes place in pharmaceutical industry but there are some other powder processing industries in which this machine is verily involved in multiple ways.

Pharmaceutical Industry

Pharmaceutical industry always comes on top when you talk about powder processing because there are multiple equipment’s that are used in powder processing and powder mixing machine is one of them.

As you know drug is a combination of different particles mixed well in the form of powder to prepare a single authentic & powerful dosage.

Different kinds of tablets material or capsule filling material as well as other powder drug is mixed with the use of powder mixing machine.

Chemical Industry

When you require mixing of different powder chemicals to make a single dose then powder mixing machine is important.

In chemical industry some solid products in the form of powder and granules also require mixing where powder mixing machine is vitally used.

Cosmetics & Beauty Industry

Different beauty items that we often use in our daily life such as face powder etc are all made with the combination of different raw materials when mixed together.

So, powder mixing machine is useful in cosmetic and beauty industry for mixing different vitamins etc to make a cosmetic item.

Detergents Industry

Cleaning items of different types are also prepared in the form of powder with the use of powder mixing machine such as cloth cleaning detergents & dish washing detergents they often come in wet powder form or dry granules.

Ⅲ.Why mixing of powder is important in pharmacy industry?

Mixing is an important step in processing a drug when you are dealing in pharmaceutical industry because to make the content uniform whether it is powder or granule.

Sometimes, you make drug out of different powder elements and mix them well is necessarily an important factor to make the medication proper with the combination of different elements.

During the mixing the irregular sized particles when mixed well will also change their shape and after the mixing you can easily fill mixed powder in multiple pharmaceutical items like capsules, bottle etc.

Mixing will make your powder dosage superior & in this regard you can get high quality powder with greater effectiveness.

Combination of different types of powders in large quantity is not that easy to mix, therefore, a well-structured & designed pharmaceutical powder mixing machine can help you to perform your mixing operation easily.

Ⅳ.How to select a powder mixing machine?

While selecting with a pharmaceutical powder mixing machine you need to understand some of the following four key points.

Machine Size & Design

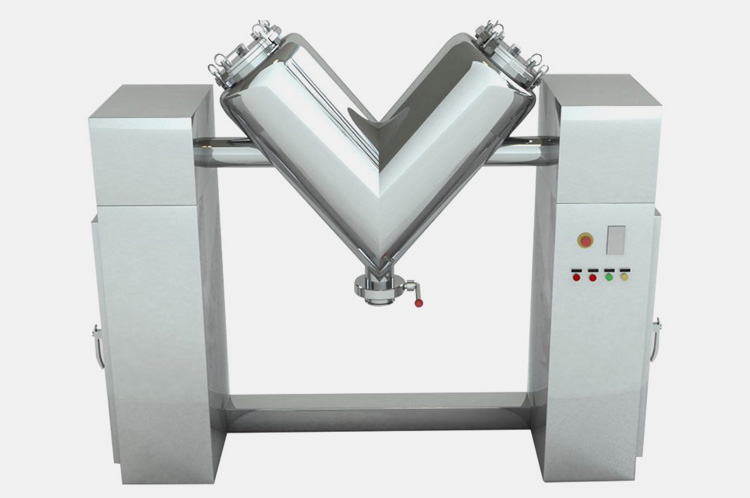

Aipak V-type cone mixing machine

It is important to know what size of mixing machine is available for your production process because sometimes you may face area fitting problem while installing the mixer.

As explained above there are multiple shape & design pharmaceutical powder mixing machines that you can get, always select the design that fits best for your requirements.

Automation & Production Speed

To make sure you get the right product after the mixing you have to check the automation level of your powder mixer that will decide how your machine going to proceed in the future during mixing.

A fully automatic powder mixing machine can give you great benefits although it is expensive as well as compared to semi-automatic and manual powder mixer.

Greater the automation level of your powder mixer greater will be the mixing rate vice versa because mixing takes time it is a continuous process that is why fully automatic machine is suitable.

You simply check RPM (Round per Minute) speed of the mixing tank until the final output and in this way you can get production speed test.

Certification & Customization

It is vital to check the certification level of your powder mixing machine this way you can decide if the machine is made through best practices & quality element is used during its manufacturing.

After checking the certificates & other standard points you also need to check if the powder mixer can be customized easily through control system as most of these machines have PLC visual screen panel for comfortable & friendly customization during mixing.

Cost

Cost and expense of a mixing machine also plays an important role when you are purchasing a right type of machine for powder processing.

Mostly, the buyers made a range about cost while selecting a powder mixing machine for pharmacy in which they simply decide affordable money that they can invest.

So, you also need to set your cost or expense range while doing the purchasing of a powder mixer.

Conclusion

Powder mixing machine in pharmaceutical industry and in other industries becoming popular & productive you might made up your mind to buy one for yourself. Deep inside your mind there might be a question that will irritate you e.g What are the types of powder mixing machines for pharmacy and how can get information about them. Well, take a breath AIPAK is your pharmaceutical solution partner and always there to help you achieve your required product with proper guidance & information. We are comfortable to provide you every kind of information. REACH US.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours