Types Of Pharmaceutical Manufacturing Equipment

Globally, China is having the best pharmaceutical manufacturers in the world and they are at the top of the list in terms of export ration providing multiple pharmaceutical machines with less cost.

To find the best pharmaceutical manufacturer from china has become very easy. Anyhow, pharmaceutical machines become decisive in your business development that is the reason you need to look for proper pharma machinery manufacturer from China with quality product and services.

This step by step guide will lead you to the best pharmaceutical machinery manufacturer from China with satisfied machines within low price range.

Table of Contents

Ⅰ.What are the different types of pharmaceutical manufacturing machines?

Solid Medicine Manufacturing Equipment

Many sorts of hard medicine production machines are available to work with hard medication such as tablets, hard & soft capsules, suppository and medical film making.

Tablet press machine

AIPAK Tablet Press Equipment

Tablet press machine is a technical equipment derived equipment to make hard tablets by utilizing powder or granule in the form of medicine.

Despite having its multiple types with different working principles the main purpose of this machine is to deliver constant hard tablets through compression.

Mainly, tablet making machine is used in pharmaceutical industry to produce numerous sorts of tablets and pellets.

Production of different tablets

Not only that, in several other industries tablet making machine is becoming popular such as food, chemical and pharmaceutical. Some of the applications of the machine are defined below.

- Useful in pharmaceutical industry for manufacturing multiple drugs.

- It is also used in food industry to make chewable products and many more.

- Useful for making acid based tablets called effervescent tablets.

- It is very effective to produce uniform size and weight tablets without any contamination

Hard Capsule filling machine

NJP AIPAK Hard Capsule filling equipment

Basically, two kinds of capsule filling machines are used in the modern industry. One is called soft capsule filler and the other one is hard capsule filler.

Capsule filling machine is a multi-station encapsulation machine designed to fill hard capsules with granules or powder dosage with the flexibility to work with multiple size capsules.

The main purpose of this machine is to overcome the large capsule filling production without losing major dosage amount to get accurate filling with uniform medication quantity.

Capsule filler is one of the widely used equipment in pharmaceutical industry as well as in food industry provides variety of filling material flexibility because of its modern design with reliable working ability.

Capsule shells

These are some of the uses capsule filling machine.

- Active ingredients filling in the form of powder or granules.

- Contamination free production.

- Liquid & semi-liquid filling can also be done.

Capsule Polishing Machine

AIPAK capsule polishing machine

Capsule polisher is a strong and uniquely designed equipment to work with capsules cleaning. If there is any particle from the outside get in contact with the capsule body then capsule polishing line will clean the outer body surface.

It is very useful to make the outer surface smooth and give a glow to your product. It can provide you the flexibility to work with different size capsules, also easy to fix different parts of it.

Crusher Machine

AIPAK crushing machine

A crusher machine is simply used to crush multiple solid products into powder. You can also crush different vegetables and fruits with the help of crusher machine.

It is widely used in pharmaceutical industry to make different dosages by crushing multiple nutrients, proteins, calcium etc.

A crusher can be utilized in food production as well for example making of different spices and other products that require crushing.

AIPAK offers multiple crushing machines that can help you to work with different solid products. Here are some of the uses of crusher machine.

Swing crusher

- Useful to produce powder form of medication

- Useful in food production

- Useful in crushing different chemicals

Sifter Machine

AIPAK ZS-series pharmaceutical screening machine

A sifter machine works in the same way as the crusher machine but it is used to grand different items into low viscosity powder form for instance wheat grinding is also done with the modern technological sifter machine.

For trade purpose different sorts of products require screening and grinding so these sifter machines can help you to achieve this sort of production.

There are some following sifter machine applications and uses.

- Screening of different food products

- Production of pharmaceutical products

- Chemical and electronic products screening/grinding

Bin Blender

AIPAK bin blender

Bin blender or V blender is usually design and developed to blend large quantity medication. A technically powerful equipment used to variably blend multiple products.

Most of the tablet and capsule medication in the form of powder or granules obtained through the bin blender because of its blending opacity.

Bin blender is not only versatile in pharmaceutical industry it is also very productive for different industries.

- Useful in blending food products

- Granule and powder mixing in pharmaceutical industry

- Useful in laboratory for granule mixing

- Useful in beverage and chemical industry

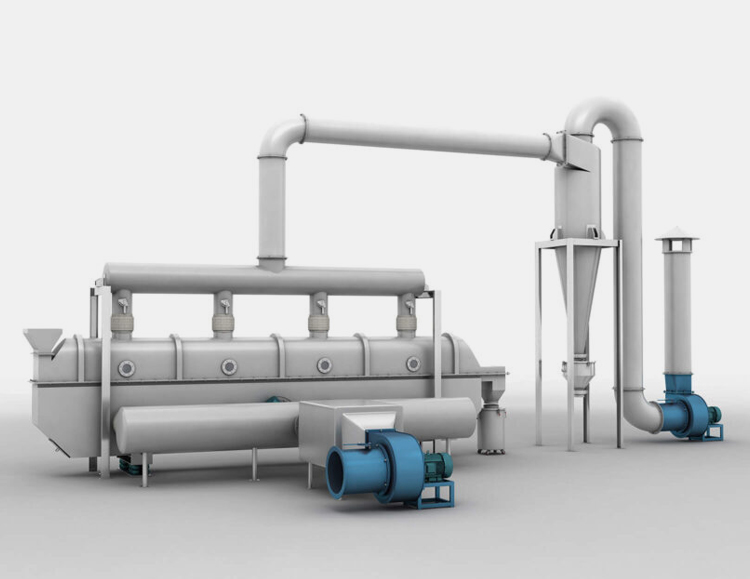

Dryer Machine

AIPAK Pharmaceutical dryer

Dryer machine is one of the pharmaceutical equipment used to dry different sorts of medical products for example wet powder drying, wet granules drying,

During the drying process a customer sets the value of hot air steam that will go through your wet material and remove every kind of moisture from it.

It is very effective to diffuse moisture from wet materials to make your product dry and contamination free.

Fluid bed dryer

These are the uses of dryer machine that are followed.

- Drying food items to give them longer life

- Useful in paper production industry

- Useful in printing industry

- Dry paint production

Granulator Machine

AIPAK high shear granulator machine

A medical granulation machine is used to obtain granules from a dry solid material in a greater efficiency rate. In other words it gives better quality production by adjusting the granulation size in a sequence of stream.

Basically, there are two main granulation kinds, wet granulation and dry granulation. In dry granulation your product will mixed and then blend in the form of granules.

In wet granulation moisture granulation takes place in the early stages then granules were made while mixing different ingredients.

Granules

There are some following applications of granulator machine.

- Useful in food industry

- Useful in cosmetic and beauty field

- Useful in different feeding units

- Useful in ceramic industry

Tablet Coating Machine

AIPAK tablet coating machine

A mechanical equipment to cover the outer surface of a tablet with a thin layer of coating to make it more effective as compared to non-coated tablets.

Coating on tablets make the tablets secure for travelling. There will be no breakage in tablets during packing when they are properly coated.

However, the most common usage of this machine is to make tablets in pharmaceutical industry. But it is also very useful in different industries.

Coated tabletes

- Reliable for food industry

- Cosmetic industry

- Agriculture industry

Tablet Counting Line

Automatic tablet counting line

It is very hard to count large amount of tablets and capsules manually and to overcome this problem tablet counting machine is there to assist you. It is very precise in counting tablets of different size.

You have to adjust the sizing and shape values before start counting then machine will automatically detect different size tablets without any problem.

Mainly, tablet counting line is used in pharmaceutical industry to deal with bulk amount of tablets and capsules counting with ease and comfort.

Blister Packing Machine

AIPAK blister packing machine

A blister packing machine is mechanical equipment used to form a packet of tablets or capsules in a plastic bag by putting a seal on top of the packet.

A pocketed form cavity when fills with the tablets or capsules it forms a blister around that pocket and that blister in the form of plastic or aluminum cover the inside material.

It will equally fill all the packets with tablets, capsules or any other material. It is widely used in multiple industries for packaging purpose such as:

Blister Packing

- Pharmaceutical industry

- Food industry to process different food items

- Chemical and cosmetic industry

- Different drug packing industries

Cartoning Machine

AIPAK cartoning machine

Cartoning machine is also one of the types of packing machines used to pack different items in plastic or paper cartoons for making your product safe.

This machine can create carton boxes in real time according to the type of product that you want to pack. Very flexible and powerful to pack multiple products in fewer time period.

Almost every industry use blister packing machine to overcome packaging problems in the meantime it also make sure that your product remain in good shape during delivery.

Multiple size cartons

- Very common in food in pharmaceutical industry

- Fast food industry

- Cosmetics and health industry

- Electronic industry

- Hardware industry

- Entertainment and education industry

- Automobile and plastic industry

Strip Packing Machine

AIPAK Strip packing machine

A strip packing machine is a technically manufactured pharmaceutical device used to pack tablets and capsules of different shapes and sizes, and pills in a blister.

A normal strip pack contains a thick material at one side and thin material on the other side whereas, the dosage remain inside sealed perfectly.

It helps to increase the protection of your dosage. You can easily carry around your medicine along with you without facing ant bacterial problem as the strip is well sealed.

Let’s see different applications of strip packing machine.

- Commonly used in pharmaceutical industry

- Chemical industry

- Pesticide industry

- Food industry

Semi-Solid Medicine Manufacturing Equipment

There are several semi-solid medicine making machines that are now used globally by different pharma companies. Here is a list of these machines.

Vacuum Emulsifying Mixer

Different vacuum emulsifying mixer types

Vacuum emulsifier is technically a well-designed and stable equipment used to mix different ingredients with the combination of oil for example silicon oil or may be with mineral oil.

Most of the semi-solid production companies use shear mixers to create suspension of different ingredients to get maximum yield with hydration & dispersion.

It can help you to work with the creation of food items, cosmetic products such as creams or lotions, plastic production companies also use shear mixers for mixing different nature ingredients.

Here are some of the vacuum emulsifying mixing machine uses.

- Useful for Emulsion creation

- Powerful in dissolving of multiple solutes and solvents

- Granulation production

- Effective in homogenous mixing

Tube Filling machines

Tube Filling Machine

Tube filling machine is a sequentially well-structured technical machine. It works in a sequence to fill multiple size tubes or containers. Working of every tube filling machine is typically different from the other because of its design and structure.

However, if you want to fill tubes in bulk amount within perfect size and weight then tube filler machine is a powerful asset.

The industrial usage of tube filling machine is taking over many other machines because of its cost effectiveness with low electricity consumption rate. There are many medical products that can be filled with this machine.

Tubes

Variety of other semi-solid material filling in different industries can also be done by the help of tube filling machine. Here are the different application and uses.

- Filling of cosmetic products in different size tubes

- Food items filling in tubes

- Gel, cream, ointment etc tube filling

- Paint items & adhesive items filling in tubes

- Chemical filling in tubes

Suppository Filling Machine

AIPAK Suppository filling machine

A suppository filling machine is a mechanical device used to fill suppository tubes with semi-liquid. These suppository tubes looks same like capsules but of different shapes.

These suppositories were filled with drugs for those patients who are not wishing to take medicine through mouth or by injection.

The automatic nature of suppository filling tube makes it quick to fill bulk amount of suppository tubes with precision.

The main usage of this machine is for pharmaceutical industry.

Suppository

Gas Medicine Manufacturing Equipment

Aerosol Filling Machine

AIPAK Aerosol filling machine

Aerosol filling machine is a highly durable equipment used to fill gasses in a tinplate or aluminum cane with the help of vacuuming and crimping without any interruption.

It is not limited to work only with gases but it has the flexibility to work with liquid vacuum filling and crimping.

Most common purpose of aerosol filling machine is to produce aerosol products. It is widely used in the production of pharmaceutical products.

Here are some of the applications of aerosol gas filling machine.

- Useful in Automobile system

- Industrial production

- Cosmetic production

- Pharmaceutical production

Liquid Medicine Manufacturing Equipment

Liquid medicine manufacturing is done by different sorts of machines. Anyhow, all of the liquid medicine manufacturing machines are different from each other in working as well as in design.

I have explained some of the liquid medicine filling machines below.

Ampoule filling line

AIPAK AKA-series Ampoule Filling Machine

Ampoule filling machine is one of the kind of liquid fillers more specifically it is a precise equipment designed and structured to fill liquid dosage in an ampoule or container.

Multiple types of injection ampoules can be filled & sealed easily by using ampoule filling machine. It also has the tendency to fill powder or liquid in a container just by changing the production phase.

Most of the usage of this machine takes place in pharmaceutical production for example perfectly sealed injection bottles to make the inner dosage contamination free.

Ampoules for injection filling

Also, multiple liquid filling machines are there that are used in many industries including food, chemical, pharmaceutical and many more.

- Water filling

- Alcohol filling

- Chemical filling

- Carbonated drinks filling

Syrup filling machine

AIPAK Auto syrup filling machine

Syrup filling machine comes as a complete production line along with capping machine which initially works to fill oral liquids in containers and then seal these containers with caps.

Usage of oral syrup filling machine in pharmaceutical industry is to fill multiple sorts of syrups such as cough, anti-bacterial, fever etc.

There are wide variety of applications in which oral syrup filling machine is used but the most common ones are pharmaceuticals, agriculture and automobile industry. There are some following oral syrup filling machines uses and applications.

Syrup

- Comfortable thin viscosity liquid filling

- Used by multiple water filling industries for multiple size bottle filling

- Used by food companies for juice, drinks etc filling

- Used by dairy companies for dairy product filling

- Used by cosmetic and detergent companies as well

- Used by chemical and paint companies for oral liquid filling

Vial filling machine

AIPAK auto vial filling machine

Vial filling machine works familiar to other syrup or liquid filling machines the only difference is the filling nature of liquid and there is a liquid extracting stick inside the vial.

More specifically a vial syrup filler is developed to only fill liquid dosage in a container in the form of tincture. Multiple labs and chemical industry units use vial fillers to fill different chemicals.

It is also very effective in filling medicines for children as the liquid is directly extracted from plants and trees.

Many industries use vial filling machine to fill different tincture liquids and here are some of those following uses.

Different size vials

- Vape flavor vial fillings

- Eye drops bottle filling

- Nail paints vial filling

- Multiple essential oil bottle fillings

- Cannabis bottle filling

Eye or Ear drop filling machine

Eye drop filling machine is used to fill small containers from 2cc to 100cc with liquid dosage. It can also do sealing and labeling in the same phase.

It is used to make sure that the sealing of the vial is perfect so that the inside material remain harmless without any interaction with outside material.

Mostly used to fill vials that can be used in the treatment of ear, eye or any other part of human body where you want to inject specific dosage. It is also very commonly used in automobile industry for oil filling.

Several industries use eye or ear drop filling machine to overcome multiple filling problems.

- Useful in biopharmaceutical filling

- Useful in chemical industry for chemical filling

- Useful in cosmetics and beauty items filling

- Food and light industry also use eye drop filling machines

Spray Filling Machine

AIPAK spray filling machine

Spray filler is one of the types of liquid filling machines which is designed and manufactured mechanically to fill multiple size bottles or containers with liquid.

The only difference between spray filling machine and other liquid filling machines is there sealing difference. As the spray nozzle is placed on the top of a filled bottle instead of cap.

There are numerous applications of spray filling machine.

- Cosmetics and beauty industry

- Detergent industry

- Chemical industry

- Lubricants industry

- Cleaning industry

Horizontal Liquid Filling Machine

AIPAK Horizontal Filling & Sealing Line

Horizontal liquid filler is a modern liquid filling machine that can work to fill the bottle/container and seal it at the same time.

It is very reliable to work with different types of containers such as vails, ampoules, injection bottles etc.

More advanced working environment of horizontal filling machine make it more demanding in different industries such as:

- Pharmaceutical and medical industry

- Chemical filling in chemical industry

- Cosmetic items filling

- Food and cold-drink industry

- Germs and pesticide industry

- Beverage industry

Liquid Glycerin Suppository Filling Machine

Liquid glycerin suppository production line

Glycerin suppository filler is also used as filling equipment manufactured to fill glycerin inside a container. It is one of the mostly used pharmaceutical machines for filling glycerin oil in different containers and sealing.

Suppository containers that are used in this machine are quite different as compared to other containers. These containers contain an exhausting back, when you press that back liquid came out easily from the other size through mouth or pipe.

This machine is highly usable in pharmaceutical industry. There are some other applications of glycerin suppository filling machine.

Glycerin suppositories

- Beverage industry

- Food industry

- Detergent and chemical industry

Ⅱ.How to select best pharmaceutical manufacturing equipment?

There are some key facts and figures that you need to keep in mind while purchasing any medical manufacturing machine.

Different pharma products

Production Category

What kind of product you want to produce by using that machine.

Automation level

Basically, automation level tells you about the nature of a machine like fully automatic, semi-automatic or manual.

Certificates

The product you are purchasing from a manufacturer needs to fulfill some standard set by the mechanical industry such as GMP, CA, EEE, etc.

Conclusion

Well, in almost every field pharmaceutical manufacturing machines are used for multiple tasks and operations.

As I have explained multiple kinds of pharma manufacturing machines such as liquid product manufacturing machines, gas product manufacturing machine, solid and semi solid product manufacturing machines.

Aipak facilitates you with every type of pharmaceutical machinery that you are looking for your production line. Our work ethics, quality production and experienced engineering team lead us to set new market trends by reaching more customers.

Multiple types of pharmaceutical manufacturing equipment are available for you with different automation level and in different sub-categories to work for specific production.

If you have anything in your mind, please write a short note. We are eager to help you!

Don't forget to share this post!

Vacuum Emulsifying Mixer Related Posts

Vacuum Emulsifying Mixer Related Products

Vacuum Emulsifying Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine