With The Increase Permeation, Traditional Chinese Crusher Machine Building Innovative “Strong Magnetic Field”

Crushing is an obbligato step in medicinal materials processing, which uses mechanical force to crush large solid materials of traditional Chinese medicine into appropriate fineness.

The difficulty of crushing the drug mainly depends on the structure and properties of the substance, but the magnitude of the external force is also closely related. Therefore, the use of traditional Chinese medicine crusher machines play a key role.

The traditional Chinese medicine crusher machines are mainly suitable for small traditional Chinese medicine factories, traditional Chinese medicine stores, traditional Chinese medicine hospitals, etc., and also suitable for chemical, mining and scientific research units.

It has the characteristics of high work efficiency and simple operation, and can achieve good crushing effect on plant fibers, high hardness and high toughness materials, such as Chinese herbal medicines, inorganic substances, minerals, etc.

With the improvement of traditional Chinese crushing technology and development of science technology, the traditional Chinese medicine crusher machine is gradually integrated into the new production type. And combined with industry trends to upgrade.

It is reported that, in order to develop the traditional Chinese medicine crusher machine more scientifically and comprehensively, some pharmaceutical machine companies use the virtual assembly (Virtual Assembly, VA) technology to analyze the assembly level and assembly relationship of the integrated traditional Chinese medicine crusher and key components.

The so-called VA technology is a crucial part of virtual manufacturing. By making use of Virtual Assembly, you can verify whether the equipment design and operation are right so that

operators can find problems in assembly as soon as possible, make modifications to the model and visualize the assembly process.

The key technologies in VA, assembly modeling, interference detection, assembly sequence planning, etc., can all bring important impetus to the integrated research of traditional Chinese medicine crusher machine, including structural design and construction of virtual prototypes of equipment.

VA technology also optimizes the model construction and assembly sequence of the traditional Chinese medicine crusher machine, which promotes the successful one-time assembly of the traditional Chinese medicine crusher machine during the assembly trial production process, thereby reducing the R&D cost of the companies.

Not only VA technology, but some pharmaceutical machine companies also use cloud computing, big data, black technology and other means to speed up the research of traditional Chinese medicine crusher, strictly control daily production, and accelerate the pace of research and development of traditional Chinese medicine crusher machines.

However, in addition to the new technology of traditional Chinese medicine crusher, the overall research and development direction of the industry is also the focus of many pharmaceutical machine companies.

Taking the low-temperature dust-free crushing direction as an example, the pharmaceutical machinery company has adopted innovative grading wheel technology.

Specifically, the material can enter the grading area with the airflow, and a horizontal centrifugal force field is generated under the action of the high-speed rotating force of the grading wheel.

The powder particles can be subjected to two forces in the centrifugal force field, one is the centrifugal force generated by the rotation of the classification wheel to drive the particles to rotate, and the other is the centripetal force that the particles run toward the center of the classification wheel rotor due to the influence of the induced draft fan.

In addition, there are some companies developing the traditional Chinese medicine crusher to effectively solve the high temperature problem in the low-temperature crushing process.

Specifically, through the relative separation of the crushing chamber and the grading city, the equipment can prevent the crushed materials from staying in the crushing chamber for a long time due to the "screening" of the pallet, and avoid the phenomenon of "over-crushing".

The specially engineered cold air system can also make the temperature generated during pulverization taken away by the induced air, so as to solve the problem of excessive temperature in the process of low temperature crushing.

In the fierce market competition, China’s crusher machines still have many deficiencies. It is still hard for us to manufacture high-precision crusher machines and the core technology and key products still depend on export.

The processing allowance is large, the energy consumption of the crushing equipment and the consumption of raw materials are serious, the processing cycle is long, and the production efficiency is low.

Therefore, in the future development process, companies need to continuously strengthen industry innovation, strengthen the research and development of environmental protection and energy saving technology, and promote the sustainable development of the crushing equipment industry.

At a time when domestic energy conservation and emission reduction and environmental protection voices are getting stronger and stronger, the crusher products equipped with energy saving and environmental protection are undoubtedly the leading direction of research and development and production of crushing machinery in the future.

For all industries, crusher machines play an important role.

It can reduce the particle size of materials to a certain size, such as grinding flour, crushing feed, grinding raw and clinker of pigments, dyes and cement, grinding slurry to prepare suspensions, and increasing the fluidity, filling and easy to package, store, transport, etc.

The material can be crushed and sieved into small pieces, fine grains or powders of different particle size levels, such as the preparation of block stone, crushed stone and artificial sand for concrete and road construction, and the raw coal can be crushed into medium, small and artificial sand according to user needs. pulverized coal, etc.

The surface area of the material can be increased to improve its physical effect or the speed of the chemical reaction, such as grinding the material to be artificially dried to speed up its drying speed, and grinding the catalyst and adsorbent to strengthen its catalytic performance and adsorption respectively.

Similarly, in the pharmaceutical industry, the crusher also plays an irreplaceable role. However, environmentally friendly and energy-saving products with low noise, stable performance, cleanliness, low loss, high efficiency, and accurately adjustable fineness are more popular among companies.

Advocate energy conservation and environmental protection to save existing energy consumption, advocate the development of environmentally-friendly new energy, and benefit society under the condition of energy conservation. Energy conservation and environmental protection is an important and necessary undertaking.

With favorable energy conservation and environmental protection policies, consumers' awareness of energy conservation and environmental protection products and their awareness of subscription to purchase are constantly changing.

Under this trend, energy-saving and environmentally friendly crushers have also become a development trend.

Pharmaceutical machine companies should gradually move closer to innovation, and combine advanced technology and industry trends to develop and produce mechanical equipment that meets market demand.

However, innovation is a long road, and pharmaceutical machine companies still need to contribute to the future development of the industry under the persistence of firm thinking.

Don't forget to share this post!

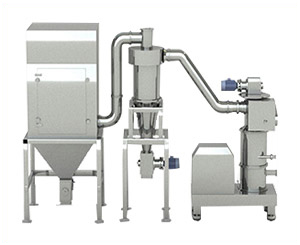

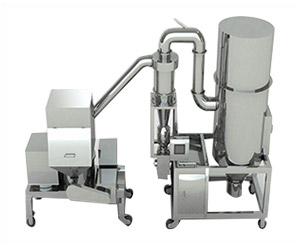

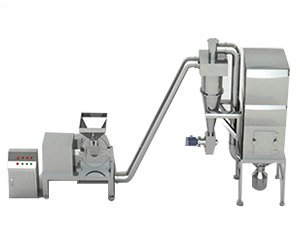

Crusher Machine Related Products

Crusher Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine