Two Major Trends In The Pharmaceutical Packaging Industry

Two important trends are emerging in the pharmaceutical packaging industry.

More robotic packaging lines are being used to improve packaging efficiency and maintain packaging consistency in order to increase the competitiveness of companies in the market; and the use of environmentally friendly packaging materials in production is being explored in order to move into a sustainable path.

Over the past decades, the pharmaceutical packaging industry has undergone several transformations; in the future, the industry's transformation will continue to occur along with technological advances.

In recent years, the emergence of new epidemics and increased public interest in sustainability and digitalisation have accelerated this transformation.

The demand for robot technology and sustainable development materials in the pharmaceutical packaging industry is growing steadily

Part I

Trends in the pharmaceutical packaging industry

Sustainability

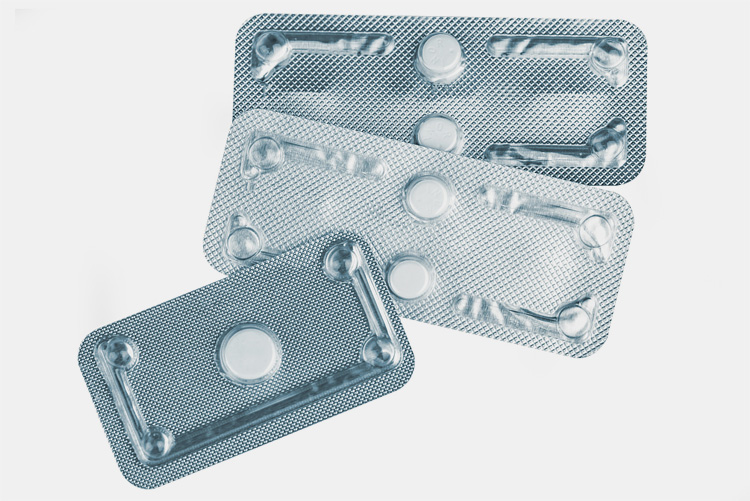

The pharmaceutical industry is increasingly working together to develop sustainable packaging materials. For example, Syntegon, a leading global supplier of processing and packaging technology, is working with finnish packaging materials manufacturer Huhtamaki to develop a sustainable paper alternative to plastic blister packaging for tablets and capsules.

In a press release, Matthias Klauser, sustainability specialist at Syntegon, said. "By applying our paper packaging with a TPU 1000 form, fill and seal machine, 3D easy-to-form Fibreform paper from Billerud Korsnäs and Huhtamaki's sealable barrier coating, we have succeeded in forming packaging that can hold tablets within a 3 to 4 mm cavity. "

The paper blister packaging solution "blister meet paper" developed by syntegon and Huhtamaki

The pharmaceutical industry has long demanded packaging materials that meet the highest quality standards," says Francesco Stanzani, Commercial Director of the Marchesini Group: "Product safety is of the utmost importance to the pharmaceutical industry, which has therefore always paid great attention to the area of safety, so many adjustments have to be made to meet the various technical specifications."

The Marchesini Group manufactures pharmaceutical packaging equipment and lines for a wide range of applications and is constantly involved in research and development of new environmentally friendly solutions to meet the needs of its customers.

“This is why our solutions are so successful, such as our MA80 case packer, which is designed to pack products into paper trays, and our FB220 thermoformer, which uses environmentally friendly materials like polylactic acid (PLA)."

IMA, a manufacturer of processing and packaging automation equipment for the pharmaceutical industry, is also promoting the use of environmentally friendly plastic alternatives in its equipment products.

For example, the paper tray packaging line range from IMA Safe, an IMA company, allows a wide range of injectable products and medical devices housed on paper trays to be packaged into cartons to make 100% paper packaging that is easily recyclable, has relatively low energy requirements and is biodegradable.

Sustainability can also be seen in the production process, adds Thomas Fricke, Commercial Director of the Ima Pharma division of the Ima Group: "The containment technology used for capsule filling has been undergoing various changes, reducing the use of disposables like plastic and water, resulting in significant energy and economic benefits. "

Robotics

The demand for robots and collaborative robots (cobots) in the pharmaceutical packaging industry is steadily increasing.

The use of robots has many advantages, such as the ability to increase efficiency, scale production freely, speed up production, take up less space and be easier to move around.

A report by market information company Beroe highlights that both large and small companies are adopting robots and autonomous mobile robots to ensure they achieve high levels of quality, remain competitive in the market, maintain packaging consistency and address labour shortages.

The use of robotic solutions in all areas of packaging is a continuing trend," says Thomas Fricke: "In the past, robotic systems were often only used to lift heavy loads or were deployed to work in hazardous areas; today, robots are everywhere, as they can be flexibly used for a variety of different products and packaging formats, such as loading products and packaging materials onto packaging lines, picking up and placing products inside packages, labelling and assembling packages." The highly precise robots can perform a wide range of tedious tasks and can operate around the clock.

Gerhard Schubert, a pioneer in the development of modular pharmaceutical packaging machines, has introduced the versatile Top Load Robot (TLM) packaging technology.

Based on a simple mechanism design, intelligent control technology and a high degree of modularity, this technology allows many additional functions to be integrated into the packaging machine, such as labelling, inserting instructions for use or using defined quality control methods. This modular packaging machine meets the requirements of a wide range of dosage forms and is suitable for all types of pharmaceutical products.

The Marchesini Group has also launched a new integrated robotic packaging line, the Integra 720V, which is used to fill blister-packed pharmaceutical products into cartons and is distinguished by its very fast packaging speed.

This compact multi-lane blister packaging line consists of two parts: a blister packaging line for forming the blisters and placing the product to be packed into the blister cavity, and a case packer for loading the blisters into cartons.

These two sections are connected by a three-axis robot, Robocombi, which can be fully integrated into the packaging line and was developed entirely by Marchesini's R&D department. This solution can pack up to 720 blisters and 500 cartons per minute and is easier to clean and change the size of the packaging as it separates the product loading section from the electrical and mechanical sections.

Part 2

New market trends

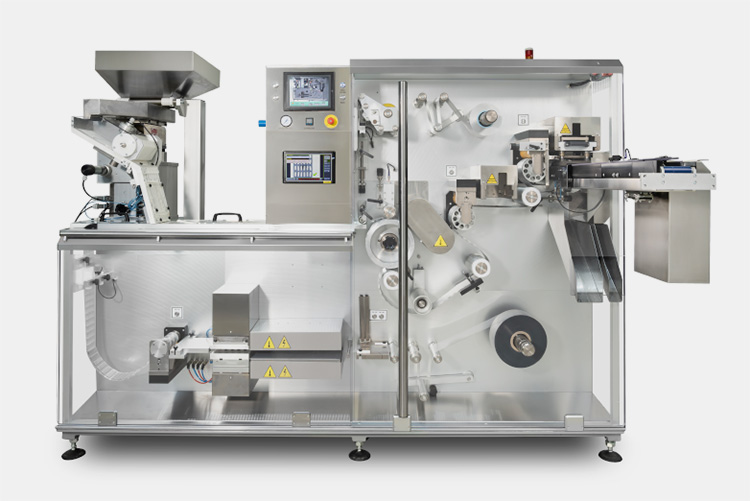

MG2, an Italian manufacturer of pharmaceutical production and packaging equipment, has launched a new blister packer designed to optimise primary packaging of capsules and tablets in the blister pack sector.

The solution, called the Blistar blister packer, has a capacity of up to 150 blisters/min and a maximum pack size of 90 mm x 140 mm, making it an excellent choice for pharmaceutical companies wishing to produce R&D grade batches. Equipped with a touch screen panel, this solution provides a real-time display of the machine's operating status. It also detects if any product has been left out of the blister cavity before the sealing operation.

Blistar blister packaging machine of Mg2 company

Optima Packaging, a German company specialising in automated pharmaceutical packaging equipment, has launched the Multiuse System. This is a new concept that offers great flexibility and efficiency for packaging expensive pharmaceutical products with unique filling requirements and can accommodate a wide range of delivery packaging formats such as ampoules, syringes and cassette glass bottles.

The system also offers a quick and easy packaging form changeover, a feature that has proven itself in practice and helps pharmaceutical companies to meet the various new demands of the market.

The system combines different types of technology to achieve high yields while offering a very good price/performance ratio. The technologies used include re-dosing, re-corking and re-capping, maintaining 100% weight control, etc.

IMA has also launched its next generation fully robotic packaging line, Tritone, which is already close to zero manual operation with fully automated product changeover, a solution that offers pharmaceutical companies many advantages such as less space, lower operating costs, increased throughput and reduced downtime.

This technology can also be used in environments where it is necessary to completely eliminate human-machine interaction.

In IMA's aseptic filling line Injecta, the robot is able to constantly switch parts of the equipment in use to avoid problems with product damage and danger to the operator.

Syntegon's Flexible Filling Platform is an innovative modular platform for filling ready-to-use (RTU) containers and bulk containers. The platform can handle different types of containers such as ampoules, syringes and cassette bottles.

This solution can be quickly adapted to the different needs of production companies. This filling platform has a capacity of up to 3600 containers/h and offers 100% half-way verification of weighing.

The platform's selling point is the complete elimination of glass-to-glass contact, which allows pharmaceutical companies to achieve excellent flexibility with the platform in its original factory configuration and to subsequently expand it with additional functions.

Conclusion

In recent years, the pharmaceutical packaging industry has shown rapid growth due to a number of factors, such as increased awareness of healthcare, the successive approval of new drugs, growing healthcare spending by people, the continued prosperity of the biopharmaceutical and generic markets, and the promotion of regulations focusing on product traceability and serialisation.

In terms of market size, the global pharmaceutical packaging market was valued at US$98.2 billion in 2020. According to a report by market research firm Researchand Markets, the global pharmaceutical packaging market is expected to reach US$161.6 billion by 2026, growing at a CAGR of 8.4%.

In the future, the pharmaceutical packaging industry will also invest more resources in the exploration, development and application of robotics and sustainable materials.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine