Types Of Capsule Filling Machine: What Do You Know?

The importance of capsule filling machines in the pharmaceutical industry is self-evident and is a long-term required equipment. Whether it is to improve the production, packaging or distribution of capsule powder and granular drugs, it is the best choice for improve your efficiency and quality.

However, there are many types of capsule filling machines. Even different models have completely different functions. If you want to learn more about different models of capsule filling machines, this post may offer you the best answers and choices. Let’s take a look now!

1.What Is A Capsule And Types of Capsules Used In Pharmaceutical Industry?

Capsules-sourced: trustar-pharma

A capsule is a miniature cylindrical package. It is used to package medicines or drug ingredients, vitamins and supplements. With a smooth surface and a suitable size, it is easy for you to swallow.

There are many types of capsules. According to the material of the capsule, it includes:

Hard-shelled capsules

Hard-shelled capsules-sourced: trustar-pharma

Hard-shelled capsules are used to fill dry medicines in powder or granular form. It has a hard shell and consists of two halves. One half is filled into the other half. The machine used to fill hard capsules is a capsule filling machine.

Soft-gel capsules

Soft-gel capsules-sourced: edymax

Soft-gel capsules are used to fill liquid or semi-liquid medicines. It is usually transparent or translucent and the shell is soft. This material is mainly made of gelatin and is easy to digest. The soft-gel encapsulation machine is widely applied for soft-gel filling and sealing.

2.What Is A Capsule Filling Machine And Why They Are Important?

AIPAK capsule filling machine

The capsule filling machine is a device specially used to fill liquid, powder or granular drugs into capsules. It can be widely used in the pharmaceutical industry to help you achieve larger-scale and more efficient capsule filling.

Why capsule filling machines are important?

It can comprehensively improve the efficiency and quality of your capsule filling. And it can help the entire pharmaceutical industry to produce high-quality and pollution-free capsules more efficiently.

3.Types Of Capsule Filling Machine: What Do You Know?

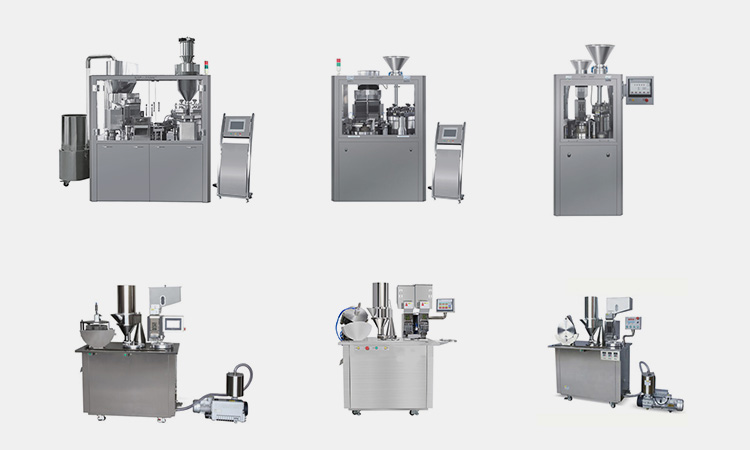

There are basic three types of capsule filling machines for your choice. Each one can meet your different needs. Let's take a look!

Manual capsule filling machine

Manual capsule filling machine-sourced: anchormark

The manual capsule filling machine is mainly used for small-scale or personal applications in the industry. It needs to manually change the mold and operate to fill the capsules. This capsule filling machine can fill about 800 capsules per cycle. And the filling quantity is very specific and the speed is slightly slower.

Semi-automatic capsule filling machine

AIPAK semi-automatic capsule filling machine

The semi-automatic capsule filling machine is a combination of manual and automatic capsule filling machine. It is less dependent on the operator. You can set the computer programming according to the speed of capsule filling you need. You can also adjust the capsule filling speed manually.

Automatic capsule filling machine

AIPAK automatic capsule filling machine

The automatic capsule filling machine is a machine that completes all the steps of capsule filling with the help of computers. It is mainly used for large-scale capsule filling production in the pharmaceutical industry. It can also be connected to other integrated equipment, including capsule polishers, dust collectors, damaged capsule classifiers and empty capsule ejectors to form a complete line.

4.Automatic Capsule Filling Machine VS Semi-automatic Capsule Filling Machine: Where Are They Mainly Used?

Different types of capsule filling machines may be suitable for different scopes and industries.

Manual capsule filling machine application-sourced:fixit

Manual capsule filling machines are best suited for:

- Personal use;

- Home use;

- Laboratories;

- Small-scale workshops;

Semi-automatic capsule filling machine application-sourced:dms

Semi-automatic capsule filling machines are best suited for:

- Hospitals and pharmacies;

- Small manufacturing units;

- Small batches and multiple encapsulation operations;

- Herbal medicine manufacturers;

- Pharmaceutical training intentions;

- Formulation filling in R&D laboratories;

Fully automatic capsule filling machine application

Fully automatic capsule filling machines are best suited for:

- Drugstore chains;

- Large pharmaceutical manufacturers;

- Pharmaceutical manufacturers;

- Veterinary manufacturers;

- Food manufacturers;

- Chemical industry manufacturers;

5.What May The Automatic And Semi-automatic Capsule Filling Machines Bring You?

The automatic and semi-automatic capsule filling machine has its own advantages and disadvantages. Let's understand its advantages first.

Semi-automatic capsule filling machine advantages-sourced: sunilhealthcare

Semi-automatic capsule filling machines are suitable for medium-scale capsule filling production. Its advantages are:

- Compared with manual capsule filling machines, it can increase production speed;

- Reduce human errors and improve product quality;

- Can handle a variety of capsule materials and sizes;

- Easy and fast to use;

Automatic capsule filling machine advantages-sourced: bangbeijian

The automatic capsule filling machine can bring you:

- Fastest capsule filling speed;

- Uniform and accurate filling volume;

- Reduce operator intervention;

- Large-scale production;

- Simple operation and reduce air pollution;

- With capsule rejection mechanism, improve filling efficiency;

6.Are There Any Drawbacks Of Automatic And Semi-automatic Capsule Filling Machines?

In addition to its outstanding advantages, the automatic and semi-automatic capsule filling machine also has limitations. They include:

Drawbacks of semi-automatic capsule filling machines-sourced: pestleanalysis

Drawbacks of semi-automatic capsule filling machine:

- Low productivity.Compared with the fully automatic capsule filling machine, the semi-automatic type has limited production capacity;

- Slow speed.The semi-automatic type is much slower than the fully automatic type;

- Increased cost.The semi-automatic capsule filling machine requires an operator. This adds extra cost;

- High human error rate.Semi-automatic capsule filling requires manual replacement of molds and materials;

Drawbacks of automatic capsule filling machines-sourced: pestleanalysis

Drawbacks of automatic capsule filling machine:

- High investment cost. The fully automatic capsule filling machine is more expensive and requires more supporting facilities, which increases your cost;

- Higher maintenance level. The fully automatic capsule filling machine is more complex and requires a higher level of maintenance;

- Low flexibility. It is impossible to replace more molds like the semi-automatic filling machine;

7.What Are The Different Components Of Automatic And Semi-automatic Capsule Filling Machines?

Learning about the structure of the capsule filling machine can help you better understand it.

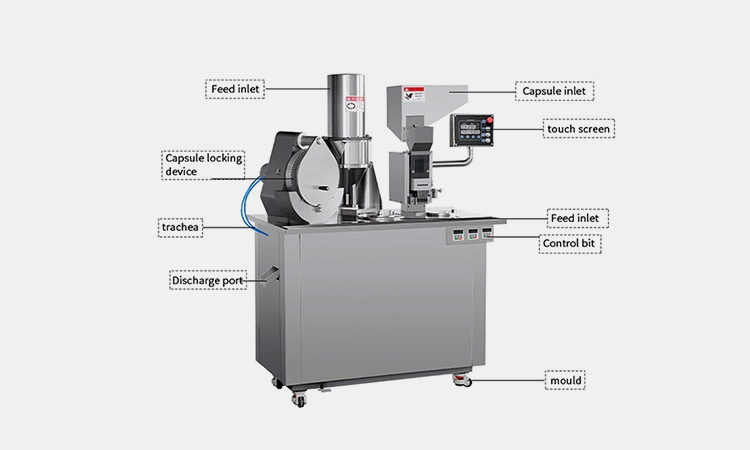

a. Components Of Semi-automatic Capsule Filling Machines

Components Of Semi-automatic Capsule Filling Machines-sourced: gainjoys

Feed inlet

Also called as feeding hopper, or powder storage hopper, is used as to store and fill the required pharmaceutical powder and granules. It requires you to feed the materials manually. It is equipped with a spiral mixing device, which is convenient for the subsequent powder filling.

Capsule inlet

Also called as capsule hopper,it used as feeding into the empty capsule shells. It also requires your manual loading.

Touch Screen

You can set different filling programs according to your needs. You can also adjust the capsule filling time and speed on the touch screen.

Capsule locking device

The capsule locking device can lock the capsule caps and bod automatically. After the seeding station has been automatically separate the empty capsules and loaded it into the capsule mold, the powder and granules will be automatically filled into to the capsules and locked securely.

Trachea

The trachea is connected with the vacuum pump to give power for the capsule locking device.

Discharging port

After the empty capsules filled and sealed securely by the filling station, they will be ejected and discharged from the discharging port. Capsules that fail to fill or are of poor quality will come out of the waste port.

Control bit

The control bit is applied for protecting the capsule filling machine from overloading.

Mould

The mould, also called as idler wheel, facilitates your movement.

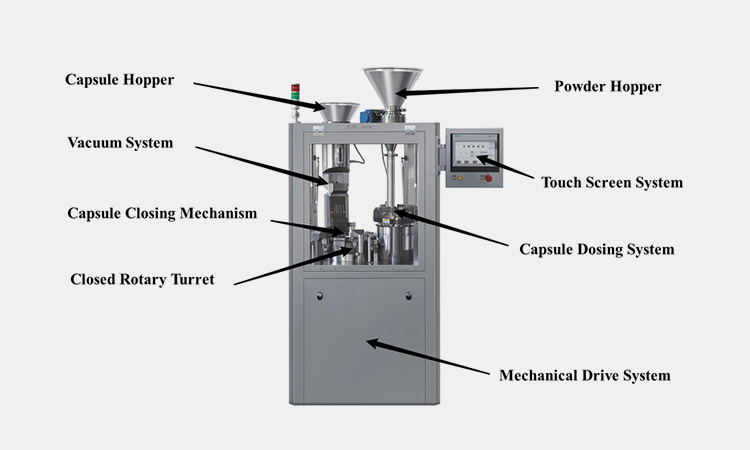

b. Components Of Automatic Capsule Filling Machines

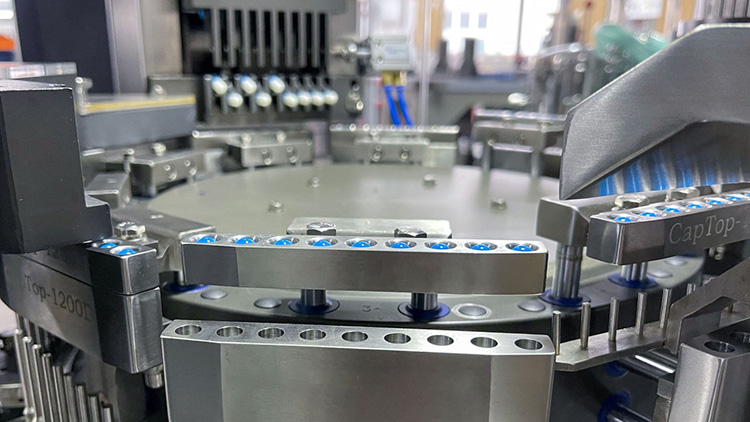

AIPAK Components Of Automatic Capsule Filling Machines

Capsule Hopper

Capsule hopper is the feeding slot for capsule shells. It can hold enough capsule shells at one time. You can choose between manual feeding and automatic feeding.

Powder Hopper

Fully automatic capsule filling machines are equipped with a powder hopper with a screw feeding mechanism. The screw conveying mechanism can convey the powder to the filling part. It is convenient for you to store and fill your capsule powder.

Vacuum System

The vacuum system connects the filling panel of the capsule filling machine to the capsule hopper. It can separate the capsule cap and the capsule body.

Capsule Dosing Unit

The capsule dosing unit is specially equipped with sensors to control the precise filling of powder.

Capsule Closing Mechanism

The capsule closing mechanism can help the separated capsule cap and capsule body to be locked and facilitate the subsequent powder filling.

Mechanical Drive System

The mechanical drive system is the core part of capsule filling. It can start the motor, gears and conveyor belts to drive the machine.

Closed Rotary Turret

The closed rotary turret can help filter out excess powder. This design is an improvement over the previous open rotary turret.

Touch Screen System

You can set and adjust the capsule filling program you need with a simple touch. Ensure the efficient and safe operation of your capsule filling machine.

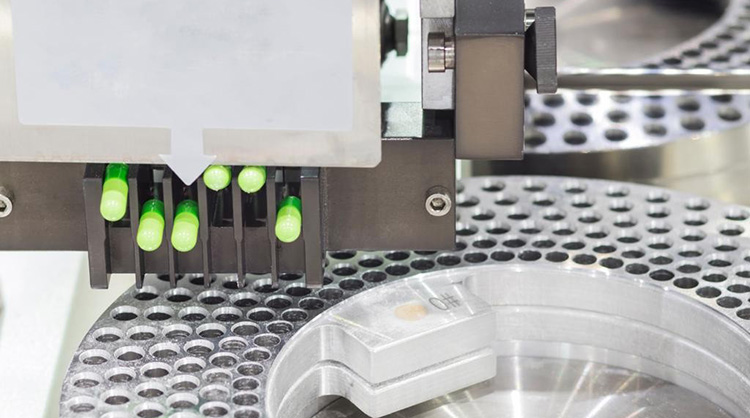

8.What Are The Working Principles Of Automatic And Semi-automatic Capsule Filling Machines?

Semi-automatic capsule filling machines require more manual work. The working principle of semi-automatic capsule filling machine is:

AIPAK working principle of semi-automatic capsule filling machine

Empty capsule loading:You need to manually load the empty capsule shells, and be careful not to overfill.

Ingredients loading: After the empty capsule shells are loaded, the drug powder or granules ready to be filled are loaded into the powder hopper.

Capsule filling: When the empty capsule shells are ready, they are inserted into the capsule plate. The precisely measured drug powder or granules are filled into the empty capsule shells one by one.

Capsule capping: The filled capsule shells are directly capped by the capsule locking plate. In this way, the capsule head and the capsule body are sealed firmly.

Ejection:The sealed capsules are automatically ejected.

The working principle of fully automatic capsule filling machine is:

Feeding: The automatic capsule filling machine is equipped with a vacuum system or vibrator. Therefore, you do not need to manually feed the capsule shells and materials, etc.

Capsule separation:It uses a special clamp to open the capsule shells and fix them on the respective filling stations.

Powder metering: The automatic capsule filling machine uses a special spiral filling technology to fill the drug powder, etc. into the capsule body. The powder is compacted using a compacting pin.

Capping: The locking mechanism directly locks the corresponding capsule lid.

Ejection: The filled and sealed capsule is automatically ejected and transferred to the next stage.

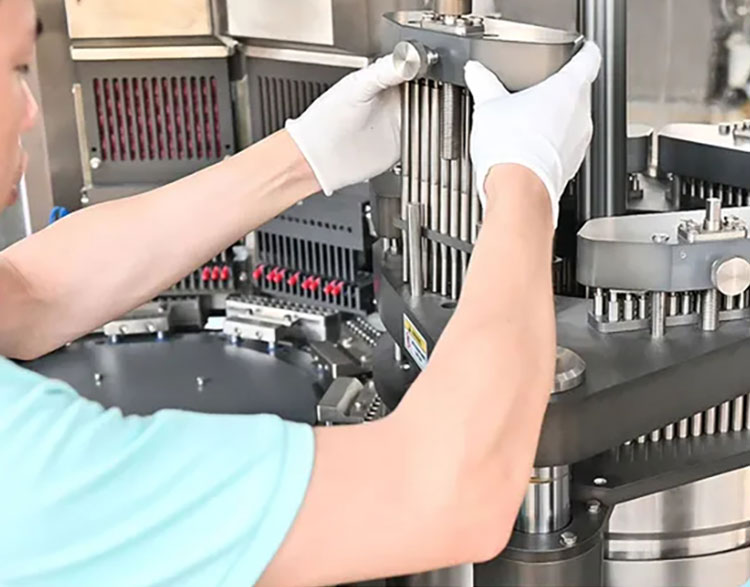

9.What Are The Maintenance And Troubleshooting Tips For Capsule Filling Machines?

Maintenance And Troubleshooting Tips For Capsule Filling Machines-sourced: pharmacy-machines

After choosing the right capsule filling machine for you, it is also very important to provide daily optimization and maintenance. Regular maintenance and troubleshooting can avoid any risks in the future use. Here are some tips for your maintenance and troubleshooting:

Regular cleaning

Regular cleaning-sourced: richpacking

After each cycle of using the capsule filling machine, you need to clean the machine thoroughly. This includes cleaning all the residues or contaminants in the machine. Then use a detergent and disinfectant to clean, and then dry it naturally.

Lubrication

Strictly follow the manufacturer's requirements and properly lubricate the machine and parts to reduce friction and prevent wear on the machine.

Calibration

Calibration-sourced: ruidapacking

Regularly perform machine calibration to ensure the correctness of the program, the accuracy of the filling dosage, etc.

Inspection

Check the machine for any signs of damage, loose bolts or worn parts. Replace damaged or faulty parts in time.

Program maintenance

Good program maintenance can ensure the correct setting of dosage levels and adjustment of filling speed in the future.

Training

Regularly provide corresponding training to operators. This will help them become more familiar with the equipment and detect potential problems with the machine in time.

10.What Are The Safety Precautions When Using Capsule Filling Machines?

Safety Precautions When Using Capsule Filling Machines-sourced: leadtop

When using a capsule filling machine, you also need to consider the safety of the operators. Reminding operators to follow these basic safety precautions can minimize the risk of accidents. The safety precautions are:

Wearing personal protective equipment

Operators are strictly required to wear personal protective equipment. This includes, but is not limited to, safety glasses, gloves, and lab coats or aprons.

Electrical safety

Before using the capsule filling machine, you need to ensure that the machine ground interface is properly grounded and plugged into a grounded outlet. Regularly check the power cord of the machine for any signs of damage.

Equipment placement

Do not place the machine on any obstacles or flammable materials. You can place the machine on a solid, level surface and away from fire sources.

Emergency start-up

Check whether the operators are familiar with the emergency shutdown procedures and the location of the fire extinguisher. If any emergency occurs, they can quickly take safety measures.

11.How To Select The Right Automatic And Semi-automatic Capsule Filling Machines For Your Needs?

If you need a capsule filling machine, choosing the right type may greatly improve your production efficiency and production volume. Here are some key considerations:

How To Select The Right Automatic And Semi-automatic Capsule Filling Machines-sourced: AIPAK

Production capacity

Evaluate the production capacity you need. You need to consider the number of capsules you need to fill per day or hour and the time.

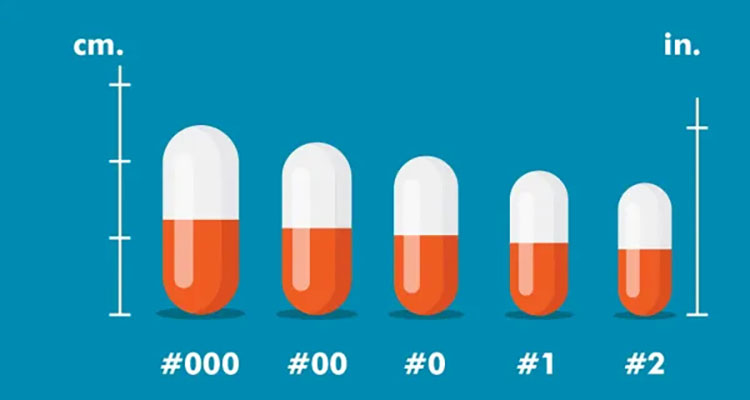

Size range

Size range-sourced: capsulesizes

Some fully automatic or semi-automatic machines have specific requirements for capsule size. You need to determine the size and shape of the capsules you need to fill.

Accuracy

If you have a general requirement for the dosage accuracy of capsule filling, then manual and semi-automatic machines can meet your needs. If you have extremely high requirements for dosage accuracy, then fully automatic capsule filling machines are more suitable for your needs.

Friendliness

The user-friendly operation of the machine can also greatly improve your production efficiency and reduce errors during operation.

Cost-effectiveness

Cost-effectiveness-sourced: isaac

Manual and semi-automatic machines have low equipment costs, but high labor costs. Fully automatic capsule filling machines have high equipment costs, but low labor costs.

12.What Are The Future Advancement For Capsule Filling Machine Technologies?

Future Advancement For Capsule Filling Machine Technologies-sourced: thefusioneer

The pharmaceutical industry is constantly developing, and so does the capsule filling machine. The manufacturers are also constantly keeping up with the times, updating technology to better meet customer needs. What progress will the capsule filling machine have in the future?

Automation

Automation-sourced: businessworldit

As the global population decreases, capsule filling machines will introduce artificial intelligence and robotics technology to achieve full automation, requiring minimal human involvement and increasing accuracy. More capsules can be processed in the same amount of time.

More adaptability

With improved automation, capsule filling machines will be more adaptable. It can adapt to capsules of different types, shapes and sizes. This will give you greater flexibility in your production.

Smart sensors

In addition to being more adaptable, future capsule filling machines are also becoming more flexible. By using smart sensor technology, it can detect any anomalies or deviations in the filling process, enhancing the accuracy of your capsule filling.

Data analysis

Data analysis-sourced: datacamp

In addition to providing capsule filling technology, quality, and speed, it can also collect and monitor filling data in real time to help you with subsequent data analysis. It can achieve predictive effects and functional optimization of capsule filling, etc.

Environmentally friendly design

The sustainability of equipment is very important in all industries in the future. Future capsule filling machines will improve waste reduction, recycling, etc. during the production process.

Conclusion:

Through this complete guide of types of capsule filling machine, you will be able to learn about the features and benefits of different capsule filling machines of different models. Do you want to know more about the best capsule filling machines or the leading capsule filling machine manufacturers? Contact AIPAK and tell us now!

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine