Tube Packing Machine:The Ultimate Buying Guide In 2025

Tube packing machine is an exceptionally multipurpose packaging solution. Depending upon the requirement, this machine is available as standalone or in line with primary packaging properties. Tube packing machine is suitable for a broad range of industrial applications.

If you are looking for a tube packing machine to upgrade your business-we aim to deliver exactly what you want. Keep reading to find relevant information about tube packing machines

1.What is a tube packing machine?

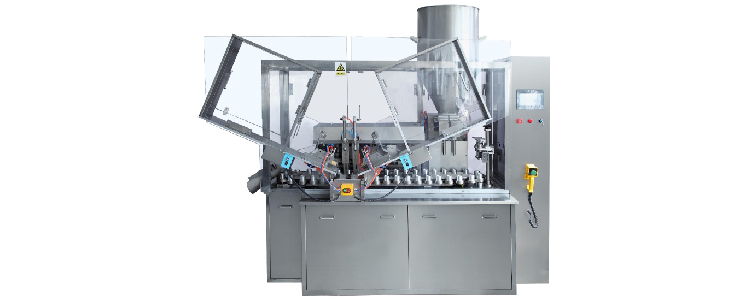

AIPAK tube packing machine

A tube packing machine is designed to fill and seal ointment, cream, toothpaste, etc. in the tubes.

This machine is a reliable, high-accuracy packaging system that enables clean and accurate filling of product at the optimum speed that gives high-quality outcomes.

This machine is constructed with the latest technology and has been monitored critically against various parameters so to yield premium-quality packaging. Tube packing machine is a bestselling machine with a high degree of automation and significant industrial applications in industries.

2.Why do you require a tube packing machine?

A tube packing machine is a piece of flexible equipment you always require in routine practices. The reason behind their huge necessity for products is discussed below:

- Containment

The containment is the most crucial factor in packaging medicinal products. Packaging must be:

- intact, do not cause leaking, permeation, and diffusion

- keeps the content balanced against alteration of formulations

- strong enough to hold content

- Protection

Your product always needs tube packaging to keep the formulation confined against external influences. For instance: - light

- humidity

- air

- mechanical and biological damage

- Stability

For primary tube packing, it is mandatory to consider the evaluate stability factor. Tube packaging must facilitate stability for filled content against internal and external factors:

For instance

- chemicals liberation during packaging

- release of visible and sub-visible content

- degradation of content

- Preserve physical properties and identity

- Storage

A tube packing machine is of prime importance when it comes to storing your formulation under specific conditions. - For tube packing, the tube packing machine must comply with cGMP storing areas and materials that ensure high integrity and firmness of formulation.

- Tube packing allows better storage for temperature and light-sensitive products

- maintains sterility of formulations.

3.What are the industrial applications of tube packing machines?

Tube packing machines have a significant role in different businesses. They are used in industries where liquid material of different viscosities is filled into tubes.

They are increasingly employed in the pharmaceutical industry, pesticide, food, stationery, and cosmetic industries.

- Pharmaceutical Industry

The pharmaceutical industry is the major industry that uses tube packing machines. In the pharmaceutical industry, tube packing machines are extensively employed to package several kinds of viscous medicine in the tubes.

Creams such as ointments used to treat skin problems, acne, and allergies are filled in the tubes by the tube packing machines.

They have applications in filling healing and burn ointments, gels to treat toothaches, creams used to treat mouth ulcers in the tubes.

- Chemical Industry

These machines are extensively utilized in the chemical industry. Different kinds of chemicals are packaged into containers by using these machines.

These machines fill solvents, bonds, glues, and adhesives into their tubes.

Chemicals like coating materials, polishes, building sealants are packed in their container by utilizing tube packing machines.

- Veterinary Industry

Tube packing machines are largely used in the veterinary industry. These machines have a role in filling the tubes with various kinds of creams and lotion to treat animal allergies and skin problems.

These machines also have used in packing food and feeding for pets.

- Hygiene Industry

Tube packing machines are the key component of the hygiene industry.

Their most important application in the hygiene industry is the packing of toothpaste in their colorful and aesthetic packs.

Various other applications of these machines in the hygiene industry are the packing of cleansers, skin lotions, deodorants, and numerous nature of gels in their tubes.

- Stationery Industry

These machines are widespread in the stationery industry. These are used to fill tubes with varieties of paints like water, acrylic, etc in the tubes.

These are also used to pack inks and glittery products in the containers.

- Food Industry

Tubes packing machines are a leading component of the food industry. These are utilized to fill and pack diverse forms of pastes in their eye-catching containers.

Various kinds of viscous sauces like pizza sauce, condiments like mustard sauce, mayonnaise, ketchup, etc are filled in tubes by utilizing these machines.

These are also used to package dips and dressings.

- Cosmetic Industry

Tubes packing machines have far-reaching applications in the cosmetic industry. These are significantly employed in packing various assortments of makeup and beauty products in their stunning packs.

These machines are applied in the packing of different foundations, skin lotions, cleaners, and makeup masks.

4.What are the advantages of tube packing machines?

Tube packing machines are one of the main components of businesses that supply their manufactured goods in the tubes.

Using a tube packing machine increases your sales and expands your market value.

Colourful packs and tubes increase the worth of your product which enhances their chances of getting sold. That is why packing is a major part of your venture. So you must buy one good tube packing machine.

If you are thinking about purchasing this useful machine, let’s learn about a few of its useful pros.

- Efficient Performance

If you supply more of your products in the market, it will increase their chances of selling. And this is only possible if you increase your production efficiency and speed of the manufacturing process.

The tube packing machine speedily fills and packs the tubes. Some machines can pack up to 120 tubes per cycle. This causes the productions of hundreds of tubes per day.

This will lead to an increase in the stock of your merchandise in the market and ultimately enhance the growth of your venture.

- Decrease Labor Cost

Tube packing machine has automatic function setting such as for filling, capping, etc. You do not have to hire labor for different procedures in tube packing operations. So this machine lowers your labor cost.

Also, you do not need a major workforce to maintain and clean this machine. This machine has an automatic cleaning operation which saves time and effort.

- Simplicity of Operation

Modern tube packing machines have computerized systems for easy handling and operation of these machines.

End users’ program different running parameters such as the number of tubes packed in one cycle, time duration of operation, volume of paste on the human-machine interface.

This interface is also used to set the temperature, humidity, and pressure of the machine.

- Reliability

Consistency is the most important factor in increasing the business. If your product is reliable and does not have variations, then it will enhance your sales.

The tube packing machine is highly reliable and precise. It measures the exact volume of paste for filling the tubes. By using this machine, you do not produce inconsistent end products.

- Wastage of Product

Tube packing machines are very precise and accurate because they estimate the right volume of paste and liquids which are to be filled in the tubes.

If you psychically fill tubes, this causes a lot of wastage of product. But these tube packing machines reduce the amount of product waste.

You simply have to select the level of tube and machine handles the rest. This machine guarantees precise paste packaging.

- Better Work Conditions

Using this machine can ensure better work conditions in your business. You just have to change some running parameters then you just have to monitor the entire operation.

This makes you productive and relaxed at your work.

- Multitasking Operation

This machine provides multitasking performance. It easily fills tubes with different levels of paste at the same time.

This machine boosts your business if you supply medicines and chemicals in different-sized packs. You can easily fill multiple-sized containers at the same time which increases manufacturing processes.

Tube Packing Machine

5.What type of material used for tube packing?

There are wide range of tubes offered by manufacturers for packaging purpose. While commonly used materials are as followed:

1.Plastic Tubes

Plastic tubes are adaptable form of material. The high grade plastic such as polyethylene is suitable for making tube material for packing toothpastes, oinments, creams etc or product with short halflife.

2.Laminated Tubes

This form of tube packing is a hybrid of plastic and aluminium material. Such packaging efficiently protects content with multiple layer coating. A laminated tube packing offer extra glossy and shiny appearance to packaging product.

Aluminium tubes are pressure sealed and develops high physical protection against microbial content thus facilitates great protection. Aluminium tubes are ideal for packaging pharmaceutical and cosmetic products and are 100% recyclable.

6.How many types of tube packing machines are there?

1.Automatic Tube Packing Machine

AIPAK Tube Packing Machine

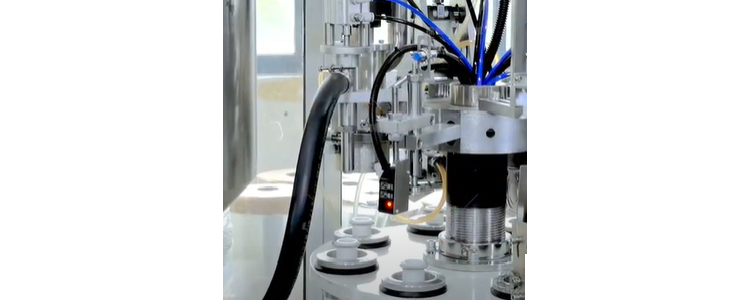

An automatic tube packing machine is primarily used to pack and seal the tubes whether laminated, aluminium or plastic for various industrial units. This is also known as ‘automatic tube filler’.

The main purpose for this technology is to allow high efficiency production and minimize user’s fatigue. Tubes from feeding to discharging all functions are carried out automatically. This machine pack variety of products with different speed of production per hour depend upon user’s choice.

Automatic tube packing machine is suitable for packing creams, ointments, toothpaste, and other relevant products.

2- Semi -Automatic Tube Packing Machine

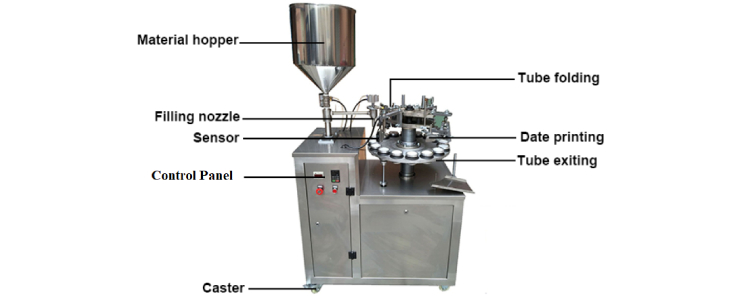

AIPAK Semi Automatic Tube Packing Machine

The semi-automatic tube packing machine is suitable for automatic alignment, filling, sealing, coding, edge cutting. This machine is extensively applied in routinely chemical, medicinal, food industry etc. This machine also deals with material with various viscosities along with dust cover.

As compared to automatic tube packing machine, this machine lacks power conveyor unit and deals with small scale packing process. Furthermore, feeding and finished product has to remove by user manually for capping unit. This machine is ideal for small scale-production unit.

3.Manual Tube Packing Machine

Manual Tube Feeding- Tube Packing Machine

7.What is the working principle of a tube packing machine?

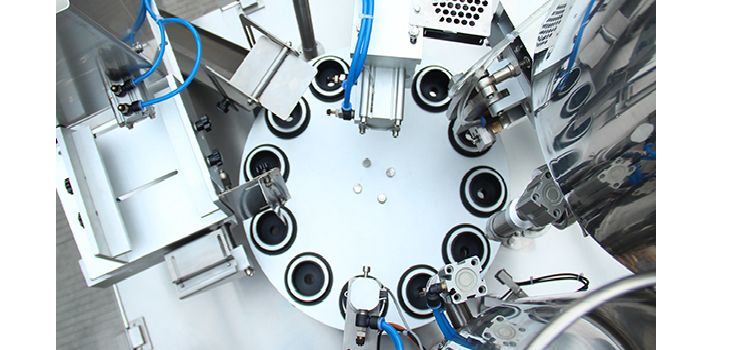

A tube packing machine is highly automated equipment and consists of a circular rotary table that contained a tube holder for placing tubes in the filling station.

- The working principle of the tube packing machine is based on volumetric measuring.

- By adjusting the required volume in the plunger using certain power for filling up the amount.

- It is a highly automated machine, and it consists of a round rotary plate at filling stations in which tubes are placed. Power implementation leads to the filling of tubes present at the rotary table of the tube packing machine.

- After filling tubes moves to seal stations and subsequent stations perform folding and sealing of tubes. After sealing they move to coding stations where coding is completed.

- The subsequent tubes are then ejected from the discharge chute to provide you with finished-filled tubes.

8.What are the special components of the tube packing machine?

The basic parts of the tube packing machine are as followed:

- Main Body

The main body of the tube packing machine is made up of stainless steel that enables firm support to the remaining parts of a machine.

- Wheels

The compact structure of the tube packing machine is supported by wheels that enable convenient movement of the machine from one place to another.

Tube Packing Machine

- Tube Container

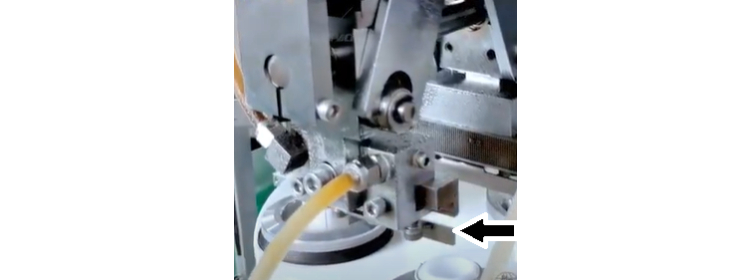

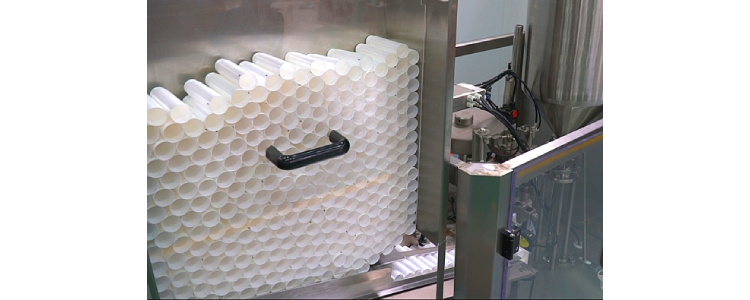

Empty tubes are manually fed into a tube container. These tubes must be supplied in aligned and stacked form. - Tube Feeding System

A tube feeding system transfers empty tubes from tube containers to rotary tables for filling purposes.

- Tube Holder

They are available in different sizes that support the holding of tubes for filling. This tube holder is accompanied by the eye-mark sensor.

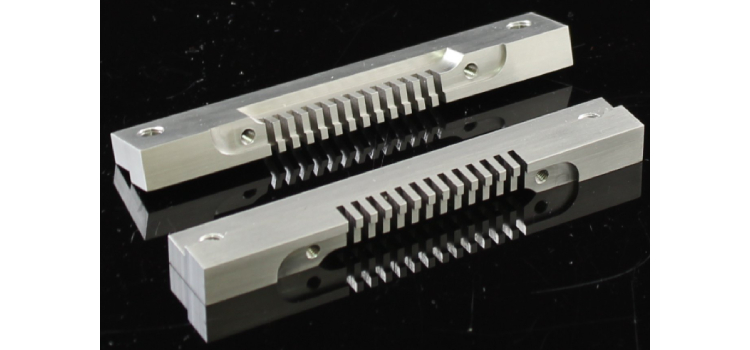

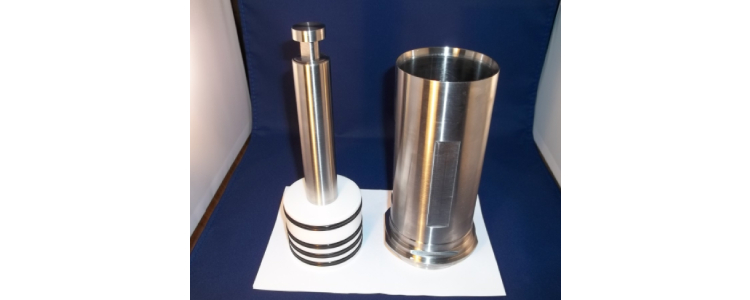

Tube Packing Tools

Different Size Tube Holders

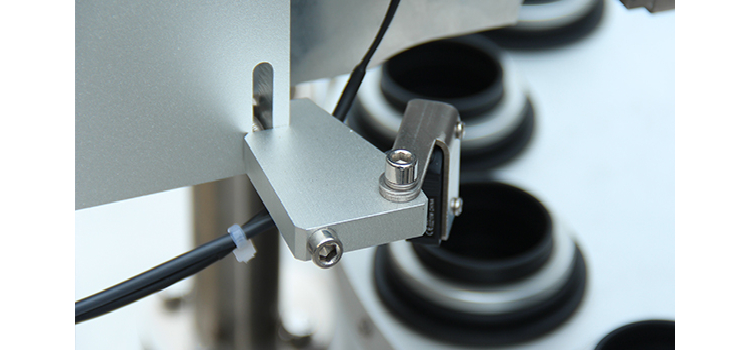

- Sensor

A tube holder in the rotary table is held with a sensor that helps to detect the tube. If a tube is present sensor detects and leads to fill or if the sensor is failed to detect the tube, no filling occurs.

Sensor - Rotary table

The tube packing machine is equipped with a rotary table, as the name suggests their rotation brings tubes for filling and leaves the filling station.

- Hopper

Hopper is a funnel-shaped device that allows easy transferring of packing material from the receptacle to the filling station.

Hopper- Tube Packing Machine

- Hopper Handle

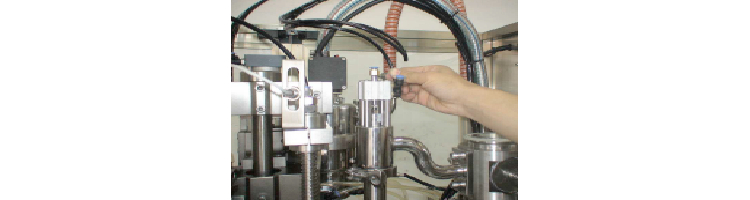

The capacity of material in the hopper is adjusted by using a handle attached to the bottom of the hopper. - Filling Head

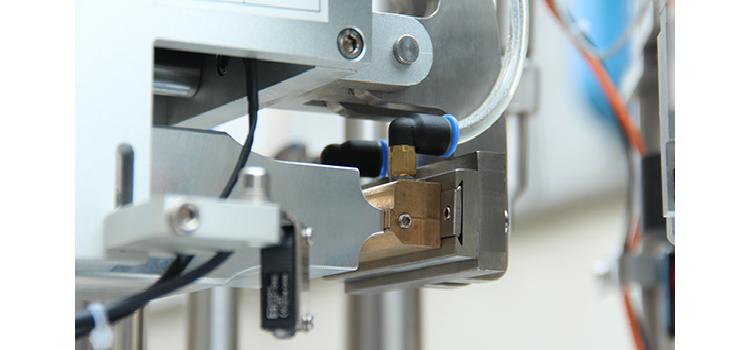

A filling head is composed of a filling valve that enables the filling of containers with accurate discharging of products.

- Filling Nozzle

This is commonly known as a filling needle or filling tube. This is a point where dispensing material is discharged straight from hopper to container. It controls the volumetric packaging of content in the tubes.

Tube Packing Machine- Filling Nozzle

- Dosing Pump

An integral part of the tube packing machine where the pre-determined amount is available to feed into empty tubes. The amount of dispensing material is dependent upon process protocol and stored data in the programming of the tube packing machine.

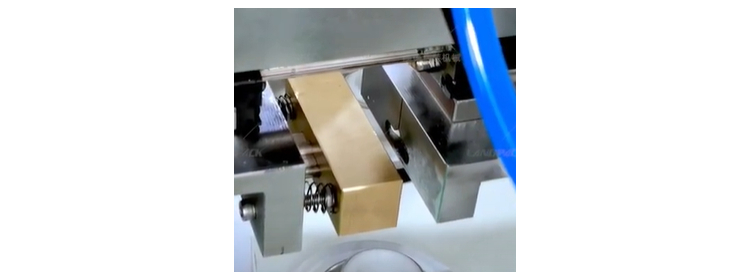

- Sealing Unit

Filled tubes are sealed with the help of heaters that combines and fold the edges of tubes and seal them properly.

- Coding Jaws

Coding jaws signifies the sealing and coding of tubes to make a finished product. - Cooling Unit- Water Chiller

Cooling unit associated with water chiller to cool outside edge of the tube to achieve good sealing effects. Most often it provides cold water up to 5-10 degrees.

- Air Heater

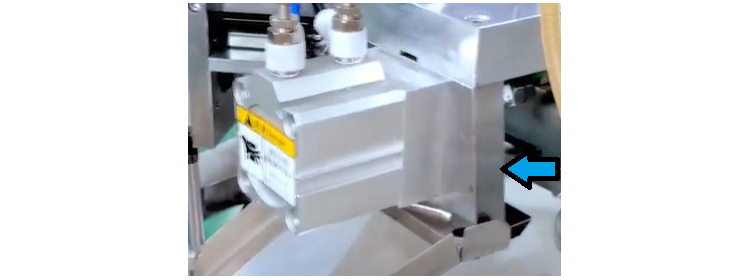

Air heater regulates air and temperature regulations of tube packing machines. - Edge Cutter

The edge cutter is regulated by the rounded or square cylinder. - Discharging Unit

The final form of the packed product leaves the system via a discharge chute. - Control Unit

The Control unit regulates various process parameters required for the packing of material. This is accompanied by a touchscreen HMI control unit

- Electronic Box

An electronic box of tube packing machines helps to regulate centralized electrical connections of the machine.

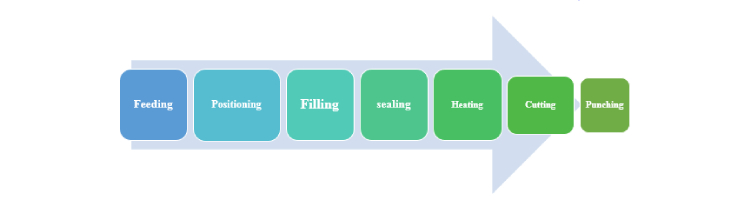

9.What is the process flow of the tube packing machine? A brief review

The workflow of tube packaging machine is based on the following eight categories:

1.Feeding Station

Feeding tubes are manually introduced into the feeding unit for filling purposes. This unit does not require much labor work. Because when tubes are stacked, the feeding unit will automatically move them into the next station.

This is the second station, tube holder that holds tubes until the sensor detects and fills them. If the sensor fails to detect the tube no filling would take place.

3.Filling Station

This is the third station that is comprised of a hopper filled with packing ingredients. The hopper is made up of stainless steel that ensures 100% safe, accurate and contamination-free formulation. You can adjust the volume of ingredients by hopper handle presented just below the hopper.

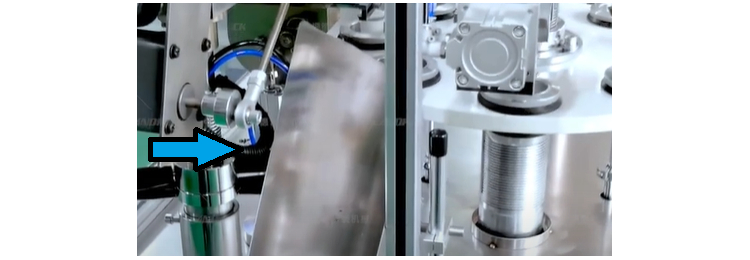

4.Heating Station

This is the fourth station, that allows instant heating, while water chiller equipment provides chilled water to facilitate a good sealing effect on the tube.

Water chiller enables good sealing effects

5.Sealing Station

After filling tubes are transported to sealing and stamp station, where a heat sealer joins the edges of tubes and sealed them followed by a stamping or printing unit where coding jaws stamps the code at the bottom of the tube.

6.Edge Cutting Station

7.Punching Station

Punching unit associated is with butterfly or round hole.

8.Discharge Station

Tube after packing and sealing are collected via discharge tube

10.What are the integrated instruments of the tube packing machine?

Tube packing machine working line is integrated with the following list of instruments:

- Washing & Sterilization System

To make packing tubes or containers dust and germ-free, this machine is integrated with a washing and sterilization system (optional) to make filling tubes free of contamination. - Auto-Feeding unit and Scrambler

This unit is of extreme importance; a large quantity of tubes is stacked into this unit for filling or packing purposes. The loaded tubes are passed automatically into the next stage without requiring technician support.

AIPAK Automatic Tube Packing Machine

The packing of tubes with various technology according to product characteristic and type of tube or jar.

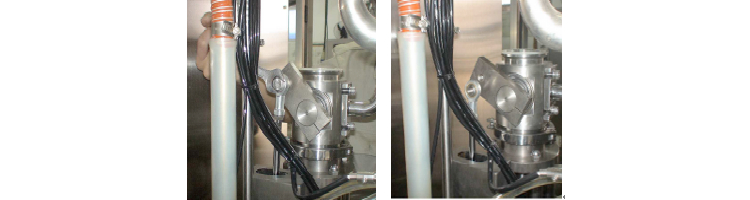

- Induction Sealing Unit

An induction sealing system is applicable to seal the neck or lip of the tubes. This unit is also known as

the inner seal which is used for safety purposes. This unit allows non-contact heating that joins a foil, laminated material. - Capping Machine

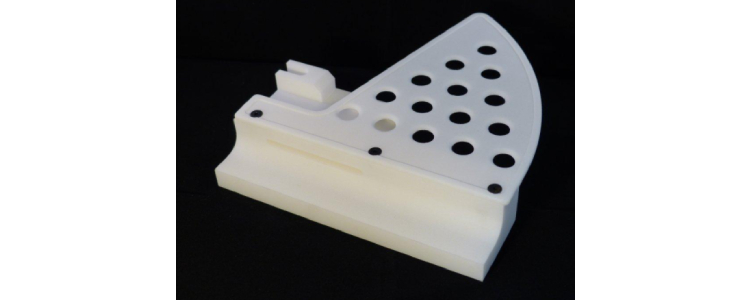

The capping machine allows enclosure application on filled tubes. - Labelling Machine

Part of tube packing machine- Tool for 3-D printing

A labeling machine is an integral unit used to apply labeling on the pack of a tube. This unit is crucial for brand promotion and relevant information of products etc.

- Batch Coding Unit

This unit is used to print batch codes, date of manufacturing and expiry, and other details. - Tube Conveyor

Tube conveyor is used to transporting tubes for different stages of the process till the discharge unit. - Bundle Wrapping Machine

This unit of packing machine helps to pack tubes in a bundle of polythene film or boxes that allow convenient traveling and distribution.

11.Structural features of tube packing machine are?

- Compact and Reasonable Structure

Tube packing machine is embodied with advanced conception design with reliability, and reasonability for handling pharmaceutical products comply with GMP requirement for processing.

- An Adequate Tube Packing Technology

Associated working units for operating auto-feeding, filling, sealing till finished product under highly synchronized manner.

Auto-Feeding Unit- Tube Packing Machine

- Safe & Contamination Free Construction

The structure of tube packing machine is carried out with stainless steel material. All material of this machine ensures safe and contamination free environment for treating product.

- Filling Nozzle

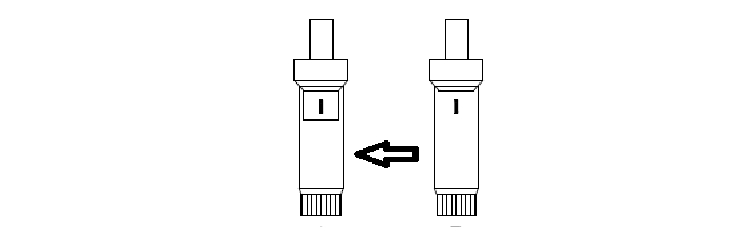

The feasible extension capability of filling nozzle ensures accurate volumetric dispensing of content into the tube. Hence this ensures a good sealing quality instead material adhesion over tube wall. - Quantitative Filling Valves

Tube packing machine features reliable piston filling valve for quantitative packing of material. You can also adjust the packing volume and packing accuracy.

Piston and Cylinder

- Convenient Assembly and Disassembly

Tube packing machine features easy assembly and disassembly of packing unit. The hopper body, filling head, tube holder etc, can easily be disassembled to carry cleaning and maintenance of machine. - Air Blowing Device

Air blowing device features high quality sealing properties due to rapid cooling down the temperature of sealing edge.

- Self- Lubrication System

The enclosed mechanical structure of tube packing machine has adopted self-lubricating system. - Safety Clutch

The allocated safety clutch effectively ensures fault overload.

12.Can you describe failure and troubleshooting for tube packing machine?

We have enlisted basic problems and the troubleshooting of tube packing machine. Lets’ have a look.

1.Problem: Deviation of color code- How to Solve it?

Troubleshooting

- Adjust the angle of photoelectric detector

- Place the tube appropriately in tube holder and turn it left or right to carry basic adjustment.

2.Problem: Horizontal and vertical coding both are punched- How to solve it?

Troubleshooting

- Tone down the light irradiation by photoelectric detector.

3.Problem: Coding on transparent tube? How to do it?

Troubleshooting

- Transparent tube can not shade light which is sent by photoelectric detector. You may not be found the colors code. You can solve this problem by code searching hammer that can be installed into diameter of tube and shade lights that is irradiated from photoelectric detector toward tube.

Troubleshooting

- Check the link between cooling ring and tube. If too loose then this problem may by occur. For this you must replace the cooling ring.

- Adjust the middle position of sealing or heating device. It must be aligned to tube holder rotary table vertically.

5.Problem: Bottom of tube contacts with heating unit- How to solve this problem?

Troubleshooting

- Too many content is packed into the tube. Hence volume of packing must be adjusted.

6.Problem: High heating temperature

Troubleshooting:

Distance between heater and tube must be adjusted, it must not be closer than 5mm.

13.What are the essential tips for selecting a tube packing machine?

It is already mentioned that tube packing machines are very useful in the pharmaceutical and chemical industry. But if you are wondering about buying these machines then you should buy high-quality and efficient machines.

As discussed, there are many kinds and forms of tube packing machines in the market but not all those machines produce good results.

A few important aspects that should be considered while buying tube packing machines are discussed below. If you follow these guidelines, then you will buy a good quality tube packing machine.

- Size

Size should be the one of main concerns when buying the tube packing machine. As of now, the machines are moving from larger to more compact forms.

When you are thinking about procuring this handy machine, first you should find out what size of machine you need.

If you have limited space, then buy a small-size tube packing machine.

Also, production capacity is the major factor in determining the size of the machine. If you want to manufacture goods on large scale, then buy those machines which have a large size.

- Safety Compliance

Before buying the tube packing machine, first, check that the machine fully meets safety compliance. You should check that machine meets all the necessary standards.

Machines require approval by the regulatory bodies before their use. So should ensure that the machine you are buying meets all the quality standards and regulations.

This will assure safe operation of the machine and ease of your production.

- Capacity

Most buyers consider capacity one of the main concerns when buying a tube packing machine.

It simply means the number of manufactured goods produced by the machine in a given time.

First, you need to understand what kind of machine is more suitable for your business. If you have a large production house, then buy the machine which has more production capacity otherwise go for a smaller one.

Packaging Machine – Picture Courtesy- Wikipedia

- Construction

Construction and type of materials is important consideration when buying the tube packing machine. Machines that are made of resistant materials that can bear extreme working conditions such as high temperature and pressure will last long. You should purchase machines made up of stainless stain as it can not only endure extreme conditions but is also rust-proof.

Type of Product

Before purchasing the tube packing machine, think about the type of product you are packing. Different kinds of tube packing machines handle paste of different viscosities.

Some are for free-flowing liquids, and some are for paste having high viscosity. So, you should ensure that the machine you are buying is right for your product.

14.What are cleaning and maintenance SOP of tube packing machine?

- Clean the components of tube packing machine (filling nozzle, hopper, rotary tube holders etc) with edible detergent and clear water followed by scrubbing of internal wall with 70% alcohol and air dry.

- You can easily dismantle the component by following manner.

a.Remove ferrule of body and hopper

b. Remove hopper

c.loose body and cylinder

d.disassembles the air-pipee. loosens body and flange

e.removes filling partg. Loosen material cylinderh.

f. removes filling part

g.Loosen material cylinder

h.Loosen screw nozzle & valve body

i. loosens the dustcover clean the dust cover

j. Take out the nozzle & core

k. loosens the dustcover clean the dust cover

l. take out – snap ring

m. hit the valve spool using a rubber hammer

n. take out the spool

Maintenance

1. Machine body

- Cut-off supply after each work, wipe the filling nozzle, cup of seat, rotary table, coding jaws, printing clamps with a cotton absorbent dipped in alcohol. Maintain all the parts of machine dust free.

2. Scale structure

A lubrication grease of large table column and scale structure of tube packing machine must be replaced biannually. Furthermore, they must be check and oiled every week.

3. Speed reducer

If the oil level of speed reducer is lower than ½ check and maintain it every week.

4.Driver System

Chain and cam plate is allocated at bottom of machine table that should checked and oil weekly.

15.What are the future trends of tube packing machines?

Tube packing machines are increasingly used in modern industry. The current demand for tube packing machines is expected to rise in the next 5 years.

The current market growth of the tube packing machines is due to the growth of the pharmaceutical industry, cosmetic and chemical industry. The need for these products boosts the purchase of food packing machines.

Besides, the pharmaceutical and chemical industry food industry also has a moderate influence on the growth of tube packing machines. The increase in the market value of tube packing machines is impacted by their demand in different industries.

COVID-19 has negatively hampered the growth of tube packing machines. Also, it has been estimated that high prices and complexity in operating tube packing machines hinder the expansion of the tube packing machines market.

With the ease of COVID-19 restriction, it has been forecasted by the global report on the market value of tube packing machines that this market during 2021-2028 will face expansion due to increasing demands of chemicals and medicines.

Tube packing machines manufacturers are employing the latest technologies such as the use of robots to produce the tube packing machines. This will create new opportunities for the growth of the tube-packing machines market.

It has been expected that the demand for automatic tube packing machines will rise during the next 5 years. This is due to their simplicity of operation, multitasking, and packing many tubes at the same time.

Conclusion

Tube packing machine is a versatile machine that can perform concurrent packing and sealing processes. This machine is extremely applicable in various industries like pharmaceuticals, food, chemical etc.

As we discussed complete processing can be conducted automatically devoid of much labour work and time. We understand your need and hope you’ve found this blog productive & understood basic advantages, application, technical points and much more related to tube packing machine. So, you will be able to choose suitable machine for your business. Happy Shopping!

Tube Filling Machine Related Products

Tube Filling Machine Related Posts

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours

A filling head is composed of a filling valve that enables the filling of containers with accurate discharging of products.

A filling head is composed of a filling valve that enables the filling of containers with accurate discharging of products.