Types Of Cartoning Machine For Pharmacy

A cartoning machine is a versatile option to construct folded boxes, collapsible cartons, and slotted containers for the packaging of products. For instance, medications, food, electronics, beverages, and many more items. Additionally, these machines ascertain the safety and security of your products. Cartoning machines are a cost-effective solution for sturdy packaging.

Looking for a cartoning machine to pack your product? Let’s talk!

This blog is specially designed to guide you on how various types of cartoning machines for pharmacy help to improve your business.

Table of Contents

I.How are types of cartoning machines for pharmacy classified?

Cartoning machines are classified in several ways such as automation, motion, and direction of product feeding. Detailed below are some important categories for your understanding.

BASED ON AUTOMATION

Semi-Automatic Cartoning Machine

The machine performs the packaging process both autonomously and with human assistance. These packaging machines are not equipped with automatic in-feed components and materials are packaged inside the cartons by humans.

Due to human intervention, the packaging output is significantly reduced and the rate of errors is also increased. However, these cartoning machines are ideal for small and medium business setups.

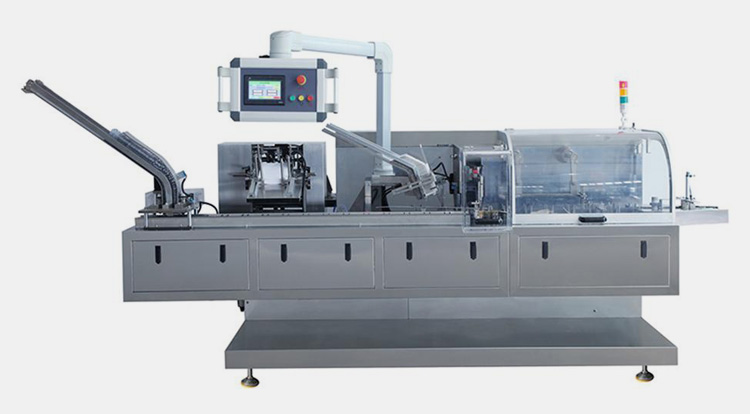

Automatic Cartoning Machine

Automatic carton machines are perfect for a business that packages goods on large scale because of their high packaging rate with minimal chance of error.

They carry out every packaging function -from loading cartons to filling products, from closing cartons to sealing- themselves with little human involvement. Every process is controlled and regulated by the machine control unit. This equipment is also capable of self-diagnosis and rejection of faulty cartons.

BASED ON MODE OF MOTION

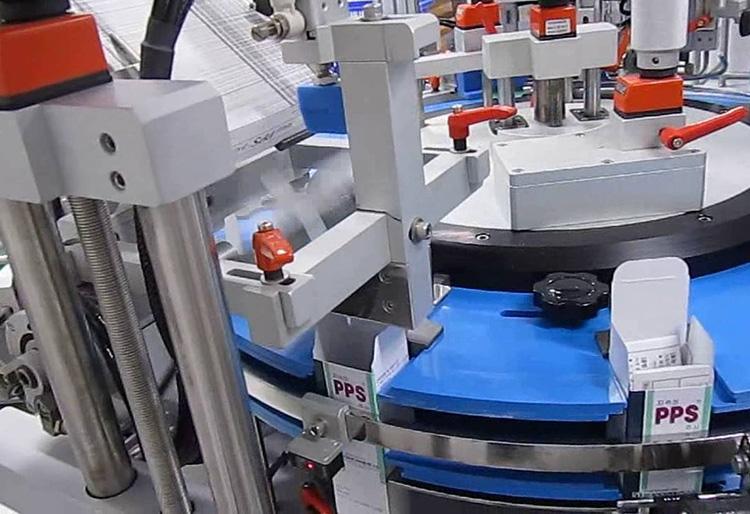

Continuous Cartoning Machine

These machines adopt circular rotary motion and pack products without stopping. The motion of conveyors, carton picking assembly, and product feeding units are in complete synchronization for achieving high production efficiency.

These instruments can package about 60-400 cartons per minute. The limitation of these automatic cartoners is that they cannot pack the product in various-sized cartons.

Intermittent Cartoning Machine

These are the type of automatic cartoner in which machines stop for the completion of the packaging cycle. This equipment move-in a linear direction but its components are not in synchronization.

The speed of these machines is 150 times less than continuous ones. It packs about 50-100 cartons per minute. It can pack products into different sized and shaped cartons.

BASED ON PRODUCT FEED

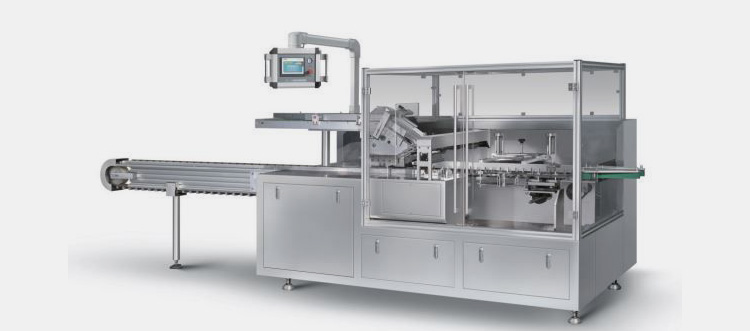

Horizontal Cartoning Machine

As the name indicates, the products are loaded inside these machines by lateral drawing. This means that products are fed into the carton from the sides and then the cartons are sealed by glue or an insertion flap.

It is typically employed in the food industry for packaging rice, cereals, candy, coffee, bread, etc.

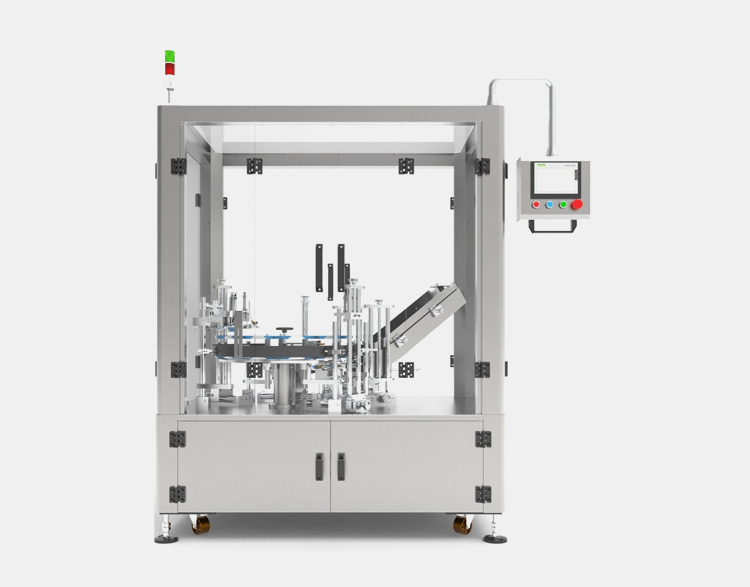

Vertical Cartoning Machine

In vertical cartoners, the products are introduced into the machine from the top. These machines package a variety of products and seal them in the folding cartons.

Vertical cartoning machines are preferably employed for packing jars and bottles in cartons because of this, these machines are highly popular in the pharmaceutical and cosmetic industries for packaging prescription medicines, syrups, injections, and foundations.

Ⅱ.What are the structural components of various types of cartoning machines for pharmacy?

Structural components of every machine are important to understand by the operator since it helps in handling and cutting down your downtimes. Some important parts are detailed below:

| Electric Unit

This is the part where switches and wires are located. It also comprises a motor or gearing system. Motors are vital parts that provide mechanical energy for the movement of various parts. |

|

| Carton Magazine

It is the part of cartoning machine, where flat paper boards are stacked. Servo-driven belts are essential in holding a flat board at an accurate angle in the throat. |

|

| Carton Picker

It pulls single flat cardboards from carton magazines and transfers them to guide feed where flat cartons are erected using force. |

|

| Press Device

It is located at the front of carton magazine. Its function is to instantly stop the machine if there is blockage or damage in the cartoning machine. |

|

| Leaflet Feeding Unit

This part is present at the back of the press device and it automatically places leaflets inside pins for folding. |

|

| Carton Closing Station

This part is equipped with guns for applying glues along the sides of filled cartons. The glue dries after a few minutes and flaps of cartons are sealed together. |

|

| HMI Display

An interactive touch screen display facilitates the programming of commands for operation. This component makes the job of the operator extremely easy. It also provides self-diagnosis in case of machine failure. |

|

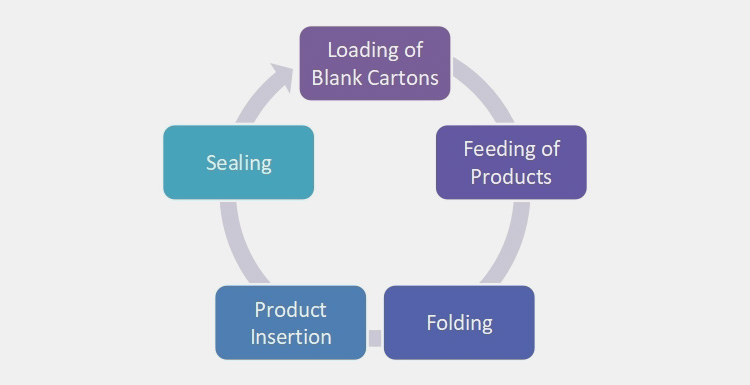

III.What is the working principle of various types of cartoning machines for pharmacy?

There are various makes and models of cartoning machines varying in design but the general working principle of these cartoners is the same. Some steps involved in the functioning of cartoning machines are:

Loading of Blank Cartons

A blank stack of cartons placed in the carton magazine is moved by carton pickup assembly. These cartons are carried to the loading area via a conveyor belt. Furthermore, this assembly will remove damaged or flawed cartons from carton magazines.

Feeding of Products

This stage varies in different types of cartoners. It is usually made up of a feeding tank and material feeder.

Folding

In this stage, the leaflet is folded by the means of a leaflet folder. During the carton folding process, the suction nozzle is set at the highest point for easy access to the bottom of carton.

Paper is fixed at the lowest point for easier suction of paper. A push plate is employed for closing the upper and lower ears of cartons. Ultimately, cartons are folded using a tongue and push plate then bends the carton.

Product Insertion

The products from the feeding unit are gently and slowly inserted into cartons to avoid product damage.

Sealing

The big tongue component of carton closing section will bend and seal the carton while the small tongue is present on either side of the conveyors for holding carton in place.

Hot melt glue is sprayed on both sides of cartons while they are moving slowly on the conveyors. After some time, the glue solidifies and the inkjet printer prints the date and stamp on sealed cartons.

IV.What are the benefits of types of cartoning machines for pharmacy?

Cartoning machines have earned their place in almost every industry. These machines are need of the hour in post-pandemic world for keeping the products safe and free from contamination.

The following benefits make these machines a worthy investment for your business.

| Protection | Cartoning machines pack products in cartons for protection, especially delicate items like electric bulbs, medicine bottles, etc. The cartons also make products safe during long transport trips. |

| Low Market Price | By using cartoning machine, you can pack your products in bulk quantities and can sell them at a low market price. |

| High Production Capability | These machines are extremely fast and can package up to 180 cartons per minute. Cartoning machines scale production efficiency up and down depending upon the demand for products. |

| Quality Assurance | Human involvement can result in over-packing of cartons and the application of wrong labels. But with the application of cartoning machine you can have consistent and high-quality packaging results. |

| Cost-Effective | These machines have an extremely low rate of errors in packaging products and also have decreased material wastage, this feature makes them a cost-effective solution for businesses. Moreover, these cartoners cut down your labor cost. |

| Product Flexibility | The equipment has ability to process various type of products simultaneously and can also handle different cartons formats such as folding cartons, rigid boxes, or collapsible boxes. |

Ⅴ.What are the differences between horizontal and vertical cartoners?

Both horizontal and vertical cartoners are an integral component of the secondary packaging line and use cartoning folding and sealing mechanisms for packaging products but some major differences in both these types of cartoners are detailed below:

| Horizontal Cartoning Machine | Vertical Cartoning Machine |

|

|

| This cartoner is end loaded and products are inserted in cartons from the side. | This is top loaded cartoner and products are filled in cartons from the top. |

| These are suitable for packaging products that are tightly fitted in the box and usually, one or two products are packed in cartons. | These cartoners are suitable for free flowing and delicate items like rice, glass bottles, jars, etc. |

| Horizontal cartoners occupy large floor spaces and are not easily fit in small spaces. | Vertical cartoners generally have a small footprint and can be installed in small spaces. |

| This equipment can easily handle items in bulk quantities since it is easier to assemble products moving in a horizontal direction. | These machines cannot handle and assemble products in large quantities due to their vertical in-feed system. |

| Fragile items can be damaged while being processed by horizontal cartoners. | These cartons pack delicate items with a low chance of damage. |

| There are long in-feed systems in horizontal cartoners due to the movement of products in a straight direction. | These machines reduce delay in in-feeding systems. |

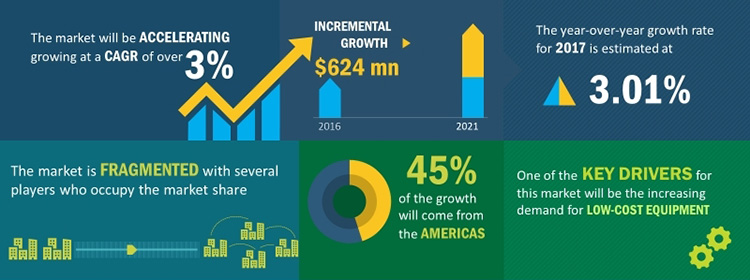

Ⅵ.What is the future perspective of types of cartoning machines for pharmacy?

The demand for cartoning machines is all-time high owing to customer interest in packaged goods. Customer preference and inclination toward innovative packaging are the main factors that contribute to the expansion of cartons market.

It is anticipated that cartoning machine market size will be US $3.02 billion by the end of 2027 and will grow with CAGR of 3.8% from the US $ 2.26 billion in 2019.

The need for packaged pharmaceutical and food products has increased post-pandemic which in turn increases the purchasing rate of cartoners. To meet this high demand-supply, manufacturers are concentrating their effort for bringing design improvement in cartoners, enhancing their automation capability, and manufacturing machines with quick format change-over.

Conclusion

Cartoners have a significant role in secondary packaging. With each passing day latest cartoners having innovative technology are coming in market. These cartoners are efficient for both small and mass-scale businesses. ‘Types Of Cartoning Machine For Pharmacy’ provide knowledge about features of different kinds of cartoners and their benefits for your packaging plant. If you still have queries about cartoners you can contact our expert customer operators that are always keen to help you.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine