Types of Oral Solid Dosage Form

Have you ever thought about what oral solid dosage form refers to? You may experience picking out tablets or capsules from their packaging for safe and effective treatment. You take them via mouth to dissolve them in your digestive tract. Such types of medication mainly come under the category of oral solid dosage form. Wait a second, do you think just a tablet or capsule is known as an oral solid dosage form? Indeed not, there are so many types of oral solid dosage forms that we are going to sprout in this article.

Apart from their standard types, we will also discuss types of oral solid dosage forms based on their release action and so much more. We would love to see your attention to this blog post from start to finish. Because you will find everything with supporting illustrations that you will find worthwhile in understanding the concepts. So have a look at the discussion.

1.What is an oral solid dosage form?

Oral solid dosage form

An oral solid dosage form is a popular type of medication where you are addressing the medication prepared in a solid formulation. For instance, there are various types of medications available in the type of liquids, injectables, topical applications, etc.

However, when it comes to oral solid dosage form, one must be clear that your formulation is composed of a unit solid dose with high strength to retain the texture and structure. For example, you have seen powders, capsules, tablets, etc. These are the easiest and most convincing examples related to the oral solid dosage form.

Secondly, these medications are intended to be administered by following the oral route, that’s why you can call it an oral solid dosage form which ensures promising therapeutic effects once you take them. So, the common examples of oral solid dosage form are voren tablets, Vitamin E capsules, anti-inflammatory pills, and various coated medications carrying potent pharmaceutical ingredients APIs, and so on.

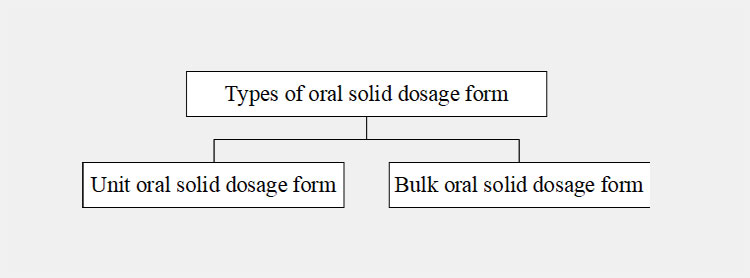

2.What do you mean by types of oral solid dosage form?

Nevertheless, the types of oral solid dosage forms are mainly intended to be taken by you using the oral route and are divided into two broad sections. One is the unit oral solid dosage form, and the other is the bulk oral solid dosage form. Each type has itself broad meaning and broad formulation types. So, you can’t ignore any of them when it comes to processing the pharmaceutical formulation.

Unit Oral Solid Dosage Form

Unit Oral Solid Dosage Form

Unit means one, single, individual, or single portion. Whenever you coin this term, it directly depicts the predetermined formulation that is suitable once taken as a whole. The unit oral solid dosage form is prepared by already designed and measured different substances that are involved in the preparation of medication, so it offers a flexible way to consume with high patient satisfaction.

So various medication such as capsules, tablets, pills, and effervescent doses comes in this category.

Classification of Unit Solid Dosage Form

The types of unit solid dosage forms are described below:

Tablets

Tablets- Picture Courtesy: Brut’s pharmacy

This is the most conventional type of oral solid dosage form which is truly defining the unit dosage. It is mainly prepared by a number of substances and an active ingredient giving a therapeutic response. The shapes and sizes of the tablets are now presented with so many variations, but a standard tablet is best known for its flat and convex shape. The tablets are also classified into various types. For example:

Compressed Tablets

Compressed Tablets- Picture Courtesy: Scientist Live

This type of tablet is known as a backbone of the medication world where it is mainly prepared by simply pressing various dry ingredients with active pharmaceutical ingredients by using a specialized machine known as a tablet press. This is a simple formulation prepared from powdery ingredients and transforms the medicine into a solid dosage form.

Mini Tablets

Mini Tablets- Picture Courtesy: CPHI

As its name shows, these are miniature tablet formulations with diameters of less or equal to 3 mm. It is worth mentioning that the standard tablet ranges from 8 mm to 22 mm but not less than the mentioned value. However, the mini tablets are composed of granules and pellets offering high flexibility in dose disintegration and distribution for specialized classes of patients such as children or people suffering challenges in taking medication.

Effervescent Tablets

Effervescent Tablets

This is the popular and most preferable type of tablet in solid dosage form where the tablet starts dissolving when you drop it into a glass of water or any other liquid vehicle such as juices. The effervescent tablet can dissolve evenly and sparingly by the action of water and produces a fizz that makes you feel good as well. So, once it is dissolved completely you can enjoy a refreshing glass of effervescent medication just like regular drinks. This is mainly useful for people who face difficulty in tablet swallowing or taking large doses.

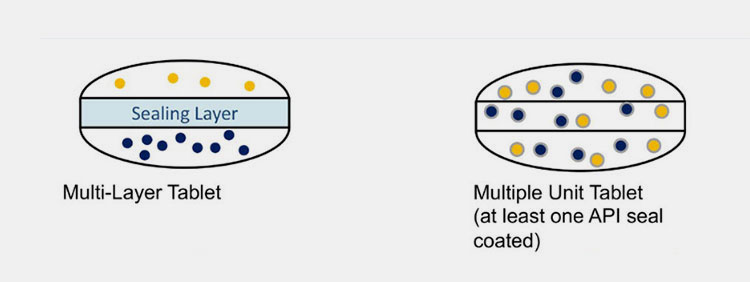

Multi-layer Tablets

Multi-layer Tablets

A multi-layer tablet is the solution for the administration of more than one active pharmaceutical ingredient. This tablet is composed of multiple layers of different APIs that are distributed, disintegrated, and release the therapeutical effects differently. For example, one of the APIs can be released immediately while the other can produce sustained effects.

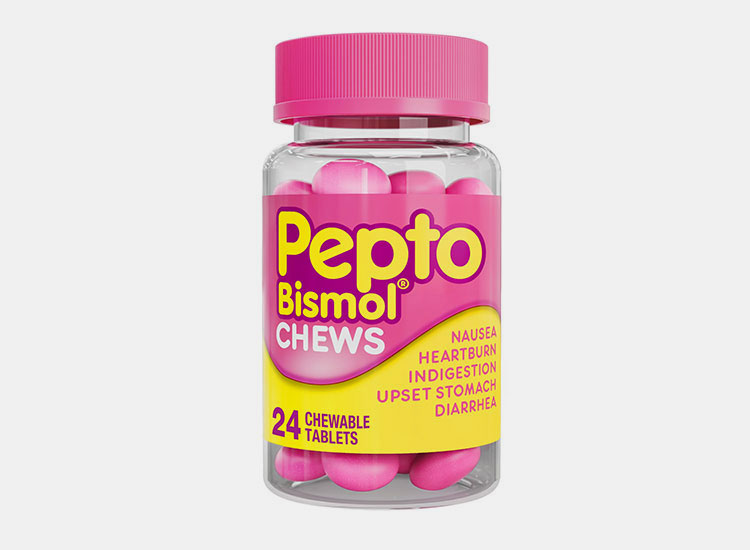

Chewable Tablets

Chewable Tablets

This is a versatile category of offering therapeutic effects without requiring water or any source. You just need to pick and chew the tablet as it is producing the medication effects once you chew it properly. This type of tablet is considered more beneficial in a certain type of patients who are suffering nutritional deficiencies or digestive problems as this is a good approach for drug delivery. Also, patients who face tablet problems such as old population, pediatrics, or for veterinary purposes need chewable tablets where intake and chewing do not need any special effort.

Sublingual Tablets

Sublingual Tablets

These tablets are specialized and fast-acting tablets that are capable of melting or dissolving once you place them in your mouth. Moreover, it doesn’t leave any medication leftover or residue, which means each particle of the tablet is capable of dissolving uniformly once positioned in a favorable environment. These medications simply bypass the first pass effect therefore simply offering a high absorption rate in order to enter the systemic circulation.

Buccal Tablets

Buccal Tablets- Picture Courtesy: Semantic Scholar

This type of solid dosage form mainly produces action when you place them in between your gums and the inner lining of the cheeks. The described region is also known as a buccal pouch which is mainly composed of a high-absorption site for buccal tablets and provides quick action upon tablet absorption. This is mainly administered when a patient is requiring emergency treatment or is in an unconscious condition and is mostly prescribed in hospital and healthcare setups.

Capsules

Capsule

After tablets, capsules are the most commonly used types of oral solid dosage form prepared in pharmaceutical and related sectors. Just like tablets, they are designed with different doses and sizes which is required for specific needs. It mainly has single APIs with filling or excipients.

The capsule is also described in various available types such as:

Hard Gelatin Capsules

Hard gelatine capsules

This is the popular and cost-effective type you see in capsule oral solid dosage form. They are capable of separating from each other by removing the body and head. While once they are filled, you can re-join them for final consumption. It is the perfect route of administration medication when it is available in the powdery formulation, so it reaches your systemic circulation once reaches the target site. The purpose of a hard gelatin capsule is to provide a protective covering in the form of a shell to carry the medicine in a unit dose.

Soft Gelatin Capsules

Soft gelatine capsules

They are smooth, softer, and flexible without any splitting or breaking portion in their design. It is hermetically sealed and supposed to be consumed by direct swallowing. The main purpose of these capsules is to provide vitamins or supplements in an oily texture in a safe formulation. These capsules are mainly prepared with different principles therefore providing extra protection for sensitive substances to retain their nutritional value.

Vegetable Capsules

Vegetable capsules

These are the type of capsules that are manufactured from plant-based sources therefore it is mainly suggested and suitable for those individuals who prefer plant-based medication or vegan loving. This is mainly replacing the gelatin capsules and is utilized for medicinal and herbal supplement dosage formulation.

Gummies

Gummies

With an appealing and sweet taste, the gummies are the most demandable types of oral solid dosage form. They are commonly available with health-related supplements, also you can also find therapeutic gummies. For example, gummies for inducing sleep, stress-related disorders, etc. However, the primary design of gummies is based on nutraceutical uses.

They are prepared in different vibrant colors, flavors, and shapes with the ability to hold small to large amount doses. That’s why, account to studies it was concluded that approx. 41% of consumers loved to take gummy supplements over traditional mode of medications.

Lozenges

Lozenges

These preparations are mainly intended for systemic absorption via buccal and sublingual routes and disintegrate slowly in your oral cavities. They are also referred to as troches and are mainly considered as an extemporaneously prepared medication. However, they are also presented in three forms hard, soft, as well as in chewable preparations.

Pastille

Pastille

These are small oral solid dosage forms that are mild therapeutic in nature and capable of dissolving slowly in your mouth often used for certain throat-related complications. It acts as a freshening agent once taken; you will start feeling fresh breath and soothing effects.

The pastille is mostly available as a medicated and non-medicated pastille. The medicated pastille is composed of an active ingredient in formulation and is used for particular conditions related to allergies and cough problems.

However, the sweet pastilles are enjoyed by many users due to their good flavors, taste, and texture.

Powder

Powder

Powder, a small and delicate particle mixed with active pharmaceutical ingredients is dosed with a divided formulation and you can call it Chartulae or Powder paper as a unit formulation. This is mainly packed in either a small bag or foil which you can open at the time of administration and won’t need to make or measure the dose.

Bulk Oral Solid Dosage Forms

Bulk powders- Picture courtesy: Bulk connection

This simply means a large quantity; this is generally not referring to medication that is a pre-determined dose. Rather, it is a huge quantity of substances that are meant to be mixed or mingled with other substances to make a dosage formulation. Moreover, in mostly clinical and pharmaceutical setups, this is estimated and often taken as divided doses in order to reconstitute prior to taking them as a dose.

Various antibiotics, topical powders, and granules come under this category and require special attention and dose calculations before you take them.

Have you heard about powdery formulations such as laxatives, antacids, as well as dietary supplements? They are relatively considered a non-potent formulation and safe to use by using simple measurements of teaspoons, tablet spoons, or caps. The bulk powders itself are divided into two basic types:

Internal bulk powder oral solid dosage form

Internal bulk powder oral solid dosage form

These bulk powder doses are mostly used for internal or oral applications, such as you can prepare the prescription by measuring the calculation and intending them with the help of water or any vehicle.

External bulk powder oral solid dosage form

External powder- Picture Courtesy: Battle green

Many antiseptic, anti-inflammatory powders that are subject to use for topical applications are known as external bulk powders. For example, astringent powders, lubricant powders, etc.

3.Why do you need types of oral solid dosage forms?

In the world of pharmaceuticals and associated fields, the types of oral solid dosage forms give you tremendous benefits. That’s the reason behind its non-stop production and high production demands. Why is that so? We have described the following principal advantages of types of oral solid dosage forms just right below:

It is easy to use and carry everywhere

Easy to use

Every one of you might have used to carry tablets, capsules, or any type of solid dosage form in your bags, pockets, or cars in some cases without worrying about leakage or spillage. Also, it is flexible to take despite considering dose management. So, the primary reason behind its demand is that they’re quite flexible for everyone in their general routines including traveling, work life, homes, educational sector, etc.

It gives you exact active pharmaceutical ingredients

Exact active pharmaceutical ingredients- Picture Courtesy: Hosokawa Micron

When you’re prescribing any type of solid dosage form to any patient or user; you must be satisfied enough to offer them medication with already exact volume or concentration of APIs. So, you just need to provide them administration schedule that’s it. You won’t be worried about whether the patient must reconstitute the dose or use proper handling. They just need to pick the box and consume the dose as you recommend with no dose mismanagement or risky errors.

Extremely stable formulation

Stable formulation-Picture courtesy: Salon

If your outside climate is hot or humid, or facing a similar challenging atmosphere such as extra light, air, dust, etc. The types of oral solid dosage form would be intact and remain stable in all mentioned conditions or less likely to get harmed. This is because its formulation and packaging can combine and exert positive effects on medication to make it safe and secure till you get it. Moreover, as compared to other dosage formulations, the types of solid dosage forms are way more effective with extended shelf life and high potency.

Easier trading across the globe

Easy transportation

They are lightweight, stable, and not prone to get damaged by shocks. Unlike liquid or other formulations, they’re heavily transported all across the globe in a lesser transportation and trading expenditure. Therefore, it directly impacts the pricing of the medication which is very cost-effective compared to various other formulations.

A greater control over releasing profile

Excellent releasing profile

The types of oral solid dosage forms are prepared in various therapeutic designs. Such as it can give you an emergency response by offering an immediate releasing medication, similarly, the sustained release solid dosage form produces the sustained and steady release by inducing slow disintegration and dissolution of substances. Therefore, you don’t need to retake the dose with a short gap once you take the extended-release solid dosage form providing you with a greater treatment regimen.

Greater range of sizes and tastes

Improved taste & presentation

This is well understood that children directly refuse the medications due to unpleasing taste. But types of oral solid dosage forms are available in attractive shapes, colors, sizes, and importantly with tastes. For instance, sugar-coated, film-coated, etc, so to make users accept the medication without chances of refusal. In the same way, the geriatric population also gets sensitive to bad taste. So, types of oral solid dosage forms are prepared in a way that facilitates high user compliance therefore showing high patient demands.

4.How do you prepare types of oral solid dosage form?

To prepare types of oral solid dosage forms, you need to initiate the process by formulation development where you subject the active pharmaceutical ingredient with an optimized concentration of excipient to give rise to an effective approach that provides you an effective releasing profile towards its target sites. Let’s have a look at the following steps briefly.

STEP 1: Sifting & Milling

Sifting & Milling

This is the initial step where the particle size reduction and filtration process take place. It ensures the unwanted particle sizes are removed and offers you uniform particle sizes that you can utilize for the types of oral solid dosage form formation.

The powder bed is milled and is carried out by effects of either vibration or gyration that moves the particles via a mesh screen.

Remember for the pharmaceutical preparation, there are a specified number of pore sizes that are proposing your particular sizes screening. For instance, if the mesh size is given as 100, it will indicate that 100 pores in a linear inch.

What are the machines involved:

There are various types of sifters and milling equipment such as:

Vibratory sifter, gyratory sifter, centrifugal sifter, cutting mill, hammer mill, and conical or con- mill.

STEP 2: Granulation

Granulation

The particles are mostly irregular and some of them flow firmly while some resist. The granulation process is involved in the continuous preparation section when it comes to manufacturing the types of oral solid dosage forms where the particles are treated in a way to makes them agglomerate or stick to improve their uniformity and flowability.

When it comes to talking about pharmaceutical manufacturing, there are the following main procedures are used for achieving the granulation including:

| Wet Granulation | Dry Granulation |

| Here the powders are subjected to form a mass by the involvement of the liquid vehicle known as a granulating fluid and you must emphasize to use of a volatile solution as later on upon the drying process the fluid has to be eliminated.

However, the commonly used solvents are mostly nontoxic to your health such as ethanol, isopropanol, and others with some ratio of water. The content of water also evaporates and doesn’t create a firm bond so once the granulation is done the particles are milled. What are the machines involved? For wet granulation, there are various machines used such as rapid mixer granulator, and fluid bed dryer. |

Powders that are moisture-sensitive or temperature-sensitive in nature, are treated with dry granulation where the procedure is based on the slugging which is the compression of the powder layer to create a slug by using the compression machine known as a roller compactor.

The compressed sheet of powder is formed by a high-density layer and is milled by using a low-shear mill and blender before making types of oral solid dosage form. What are the machines involved? For dry granulation, a roller compactor machine is used. |

STEP 3: Drying

Drying process- Picture Courtesy: food drying equipment.

During the above steps, the ingredients may be exhibiting some moisture content and for that reason, the drying step is conducted. This is mainly done to provide high stability, reduce the chances of early degradation of APIs, and improve the flowability properties of your powders.

What are the machines involved?

It can be achieved by using various machines like fluid beds, spray dryers, tray dryers, vacuum dryers, freeze dryers, etc.

STEP 4: Blending & Mixing

Blending and Mixing- Picture Courtesy: syntegon

Now the materials are ready for blending and mixing. This is included with the combination of API and excipients to offer an excellent distribution and uniformity of the particles throughout the particle bed. This is to keep in mind that without this step, the quality production of types of oral solid dosage forms is not possible therefore to ensure consistency it is a must-follow step to conduct.

What are the machines involved?

The process can be achieved by equipment such as a high shear mixer, V blender, bin blender, planetary mixers, double cone blender, etc.

STEP 5: Making of the types of oral solid dosage form

For different types of oral solid dosage forms, there are different making methods. Such as:

| Tablet | Capsule |

| This is kind of the most challenging process where the entire hardness and quality of the tablets, pellets, and pills, are based on. It is also associated with providing integrity, stability, disintegration, and the shape of the formulation. Here, the blended material is subjected to the heave compression machine known as a tablet press that ensures the making of tablets with the help of heavy compression forces.

What are the machines involved? A tablet press machine is used for tablet tablet-making process. |

The capsule filling is carried out by different methods, such as hard gel capsules and soft gel capsules.

The hard gelatin body is filled and then sealed with the help of the machine by positioning the head over the automatic features of the machine. However, in the case of liquids, you will need a soft gel encapsulation unit that creates and fills an optimized level of the liquid into each capsule and seals by utilizing the automatic features and gives you the final product effectively. What are the machines involved? A hard gel filling machine is used for hard shell capsules, soft gel encapsulator is used for soft gelatin capsules. |

| Gummies | |

| This is a challenging process composed of various intricate steps involved with melting the ingredients, mixing, molding for particular shapes, cooling, and drying to provide the required gummies with a high degree of stability and potency.

What are the machines involved? For gummy making, the melting tank, mixing and storage tank, gummy-making machine, gummy tunnel, and gummy trays are involved. |

|

STEP 6: Coating

Coating- Picture Courtesy: Konica Minolta

For types of oral solid dosage forms, this is considered an important step where the aesthetic and taste-masking properties are involved. The coating process is associated with enhancing the releasing profile of the types of oral solid dosage form such as by producing enteric coating, sustain releasing coating, and others.

What are the machines involved?

There are a variety of machines involved such as standard coating pan, auto-coater, fluid bed coating machine, or air suspension system, etc that help in the modification of oral solid dosage characteristics by layering the coating solution evenly on the coating bed.

STEP 7: Packaging

Packaging

For the types of oral solid dosage form, the packaging is the most important step. Once the formulation is manufactured, to make them protected and safe from the external environment and other factors such as humidity, shocks, temperature, etc the packaging is done. It is up to your choice if you can select blister packing, strip packing, or bottle packing for your materials to be marketed.

What are the machines involved?

There are various machines such as blister packing machine, strip packing machine bottle counting and filling machine, pre-made pouch filling machine etc are used.

STEP 8: Labeling

Labeling

The brand and information related to types of oral solid dosage form are provided with the help of applying labels. This is an important step that ensures your business boosts properties by attracting consumers by noticing visually appealing labeling and knowing about the product simply by reading the information you mention on it.

What are the machines involved?

The labeling machine is used for facilitating the labeling printing and application task.

5.Where types of oral solid dosage form are mostly prepared?

The types of oral solid dosage form can be designed in the following sectors:

Pharmaceutical Industry

Pharmaceutical industry- Picture Courtesy: prosple Australia

Whether it is chronic complications or local or acute ailments, the pharmaceutical industry is mainly based on the formulation and day to day designing of the types of oral solid dosage form for every age group population such as old, young, and pediatrics. It includes tablets, capsules, pills, granules, etc.

Nutraceutical Industry

Nutraceutical industry- Picture Courtesy: Essentia Pura

Formulation based on dietary essential requirements, and natural functional foods are mainly proposed and prepared in the nutraceutical industry. However, the types of oral solid dosage form nutraceutical tablets, gummies, lozenges, etc are quite popular in this sector. This is mainly included in the composition of vitamins, minerals, probiotics proteins, fatty oils, etc.

Veterinary Industry

Veterinary industry- Picture Courtesy: veterinary disinfectant

In the veterinary industry, the manufacturing of types of oral solid dosage form is quite prevalent, because the health and safety of pets can’t be ignored. The oral administration of certain medications such as pain killers, anti-allergic, anti-infective, anti-viral, etc can be subjected to animals by offering types of oral solid dosage form and it exactly distributes the required number of APIs in the gut of animals.

Herbal Industry

Herbal Industry

You have used many herbal supplements in the form of tablets, capsules, granules, and even powders. They are mainly prepared in the herbal industry to offer you a sense of satisfaction that you are taking well-standard and quality products. For example, moringa powder capsules, turmeric tablets and capsules, garlic extracts, etc.

Confectionery Industry

Confectionery industry- Picture Courtesy: Best of British

The enticing gummies, food-related tablets that are composed of functional elements, mouth fresheners, and sweeteners, are the main types of oral solid dosage form that are prepared in the food industry.

6.What is the new trend in type of oral solid dosage form?

The types of oral solid dosage form are driving a high demanding profile and day by day unique advancement trends are notably adopted by various manufacturing sectors of pharmaceuticals nutraceuticals, and foods. Let's have a look at new developments by types of oral solid dosage forms.

Gummies and soft chewable

Gummies and chewable

These types of formulations were first adopted by food companies, but their huge popularity has turned over a new leaf for development in the form of medication. Today, gummy and chewable medications are considered a significant source of oral administration as they are more appealing, and do not require intake of water during their management. Additionally, it is very popular among the children, youngsters, and old population.

Mini tablets & multiarticulate systems

Mini tablets and the multiarticulate system- Picture Courtesy: L'Usine Nouvelle

The mini tablets and the multiarticulate system emerged in the area of types of oral solid dosage form during the 2000s. Due to ease of administration and more patient compliance, these are now becoming the most popular trend in pharmaceutical manufacturing, and it is expected to hook up with a new possibility in the coming years.

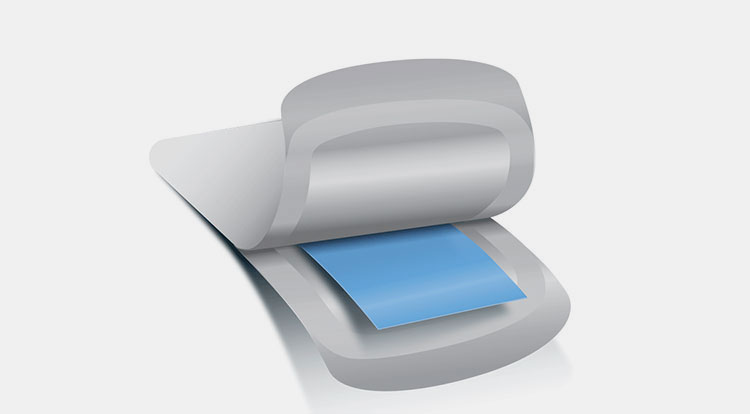

Oro-dispersible tablets and Oro-dispersible films

Oro-dispersible tablets and Oro-dispersible films – Picture Courtesy: IBSA

Although they have been developed for many years, the new trends in their taste, flavors, and properties are involved nowadays for different prescriptions of medications. As these tablets are easy to dissolve and disintegrate in your mouth and offer a rapid releasing action with a greater bioavailability it is now a major entity in the world of types of oral solid dosage form that are emerging with new alterations.

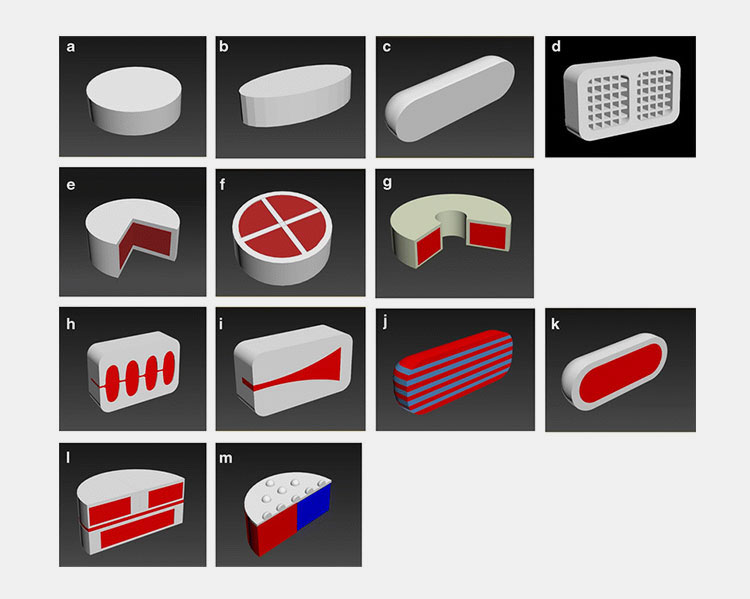

3D printing types of oral solid dosage form

3D printing types of oral solid dosage form- Picture Courtesy: ResearchGate

This is a truly tremendous trend that is subjected to personalized medication where the formulation and its releasing profile can be tailored related to each individual reducing medicinal errors. Due to so many challenges, this medication is still not able to commercialize yet.

Conclusion

The healthcare and pharmaceutical sector always strives in many ways to improve the user’s well-being and offer quality medications. Various types of oral solid dosage forms have emerged with a particular focus on your needs and minimizing therapeutic errors. In this blog, types of oral solid dosage form, we have tried to elaborate on the brief discussion about the major categories of oral solid dosage forms. At AIPAK, we are the experts and have been assisting our customers to find their solutions associated with overall production. If you need to discuss about equipment purchases or unusual challenges related to types of oral solid dosage forms, we suggest contacting us to talk how we could assist you.

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine