Top 10 Global Cartoning Machine Manufacturers:the Definitive Guide in 2025

Cartoning machine is innovative solution to package different consumer items into boxes. Carton is not just a box; it is the way to increase the worth of your product and ensures safe delivery of your product in the market. That is why cartoning machines have a central role in the packing of goods.

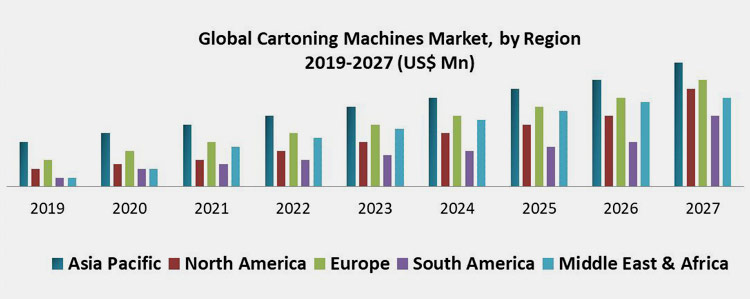

The worth of cartoning machine market was worth in US$2.2 billion in 2019 and it is predicted that by the CAGR of 3.8% it will continue to grow and reach about US$ 3.02 billion in 2027.

It is projected that Asia Pacific will highest growth in cartoning machine market due to introduction of carton 4 technology. The demand of cartoning machine is also surged in China and India because of increased popularity for packaging good.

What are major end-user industries of cartoning market?

Cartoning machines have significant use in food and beverage industry because of consistency and product competence. In future major application of cartoning market will be pharmaceutical industry due to introduction of innovative technologies in cartoning machines.

Horizontal and vertical cartoning machines are utilized in pharmaceutical industry. The market of horizontal machines is worth more because of its affordability and carton flexibility.

Top 10 Best Cartoning Machine Manufacturers

If you want to add cartoning machine to your production line or want to upgrade your existing one but are unable to decide among many options available in market, then this buying guide will aid you in your selection.

Without further ado let’s get started!

| Rank | Manufacturing Company | Head Quarters |

| 1 | Uhlmann | Kent, United Kingdom |

| 2 | Romaco | Laupheim, Germany |

| 3 | Syntegon (Bosch) | Minnesota, USA |

| 4 | Norden | Coventry, United Kingdom |

| 5 | IWK | Baden-Württemberg, Germany |

| 6 | AIPAK | Wuhan, China |

| 7 | Jacob White Packaging Ltd. | Karlsruhe, Germany |

| 8 | Bergami Packaging Solution Srl | Bologna, Italy |

| 9 | Douglas Machine Inc. | Kalmar, Sweden |

| 10 | Mpac Langen | Waiblingen, Germany |

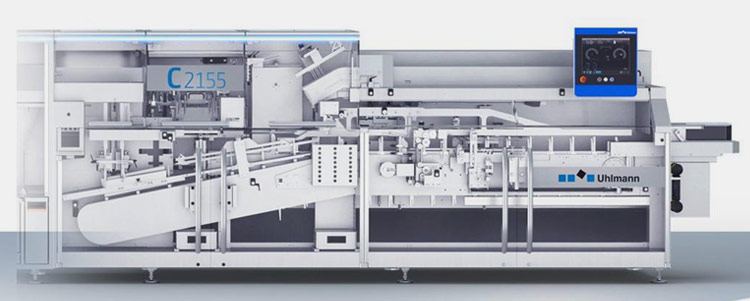

1. UHLMANN

Uhlmann Background:

This group of company was first started in 1948. Various groups like Uhlmann, Koch, Cremer, Axito, and Wonder are operating under the Uhlmann Group.

Uhlmann group is working in 19 different regions of 14 countries. They provide wide-ranging types of machines, services, technologies, and turnkey solution to several industries like pharma, health care, food, consumer items, and agriculture industry.

Uhlmann Pac Systeme is the leading producers of pharmaceutical machinery and is known all across the globe for its robust range of processing and packing solutions. They offer their product to international pharma firms, generic producers, and service providers.

They provide flexible and superior quality products like blister packing machines, bottle filling lines, cartoners, feeders (for solid dosage as well as parenteral drugs), case packers, benders, and labelers.

Key Products

Uhlmann Pac Systeme is providing both continuous and intermittent cartoners. These cartoners are very efficient in processing large number of products. These machines have been at height of excellence, deliver fast and competent performance.

Some of worth penning products by this company are:

- Cartoner C 2305

- Cartoner C 2156

- Cartoner C 2155

Recommend Reason

These machines are used to pack various kinds of pharmaceutical products like blisters, bottles, tubes, etc. These machines have straight-forward operation. These machines are used to pack wide range of the products. Additional material like leaflets and booklets can be included in the cartons.

Some of the important features of these machines are:

- These machines have robotized loading systems.

- Balcony design with stainless steel stands.

- Leaflets can be folded in different styles like stack and reel.

- Stack height is mechanically adjusted for different carton sizes.

- Glass doors provide easy management of the products.

- They are GMP compliant.

- These machines have different options for feeding which are used depending upon the size of products.

- Marking and inspection systems can be installed to these machines.

- Format of operations can be rapidly changed.

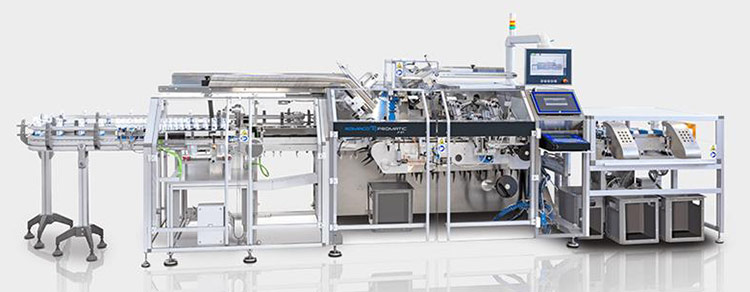

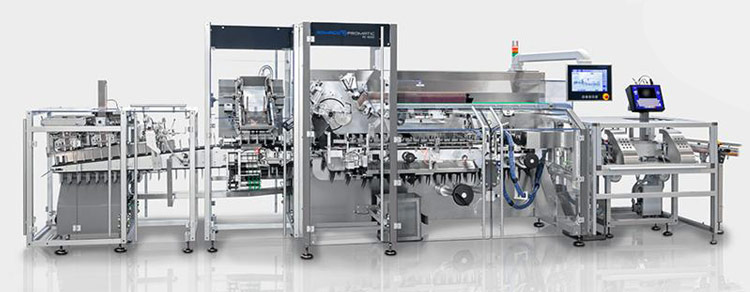

2. ROMACO

Romaco Background:

This company manufacture several products for pharmaceutical industry like granulators, tablet compressors, tablet coaters, blister packing machines, strip packaging solutions. This company also produce filling machines for tubes, powders, and bottles.

Many brands are working under Romaco, like Kilian, Noack, Siebler, Macofar, Bosspak, Promatic, and Innojet.

Romaco is developing cutting-edge technologies and synergic products that are have best work to cost ratio. These products are used in several widespread fields like healthcare, makeup, food, and chemical industry.

Romaco is providing green, sustainable and environment friendly innovative solutions. This company is providing solutions which reduces the carbon emission. These technologies also decrease the product loss. These machines cut the energy consumption and enhances the recycling capability of the materials.

This group also offers spare parts, installation services, maintenance assistance, tools, and upgrades.

Key Products

Romaco group supplies both type of continuous and intermittent cartoners. These machines have ergonomic design, highly reliable and safe to use.

Some worth mentioning products of this group are:

- Promatic PC 4000 Series

- Promatic PC 91 Series

Recommend Reason

These machines have a variety of options for speed and are provided with various feeding selections. These easily handle various types of products and different carton sizes. These machines also decrease the chances of product contamination.

- Machines are easily accessed and cleaned.

- These machines have compact floorspace and can be effortlessly integrated with existing systems.

- Machines are equipped with HMI for trouble-free adjustments to machine operation.

- Machines fulfill GMP safety regulations.

- Have servo technology.

- Have low rate of vibration and sounds.

- Different options for carton closing like tuck in and hot melt.

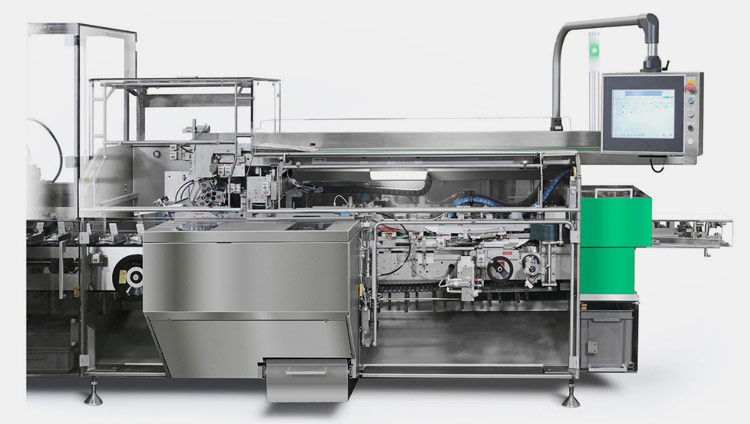

3. BOSCH

Bosch Background:

Bosch Packaging Technology now known as Syntegon Technology has been in business for over 50 years. The high-tech and sustainable products offered by Bosch Packaging are used in pharmaceutical and food industry.

These manufacturers are operating in 15 countries across the globe and have installed 64,000 machines till now.

They are supplying machines for tablet manufacturing, processing, and packaging in the Pharma industry. The solutions provided by Bosch Packaging for food industry include filling machines, confectionary processing machines, and packaging machines.

Bosch Packaging machines have modular and sustainable technology. These machines are decidedly affordable. These turnkey products are equipped with world-grade software for efficient maintenance, operation, and performance.

Their packaging is eco-friendly as they are using mono substances to produce packages and are switching from plastic to paper packing material.

Key Products

Bosch Packaging cartoning machines are flexible in packing different types of packs and products. These machines are extremely consistent and 100% safe. These machines are appropriate for delicate products as these machines gently process the goods.

Key cartoning machines of this group are:

- Sigpack TTMP

- Sigpack TTMC

Recommend Reason

These cartoning machines package cartons that are effortlessly recycled. These machines pack parenteral ampoules, tubes, pens and BFS. These machines have compact and modular design.

Some key features of these machines are

- Small foot space.

- Fully complied with GMP standards.

- Control of inspection of machines component.

- Fast and tool-less change over.

- Touch screen for programming of operation parameters.

- After filling of cartons, they are closed with glue.

- Quick and easy cleaning.

4. NORDEN

Norden Background:

Norden company first started manufacturing machine in 1934. For 80 years, this company is supplying various packing and processing solutions to many industries like pharma, food, cosmetic, toothpaste, personal hygiene and care industry. These machines are also used to pack glues and sealants.

They are expert in manufacturing tube fillers, cartoners, tray packers, de-pelletizing machines. They have delivered about 8000 machines. They have 1600 different consumers in 60 different countries. They are exporting 97% of their products.

They are providing services like technical support, maintenance assistance, machine upgrade, spare parts and different materials. They also perform the validation and inspection of the equipment.

This company is distributing exceedingly robust range of solutions that are sustainable and environment friendly. They are also presenting new packing constituents for cartons, trays, and tubes. They are work hard to introduce future-oriented turnkey products.

Key Products

Norden machines supplies both continuous and intermittent cartoners. These cartoning machines are equipped with latest technology Norden Easyware IITM. The technology aids in controlling entire operation of the machine. Maintenance and cleaning are easily done using this technology.

Some of worth mentioning products are:

- NC 1000

- NC 300

- NP 5002

- NC 850

Recommend Reason

These cartoning machines have cantilever design and progress of operation can be seen through the glass door. These cartoning machines are designed to package broad range of products. These machines also work with different sized cartons.

Some useful aspects of Norden cartoners are given below:

- These machines occupy small space.

- Touch screen displays the statistics of the operation.

- All the packing stations can be accessed without any difficulty for cleaning and maintenance.

- These machines are fully complied with all safety and food regulations.

- These machines have different options for closing the cartons like tuck in.

- These machines offer maximum security of the products.

- The machines also have the option for adding leaflets inside the box.

5.IWK

IWK Background:

IWK, a world leading distribution of packing and processing solutions was founded in 1983. This company has experience of 125 years in delivering machines and complete production lines.

Till today 10,000 IWK machines are installed at different sites in the world. Their passion is to invent new solution in filling and packing fields. They are continuously introducing latest inventions and products in the market by investing in the research and development.

They supply various services like upgrades of machines, new parts, and tools. These machines are supplied to wide ranging industries like pharma, cosmetic, and food industry.

IWK machines are technological advanced and high sustainable. They are offering innovative solutions that are efficient in saving the energy. These machines are eco-friendly which decrease the depletion of resources.

Key Products

Cartoning machines manufactured by IWK company are ideal for packing uses. The products are packed into boxes separately or are collection of products are packed in the same carton. These machines are used to package tube, spoons, canola, bottles, pouches, vials, and ampules.

Some characteristics IWK products are:

- Topload Cartoner IWK TL

- Fully Automatic Carton Infeed CFC

Recommend Reason

These machines have compact, ergonomic design and have modular structure. These machines are extremely reliable and provide safe handling of manufactured items.

- These machines highly efficient have cartoning productivity ranges from 45 to 1000 cartoning/minute.

- These machines have quick product change over.

- Machines are straightforward to use and handle.

- Provided with HMI user panel.

- Fulfill all the pharma safety regulations.

- High-tech and adaptive transport system.

- Can be installed in small spaces.

- Operation can be easily monitored and viewed.

- Products can be tracked.

6. AIPAK

AIPAK Background:

AIPAK is globally recognized well reputed market player in manufacturing and supplying pharmaceutical cartoning machines from last 10 years. During this time, AIPAK has established an outstanding profile and become most reliable professional corporation that supplies pharmaceutical equipment domestically and internationally.

Today, AIPAK is standing with world’s top-class healthcare and pharmaceutical industries and gained 100% consumer satisfaction by offering high speed automatic pharmaceutical machinery.

Key Products

AIPAK is leading pharmaceutical equipment manufacturer and supplier from China that ensure gentle, reliable and accurate operation. Mentioned below are the key products of AIPAK cartoning machines.

- WZH-120 Horizontal Boxes Packaging Automatic Cartoning Machine

- BZX-120P Full Professionally Automatic Bottle Packer Blister Cartoning Machine

- BZX- 120B Full Automatic Cartoning Machine Production Line

- BZLX- 120B Fully Automatic Cartoning Machine Production Line

Recommend Reason

The salient features of fluid bed dryers from AIPAK are

- Less time required for cartoning pharmaceutical goods so suitable for bulk items.

- Cost effective

- Low maintenance

- Highly consistent and High quality

- Fulfills GMP norms

- Pre- and post-sale services

- Meet the safety requirements

7. JACOB WHITE PACKAGING

Jacob White Packaging Ltd Background:

Jacob White Packaging is the world top supplier of packaging solution. This firm came into business in 1911. They deal in cartoners, case packers, packing machines, and sealing machines.

Products supplied by these machines are being operated in 62 countries all across the globe. About 6,000 machines are installed on 5000 different sites. These machines are high in demand because of their product handling.

Their machines are designed and furbished with cutting-edge technologies. They offer standard systems and also the machines that are built on demand. These machines are extremely productive, safe, and have ease of operation.

These sustainable solutions are installed in wide ranging industries like healthcare, hygiene, food and beverage industry.

Key Products

Jacob White cartoning machines can package variety of products and high-quality control. These machines are consistent in packing operation. These cartoners have built-in overloading protection and have decreased power consumption.

Some of noteworthy machines are:

- NS-X 5

- NS-X 6

- CP-400

Recommend Reason

These machines have robust design that allows packing of flexible range of products. These machines package fragile items with great care and have meticulous performance. These machines are used without any extensive training.

Some useful aspects of these machines are discussed below:

- Have variable speed range.

- Main structure and stands are made up of stainless steel.

- Quick change-over for different sized cartons

- Have PLC control and HMI for setting machine’s functionalities.

- Cartons are loaded on the system by the means of vacuum pickup.

8. BERGAMI

Bergami Packaging Solutions Background:

Bergami Packaging Solution was found in 1982. They are offering various kinds of packing solutions. In 90’s, they started manufacturing case packers and cartoners. They are providing cutting-edge turkey solutions to satisfy the growing needs of industries for packing and processing machinery.

Currently, they are exporting 90% of their machinery. They are recognized throughout the field for their efficient and outclass state-of-the-art products. They have exported 1,500 machines all over the world.

They are offering machines like cartoners, tube filling machines, pelleting machines, melters, tray formers, wrappers, display box machines. They also provide complete productions lines like syringe packing lines, stick filling and packing line, and also hair color kit carton.

Pharmaceutical industry and cosmetic industry are the top consumers of Bergami manufacturing solution. Their machines are also applied in food and non-food industry.

Key Products

Cartoning machines are designed to fulfill the packaging demands of various industries. These machines are greatly reliable, safe, and have superior quality. These machines are able to troubleshoot themselves.

Some key products are:

- ASV 60 Pharma

- AS 200 L

- AS 350

Recommend Reason

These machines are used to package vials, capsules, and ampules, etc. The products that are to be packed are either fed to cartoning system via automatic fillers or labelling fillers. These machines are furbished with vacuum technology for product safety.

- These machines have 10-35% reduce cost of packing.

- These machines are adjusted to handle various sizes of cartons.

- Machines have compact balcony design.

- These machines are installed in small spaces without any difficulty.

- These machines are complied with GMP standards.

- Machines have rapid change-over feature.

- Use of carton conveyors decrease the level of noise and reduce the need for lubrication.

- With the help of transparent screen, entire packing process can be easily seen.

- Gentle processing of products to decrease the product injury.

9.DOUGLAS

Douglas Machine Inc. Background:

Douglas Machine Inc was started to produce automated machines in 1964. This company has installed 12,000 machines in 30 different countries.

Their mission is to offer high-tech packaging solution to various industries like health care, pet, and food industry. They deal in shrink wrappers, case packers, cartoning machines, different packing systems, and robotic palletizing machines.

They are striving for continuous automation in their existing products. They are offering spare parts and upgrades to on-hand machines. Machines designed by this group have adaptable platforms and are very efficient in their operation. They provide both continuous and intermittent motion cartoning machines.

Key Products

Douglas Machine Inc manufactures superior quality machines that have high packaging rate and low wastage of products. These innovative solutions effectively pack items of various types and sizes.

Some of worth mentioning products by this group are:

- VantraTM IM

- VectraTM

Recommend Reason

These machines are equipped with SmartSelectTM technology that offer fast product change-over the conveyor system equipped with this technology are easily adjusted and fixed. These machines are robust, adaptable and ergonomic.

Some of characteristics features of these machines are

- These machines do not need much space.

- These machines are effortlessly installed.

- Operation of machines can be easily monitored.

- Compact design conveniently cleaned without using pipes.

- Have ability to seal carton with glue or tape.

- Have various kinds of in-feeding systems.

10. MPAC LANGEN

Mpac Langen Background:

Mpac Langen operating under the group, Mpac has been in operation for 107 years. Mpac is inventing superior quality transformative innovations that are contributing towards the growth of world economy.

Turnkey solutions provided by this group are most desired in packing and processing business. These high-tech solutions and innovations are need of various industries like health care, pharma, food (frozen, liquid, snacks, powders), and consumer items (batteries, filters, cartridge) industry.

They manufacture equipment that fulfill the requirement of customers today and can handle their needs of the future as well. They offer different innovative products like cartoners, case packers, palletizers, product in-feeding systems as well as intelligent systems.

Their passion is to develop various products that meets the demands of the customers, to invest in the unparallel technologies, and to build highly sustainable, zero-waste products. They want to manufacture machines that reduce the impact on environment.

Key Product

These cartoning machines are highly flexible, robust, and compact design that can be expanded in the future. These pack different products like sticks, pouches, and wrapped products.

Some of useful products are:

- VENTO-C

- MAESTRO-C

- MAESTRO TISSUE

- VENTO-I

Recommend Reason

These machines provide exceedingly accurate closing and packing of cartons. These machines have open construction and made up of stainless steel.

Some useful features of these products are:

- These machines ensure the safety delicate and fragile products.

- These machines have small foot space.

- These machines are equipped with HMI that makes operation of machines easy. This HMI provides machine information.

- Rapid product change-over.

- Sterile design that is easily cleaned.

- These machines can handle cartons of different configuration.

- Adjustments can be easily made for change-over.

- Open safety guards for products retrieval.

Conclusion

Cartoning machines play a key role in packing of various form of medicine from blister to pellet. These machines boost your products sale. In this blog, different manufactures of cartoners are discussed for your information. Different key cartoners products manufactured by these companies are detailed in this blog. You will learn about special features of these machines by going through this blog.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours