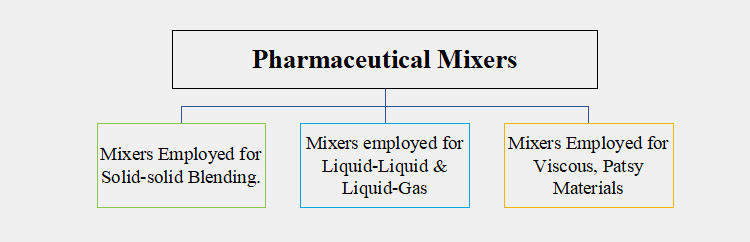

Types Of Pharmaceutical Mixer

Thinking about a mixer can bring a mouth-watering treat to everyone’s mind. Cakes, Smoothies, Pasty Products, Pizza dough, Cheese- All thanks to mixers and blenders.

Mixing plays a significant role in combining raw ingredients employed for foods, pharmaceuticals, general, and healthcare preparations. For this, choosing the right mixer is of prime importance.

Before starting the topic, you must know the difference between blenders and mixers. Both of them have the same roles then what is the difference?

Technically, there is a slight difference between mixing and blending in the pharmaceutical industry. The term mixing or mixer is often used to combine dissimilar products. For instance, mixing of cement and coal ash. However, blending is a somewhat gentle procedure as compared to mixing. It is generally the mixing of solid-solid material or mixing of bulk solid using a small ratio of liquid.

Seems interesting?

Today, you’re going to learn much more!

We are here to discuss this extensive topic in a simpler way that you’ll appreciate our knowledge.

Table of Contents

Ⅰ.What are the types of pharmaceutical mixers?

You always require mixers after granulation in the production section of pharmaceuticals. Once you get fine granules, various ingredients are to be mixed using mixers for processing. Mixer can help to incorporate the smooth properties of granules.

Pharmaceutical mixing is an essential but critical process. Because the overall quality of the finished product and its attributes are based on the quality of mixing. Poor mixing results in a heterogenous product (non-uniform) that lacks:

- consistency,

- colors mixing

- smooth texture

- content uniformity.

However, ever-increasing, and day-by-day advancement on one side improves the quality of manufacturing products but on the other side, it is increasing complexity to select the correct mixers for industrial applications. Therefore, the right choice of mixer and blender is of prime importance.

According to mixing equipment, they are classified into three broad categories.

1.Mixers Employed for Solid-Solid Blending

Mixers for solid-solid blending are used for homogenizing dry particles and granules frequently used in pharmaceutical, food, chemical, and healthcare sectors. Mixers for solid liquid improve the quality of the mixture by preventing the formation of dust, solvent emission, and caking. As we mentioned earlier these types of processes where mixing of solid and liquid takes place are called blending.

AIPAK Bin Blender

2.Mixers employed for Liquid-Liquid, Liquid-Gas

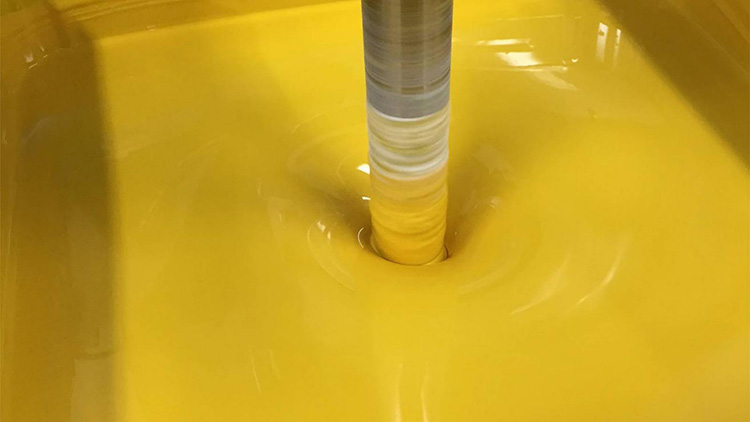

Liquid-liquid mixers are used for a variety of processes, such as blending the miscible liquids, dispersion of immiscible liquids, transferring heat in agitated liquid. All these procedures are frequently applied in formulating the pharmaceutical, food, and health sector products. Such procedures are carried out using rotating impellers.

Later in this blog, we will discuss more types of liquid-liquid and liquid-gas mixers.

3.Mixers Employed for Viscous, Patsy Materials

The mixing regime is different for different materials. You can use grind to chop the onion, neither a chopper can grind the hard nuts. Similarly, for highly viscous material mixing regime is different. For such mixers, turbulence dominates in which viscous drag forces dominate. Furthermore, some material exhibits a non-Newtonian behavior (flow properties are not described by a single continual value of viscosity). Such material requires a special mixing known as heavy-duty mixers.

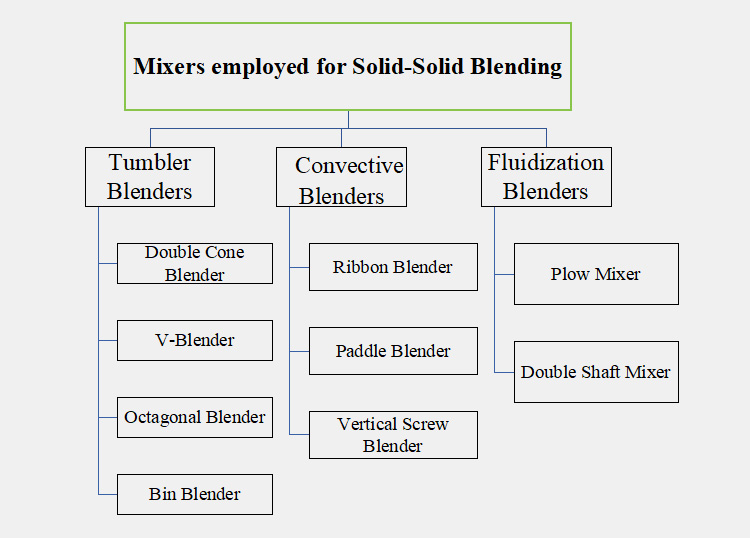

II.What is the classification of mixers employed for solid-solid blending?

A simplified table for solid-solid mixers

Considering huge applications of mixers at an industrial platform that requires blenders for bulk solids. Pharmaceutical engineering technologies have offered a wide range of blenders.

Depending upon the application, nature of the material, and mechanism of mixing, we have sub-classified blenders into the following:

1.Tumbler Blenders

Tumbler blender is equipped with double-cone or V-shaped rotatory vessels. The speed of the tumbler blender varies from 5 to 25 RPM. It is based on the diffusion mechanism of mixing in which particles are entirely distributed over the newly exposed surfaces as the rotatory vessel rotates. The batch continuously being segregated and recombined.

Benefits

- Tumbler blenders are used for mixing dense, fragile, and abrasive solids.

- The geometry of the tumbler mixer allows rapid and complete discharge of blending materials.

Limitation

- This blender is not so versatile to deal with sticky solid or pasty materials.

Types of Tumbler Blenders

The types of tumbler blenders are as followed:

Double Cone Blender

A double cone blender is a versatile equipment for the mixing of dry powders and granules. The entire structure of the double cone blender is made up of stainless steel while the effective volume for required homogeneity ranges between 35-70% of the total volume.

The double cone blender is alterative for products that require careful tumbling rather than stirring.

AIPAK Double Cone Blender

Benefits

This equipment is suitable for treating gentle, low energy tumbling action. Hence, this is ideal for dealing with sensitive, delicate, and fragile products as well as you can use them for mixing heavy and abrasive products.

Application

Mixing of flour, protein powders, baby food, pharma-granules, creams, soap flakes, fertilizers, etc.,

V- Blender

AIPAK V-Blender

The V-blender is designed in a way to manage the dry blending of free-flowing substances. The substances being blended in these units have various bulk densities. As the shell rotates the material is segregated and intermixed together. A normal run time has a range of 15 minutes. But it can be less which depends upon the type of blending material.

Benefits

As a V-shape mixer rotates, it produces a high shear mixing without attrition and excessive fines that result in a short blending time. V-blender is only ideal for dry mixers and does not have packing glands or seals around the shafts hence eliminating the chances of cross-contamination.

Application

V-blender is commonly applicable in healthcare, pharmaceuticals, cosmetics, colorants, and the plastic industry.

Octagonal Blender

AIPAK Octagonal Blender

An octagonal blender can mix a large volume of ingredients due to its octagonal shape. As compared to V-blender, and double cone blender, an octagonal blender occupies a lesser volume. Due to high capacity and low mixing speed, an octagonal blender gives the best results for treating granules.

This machine is suitable for the mixing and lubrication procedure of dry granules and powders. This is a completely closed system hence safe for charging and discharging powders and granules.

Benefits

Octagonal Blender is a less-energy consuming, compact, and low-speed operating system. This system is well-balanced even at very high capacities. It is ideal for the gentle blending of dry powders.

Application

It can be utilized for bulk production in pharmaceutical, foods and cosmetic products, etc.,

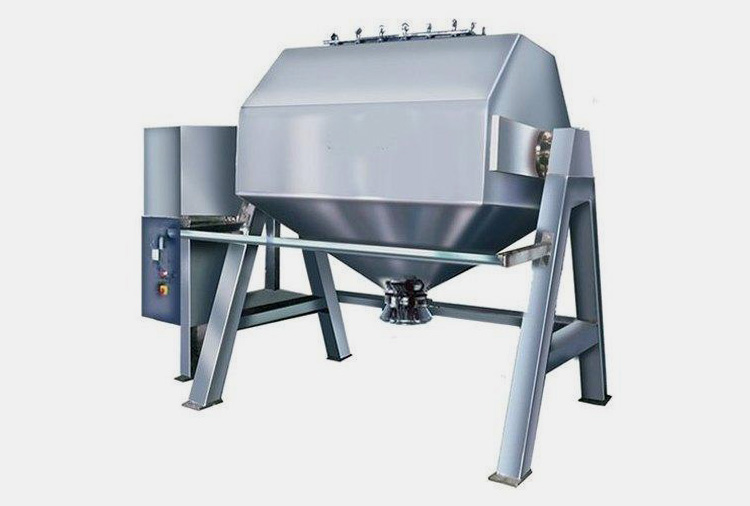

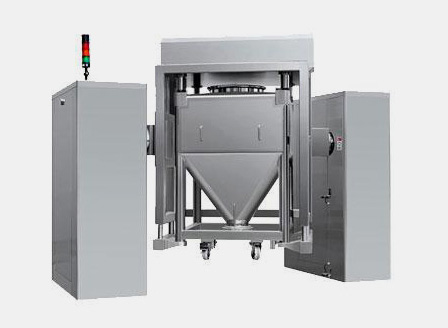

Bin Blender

AIPAK Bin Blender

A bin blender is a special form designed as a free-fall blender. You can use a bin blender wherever a fixed clamped blending container is required. The design of the bin blender can be customized according to specific use and production capacity. Bin blender is widespread in process industries for encountering bulk mixing.

Benefits

Bin blender is simple equipment for high mixing uniformity. It reduces blending time and does not require batch cleans-ups. Furthermore, bin blenders also reduce the risk of developing product segregation, air-borne, and cross-contamination.

Application

Bin blenders are used in the pharmaceutical, food, and chemical industry.

2.Convective Blenders

A convection mixer consists of a vertical or horizontal shell or a container that holds powders to circulate a rotating blade, paddle, or screw. This mixing follows a diffusive, and shear mechanism.

Types of Convective Blenders

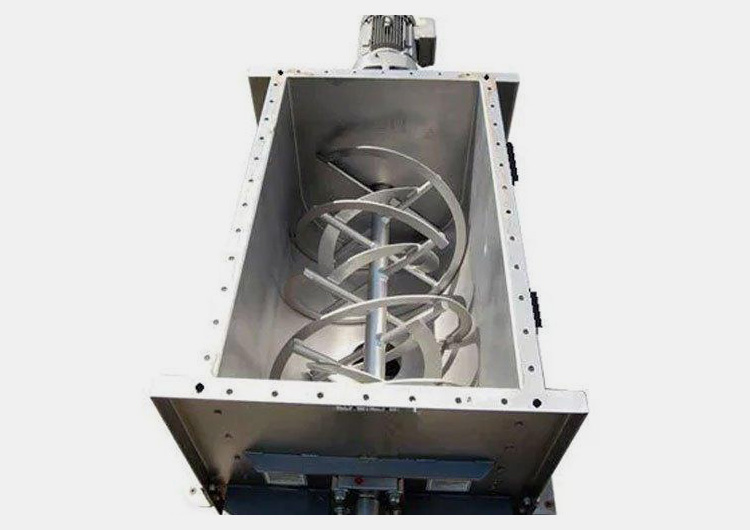

Ribbon Blender

A ribbon blender as its names sounds resembles a long strip of ribbons. Ribbon blenders are designed and created to be twisted metal ribbons ideal for eliminating lumps during production. They are mostly preferred for mixing solids and light pastes. Some ribbon mixers use shear movement that facilitates easy blending.

Benefits

A ribbon mixer is an effective machine that gives efficient and smooth results at the end of the procedure. The presence of sealing protects the ribbon mixer from the leakage of the material from the mixer that’s why ribbon blender is also considered as one of the cost-economical ways of blending.

Application

Ribbon blender is truly a most versatile and commonly used equipment for mixing the dry solid in various process industries ranging from general to large pharmaceutical production, agrochemicals, polymer, etc.,

Paddle Blender

A paddle blender is exactly what it sounds like. A mixing paddle is a device typically mounted over a shaft and can also be inserted on the shaft end into a motorized drive for mixing liquid, solid, or both. Paddle blenders are believed to very easier to clean and maintain.

People love the mixer due to its simplicity and cost-efficiency. Various speed ranges are available for paddle blenders as it ranges from 20 to 200RPM.

Benefits

A paddle blender is the most efficient and universal equipment when it comes to blending time. It can mix/blend the entire dry batch in a fraction of minutes. To deal with ingredients like plasters, gypsum, paints require rapid mixing, and a paddle blender is ideal for them.

Application

Paddle blenders are commonly used for starch, pastes, paints, pharmaceutical, and the cosmetics industry.

Vertical Screw Blender

A vertical screw blender consists of a conical-shaped device with a screw agitator which rotates around a fixed axis while orbiting around the vessel’s periphery as well. The drive system of a vertical screw is composed of two motors; one of which is meant for rotation of the main drive, while the other one is for the rotation of the screw.

Benefits

You can get better work efficiency when acquiring a vertical blender rather than a ribbon blender. This is because the gentle and slow speed of a vertical screw blender enables the safe blending of friable, and heat-sensitive products.

Application

A vertical screw blender is commonly used in chemical, food processing, colorant, paint, cement, cosmetics, detergents, agriculture, and the pharmaceutical industry.

3.Fluidization Blender/Mixer

A fluidization mixer is the fastest mixer with gentle action among all mixers. It improves batch uniformity and overcomes the chances of degradation when blending liquid with dry ingredients is required.

Types of Fluidization Blender/Mixer

Plow Mixer

The plow mixer works by the principle of mechanical fluidization. A unique shape, rotation, and dimensional movement allow different particles to be mixed and dispersed. Plow mixers generate a high-mixing accuracy despite different particle sizes and weights.

A plow mixer can be applied for several processes, such as compounding, fine mixing, suspension, emulsification, deaeration, granulation, and breaking of agglomerates.

Benefits

Plow mixer offers short time mixing and excellent productivity for each batch. Plow mixers are designed for blending heavy-duty ingredients. This machine produces high turbulence with high speed. The fast choppers can break caking material easily, i.e. powdery lumps.

Application

The plow machine is suitable for food processing, cosmetics, types of cement, pharmaceuticals, and sugar mills.

Double Shaft Mixer (Forberg Mixer)

Powder and particles to be granulated are independent of sizes and shapes when subjected to a twin shaft mixer. A twin paddle mixer is also known as a Forberg mixer. As the name shows, it is composed of twin counter-rotating shafts with fused paddles.

This equipment is ideal to obtain mixing for the shortest possible time. The twin shaft paddle batch mixer forms fluidization in which components are efficient blend into an accurate and precise homogenous mixture.

Benefits

Double paddle mixers are ideal for efficient mixing in a shorter time such as mixing times ranging from 10 seconds to 1 minute. A stainless-steel mixer protects the valuable ingredients and causes no heat production.

Application

Food industry (dairy powder, bakery items, coffee), feed industry (animal, aqua, and pet food), nutraceutical products, Chemical industry (detergents, color pigment, fertilizers, explosive, etc).

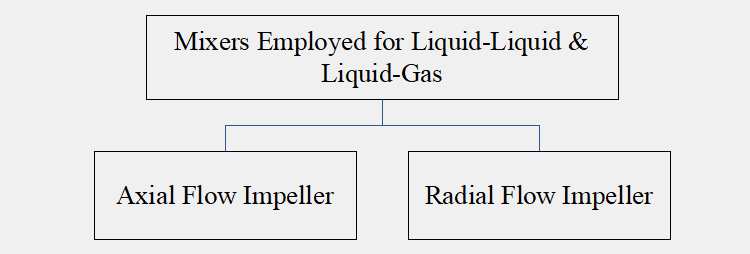

III.What is the classification of mixers employed for liquid-liquid & liquid-gas?

In washing machines, you must have observed the agitation movement. Like in the centre, an agitating blade is present which is remained static, but it agitates and circulates the water present in it.

In pharmaceutical, and food processing industries such type agitators are in high demand. The impellers hooked to the central shaft cause rotation of liquid cause agitation of liquids. Keep in mind, you can’t use them for mixing high viscous materials.

Types of Liquid-Liquid & Liquid- Gas Mixers

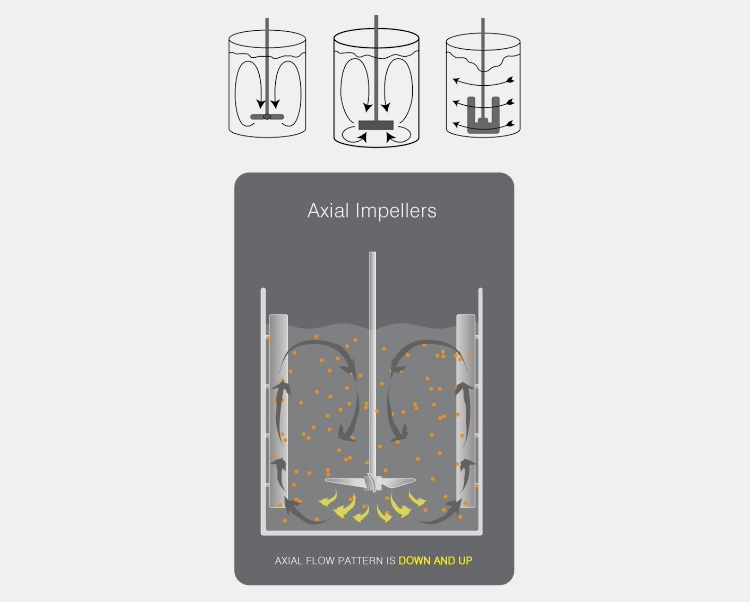

These types of mixing are categorized into two types- axial and radial.

Axial Flow Impellers

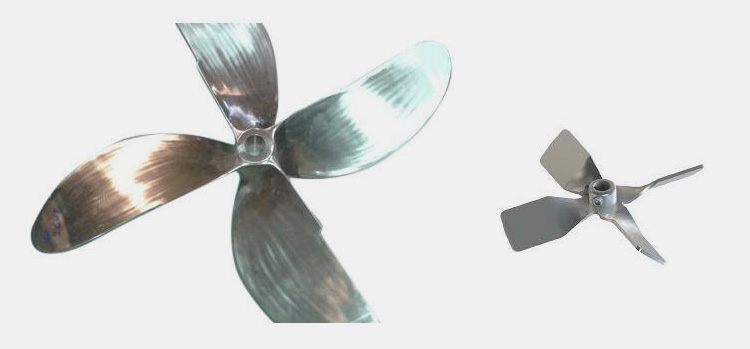

The impeller blades work by making an angle less than 90° with a plane rotation. Due to this, a locus of flow forms along with the axis or parallel to the shaft of the impeller.

For example, Marine Propellers or Pitched Blade Turbine.

Marine Propellers and Pitched Blade Turbine

Benefits

Axial flow impellers provide laminar flow in low energy demand. These are important for mixing solid-liquid suspension as they protect and prevent the solid particles to settle at the bottom of the tank. Moreover, this is a cost-economical and simple procedure that gives you a superb pumping rate under low shear conditions.

An Illustration of Axial Flow Pattern

Application

In pharmaceuticals (preparing biphasic preparation), food industry, and chemical industry

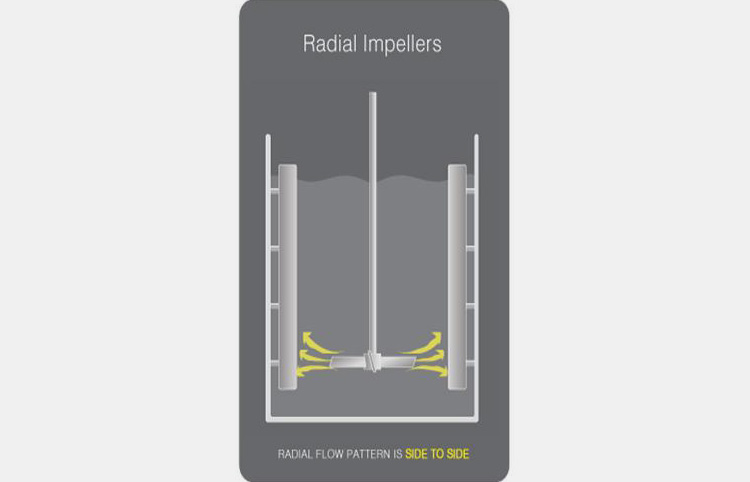

Radial Flow Impeller

In radial flow impeller, the impeller blade is parallel to the axis. Due to this, the radial flow impeller releases the flow with impeller radius in a distinctive manner.

For example Flat Blade Turbine, Paddle, And Anchor.

Flat Blade Turbine, Paddle Agitator Blade, & Anchor Agitator

An Illustration of Radial Flow Pattern

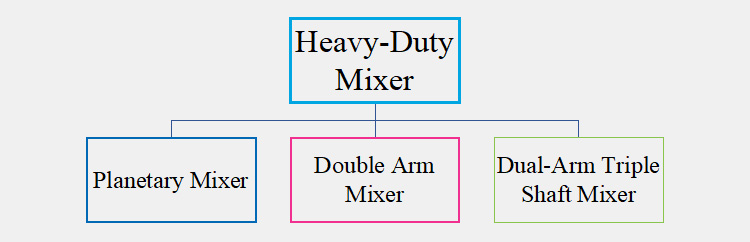

IV.What is the classification of heavy-duty mixers?

Imagine a single shaft mix encountering a thick heavy paste. Of course, it will generate extra load on the machine. Despite giving efficient mixing, it will cause the mixing apparatus to buckle and fail to get significant output.

Thankfully heavy-duty mixers like planetary mixers, double arm, and multi-shaft mixers offer you excellent mixing for highly viscous material ranges of more than 750,000 centipoises.

Types of Heavy-Duty Mixers

Planetary Mixer

A more versatile mixer is often referred for ‘All-Purpose Mixing’. They help you to turn highly viscous and pasty material into a fine homogenized form. A multi-purpose equipment best fit for pharmaceutical industries. Their attachment moves in a planetary fashion and gives you actions like whipping and mixing.

It is consisted of a stationary bowl, a base that holds the mixing materials, and beaters rotate at the top hence resulting in a homogenous mixture.

Planetary Mixer

Benefits

A planetary mixer can handle all difficult materials to give an amazing mix. It reduces operating hands and controls the mixing time. Hence excellent mixing and cost-economical machine enable modulate mixing patterns.

Application

Planetary mixers are an acceptable tool for competitive pharmaceutical and healthcare industries for manufacturing potent formulations in a bulk quantity. Additionally, they are also preferred in the food processing, cosmetic industry (creams, motion, shampoos, etc), and relevant fields.

Double Arm Mixer

Double arm mixers are robust, and heavy-duty mixers specially designed for high production and highly viscous ingredients of 1,000,000 to 10,000,000 centipoises, and beyond.

The machine is composed of a ‘U’ trough bowl and two ‘Z’ shaped tangential blades with a high-speed disperser. Each blade rotates in an opposite direction and gives a uniform mixing.

Double Arm Mixer

Benefits

A twin arm mixer generates a higher volume mixing of pasty and viscous products with continuous and high speed. This machine has a better cleanability rate, lower capital cost, and labor-saving properties.

Application

A double arm mixer has huge applications and is generally used for the pharmaceutical industry, food, and bakery, soaps, creams, chewing gums, rubber, paint, chocolates, wood, road coating, and much more.

Dual and Triple Shaft Mixer

It is used nearly in every processing industry. A dual and trip shaft mixer is available in a variety of configuration that depends upon the characteristic of the batch. This machine has the capability to accommodate a flexible series of shear input for various viscosities up to several hundred thousand centipoises.

The mixer is designed with two or more independent-driven agitators that work in tandem to ensure a fine solid dispersion as well as assures uniform heating.

Dual and Triple Shaft Mixer

Benefits

A powerful multi-shaft mixer with counter-rotating shafts releases fast mixing action and rapid delivery of mixed ingredients. This system is a closed unit that offers benefits in vacuum mixing universally acceptable for viscosities up to 2,000,000 mPas.

Dual and Triple Shaft Mixer

Application

This mixer is an ideal choice for challenging materials. The prime applications of dual and triple shaft mixer include Pharmaceuticals, Plastic, Printing, Paint, Adhesives, Creams, Foods, Coating industry, etc.,

Conclusion

Knowing proper knowledge about each type of mixing equipment leads you to the best options.

There are uncountable types of industrial mixers and manufacturers that you can choose for mixing applications. AIPAK is a leading company designing and manufacturing a broad range of industrial mixers and blenders with high mixing technologies.

For inquiry about the type of best fit mixer for your application, don’t hesitate to contact us Right Now.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours