Types Of Packaging Cans And Sizes

It all started when Napoleon famously quoted an army “travels on its stomach” and promised 12,000 francs for inventing a method for preserving food for his army as his men were dying more of scurvy and hunger than war. Nicolas Appert, later to be known as father of canning invented cans and won the prize set by Napoleon.

What are different types of cans? How these innovative containers are manufactured? Their sizes and many more interesting topics are discussed in this article TYPES OF PACKAGING CANS AND SIZES. Without further ado let’s proceed!

1.Why use cans for packaging?

Cans are utilized for packaging owing to their ease in accessibility, conservation and safety, and sustainability of product. In terms of easy accessibility they’re convenient to use outdoor.

Cans are made up of metal which as a material provides good barrier and protection against heat, sunlight and microbial degradation for most products. They present attractive looks to customers because of appealing graphics printed on their surfaces and the great thing about can is they’re environmental sustainable and can be recycled and reused.

2.Packaging can production: A global market review

Packaging cans are made from different materials like tin, aluminum and steel due to their durability, versatility and aesthetics every year there is an increase in demand for can production. As a result more than 300 billion cans are produced globally for beverages only.

Aluminium was the most used materials for packaging can in 2014, approximately 90% can were made up of aluminium followed by steel 10%. In 2013 approximately $39 billion were earned by manufacturing packaging cans.

Multiple applications of can packaging are found in food, beverage, chemical and pharmaceutical industries. As a response to increasing global demand for canned products and changing consumer lifestyle there is an expected 6% growth rate in can manufacturing till 2028.

3.Materials that are used for manufacturing packaging cans and their advantages

Packaging cans can be made with different materials. Most commonly used materials are metals and paper. Let’s see one by one what characteristics, benefits and drawbacks do different materials might present.

Metals

Metal based cans provide tough resistance and rigidity to outward pressure such as being stacked or for allowing collision which makes them suitably perfect for easy transportation. They also provide a barrier against light, air and other gases which prevents the product from any sort of degradation.

Furthermore, metal cans are coated with materials that prevent container leaching maintaining safety and product hygiene. They have an aesthetic shiny appearance which allows attractive graphic printing on surface. They are simply convenient to use anywhere and are also recyclable.

Tinis the prevalent material for manufacturing of cans; it has longer shelf life compared with other materials and it has least chance of leaching which means it is unreactive. It offers good flexibility and strength. These cans are used in pharmaceuticals, cosmetic and food industry.

Aluminumis lightweight and cost effective. Packaging can made from aluminum can be recycled. Aluminum provide easy handling and transport. These are used for packaging drinks, food items and paint.

Paper or cardboard

Packaging cans that are made out of paper or cardboard has made their way into the market due to eco-friendly nature and diversity of the material which can be recycled and remade into any shape.

Cardboard containers can hold heavy load and can keep away pests and any odors making them favorable for food items. Paper based cans are used for dry food, bakery items and drinks.

4.What are the cons of different types of packaging cans?

We have seen different materials being used for the manufacturing of cans and discussed above their advantages; don’t want to leave the disadvantages do we? Given below are some disadvantages of different types of materials used for packaging cans.

Disadvantage of metallic cans:

- As with other raw materials there are some disadvantages of packaging cans manufactured from metal such as they are a bit expensive if prices are subjected to inflation.

- Metallic cans are prone to corrosion and can readily react to change of pH, however this problem is solved by the availability of good coating material.

- Low quality material used for coating may be dangerous due to increased BPA levels. Tin containers might be subjected to corrosion and so acidic substances cannot be filled inside them.

Disadvantage of card board packaging cans:

These are less sturdy than metal and do not provide adequate moisture resistance.

5.How packaging cans are manufactured?

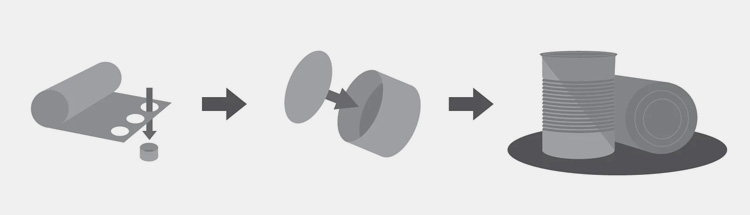

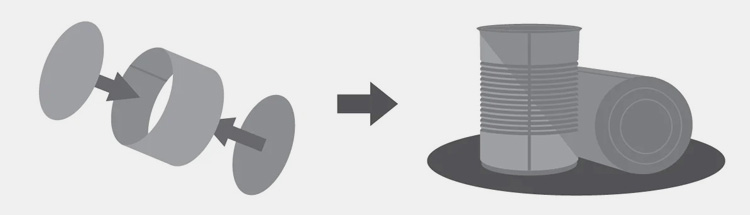

Cans are produced in the form of two or three pieces of metal i.e. by definition they can be classified as two piece packaging cans or three piece packaging cans

Two piece packaging cans

These are manufactured using a circular sheet of metal which is transformed into metal with an end. The height of the metal can is changed without affecting its diameter and the walls can be thinned by passing through circular die cavities, and both these processes result in drawn and ironed cans. The top lid is attached later on providing a hermetic seal.

Three piece packaging cans

These are made up of a) bottom lid, b) body c) top lid. Three piece cans possess a cylinder shaped body designed by rolling metal sheet, the can ends are attached by a process called as double seaming providing a hermetic seal. The opening or lid of cans are called as ‘can ends’.

6.Sizes of commonly used packaging cans

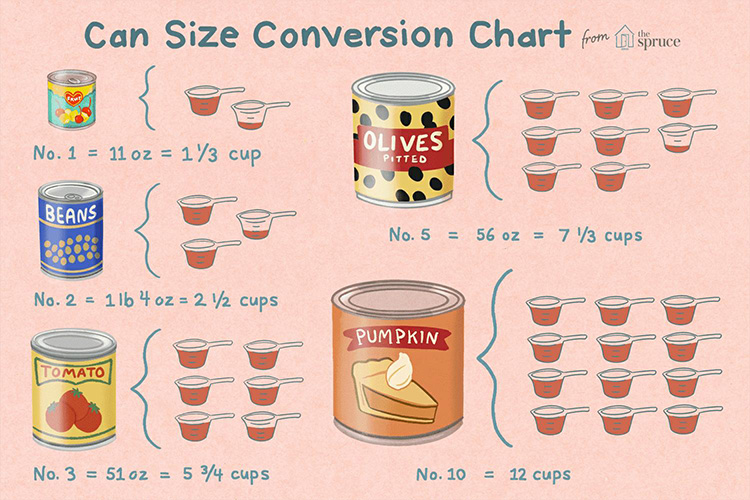

The chart you can see above shows different measurement sizes of packaging cans that are evaluated according to different measuring units like in cups or Oz. However the standard approach is mentioning a digit number to each particular size of packaging can.

- #1: This can size has a volume of 11oz which is equivalent to 11/3 cups.

- #2: Its can hold 1 pound and 04oz of product which is equivalent to 2 ½ cups.

- #2.5: This can size can hold 1 pound and 13oz which is equivalent to 3 ½ cups

- #3: A packaging can of #3 can hold enough product that would be carried in 4 cups. Its weight is approximately 51oz.

- #5: Equal to 7 cups this packaging can size weighs around 56oz.

- #10: The #10 can holds about 3 quarts of volume or carries almost 6-7 pounds depending on the product. It measures 6 inches tall and 7 inches by breadth. You can call it as a family pack suitable for cost effectiveness.

- #300: The #300 sized can measures about 1 ¾ cup or carries 15 ounces, usually found in the kitchen in canned beans or vegetables etc. The measurement size is 3 inches by breadth and 4 inches by length.

- #303: This can size can carry about 16-17 Oz of volume.

- Picnic Can: This can effectively holds up to 10 to 12 ounces.

7.What are different types of coating used in packaging can production?

In order to preserve the freshness, hygiene and protect the product packed inside from environmental factors as well as from primary container itself, packaging cans are coated with different materials usually about 10-15 μm thick. Coatings hold various additives which support their functionality.

Epoxy resin

In the beginning epoxy resin were employed for coating inside steel and aluminum cans due to their strength and preservative properties but as they also contained BPA which is a toxic and harmful compound for humans companies began replacing it.

Oleoresin

Oleoresin coatings are also one of the forms of coating material but packaging cans coated with oleoresin are not used for packaging food or beverages as they do not have good corrosion free properties and can interact with your product.

Vinyl coating

Vinyl coatings are produced from vinyl chloride and vinyl acetate. Even though they’re stable in both acidic and alkaline conditions and are also pliable they require often additional resins as they individually do not adhere well on metallic surface and also cannot undergo high temperature. However, organosols made from vinyl resins in organic solvents provide efficient coating.

Phenolic resins

Phenolic resins provide high corrosion resistance and also safeguard the can from sulfide staining but their drawback is that they do not adhere well to metal and also interact with food's odor and flavor.

Acrylic and polyester resin

Acrylic resin provide corrosion and sulfide protection but is known to impart bitter taste to food materials. Similarly, Polyester resins is easy to handle and stick well to the metal container but have low resistance to corrosion and are also known to interact with food.

Polyolefin

Polyolefin a recently introduced coating is gaining popularity according to manufacturers as it provides corrosion free, inert and pliable service to any container.

8.Are packaging cans environmental friendly?

Yes they are! Packaging cans are environment friendly because the raw materials that is used for their manufacturing are biodegradable, obtained from naturally existing sources such as trees in case of paper or card board and can be recycled or remade in case of metal. Some interesting facts of eco-friendly nature of cans are given below.

- Packaging cans made from aluminum can be recycled multiple times and back on shelves within 60 days.

- Nearly 75% of aluminum is still used as recycle packaging cans in the USA.

- Steel can be recycled without losing their sturdiness and strength.

- Recycling steel is 2.5% more than any other material. And for every ton of recycled steel a ton of iron, half a ton coal and 18kgs of limestone is saved.

Conclusion

Since their invention packaging cans are available in different sizes and shapes and are used for food items but are also used for cosmetic, chemicals and pharmaceuticals. In this blog the information provided was gathered from authentic and reliable sources. Hope you enjoyed it. For further queries please contact our 24/7 customer service representatives. We also recommend you loads of other interesting articles on this website. Till next time. Ciao!

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine