Types of Cartoner

When it comes to product sales and transportation, you can not neglect the importance of cartoning. It makes a great protection and propaganda for products of so many different industries. With the help of different types of cartoner, you can produce cartons with good quality and high efficiency.

Cartoner can package small fragile products as well as huge sturdy products. The different types of cartoner make different cartoning processes. You would have a deep knowledge of its types to get the one that suits your production most.

How many types of cartoner are there? What is the working function of different types of cartoner? What are the benefits of different types of cartoner? How to select a suitable one from different types of cartoner? Do you have the same questions? Then, don’t hesitate, read this post.

1. What Is Cartoner?

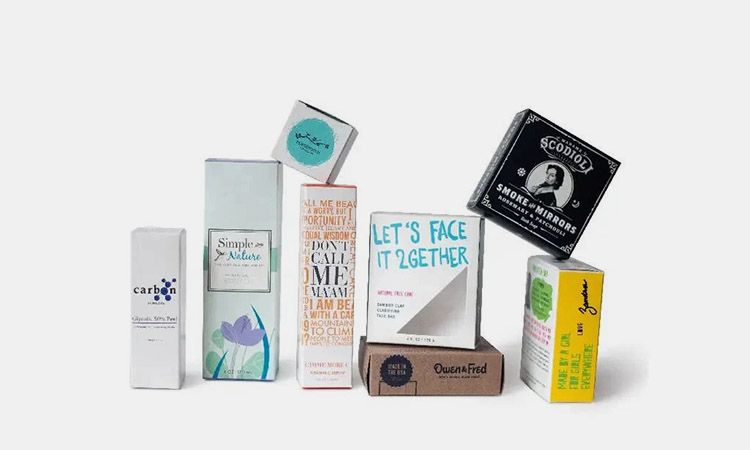

A Type Of Cartoner-Sourced:serpapackaging

There are various product packaging style on market and the most common one is carton packaging for its features of cheap, protective, and light. Cartoner is the machine used to make different cartons for various-sized products. There are so many types of cartoner, though all play the same role as making carton.

Cartoner can finish a series of process like forming cartons, filling products and brochures, sealing cartons, and even printing information on carton. It can do so many different processes by itself efficiently and precisely. Because the industry has high standard on hygiene and quality, every type of cartoner can do a good job.

2. What Industries Can Cartoner Be Applied?

All products on the market have packaging requirements, and the different types of cartoner can fulfill the most needs on carton packaging of different industries and different sizes.

Food and beverage industry

Food And Beverage Carton-Sourced:nepacartons

The various types of cartoner play an essential role in food and beverage industry. It provides the necessary protection for products from damp, dust and light. The nice cartoning prolong the life of fragile and fresh products. And the colorful or informative cartoning appearance can also attract the customers.

Cosmetic industry

Cosmetic Carton-Sourced:davidbrown23

You may feel the extra need of cartoning in cosmetic industries as customers have a further care on harmonious beauty and effect of product. The appealing carton which shows the nice principle of cosmetic company can attract customers naturally. The various types of cartoner can also help store the effect for fragile products.

Pharmaceutical industry

Pharmaceutical Carton-Sourced:mahasaraswatiprinters

The special types of cartoner can make the unique carton for pharmaceutical industries which can make extra fix parts for special products like ampoule or injection, and anti-counterfeit labeling. It can thus prove the safety of products as well as protect customers.

Electronic industry

Electronic Carton-Sourced:Dieline

The different types of cartoner can also be used in electronic industry to product the cartons for phone, batteries, watch, remoter, radios, electronic gadget and so on. It can be fixed with other setting to get a better protection for products and make fantastic appearance for attracting.

Toy industry

Toy Carton-Sourced:nbcnews

Different shaped tops can all get a great carton packaging by various types of cartoner. It can package your ball, toy car, doll, bear, robot and so on in a great condition to face the long transportation and storage. And it is also an important part in drawing attention and improve sales.

Sports industry

Sports Carton-Sourced:customdesignsboxes

Sports industry have a wide range of products from cloth, balls to sports equipment. And for all these products, you can always find the nice and reliable packaging solution from the different types of cartoner.

3.What Are The Types Of Cartoner?

The ways to divide different types of cartoner can be classified as the loading way, automation level and motion manner.

Loading way

- Vertical cartoner

Vertical Cartoner-Sourced:kansasglobal

Vertical cartoner, also called as top-load cartoner, gets its products in above. This loading way can reduce the damage to products greatly, and is thus more suitable for bottle, vial, ampoule, vegetables, and so on. For bare product packaging, it plays a more excellent job as top-loading makes the precise and safe packaging.

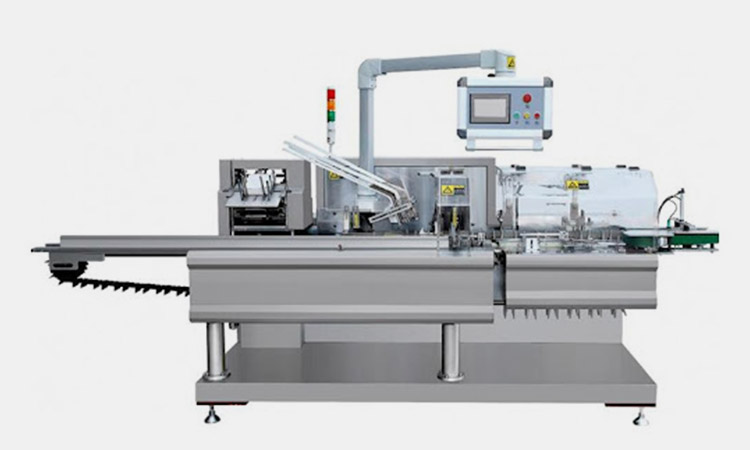

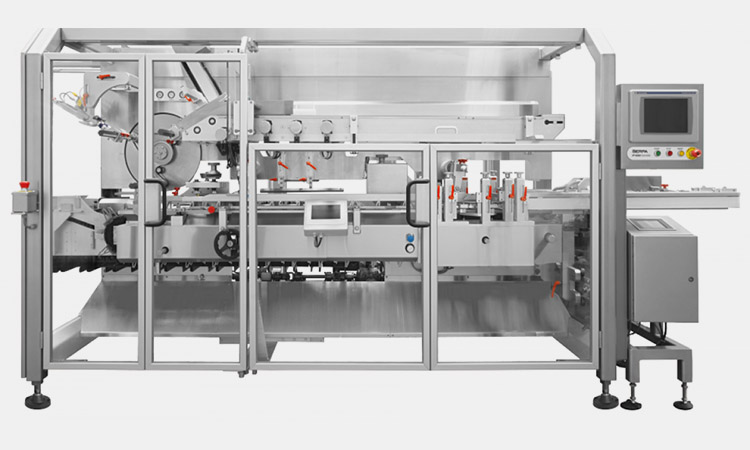

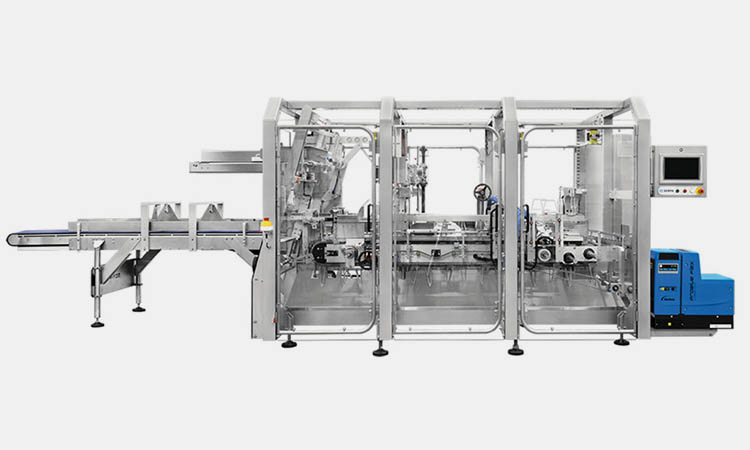

- Horizontal cartoner

Horizontal Cartoner-Sourced:zhpackagingmachine

Horizontal cartoner can also be called as side-load cartoner . In contrary with top-load one, it gets products in from side and then makes the later packaging work. This types of cartoner also plays an efficient and versatile work. For tight cartoning and multiple cartoning, this type is your best choice.

Automation

- Semi-automation cartoner

Semi-automation Cartoner-Sourced:jw-packaging

Semi-automation cartoner can’t finish its whole work all by itself though it plays a rather good job in carton making. It needs hand loading and other help for a smooth cartoning.

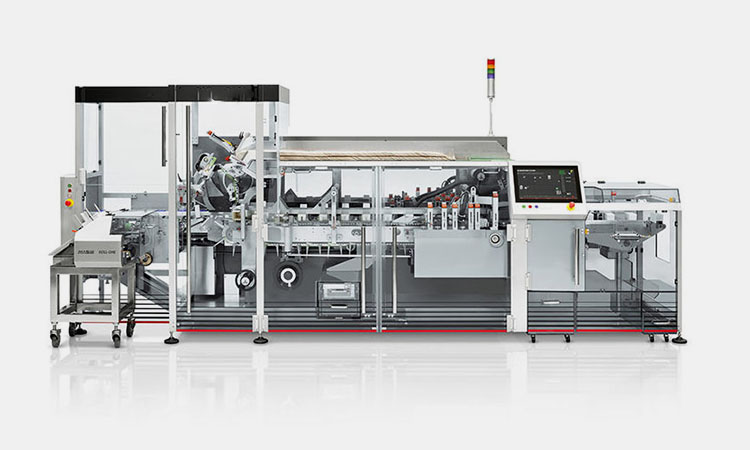

- Full-automation cartoner

Full-automation Cartoner-Sourced:tfreemantle

Full-automation cartoner makes the whole cartoning process after setting the relative panel. There is no need to break the carton packaging for the smooth cartoning. This type of cartoner save a lot energy and also improve the working efficiency as it works continuously.

Motion manner

- Intermittent motion cartoner

The intermittent motion cartoner has cartoning process go on intermittently as it is interrupted occasionally by products loading. And the intermittence may also interrupt cartoning work in moment like carton erecting or filling. This kind of cartoner is cheaper for its occasional intermittence, but it reduces the efficiency of cartoning.

- Continuous motion cartoner

Continuous Motion Cartoner-Sourced:ima

Continuous motion cartoner has almost no pause when making cartons. The product loading makes little effect on its whole cartoning process. Though run out of products, the other motions go on smoothly til all products get packaged. It is thus much faster and more efficient in cartoning compared with intermittent motion one.

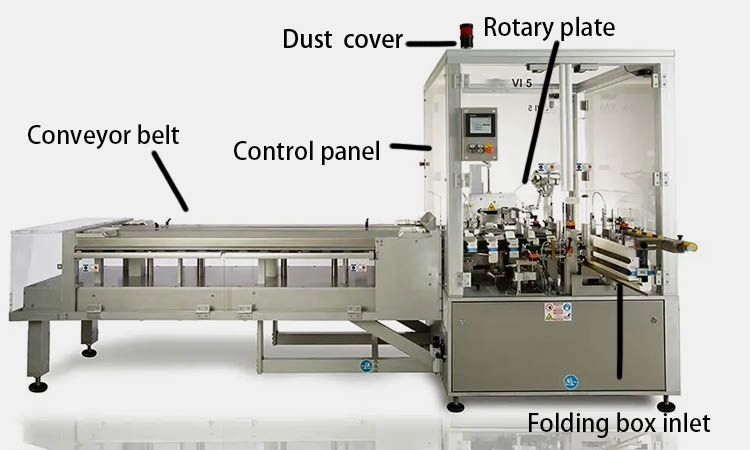

4.What Are The Parts Of Types Of Cartoner?

The semi-automation, full-automation, intermittent motion and continuous motion cartoners share difference mainly in motion way and automation. The differences are mainly in vertical and horizontal cartoner. These two share the essential parts like electronic system, control panel and so on for operation, but there also exist difference.

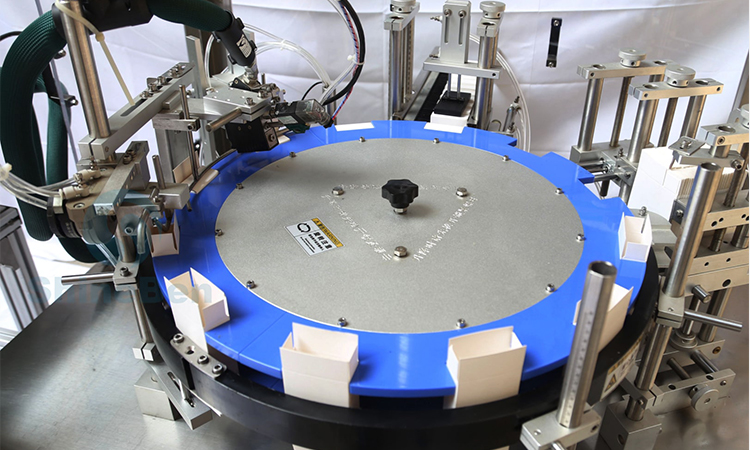

Vertical cartoner

Vertical Cartoner Component-Sourced:iwk

- Control panel

Control panel is the control center of whole machine which sets the relative operating panel like carton size, carton number, printing information, sealing way and so on.

- Conveyor belt

Conveyor belt makes the important linking role which takes the products to the series of cartoning procedures and leads them out machine.

- Dust cover

As gets products in from the box, there may be some dust in this process. The dust cover is the part which lead out dust and make a cleaner packaging environment.

- Rotary plate

Rotary plate is the special part of vertical cartoner which filled the products in from the plate vertically. This way can reduce the damage on fragile products.

- Folding box inlet

Folding box inlet plays a series of work like get carton, fold carton and fill carton. It’s one of the most important part as it decides the carton appearance and quality.

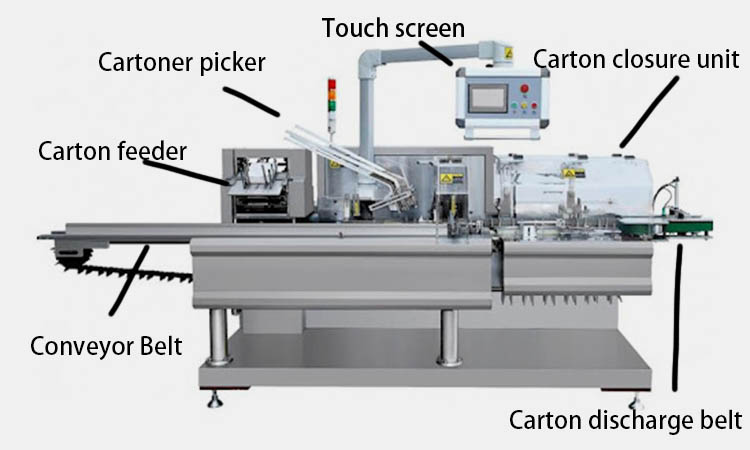

Horizontal cartoner

Horizontal Cartoner Component-Sourced:zhpackagingmachine

- Touch screen

Touch screen is another form of control panel which sets panels and decides the working or machine on a small screen.

- Carton feeder

Carton feeder sends piles of cartons in the machine and leads them join the cartoning process.

- Carton picker

Carton picker is just like a hand which pick the flat of carton and get it to the next folding process.

- Carton closure unit

After being filled with carton, carton closure unit closes the carton according to the settled model and seals it tightly.

- Carton discharge belt

The well-packaged carton will be leaded to carton discharge belt and get out the machine to prevent piling.

5.What Is The Working Function Of Different Types Of Cartoner?

As the type of cartoner has its difference working function majorly from the loading way. You can focus on vertical and horizontal machines.

Horizontal cartoner

AIPAK Horizontal Cartoner

- A pile of flat cardboard are folded to box shape and wait for the filling of products.

- The products get into the machine horizontally and are transported to the cardboard place.

- Products are filled into the box by mechanical hand and then get to the next process to be printed and then sealed.

- The brochures or instruments are also stick into the box before it get sealed.

- The well-packaged cartons then get out the cartoner by conveyor belt and get out from carton chute.

Vertical cartoner

AIPAK Vertical Cartoner

- Products get into the manufacturing process from rotary feeder in the vertical way.

- The products then are taken by mechanical hand to the cartons which are folded well and left one side for filling.

- After being filled, the carton can’t be sealed instantly for its may have extra need in filling brochures of instruments.

- The carton, filled all things well, can get into printing and sealing process.

- Finally, the well packaged products finish all its manufacturing process and get out the machine from carton chute.

6.What Are The Benefits Of Different Types Of Cartoner?

The different types of cartoner can benefits your industries in an all-around way.

Vertical cartoner

- Versatilityin product type

Versatile Product Type-Sourced:packagingcorp

You can make cartons of different products type from vertical cartoner as it can handle the normal products as well as the breakable and fragile products. For bottle, can, vials or other products which can easily get their appearance affected in packaging, vertical cartoner is a good packaging choice.

- Smaller footprint

Footprint-Sourced:iconexperience

The vertically standing way of vertical cartoner takes less space compared with the horizontally standing one. For factory has restricted manufacturing space, vertical cartoner is obviously a more suitable.

Horizontal cartoner

- Versatilityin packaging form

Multiple Packaging Carton-Sourced:lxlovemk

Vertical cartoner is versatile in the packaging products, while horizontal one is versatile in packaging form. For the packaging needs such as tight packaging and multiple packaging, horizontal cartoner makes a more outstanding job.

- Bulk and shaped handling

Carton Of Different Shape-Sourced:alamy

Horizontal cartoner is real suitable for bulk and shaped product packaging. It can adjust itself to fit products with various weight and shape. If you have large need in this kind of product packaging, horizontal cartoner can do an excellent job.

Semi-automation cartoner

- Easy operation

Easy Operation-Sourced:shineben

Semi-automation cartoner is easier for operation as it has less requirements on information settling. The easy operation takes high efficiency, semi-automation cartoner can thus make you great benefits.

- Easy maintenance

Machine Maintenance-Sourced:yamatoscale

The less level of automation makes easier structure. In the process of maintenance and repairing, it saves more efforts and money. The worker teaching can also be easier and more efficient.

Full-automation cartoner

- Labor saving

Machine Saves Labor-Sourced:rajones

Full automation has no further ask for workers in the cartoning process as the one settling of panel can make the whole cartoning process. It dose not need the joining of worker in cartoning process and thus saves extra work, And the easy panel settling also makes the carton manufacturing easier.

- High efficiency

Efficient Cartoner-Sourced:sirosilo

Full-automation cartoner can play a more efficient work as it is smart and high-automated which means it can measure the whole need of a cartoning process and makes the whole process smooth with no pause. This manufacturing is of course more efficient than the interrupted one.

Intermittent motion cartoner

- Lower price

Lower Price-Sourced:clockspot

Intermittent motion cartoner has a lower price compared with continuous motion cartoner with the similarly excellent cartoning job being finished.

Continuous motion cartoner

- Time-saving

Time Saving-Sourced:managers

Continuous motion cartoner unlike the intermittent one which is always interrupted in the cartoning way. It can save more time. It won’t be interrupted by the lack of material of products, as long as there is products in machine, it has the cartoning procedure go on.

- More efficient

More Efficient-Sourced:infinancialservices

The continuous and unaffected cartoning process makes the whole cartoning manufacturing more efficient. For factory has high production scale need, continuous motion cartoner is better for them.

7.How To SelectSuitable One From Different Types Of Cartoner?

Select-Sourced:janzednicek

Cartoners, vertical or horizontal, semi-automated or automated, intermittent motion or continuous motion, share the relative selecting principles. Don’t be confused by so many different types of cartoner, you can get the suitable and nice one by considering those tips.

Vertical and horizontal cartoner select

|

Tips |

Vertical cartoner | Horizontal cartoner |

| Floor area | Smaller floor print as stand vertically. | Bigger floor print for its horizontal standing way. |

| Fragile packaging | More suitable for fragile packaging as the rotary feeder makes less damage to products. | Handle most products but can’t do a better job in fragile packaging compared with vertical one. |

| Tight packaging | Make safe and delicate packaging, but not the tight one. | Make the tight packaging by pushing the products into cartoner tightly. |

| Bulk packaging | Make bare products packaging but not do so well in bulk packaging. | Make bulk packaging at high speed. |

| Multiple packaging | Can’t make brilliant multiple packaging. | Superior in making multiple and stackable packaging. |

Cartoner of different automation level and motion manner select

| Tips | Full-automation

cartoner |

Semi-automation

cartoner |

Intermittent motion

cartoner |

Continuous motion

cartoner |

| Budget | Higher budget for its intelligence and automation. | Lower budget compared with full-automation one. | Lower budget compared with continuous motion one. | Higher budget for its higher efficiency. |

| Speed | Higher speed as has full-automation cartoning procedure. | Lower speed as it needs extra help and labor work in cartoning process. | Lower speed as can be interrupted by material or product lacking condition. | Higher speed as work with less interruption in cartoning process. |

8.Future Trend Of Types Of Cartoner

As different types of cartoner share the same future and has its major difference in vertical and horizontal parts, let’s take a look in these two parts.

Types of cartoner future market trend

Future Trend-Sourced:startupsmagazine

Cartoner market has a gorgeous and bright market for the later ten years. The global cartoning machine market has about 4748.10 million dollar in last year, and it’s expected to reach 7734.15 million dollar ten years later. All in all, the types of cartoner with higher efficiency, more intelligence and better combination with AI can get the booming market in later ten years.

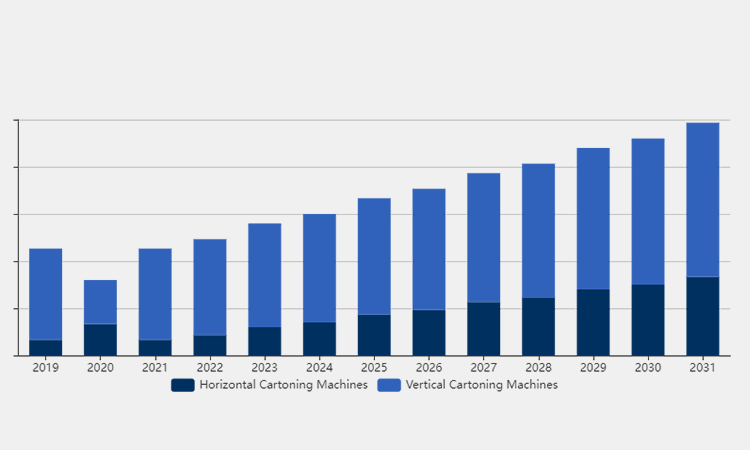

Vertical and horizontal cartoner future market trend

Vertical And Horizontal Cartoner Future Market Trend-Sourced:cognitivemarketresearch

- Vertical cartoner

Overall, the need of cartoner is booming in past years and also in future, and vertical cartoner has a better market share compared with the horizontal for its versatile packaging ability and fragile packaging. Its larger market share will continue to several further years.

- Horizontal cartoner

Horizontal cartoner will have a faster speed growth compared with the vertical one and may even exceed the market share someday in future. This is because of the great accommodation of horizontal cartoner. The high suitability for horizontal cartoner to high speed production line is also adapt to future need and make it more popular.

Conclusion

Cartoner is the essential machine for your products manufacturing and the suitable one plays an unshakable role in the whole producing process. There are different types of cartoner, and you can get your dreamed one after the deep investigation and patient finding. Don’t hesitate to contact us if you have any doubts.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours