Industry Leading Tube Filling Equipment Manufacfurer

- China Best Tube Products Manufacturer&Supplier

- High-speed Tube Filling Equipment

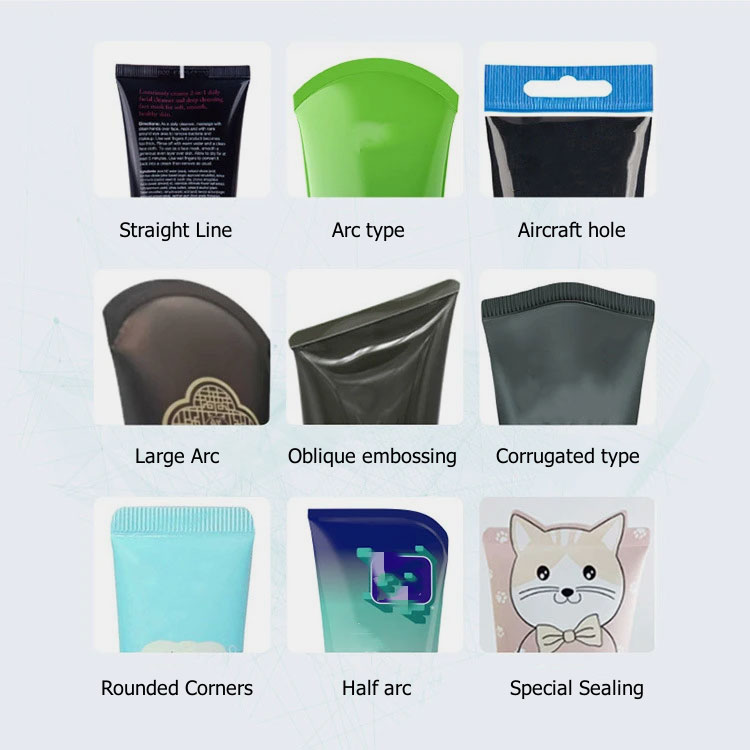

- Various Sizes&Shapes Tube Making

AIPAK Tube Filling Equipment

AIPAK Tube filling equipment is widely used in the filling of various semi-fluids, pastes, viscous bodies, sauces and various granule-containing materials,such as pulp-containing beverages, honey, jams, ketchup, chili sauce, bean paste, shrimp paste, apple sauce, salad dressing, etc. It is widely used in many industries, such as toothpaste, cosmetic and food industries. This equipment has a high degree of automation, automatic tube loading, automatic color marking, automatic tail sealing, batch number printing, and automatic tube discharge.

AIPAK Tube Filling Equipment Applications

AIPAK tube filling equipment is suitable for ointment, toothpaste, facial cleanser, conditioner, shampoo, hand cream, eye cream, hair color cream, shoe polish and other products.

The Buyer's Guide

Tube Filling Equipment: A Complete FAQ Guide in 2025

Do you know how tubes are filled with creams, gels and many more? The answer lies in a tube filling equipment. These equipment works as a game changer for industries such as food, pharmaceutical, cosmetic, and chemical industries where tubes are filled with medical creams, lotion, and or sauces.

There are different types of tube filling equipment available in the market, but choosing a better one might put you in tangles. Then, how to come out of this? You are on the right platform where you will get to know the factors to consider when selecting a tube filling equipment.

Don’t worry! You are in right place. This FAQ guide will provide you with fruitful information that is important to know. Stay with us. Let’s get started.

1.What do you know about tube filling equipment?

AIPAK NF-60 Tube Filling Equipment

Tube filling equipment is also known as tube filling machines or tube fillers. This equipment is designed to tube fills from lotion, creams, gels, and other liquids. Different filling and sealing methods are used in this whole process. Filling tubes are made from different materials such as aluminum and plastic.

2.How is tube filling equipment beneficial?

There are various physical ways to fill tubes but it has disadvantages. Tube filling equipment has proof fruitful for filling. Let’s take a closer look at benefits.

Accurate filling

Accurate filling

Tube filling equipment accurately fills tubes. It fills tubes equal in volume and weight, so errors are not as high as typically high when filling physically.

Versatility

Versatility of size

Tube filling machine can handle various liquids and semi-liquids to be filled in tubes. These tubes are of various sizes and shapes.

High efficiency

Due to the automated system of tube filling equipment, it operates at high speed which helps to fill hundreds of tubes in a short time, and also meets demands of customers in short time. It helps comply with requirements where air, moisture, and the light is not suitable for a product.

Reduce waste

Reduce waste

Human error in manual filling can cause inaccurate filling leading to product wastage. Tube filling equipment precisely dispenses different products such as gels, creams etc in tubes. Volumetric and weight-based tube filling equipment provide solutions to problems of product waste.

Cost-effective

Another benefit is that it is cost-effective. You do not have to buy separate equipment for sealing and packaging of tubes. Small businesses can buy manual tube-filling equipment, which is less expensive, and then upgrade to automated tube filling equipment.

3.Do you know the industrial use of tube filling equipment?

Tube filling equipment is used in various industries for its high precision and accurate filling. Following are the applications of this equipment.

Veterinary industry

Veterinary industry

The veterinary industry uses tube filling equipment to pack animal’s mediational fluids, oral pastes, and nutritional gels in tubes. To be successful effect, exact dosage is necessary for veterinary.

As most of the veterinary tablets and creams are sensitive to moisture, air, and light, to keep them safe from spoiling and guarantee a long shelf-life tight tube packaging is mandatory. Veterinary products for different animal species may require different size packaging.

Food industry

Food industry

Another industry that uses tube filling equipment is food industry. Here, various liquids are handled of thin to thick viscosities such as honey, tomato ketchup, and many more. Food items are sealed with high precision and accuracy.

Tubes provide environment to the internal materials that are heat-sensitive like cream and sauces.

Cosmetic industry

Cosmetic industry

Cosmetic industry uses tube fillers to package lotions, serums, and foundations. As you have seen that cosmetic products come in various densities. These all package in tube to maintains freshness, purity, and safety, protecting them from external pollutants and oxidation.

Chemical industry

To package chemicals, lubricants, and adhesives, tube filling equipment is used. These are seal tightly to keep them from external reactions. Chemicals substances are packed in plastic, aluminum, or laminated tubes to prevent them from degradation.

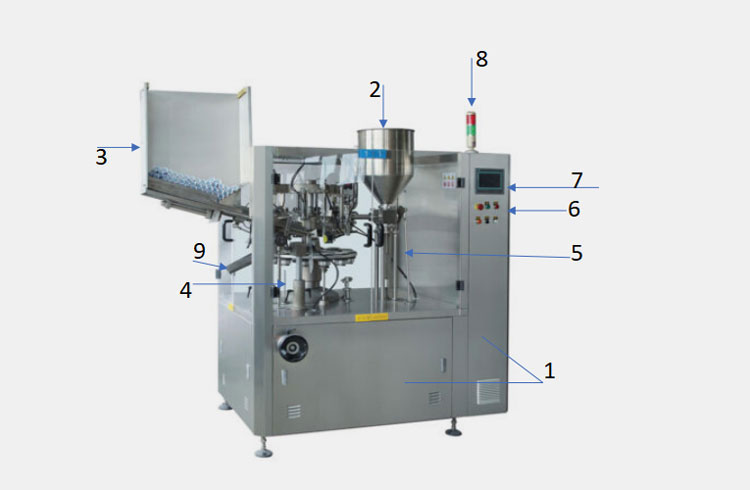

4.What are the components of tube filling equipment?

Components of Tube Filling Equipment

1.Electric box

2.Hopper

3.Tube feeding

4.Filling nozzles

5.Feeding pump

6.Safety buttons

7.Control panel

8.Safety alarm light

9.Discharge tube

|

Electric box

|

Electric box consists electrical components of machine which safely operates and control system of machine. It ensures smooth and efficient function of machine parts. It comprises circuits, wires, and automation system. |

| Hopper | Hopper is stainless steel. It holds materials before filling. It makes the product flow to tubes. |

| Tube feeding | By tube feeding, tubes are load into machine for filling. As they are positioned in tube holder for fillings. In manual equipment, tubes are manually feed in machine. |

| Filling nozzles | Filling nozzles fill tubes with high accuracy and precision. It handles liquids with different densities from thin to thick. Number of nozzles may be varied according to models of tube filling equipment. |

| Feeding pump | Feeding pump takes product from hopper to filling nozzles in order to fill tubes. It is important where accurate dosage is required. |

| Safety buttons | Safety buttons are used at time of emergency to alert workers at time of emergency. It also prevents machine from damage. |

| Control panel | Control panels allow users to monitor, adjust, and manage machine. It has digital display and touch-screen features. |

| Safety alarm lights | Safety alarm lights aware operators if there is low level of products in hopper, any malfunction or error in machine |

| Discharge tube | After products are prepared, the next step is to take them to discharge tube for further processes such as labelling, cartooning, and quality inspection. |

5.What is the working principle of tube filling equipment?

The step-by-step overview of working principle of tube filling equipment is as following:

Tube feeding

Tube feeding

The first important step is tube feeding. Tubes are loaded into the machine through hopper. You will see that tubes are either fed manually or automatically, depending on the type of machine.

Another important thing that you must keep in mind is that tubes are must be positioned correctly, to ensure no misalignment and tubes are kept firmly in their place.

Filling

Tube filling

After tube feeding, the next step is filling. In filling step, tubes are filled from with the desired stuff. Here, it is made sure that each tube is filled equally and ensures no contamination and spillage when dispensing.

Different dispensing methods are used to fill tubes. Such as:

Volumetric method

As the name shows that in volumetric method, each tube is filled equally in volume to ensure uniformity in volumes of substance in tubes.

Piston fillers

Here, the piston is used to fill tubes by pushing substance in tubes through pressure of piston.

Peristaltic pump

In this, roller is used to push substance or product into tubes.

Sealing

Tube sealing

After feeding and filling, sealing is done on the open end of tubes. Now you will think how sealing will be done. Different sealing methods are used to seal tubes. Here are the methods.

Ultrasonic sealing

Tubes are closed by heat produced by high-frequency sound waves. A very clean and clear is done by this method.

Hot-air sealing

Hot air is put on the tubes to soften the open ends of tubes. These softened tubes end fuse together and sealed the tubes.

Crimping

Crimping method involves crimpling or compressing of tubes open ends. This process is done mechanically.

Cutting

Cutting blades are used to cut or remove the excess materials at the open end of tube. As for the customer attraction and attractive and clean appearance, cutting process is carried out.

Labeling

How customers will know about the product ingredient, expiration date, and other product related information? Labeling is done to print batch number, product’s ingredients, expiration date.

Packaging

After the above steps, last but not the least step is packaging. Tubes are ejected to packaging station to pack, cartooning the tubes.

6.What are the types of tube filling equipment?

Followings are the types of tube filling equipment.

Fully-automated tube filling equipment

AIPAK NF-60 Fully Automated Tube Filling Equipment

This type of tube filling equipment is ideal for industries where high production of tubes are necessary. It is highly efficient and operates at high speed.

Each part of machine is working automatically. Feeding, filling, sealing, and other steps are done automatically, without use of man-labor.

Semi-automated tube filling equipment

AIPAK NF-30 Semi-automated Tube Filling Equipment

You will see in semi-auto tube filling equipment that some of the work is done manually and some automated. It is suitable for small-scale industries.

Tubes are loaded manually in machine. Filling and sealing are done in automated way. Ejection is done by operator for further process. So, operator is needed in some of steps.

Piston tube filling equipment

Piston Tube Filling Equipment

Piston tube filling equipment is used when the product is of high viscosity that needs pressure to be filled in tubes. In this type of equipment, piston draws product in cylinder. From there, piston puts pressure on product to be influx in tubes.

This is applicable in industries such as cosmetic, pharmaceutical, and food where accurate dispensing is required.

Rotary tube filling equipment

Rotary Tube Filling Equipment

Rotary tube filling equipment operates at high speed. As the name indicates, this type of machine allows you to do filling, feeding and sealing in one transaction.

The accuracy and precision of this type of tube filling equipment are top-notch. If you talk about the versatility of this equipment, it can handle various tube sizes, materials, and type. It is best used for pharmaceutical, food, and other industries.

Plastic tube filling equipment

AIPAK NF-80 Plastic Tube Filling Equipment

Plastic tube filling equipment is used to load, fill, seal the plastic tubes, and can handle plastic tubes with high precision. In this, plastic tubes are loaded into machine, then filled with the desired product, and sealed with the process of hot air sealing or crimping.

It is ideal for industries where large-scale filling of plastic tubes is required.

7.What type of products can be filled using tube filling equipment?

Different type of products can be filled using tube filling equipment. Here are the following products.

Lotion

Lotion-Picture Courtesy: lesopack.com

Lotions come in thin to thick liquid used for moisturizing skin. Lotions are being filled using tube filling equipment which precisely fills these tubes.

Gel

Gel

Gels are used in cosmetic and pharmaceutical fields. In cosmetics, gels are used for hair and as moisturizers while in pharmaceuticals, gels are used for pain treatment and other treatments. These are packed in various- sized tubes using tube filling equipment which pack products in tubes in such way as to prevent them from germs.

Food pastes and liquids

Food paste-Picture Courtesy: thisismold.com

Food pastes and liquids such as mayonnaise, sauces, honey etc are packed in tubes through tube filling machine. These are sealed to keep them fresh and prevent them from spoiling.

Adhesives

Adhesive

Adhesives such as glue that is used for consumer purposes and in industries. Different viscosity adhesives are packed in tubes using tube -filling equipment.

Paints

paints

Paints are used by artists. These are filled in tubes through tube filling equipment. Sealing is done to protect paints from drying out.

8.What is the difference between tube filling equipment and lotion filling equipment?

There is difference between tube filling equipment and lotion filling equipment on some of the areas. What are you waiting for? Let’s get started.

AIPAK NF-120 Tube filling equipment AIPAK NF-100 Lotion tube filling equipment

| Tube filling equipment | Lotion filling equipment | |

| Viscosity handling | Tube filling equipment can handle liquids of various viscosity, from thin to thick. | Can handle thin liquid such as runny lotion. |

| Filling process | Depends on product viscosity, it uses different filling mechanism such as piston, volumetric, and peristaltic pumps. | It uses gravity and piston fillers in filling process. |

| Sealing mechanism | Seal tubes, ultrasonic, hot air and crimping methods are used, to ensure tight sealing. | As for seal the lotion tubes, flip caps and screw caps is used to air-tight the sealing. |

| Types of products | This equipment can handle various products such as sauces, adhesives, gels, pastes etc. | It can handle thin-liquid based products such as lotions. |

| Cost | It is expensive as it handles various viscosity-based products. | Lotion filling equipment is more expensive than the tube filling equipment. |

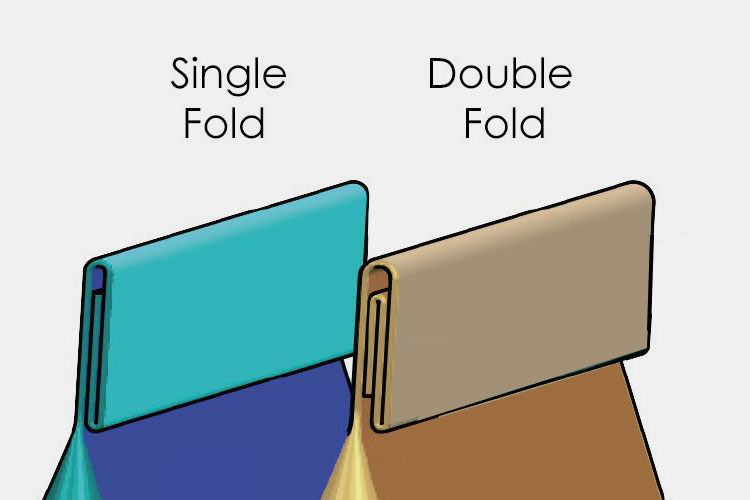

9.What are different folding types offered by tube filling equipment?

Once the tubes are filled, they are sealed using different folding types. Here are the folding types offered by tube filling equipment.

Single and double fold-Picture Courtesy: makwell.com

Single fold

In single fold, tubes open ends are sealed once to ensure accurate sealing.

Double fold

As you can know from the name, in this folding type, tubes are sealed twice. It is affected for products with sensitive characteristics.

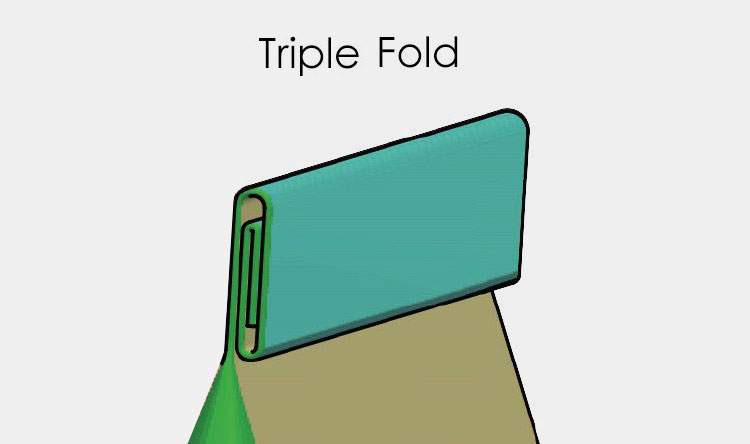

Triple fold

Triple fold-Picture Courtesy: thetubecouncil.com

In this folding type, three folds are done as sealing.

Crimp seal

Tubes are sealed by mechanically crimping technique, prevent leakage.

Roll-over fold

For clean and uniform sealing, roll over folding is used.

10.How to choose the best tube filling equipment?

Choosing the best tube filling equipment depends on different factors which are:

Budget

Budget

To choose tube filling equipment, first look at your pocket whether it coordinate with your budget or not.

Speed

Speed of equipment is very necessary in production capacity. If you want a limited production speed, semi-automated equipment is best. But if want a large-scale production, automated tube filling equipment is ideal.

Flexibility

flexibility-Picture Courtesy: casma.com

If you want equipment that can handle various types and sizes of tubes, then choose that tube filling equipment that has the ability of do so.

Accuracy

As in pharmaceutical industry, filling accurate tubes is important. Choose an equipment that can fill tube with high precision and can handle if tubes are overfilled and underfilled.

Conclusion

To conclude this, a tube filling equipment offers you with lots of benefits and you can choose this by considering factors that you can comply with. Tube filling equipment is used in various industries such as cosmetics, food, pharmaceuticals and many others. If you want to buy tube filling equipment then you can visit our website and choose amazing tube filling equipment.

Tube Filling Equipment Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586