Top 10 Fluid Bed Dryer Manufacturers in Germany

Fluid bed dryer machine is an amazing solution when dealing with amount of moisture content present in raw ingredient. It gently treat them and assures high purity without damaging any sensitive ingredient.This innovation has high a thermal efficiency with low capital cost.

Whether you are in pharmaceutical industry or in food industry, chemical or agriculture industry, this product is worth investing in. Fluid bed dryer helps you to achieve drying of pellets, granules, powders, slurries in no time.

Want to buying fluid bed dryer? Want to learn top manufacturers available in Germany? This review post is exactly focusing to provide you Top Ten Manufacturers of fluid bed dryers in Germany. By going through this guide, you will learn about distinct features of each manufacturer.

Germany is the top third countries exporting about $740 million worth of industrial heaters and coolers. You will get excellent quality fluid bed dryers at very affordable rates from Germany.

Let’s start reading to learn about major players in German fluid bed dryer industry.

| RANK | MANUFACTUER OF BLISTER PACK MACHINE | HEADQUARTERS |

| 1. | VIBRA MASCHINENFABRIK SCHULTHEIS | Offenbach am Main |

| 2. | Lödige | Paderborn |

| 3. | Diosna | Niedersachsen |

| 4. | AIPAK Pharmaceutical Machinery | China |

| 5. | Allagier | Uhingen |

| 6. | GEA | Düsseldorf |

| 7. | Glatt | Binzen |

| 8. | JÖST | Dülmen |

| 9. | L.B. Bohle | Ennigerloh |

| 10. | Nara Machinery | Frechen |

1. VIBRA

Company Background & Information

Founded in 1948, more than 70 years ago, VIBRA SCHULTHEIS has earned recognition throughout the world for its competent performance, technical know-how, unique automations, and superior quality. It is major developer of vibration and fluid bed technology, which is used in chemical and food industries for processing of plastics, snacks, dairy products, coffee, and sugar among various other consumer items. Their automations are successfully operating in 80 countries.

170 skilled employees are working dedicatedly to create best experience for their clients. Due to positive experience, their customers trust them to develop unique custom-fit products for them. They manufacture their machines by taking into account their customers’ suggestions. Responsibility and integrity are the values by which Vibra earn the trust of its customers. Their aim is to develop innovations that fulfil varying demands of their clients. Their sustainable actions for environmental protection, makes them a forward looking firm.

Key Products

Vibra fluid bed dryers are suitable for materials that have poor flow. Some remarkable fluid bed dryers by Vibra are:

- Vibrating Fluid-Bed Dryers / Coolers

- Static Fluid-Bed Dryers / Coolers

Recommend Reason

- High temperature endurance

- These machines have hygienic design and operational safety

- Use energy efficiently

- High drying ability

- Control of retention time

2. Lödige

Company Background & Information

Gebrüder Lödige Maschinenbau founded in 1938, is the pioneer of Ploughshare® Mixer and has emerged as a leading developer of processing instruments and partial solutions for pharmaceutical, foodstuff, ecological, metallurgy, minerals, and chemical industries. These automations are utilized to process pellets, dusts, slimes and slurries.

Proficient employees, technical knowledge in processing and manufacturing are the pillars of Lödige’s success. They remain in close contact with its clients- from initiation of ideas till running of machines. Their machines are approved by local and international regulatory bodies having certifications like DIN ISO 9001 and EN ISO 3834-2. They are diligently working to innovate and upgrade their products.

Lödige is always ready to help you in everything you need. They provide custom consultation services so that their machines meet all your requirements. They assist in planning and feasibility testing. It is their belief that support does not stop after installation so they assist you in maintaining your system both remotely and personally.

Key Products

The Lödige fluid bed processors are used in research and development laboratories. These are used to process both small and large batches. Some key products are mentioned below:

Some major fluid bed dryers are:

- Fluid Bed Processor Type LFP 8

- Fluid Bed Processor Type LFP Mini

- Fluid bed dryer LCF for continuous operation

Recommend Reason

- These machines are fully complied with GMP standards

- Stainless steel body houses air inlet, air outlet and controls

- Touch screen for controlling machine operation

- Quick cleaning in no time

- Explosion proof configuration

3. DIOSNA

Company Background & Information

DIOSNA Dierks & Söhne initiated in 1885, more than 135 years ago, is a world renowned firm recognized globally for its processing automations used in the pharmaceutical industry. This firm first designed machines for agriculture and domestic industry. DIOSNA is the leader of high shear mixing technology. They have variety of machine collection including fluid bed dryers, tablet coaters, mixers, and granulators. The reliability and superior quality of DIOSNA machines is appreciated by their customers. They are also praised for competence and professionalism of their employees, ability to shape ideas into products, and efficiency in project handling.

They excel in satisfying its customers by providing them opportunity to test DIOSNA machines and to rent out DIOSNA machines. DIOSNA provides training services to its clients for running and safe operation. Their training courses include classical commissioning, cleaning, maintenance, and troubleshooting. Their customers can also learn about time saving hacks from DIOSNA expert specialists. They offer upgrades and calibration services so that machines are up to date and have best performance throughout their operational life

Key Products

The fluid bed dryers by DIOSNA are used for variety of purposes such as R&D, processing of clinical samples, and mass productions. These fluid bed dryers offer huge profitability and occupy small space. Some best fluid bed dryers by DIOSNA are:

- MINILAB RC

- MIDILAB RC

- CAP 10-80 RC

- CAP 150-1250

Recommend Reason

- Glass doors offer good visual inspection of process

- Graphical display for ease of operation

- Tool free disassembly aid in quick cleaning

- Ergonomic maintenance

- GMP regulated configuration

- Fast changing of batches

4. AIPAK

Company Background & Information

AIPAK Pharmaceutical Machinery is well known for its filling, milling, drying, and packaging technology for both locally and internationally firms was established since over a decade. This firm issued its first capsule filling machines few years later after its start; and now manufactures a huge production lines for various fields. Today, it is top notch manufacturer of fluid bed dryers with particle reduction technologies with 100+ countries and exporting 80% of their machines.

AIPAK is committed to serve its clients and develop high-class products. The innovations designed by AIPAK are made with superior quality parts and skilled craft. This assures the reproducibility and ease of operation. The innovations of AIPAK such as mills, dryers, and feeders are serving many industries like agriculture, biotech, plastic, electronics, food, medicine, glass, and geology.

AIPAK team of skilled technicians provide extraordinary after-sales services to troubleshoot machines and optimize their competence. This team respectfully interact with customers to solve their problem. AIPAK also offer remote product demo so that customers can see their machines in operation from the home.

Key Products

The fluid bed dryer of AIPAK is used in large quality control processes and in R&D plants. This is employed in the processing of pharmaceutical products, plastics, foods, soils, and waste materials. The fluid bed dryer of AIPAK is:

- FG Series Fluid Bed Dryer

- LPG Series High-speed Centrifuge Atomizing Pharmaceutical Dryer

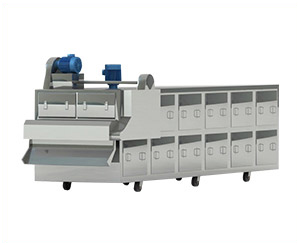

- DW Series Mesh-Belt Pharmaceutical Dryer

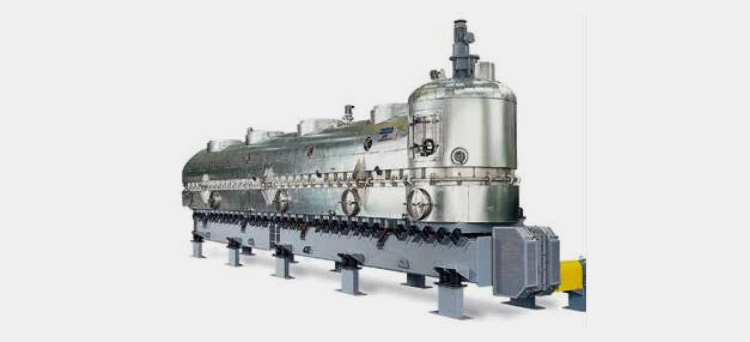

- ZLG Series Vibration Fluidized Bed Dryer

- SZG Series Double Cone Rotary Vacuum Dryer

- GFG Efficient Boiling Pharmaceutical Dryer

- FL300 boiling granulating Pharmaceutical Dryer

- Model RXH Series Hot Air Circulating Pharmaceutical Dryer

Recommend Reason

- Gentle mixing of heat sensitive products

- Rapid drying in 5-20 minutes

- Ease of operation

- Long operating life due to motors with no brushes

- Fan for dispersing heated air.

- Uniform heating of raw ingredients, its comparison to ordinary fluid bed dryer can save 30% energy.

- Balanced operation, low-noise, and extended shelf life.

- On-date- promising transport at your doorstep.

- Pre-sale and post-sale services.

- Compact structure avoids cross pollution between raw material and air.

5. Allgaier

Company Background & Information

Allgaier Process Technology emerged as a main player in processing technology more than 50 years ago. Over the years, it has gathered comprehensive knowledge of various processing solutions so if you need any machinery related to processing you can visit them. Allgaier Process Technology is a huge group under which four major brands Allgaier, Mogensen, Gosag and Mozer are working. This group has the presence in 40 countries and has supplying both standard and custom made innovations to various industries like pharmaceutical, stone, mineral, food, animal feed, plastic, and chemicals.

They have provided machines like washers, dryers, coolers, and screeners to more than 30, 000 customers and this number is growing day by day. Integrated thinking and hard work provide them edge on their competitors. They are here- all over the globe for their customers. Their customers can get technical advice, testing, and installation service. Their expert technicians help their customers to increase machine capability and provide guidance during start up phase.

Key Products

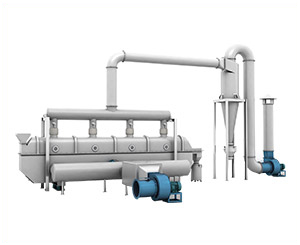

These fluid bed dryers effectively dry sticky products, granules and suspensions. The contact between particles and air result in uniform drying of products. Some best products are mentioned below:

- Fluidized Bed Vibration Dryer/Cooler WS-V-T/K

- Static Fluidized Bed Dryer/Cooler WS-T/K

- Fluidized Bed Dryers/Coolers with Heat Exchangers WS-HF-T/K

Recommend Reason

- These machines operate on low temperature.

- Distribution plate is changed easily

- Explosion proof

- GMP design with CIP and WIP systems

- Gas scrubbers to remove dust

- User friendly process controls

6. GEA

Company Background & Information

GEA was established in 1903 as a manufacturer of dairy automations. Now, GEA is one of the major developer and supplier of food processing innovations. GEA Company has five divisions in which 18,232 skilled employees in 64 countries of world are working night and day to develop solutions and provide services that impress their customers. GEA is tremendously beneficial for its clients as it has far reaching global presence, years’ worth of knowledge, varied portfolio and strong sense of commitment and dedication.

They have been developing by leaps over the years, in 2021; they generated revenue of 4,635 million euros. GEA machines are used in several industries such as dairy, food, chicken, pharmaceutical, health care, beverage, environmental, chemical, marine, oil, and gas industries to process various materials. At GEA, they are committed to achieve excellence and are working with passion to support their customers. They respect opinions and believe in sharing for information. They are dedicated to develop innovations that create a better tomorrow.

Key Products

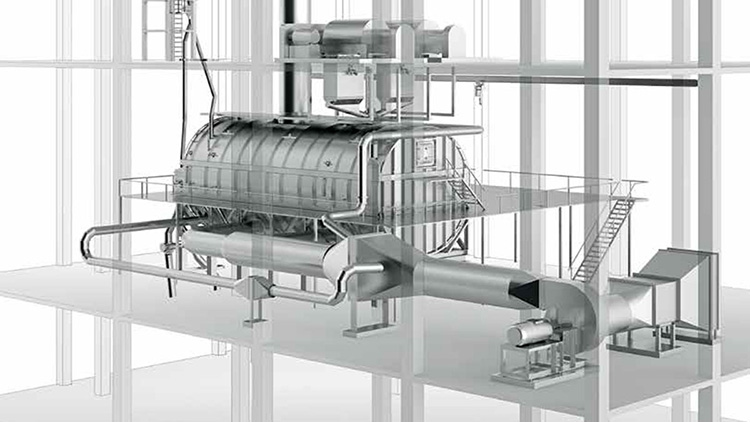

Fluid bed dryers are main technology of GEA Company. It is designed according to the customers’ needs and is used in pharmaceutical, food, milk, and chemical industry. Some of the main fluid bed dryers are:

- Fluid Bed Dryer (Static)

- VIBRO-FLUIDIZER®Fluid Bed

- CONTACT FLUIDIZER™ Fluid Bed

Recommend Reason

- These machines have many zones for temperatures and speed

- Close contact between particles and drying gases

- Energy conservation

- Quick format change decreasing time between batch processing

- Prevent large carry-over

- Process variety of the products

- Reduce operational expense

7. Glatt

Company Background & Information

In 1954, Glatt ventured in business as a small firm that manufacture stove pipes. Later on, they expanded to a large company that have strong partners in various industries such as pharmaceutical, food, pet, and chemical industries. They have distinct catalogue of various machines that are extremely useful in boosting process chains from formulation development, to planning and construction. The mission of Glatt is to design efficient innovations, exchange ideas, and share their expertise.

In pharmaceutical industry, they have diverse specialities develop over 60 years such as development of drugs, analytics, management of clinical samples, contract manufacturing, and pharm- logistic services. They also aid in improving existing formulations and assist their customers in conducting feasibility studies and scale-up.

Their mission is to provide comprehensive solutions for processing technology. They develop custom-made solutions for medium and large productions. They are known for their cutting-edge technologies for granulating, coating, and drying processes.

Key Products

Glatt offers diverse types of fluid bed dryers, effectively used in all kinds of productions like in pilot plants or in large processing units. These fluid bed dryers can handle few grams to several tons of materials.

Some useful fluid bed dryers include:

- Mini-Glatt

- GPCG 10

- Fluid bed dryer WST

Recommend Reason

- Gentle and rapid drying

- Modular and hygienic design

- Easy handling and cleaning

- Exhaust air is filtered before its release in environment

- Solvent recovery provide economical and environmental benefit

- CIP and WIP systems

8. JÖST GmbH Co. KG

Company Background & Information

JÖST is a specialist in manufacturing equipments having vibratory technology. Established more than 100 years ago, JÖST has evolved from small workshop to a top notch firm that enjoys strong partnership with various industries. They have set themselves apart from other processing manufacturers by their innovative vigour and creativity. They are always at work to introduce new and efficient innovations in the market. They design feeders, coolers, screeners, dryers, and weighing scales.

They have a team of 850 passionate peoples that are driven by their commitment to serve their customers. Their values are quality, trust, and competent services. JÖST solutions are used in various industries including chemical, food, steel, and animal feed. They have subsidiaries in 9 countries of the world.

Their mission is to become a major player in processing sector. They are committed to develop sustainable machines that reduce environmental degradation. They maintain a safe and healthy work environment as health of their work force is their prime concern.

Key Products

JÖST fluid bed dryers have uniform air distribution that cause consistent drying of the products. These machines have direct head transfer achieved by warm air. Some worth mentioning fluid bed dryers by JÖST is:

- JÖST Vibrating Fluid Bed Dryers

- Efficient heat transfer

- Low power use

- Compact configuration

- Use of energy resources like methane, petroleum, steam and hot water

- Handle air temperature of 400 °C.

- Easy and rapid cleaning

9. L.B. Bohle

Company Background & Information

L.B. Bohle Maschinen und Verfahren GmbH came to the fore as a prime innovator of processing technology for pharmaceutical industry in 1981. For the past 35 years, it has continued to grow and today, it is a medium sized business firm. Their claim is to satisfy their customers by developing and innovating superior class and eco-friendly solutions that increase their profitability. Their wide-ranging machines catalogue includes granulating machines, blenders, tablet coaters, mills, and sieves.

They have achieved repute all across the globe for their exceptional manufacturing and unmatched mechanical skills in producing both individual machines and complete turnkey lines. They have an exceptional export rate of 80%. Till now, they have installed thousands of machines that surpass all others due to their durability, high-performance, safety, and environment protecting capability.

L.B. Bohle offers complete support to their patrons for setting up and properly maintaining the machines. Their motto is that: the service has no time limit. They are eager and accommodating to help their client anywhere in the world. Their expert team perform routine calibration of machines for clients.

Key Products

These fluid bed dryers are equipped with Bohle Uni Cone BUC® and Process Analytical Technology. These technologies aid in easy fluidization of powders. This reduces cost, installation height requirement and floor space. The fluid bed dryer by L.B. Bohle are:

- Fluidized Bed Dryer BFS

- Continuous Fluidized Bed Dryer – BCD

Recommend Reason

- Simple cleaning with frameless plate

- Uniform drying

- Straight forward operation

- Prevent cross contamination in dryer bowl by back pipe

- Touch screen PLC control panel

- Ergonomic design and smaller footprint

- Fast changeover due to smaller transfer time

10. Nara

Company Background & Information

NARA Machinery Co. Ltd. entered in processing arena in 1924 and was the pioneer of latest powder processing in Japan with manufacturing branch in Germany as well. Nara’s engineers have never lost their passion to produce unparalleled powder processing machines that are flexible and robust. Due to enthusiastic management, Nara has become the one of finest manufacturer of processing equipment internationally.

Technical knowledge and innovation spirit is passed through the generations are the main aspect of Nara’s philosophy. They have built their business on values of novelty, customization, and prowess. Their focus is on drying, crushing, and particle design. Their product portfolio includes mills, grinders, mixers, granulators, dryers, and nebulisers.

They perform testing, feasibility studies, and toll processing. They provide renting facility as well. Their technical experts are ready to deliver maintenance services, repair, remodelling, relocation and spare parts assistance.

Key Products

Fluid bed dryers of Nara Machinery are used for the drying of resins, chemicals, food, agricultural products, animal feed, minerals, and pigments.

Some best fluid bed dryers of Nara Machinery are:

- Batch Type Fluidized Bed Dryer (B-FBD)

- Continuous Type Fluidized Bed Dryer (C-FBD, CT-FBD)

Recommend Reason

- These machines are furbished with heat transfer panels that offer high drying rates

- Easily removable parts

- Low amount of gas is required because of large surface area of these machines

- Reduce damage to the products

- User friendly operation

Conclusion

There are many more fluid bed dryer manufacturing platforms for business in Germany that you can use to grow your production line and business effectively. However, we have tried to list those that are leading among brands and have many potential consumers. AIPAK Pharmaceutical Machinery is one of them. AIPAK has maintained its followers, clients, and services by providing them exceptional pharmaceutical machinery and services. You can search for AIPAK’s outstanding equipment and amazing offers RIGHT NOW!

Don't forget to share this post!

Drier Machine Related Products

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours