Top 10 Global Fluid Bed Dryer Manufacturers:the Definitive Guide in 2025

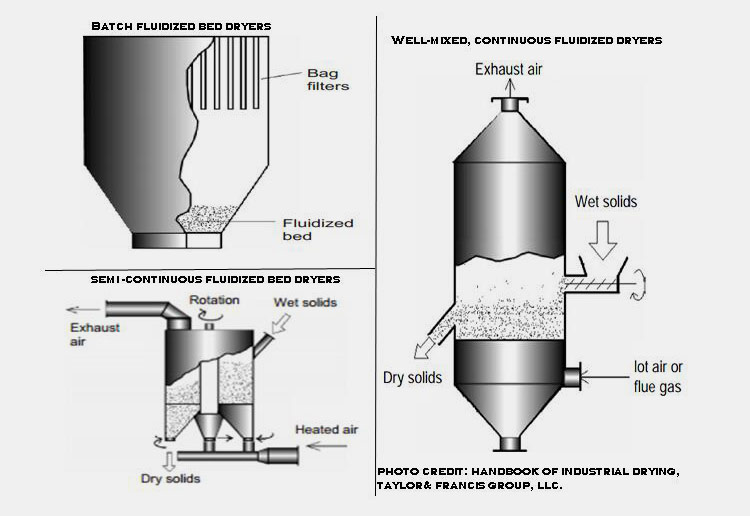

Dryers have become the imperative part of process industry as the quality of product is greatly dependent upon the drying process. Fluidized bed dryers are highly efficient in drying and designed for processing broad collection of materials.

Fluidized bed dryers are utilized in pharmaceutical, chemical and food industry. They were first brought in to practice in 1920’s and after a century has become well established in the whole processing industry.

In these scenarios where the demand of such equipment has increased to high levels, used in almost all vital industries, it has become equally vital to regulate the market for energy efficient and less costly equipment.

If you are in the need of buying fluid bed dryers, we have a best solution for you. You can find the information of the top ten manufactures of fluid bed dryers for processing industry.

This article will cover top ten companies that manufactures energy efficient fluid bed dryers.

| Rank | Manufacturing Company | Head Quarters |

| 1 | TEMA PROCESS | Wapenveld, The Netherlands |

| 2 | ROMACO | Duelmen, Westphalia, Germany |

| 3 | VENTILEX | Paderno Dugnano (MI), Italy |

| 4 | JOST | Washington, USA. |

| 5 | AIPAK | Wuhan, China |

| 6 | VIBRA MASCHINENFABRIK SCHULTHEIS GmbH & Co. | Hesse, Germany |

| 7 | COS.MEC | Heerde, Netherland. |

| 8 | Witte | Karlsruhe, Germany |

| 9 | XIAOLUN | Zhejiang Province, China |

| 10 | GEA | Dusseldorf, Germany |

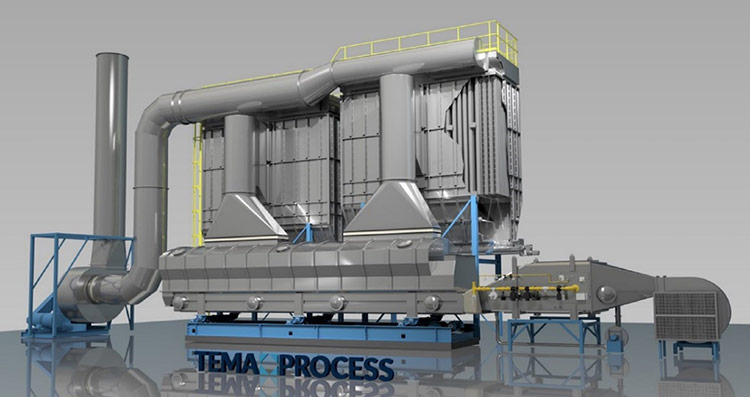

1. TEMA PROCESS

TEMA Process Background:

TEMA PROCESS is a leading manufacturer of fluid bed systems for drying wide range of materials including minerals, food and chemical etc. They not only specialize in manufacturing fluid bed dryers but also provide machines for cooling, roasting, sterilization, and pasturing techniques.

It is comparatively a new company, but the management and employees hold years of experience in designing and manufacturing fluid bed dryers also it belongs to group of companies which has a total number of 2700 of employees.

The fastly growing company has moved to their huge production facility in Wapenveld totally committed to providing best services of manufacturing fluid bed dryers and other equipment.

Key Products

TEMA PROCESS manufactures three types of fluid bed dryers

- Continuous fluid bed dryer

- Shaking fluid bed dryer

- Static fluid bed dryer

Recommend Reason

TEMA PROCESS provides the best solution for energy and cost-efficient fluid bed dryers. The salient features of their products are

- Less consumption of energy

- Uniform drying of product

- Variety of products so can deal with several types of materials

- Reliability

- Less cost

- Cooling section is often integrated in the dryer

2.ROMACO

Romaco Background:

Romaco is famous for developing packaging and processing solutions for pharmaceutical industry for over 40 years. Romaco being part of Truking enterprise is serving pharmaceutical industry with products ranging from tabletop to industrial scale granulating machines, tube filling machines, dryers, cartoners and tablet pressing machines etc.

Romaco is partnering with several renowned brands in the field like Innojet, Kilian, Noack, Siebler, promatic and Macofar while operating from four main sites in Europe.

Key Products

Romaco has introduced Romaco Innojet VENTILUS® Production Plant which is all in one solution for processing pharmaceutical products. The fluidized bed dryer for drying purpose only is also offered whereas the combined version with coating and granulating is also available.

- VENTILUS® LE-D- (dryer)

- VENTILUS® LE-G: (granulator)

- VENTILUS® LE-C: (granulator and coater)

- VENTILUS® Premium (All in one)

Recommend Reason

- Romaco partnered with Innojet offers all sort of services from installation to training the clients

- Product support available

- The products follow GMP’s standards and safety regulations

- Romaco’s fluid bed dryers’ series is safe to use and have options for multiple materials for chemical, food and pharmaceutical industry.

- The Ventilus production plant is one of its kind offering solutions to all problems

- Multiple options available

- Romaco fluid bed dryers are easy to install, easy to clean and easy to maintain.

3. VENTILEX

Ventilex Background:

Since 1965, Ventilex has created significant mark in drying technology till now. Ventilex is a well-known company in the drying industry. Ventilex is continously committed to deliver tailored drying machinery for all the customer needs specifically for chemical, food, pharmaceutical, and healthcare industry.

The company started in Netherlands and started their services in Cincinnati USA in 2001, since then the company is hauling the market for its extraordinary service and provision of equipment worldwide.

Key Products

For drying the chemicals and food related materials, Ventilex provides drying and cooling fluid bed dryer. The fine combination of air velocity and motion results in efficient drying. Ventilex dryers provide uniform drying in less time and low temperature making energy conservation possible.

- Fluid bed Dryer

Recommend Reason

The prominent features of the fluid bed dryers that make the company a prominent one in the league are

- Customization is available

- Uniform drying of the products

- Less time consuming

- Easy operation and energy efficient

- Low maintenance

4. JOST

JOST Background:

JOST group is a German company providing technical equipment for over 100 years in an efficient manner. JOST provides highly efficient machines for drying, screening, conveying and almost all type of processing industry.

The dryers developed by the company follow the direct heat transfer where heat directly comes in contact with the product to be dried. Micro throwing technology is used and customized for each machine by adjusting the throw angle.

Key Products

The fluidized bed dryer manufactured by JOST group follows vibrating fluid bed technology. Different models are available having single or multiple dryers. They also provide multiple options for specific kind of materials with static or oscillating exhaust hoods.

- Fluidized bed dryer

Recommend Reason

The eminent features of this fluid bed dryer are

- It is highly efficient

- Consumes very less energy

- Compact and convenient design

- Easy to handle

- Easy to maintain

- Option to buy individual components or whole systems.

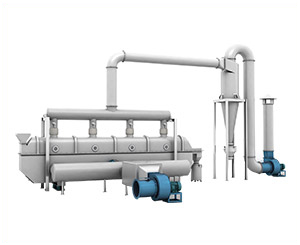

5.AIPAK

AIPAK Background:

AIPAK has dominated the pharmaceutical equipment market for last 10 years. It has become the most reliable professional company that supplies pharmaceutical machines worldwide.

AIPAK provides customized solution for all the problems related to processing industry, manufacturing almost all types of machines including tube filling machines, capsule filling machine, tablet coating machine etc.

Key Products

AIPAK develops highly efficient dryers that serves the purpose of drying and mixing pharmaceutical products, chemical and foodstuff as well. The fluid bed dryers designed by the company are ideal and easy to use.

The main versions of fluid bed dryers offered by the company are

- FG Series Fluid Bed Dryer

- ZLG series Vibration Fluidized Bed Dryer

- GF Series High Efficiency Fluidized Bed Dryer

Recommend Reason

The salient features of fluid bed dryers from AIPAK are

- Less time required for drying so suitable for temperature sensitive materials

- Cost effective

- Low maintenance

- Highly consistent and High quality

- Fulfills GMP standards

- Meet the safety requirements

6. VIBRA SCHULTHEIS

VibraIBRA Schultheis Background:

VIBRA SCHULTHEIS is known for its exceptional services in the industry for over 7- years. They have been serving chemical and food industries by providing the best vibration and fluid bed technology.

The company owns more than 170 qualified employees meeting the demand of customers by manufacturing timely and best quality products. The main services provided include products for drying and cooling, conveying of bulk materials.

Key Products

The series of fluid bed dryers by Vibra Schultheis are as followed:

- VIBRATING FLUID-BED DRYERS / COOLERS

- STATIC FLUID-BED DRYERS / COOLERS

- BATCH DRYERS / COOLERS

Recommend Reason

VIBRA SCHULTHEIS is renowned manufacturer of several products necessary for the process industry including fluid bed dryers and coolers. These dryers can be combined with other dryers and chambers.

The salient features of fluid bed dryers from VIBRA SCHULTHEIS are

- High drying capacity

- Energy efficient

- Hygienic and safe operation

- Gentle handling

- Customization of design

7.COS.MEC

COS.MEC Background:

Cos.Mec is global manufacturer and supplier for over past 25 years that offers extensively designed solution for pharmaceuticals, chemical and food industries located in Italy and worldwide. Cos.Mec pharmaceutical equipment are fully compliance with cGMP norms such as cGMP & FDA. Their quality performance and safety are the prime features that Cos.Mec offers to their consumers. Today, Cos.Mec key of success is cost-effective equipment and quality ratio along with pre- and post-sale services for local and international markets.

COS.MEC is serving the food, pharmaceutical and chemical industry by manufacturing machines and customized solutions according to the customer needs. The company has reached international standards fulfilling quality and safety requirements.

Key Products

The fluid bed dryer designed by the company suits best for granulation and drying of powders for the pharmaceutical industry.

- Fluid bed dryer

- Column lift for Fluid Bed Dryer discharge

- Laboratory fluid bed dryer

Recommend Reason

- The fluid bed dryer can be used simultaneously for drying and granulating processes.

- Can be managed automatically

- Touch screen operation available

- Air treatment unit has heap filters

- Fulfill international standards and regulations

- High quality and meet the safest criteria

- Easy to use

8. WITTE

WITTE Background:

WITTE has earned global reputation in engineering and craftsmanship. It offers various products for processing industry including dryers, coolers, conveyers, and associated equipment serving the industry since 1938.

The Washington based company is well known for its innovations in design, airflow engineering, development, and guaranteed performance of the equipment.

WITTE came in fluid bed making market in 1946 and manufactured fluid bed dryers for various food products, chemicals and pharmaceuticals and minerals since then.

Key Products

WITTE utilizes their specific vertical air flow engineering in their dryers making them prominent in the market. They are encompassed with porous conveying surface inside a vibrating vessel that allows heat hot gas to flow up generating maximum fluidization and finest drying of the product.

- Witte vibrating fluid bed dryer

Recommend Reason

WITTE ensures the products to work equally well as they have been portrayed

Here are the salient features of WITTE fluid bed dryer that makes it a suitable choice

- Uniformity of air control

- Stainless steel body meets USDA, FDA requirements and standards

- Product consistency is maintained without damaging

- Flexible i.e., Options available for most delicate to most hard materials

9. XIAOLUN

Xiao lun Background:

Zhejiang Xiaolun Intelligent Manufacturing Co., Ltd. is well known pharma equipment manufacturing enterprises. The chairperson of this company Mr.Wang xiaolun is first entrepreneur this Zhejiang province. This pharmaceutical equipment manufacturing company encompasses a huge surface area that is comprise of modern management, highly qualified technical staff and team of responsible engineers who strive day and night in bringing innovation in manufacturing equipment.

Key Products

- FLUID-BED MULTI-PROCESSOR

- FLUID BED DRYER & GRANULATOR

Recommend Reason

- Fluid bed dryer with excellent and modern operation.

- Fluid bed dryers with high level of automation and modernization.

- PLC controlled operation and qualified with cGMP norms.

- Fluid bed dryer with multipurpose line can perform drying, granulation and bottom spray all one machine.

10. GEA

GEA Background:

GEA is one of the largest companies who manufactured fluid bed technology and has showed extraordinary performance by providing best customized solutions to its customers in almost 64 countries.

A wide range of applications make it possible for delivering you the best fluid bed for customer needs. GEA has primarily served the food and pharmaceutical industry. GEA reached 4.6 billion EUR revenue in year 2020.

Key Products

The VIBRO-FLUIDIZER by GEA is recognized worldwide for drying and cooling of powders and chemicals. It can be used for both powders and agglomerated products. The following key products include as:

- FlexStream™ Technology

- FlexStream™ 90 - Contained Pharma Fluid Bed Processing

- MP-1 Pharma Fluid Bed Processor - with FlexStream™ Technology

- STREA-1™ Pharma Fluid Bed Processors

Recommend Reason

GEA group have set their mark in the industry by producing fluid bed technology with these peculiar features.

- The fluid beds are very flexible during fluctuating conditions

- Airflow angle can be adjusted

- Low Maintenance

- Processing is efficient

- Easy cleaning

- Follow the cGMP standards

- Introduction of self-emptying system

Conclusion

You have reached to the end of this blog! We have summarized ten renowned companies all over the world manufacturing fluidized bed dryers for pharmaceutical, food and chemical industry. We have confidence you must have found your solution to buying the desired fluid bed dryer according to your requirements.

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours