Toothpaste Making Machine:the Ultimate Importing Guide in 2025

Toothpaste is our most common daily necessities as its various uses,such as freshening the breath, helping to prevent oral problems including halitosis, whitening the teeth and helping with overall teeth cleanliness.

However,the effectiveness and quality of toothpastes are regarded from its different formulations each delivering unique characteristics.

Finally, its overall performance in teeth protection and beautification depends on how efficient and good mixers are in processing and manufacturing these toothpastes delivered in tubes through the toothpaste making machine.

Now I will use this guide to introduce every aspect about this toothpaste making machine.

Getting to know all of them,you will become an industrial expert .

Let's get started now.

1. What Is The History Of Toothpaste?

The history of toothpaste dates back like 1500 to the oldest times when powders were common. They were made from salt, chalk, and pulverized bricks as the main ingredients and were used along with brushes. Also, they were formulated at basic levels, but with time were found to be extremely dangerous to oral health.

Then the world shifted to other tooth cleansing recipes which were made of cinnamon, burned alum, and dragon's blood. Later during the industrial movement, the previous method was replaced by a mixture of baking soda and a chemical hydrogen peroxide. However, it wasn't until the 1939 when the world realized the need for effective toothpaste.

Hence the first toothpaste was introduced to the world by the first oral microbiologists Newell Sill Jenkins and Willoughby D. Miller in 1908. The paste, however, was called Kolynos and was a good substitute to the earlier products which failed to disinfect the teeth. In the later years, many experiments were performed and finally, the first modern toothpaste with the paste tubes was formulated in April 1908 by Leonard A. Jenkins, the son of Newell Sill Jenkins.

In the 21st century, the toothpaste industry has expanded throughout the globe and each day different flavours with innovative ingredients are reaching the marketplace. They come in various colours and also smell good. Not only that, but modern toothpastes are also much more effective than their traditional alternatives and keep the teeth healthy and fresh for a longer time.

2. What Is Toothpaste Used For?

Freshening mouth

The traditional toothpastes were formulated with the idea to keep the teeth clean. But in this day and age, there is a long list of jobs they can do. The first one is surely the maintenance of oral health. With different colours and flavours, they are also used to freshen the breath and keep the mouth odourless.

Different Colours and Flavours Of Toothpastes

Disinfection purposes

Not only that, today's toothpastes have many categories. There are different toothpastes for children which are formulated with special ingredients to take care of their fragile milk teeth. In the same way, their active constituents are preferred to keep the plaque away. And some toothpastes are also manufactured these days to disinfect the mouth from germs and bacteria just like a sanitiser.

Cleaning purposes

Now if I talk about things other than oral health, there is a huge realm of uses of toothpaste outside the oral community. Especially in household projects, toothpaste can remove stains, clean a stinking shoe, and also renew a piece of jewellery.

Other DIY uses

Toothpaste is also a great option to clean nails, polish rusty pots, defog the mirrors, as well as to soothe a burn and deodorize smelling cabinets and bathtubs. All this makes toothpaste a valuable asset that can fulfil most of your modern needs.

3. What Is A Toothpaste Making Machine?

A toothpaste making machine is simply a machine that manufactures toothpaste. Different parts make up the whole equipment and the absence of any can affect the texture of the product. It wouldn't be wrong to say that each gear is essential when it comes to the manufacturing of toothpastes.

4. How does a Toothpaste Making Machine Compare to Vacuum Emulsifying Mixer?

A toothpaste making machine is different from a vacuum emulsifying machine. Nevertheless, they both are used to mix different ingredients to form a mixture, but there are significant

As far as the differences are concerned, there are two main variations. First and foremost, the emulsifying machine is a machine to mix two ingredients that, under normal circumstances, are un-dissolving in each other. The most common example is the mixing of oil and water. The job of an emulsifier is to break down the particles of both ingredients and thoroughly mix them until they are formed into one. While contrary to this, a toothpaste making machine mixes ingredients to form a paste. Its purpose is not to mix the undissolved ingredients but to formulate a product.

The other difference between both is the filling and sealing factor. With a toothpaste filling machine, you can do many tasks with one equipment. That is to make the mixture, fill it in tubes, and then tightly seal them. However, the same is not the case with a vacuum emulsifying machine as it doesn't come with the option to fill and seal the tubes. If you use an emulsification machine, it would require you to invest separately in a tube filling machine.

Lastly, the toothpaste making machine requires proper quantities of all the ingredients to homogenously mix them and form a usable product. While all that an emulsifier does is to thoroughly mix two constituents with sheer power and though the quantities matter here too, they are less important.

5. What Are The Applications Of Toothpaste Making Machines?

As stated previously, a toothpaste making machine is a wonderful equipment to manufacture tubes and fill them with anything you like. And this takes the uses of this machine on a wider level since most of the products these days come in tubes to promote ease and comfort.

Remember that the job of such a machine is not just to fill the tube with the inner material but also to seal it completely tight so that there is no space left for any leakage. This is what makes a toothpaste machine a great option in the industrial world.

So here are those industries where the use of a toothpaste machine has brought a revolution:

Cosmetics industry

It wouldn't be wrong to say that half of the cosmetics the world uses are in tubes. Look at the long list of creams, shampoos, face washes, cleansers, and face products. Other than that, there are liquid lip products, body lotions, hair removal creams, eyelash glues, sunscreens, scrubs, toners, concealers, and the list goes long.

The reason behind this is that the tubes are easy to carry and fit in any narrow space as compared to the bottles. No doubt in this highly competitive world, a toothpaste making machine is a magical tool to boost your cosmetics business.

Food industry

Another area where the tubes are in high demand and so the toothpaste making machines. It is worthwhile to note that modern busy lives demand quick and easy methods, and tubes are one of them.

The different types of sausages - garlic, ginger, onion pastes, cheese paste, even condensed milk pastes, mayonnaise, chilli sauce, oyster sauce - all come in tubes. Snacks and sweeteners also come under this category as different chocolate pastes, ketchup, and pizza sauces come in tubes. The dishwashers and soaps are also manufactured in tubes which is why a toothpaste making machine has a special place in food industries.

Pharmaceutical industry

Here comes all the medications in tubes - gels, pastes and ointments. Some of the gels are also made to be taken for internal use. Different types of creams, face treatments, liquid syrups, and gels to soothe the burns - all can be made successfully with a toothpaste manufacturing machine.

Any liquid or tube formula that can heal the body also comes under the pharmaceutical industry. You will be surprised to know that different types of gels are also available in the market as pain relievers and are widely used before and after surgeries, in case of bone pain, and also to treat wounds.

Pesticides industry

Pesticides are something that needs extreme care in their manufacturing. Since they are made to kill pests which can be animals, insects, viruses, and even weeds, they should be sealed properly to avoid any dangerous consequence.

And that is where a toothpaste manufacturing machine comes in handy because it can do all the job. Also, unlike the bottles which are more prone to damage, tubes are an easy approach to bring comfort to daily life. Insecticides, herbicides, bactericides, parricides, fungicides - all the types of pesticides can be easily filled in tubes and sealed properly.

Chemical industry

Toothpaste making machine has also widely used to make our most daily commonly used products like the above.

6. What Ingredients Are Needed For Manufacturing Toothpaste?

Toothpastes have different varieties and each day the world is witnessing a new invention in them. This can make toothpaste manufacturing a highly complex task.

But the good thing is that you don't need to have specific ingredients to formulate toothpaste. Rather, you can just grab the basic ones as per your needs and requirements, and leave the rest on your toothpaste manufacturing machine.

One thing to keep in mind: not all the ingredients are accessible in your area, and many can require legislation for their usage. Also, the atmospheric elements play their role too. Thus, it is important to take note of everything before preparing your first batch.

Time to dig deeper into the main ingredients of toothpaste, grab a paper and pen right now!

Liquid base

A base is what sets the foundation of the product, and in the case of toothpaste, the base should be liquid. The reason behind this is the feasibility since liquid can be easily mixed with other ingredients, while a solid base would just double the hard work.

The most common liquid base for toothpastes is Polyols - it is widely used in the oral health industries to help the product retain its flavour, shape, and texture for a longer time. Sometimes, glycerine is also used but it is more of an outdated base and is not used by many industries today.

Rheology modifiers

These are the ingredients that are added to the toothpaste formula to keep it in its moderate texture. The word 'moderate' here means that the toothpaste should be neither too thick, nor too liquidly.

Instead, it should be in such a state that it can be easily used without getting wasted. To make sure of this, certain modifiers are used. Furthermore, these modifiers are also effective if the toothpaste contains any solid particles in it such as white crystals since they keep both the fillers and liquid intact.

Famous options in this regard are cellulose gum, carrageenan, and xanthan gum.

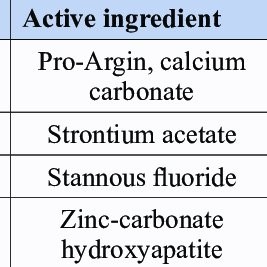

Active ingredient

An active ingredient is a must in toothpaste because all the overall behaviour of toothpaste depends on it.

The main purpose of toothpaste is to protect the teeth and though many ingredients are mixed, it is the active constituent that fits the profile. Fluoride is an effective ingredient in this context since it has natural tendencies to keep the teeth safe from decay.

Different forms are available and you can choose between stannous fluoride, sodium fluoride, and sodium monofluorophosphate depending on what's available.

Fillers and abrasives

Have you ever wondered what those white crystals in your toothpaste are for? Of course, they look like tiny white pieces but deep down they play an important role in cleaning your teeth.

Other than doing this job, they are also added to make the paste or gel attractive, especially in the toothpastes of children. Some of the famous fillers are dicalcium phosphate, calcium carbonate, sodium metaphosphate, sodium bicarbonate, and hydrated silica. Furthermore, silica abrasives are widely used in gel toothpastes to give them a proper texture.

Detergents

Don't be surprised, these are not washing powders. These detergents are formulated especially for toothpastes but have the same role as washing soap. When brushing with toothpaste, the foam is an essential factor and these detergents make sure that the frothy layers are produced when the paste is rubbed against the teeth. Besides, they are also effective in distributing the paste throughout the mouth. However, there are not many options to choose from in this area since Sodium Lauryl Sulphate is an excellent solution to all the problems.

Flavours

Flavours are essential too. In fact, without them, no one would like toothpaste since many different ingredients when combined, form a very unpleasant taste. This also related to the odour of the toothpaste as it should be fresh and not stinking at all. Most of the times, the detergent used in the formula gives all the mixture a very uncomfortable smell. To avoid all this, you should incorporate different flavours in your toothpaste formula which, most commonly, are added through the mint, cinnamon, and menthol flavouring oils.

Colouring

Different Colors of Toothpastes-Photo Credit: science ABC

Again, different ingredients and chemicals can leave upsetting shades on the paste which, though seemingly doesn't look like harm, will eventually affect the demand for your toothpaste. Besides, the custom colour of toothpaste is white, and many people prefer it.

However, other colours can also be added such as light green which shows the mint. Some toothpastes have a dark colour which is often used to cover the unpleasant shades of detergent and other ingredients. Hence it's up to y our what to go for, but as an example, Titanium dioxide is a wonderful colourant for a paste, while gels may have different food colours.

Sweeteners

Like colours and flavours, sweeteners are also an important part of the toothpaste. Before you get confused between flavours and sweeteners, let me clarify that sweeteners are used to give the toothpaste a 'sweet' taste, while flavours can be different such as mint flavour, cinnamon flavour etc. This also relates to the aroma or fragrant of the toothpaste for which a flavour is added. You can manufacture toothpastes of as many flavours as you want but the sweetener will be the same in each. And the most common one is sodium saccharinate.

Preservatives

Along with all the other ingredients, make sure your toothpaste has longevity too. And this can be done by adding preservatives that help the paste or gel retain its texture, colour, flavour and abrasives intact with the rest of the ingredients. This becomes a must when the toothpaste is to be delivered in harsh atmospheres. Therefore, make sure that your paste formula includes these preservatives: methylparaben, sodium benzoate, and ethylparaben - all are highly effective in preserving the toothpaste for a longer time.

That's all you need to prepare your toothpaste formula. However, as mentioned previously, some of these chemicals of substances may not be accessible easily, so it's better to replace them with other alternatives. Lastly, a good toothpaste formula will be achieved through the trial and error method, so make sure you have multiple options before you begin.

7. What Will You Benefit From Toothpaste Making Machine?

Various products of toothpaste making machine

These days, doctors advise you to brush your teeth twice a day, and this has increased the demand for toothpastes to a great extent. You can invest in this machine to boost your business, but that is not the only benefit you'll get. Look at the following list of all the profitable gains you can receive with an efficient toothpaste manufacturing machine:

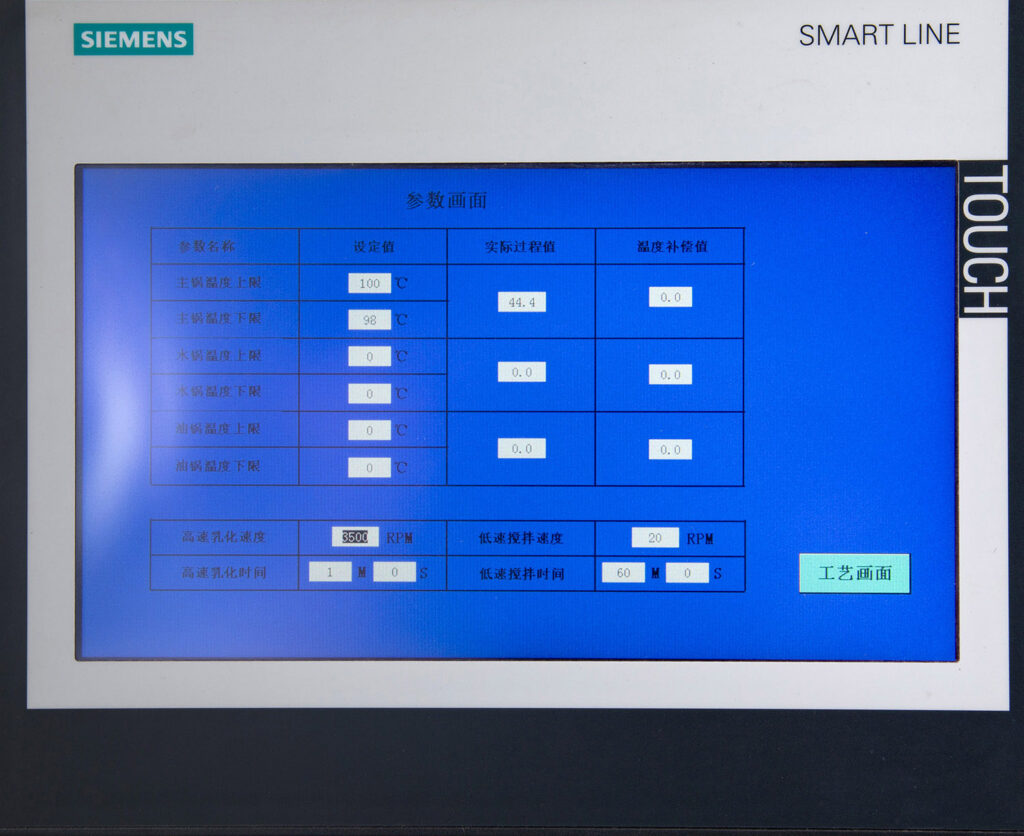

- Modern toothpaste machines come in an automated mode which means you don't need to do any labour. The programmed software will take all the instructions through the display panel and then proceed to work.

- The dosages of ingredients to formulate a toothpaste can be precisely measured and accurately processed into the final product.

- No need to buy separate machines for multiple tasks since a toothpaste manufacturing machine can mix, fill, and seal the tubes all in one apparatus.

- No need to set up expensive gear to form a machine. Instead, the machine is designed to meet the requirements of the day and thus comes with everything already attached properly.

- The ratio of substances being wasted during the formulation process has decreased to a great degree with modern toothpaste manufacturing machines. They not only take precise measurements of ingredients but also use them as effectively as they can.

- The processing time is faster than the alternatives and you can create a whole batch within several hours instead of weeks.

8. Are There Any Drawbacks Of Toothpaste Making Machines?

In terms of toothpaste making machine, the benefits are many, but at the same time, it also has some disadvantages.

- Though the machine is easy to maintain, any worn out part left unchecked can also result in the ruin of the machine.

- Sometimes, the ingredients make a sticky texture which, if fell in the machine, can clog the pipes and thus result in total breakage.

9. How Many Types Of Toothpaste Making Machine Are There?

The type of a machine refers to its mode, and since the earlier times of mechanical industry, there have been manufactured many generations of machines. Each one is built with innovative features lacking in traditional ones.

- Automatic toothpaste making machine

AIPAK Automatic Toothpaste Making Machine

This is the most advanced form of toothpaste manufacturing machine. It has all that technology introduced to the world and comes with all the features required to compete in the fast-growing industrial domain.

The most important part is the display panel which recognized the input data through graphics, voicing, and other types of records. Then the programmed software processed the information and begins working on its own. This saves not only time but also reduces many errors that were most likely to occur with human staff.

Semi-automatic toothpaste making machine

After automatic machines, the level goes down to semi-automatic ones which are half-automatic and half manual. This means some of the work will be done by the machine by giving instructions, but the user must assist it in doing that.

This type of machine comes in handy when the formulation process includes something that cannot be properly accomplished through a completely automated machine. However, sometimes users also prefer it because it is less expensive than the automated one.

Manual toothpaste making machine

Manual tube filling Machine-Photo Credit: indiamart

A manual toothpaste making machine is used rarely in today's world and the reason behind this is the long list of errors it is most likely to occur.

The manual machine is a complete opposite of an automated machine because all the work is done by the user himself. This increases the time to formulate the product, and can even take weeks for the completion of one batch.

10. What Are the Main Components of Toothpaste Making Machines?

As stated previously, a toothpaste making machine is no single equipment but a combination of different, small-level machines which are connected. This helps a lot when upgrading the machine since any part can be easily removed and assembled. Following is the list of all the main components of a toothpaste manufacturing machine and their functions:

Cream mixer

All toothpaste making machines come with a cream mixer which is a tank or vessel to mix the ingredients. All the constituents, either in solid or liquid form, are added here to form a homogenous paste. This is achieved through the rotator with its sharp blade rotating strongly against each other to thoroughly break down the ingredients and hence they are mixed under the vacuum state.

- Water phase vessel

When the ingredients are mixed in the cream mixer, they are transported into another vessel called a water phase vessel. The Water Phase Vessel is a torispherical plated tubular container and the mixture is agitated using a propeller-style blender. All this is done through the steamed water or cold liquid flow when the container is jacketed.

- The storage trolleys

Storage trolleys are the most important component of toothpaste making machines because the whole batch is kept here. Its structure is much like a cylindrical shape; however, the bottom is designed like a cone. It also comes with a top lid and a shutter base to enhance the safety.

- Display panel

This is a human-friendly operating equipment where you can give instructions on a touch screen such as setting parameters for the manufacturing process using graphics, voicing, and other data. The program is easy to install and has built-in sirens to notify the user whenever something goes wrong such as the rising or downfall of temperature than the required level.

11. How Does Toothpaste Making Machine Work?

You can check the manufacturing process of Toothpaste making machine by clicking on the below link:

Stage 1

The overall formulation process can take different timings as per the mode of the machine and the nature of ingredients. For instance, the automated machine will make toothpastes much faster than semi-automatic machines. However, the typical process begins with the preparation of the liquid base first, and then it is mixed with modifiers in the tanks.

Stage 2

There are different chambers or tanks for mixing at different steps, and the next one takes place when the prepared liquid base plus modifier mixture is to be mixed with the active ingredient. This process takes time and then all the other ingredients are mixed, which include colorants, flavors, sweeteners, and preservatives.

Stage 3

Then fillers or abrasives are added and mixed with force to interact deeply with the prepared mixture. This also helps to make both the mixture and the fillers a homogenous paste.

Stage 4

At last, the detergent is added. This step also takes time since the detergent is added slowly to avoid the formation of any foaming. And to ensure that, the detergent is added in solid form. The motor plays an important role here since it is responsible for keeping the speed at a constant pace to ensure high-quality mixing.

12. What Is The Environment Requirement For The Toothpaste Making Machine Manufacturing Process?

To maintain the quality of the products it is a must to maintain the quality of the toothpaste while making the products. For keeping the environment clean and keeps the product stable you need to take care of.

Temperature

The temperature must need to maintain that neither the paste of the toothpaste melts nor it gets too hard as well. Most of the time it is room temperature for the toothpastes making process.

Cleanliness

Cleanliness is another factor to bear in that mind that product does not hold any type of the impurities in it. The hygiene the key factor of the process.

Human intact

If there is any human being coming in contact with the items it has to be clear that they wear the necessary working gloves, mask etc so, no impurities gets in.

Humidity

Humidity is related to the dampness of the product. Though, toothpaste is not a solid thing after all but, still it should maintain it thickness that is why you need to have a humidness in the environment according to the product.

13.What Will Affect The Efficiency Of The Toothpaste Making Machine?

When investing a huge amount in a toothpaste making machine, make sure it pays you back equally through its effective working. And to ensure that, you must take care of certain factors since they can affect the working of your machine if not handled properly. Have a quick look at them:

- The capacity of the machine: this point is important because it is directly connected to the effective working of your machine. The smaller capacity the tank has, the less product will be formulated resulting in more wastage and cleansing. Overworking can lead a machine to deterioration, so keep the focus on the mixing chambers.

- The mode of the machine: The mode of the machine also decides whether it will effectively work in the long run. If possible, go for the equipment with the most advanced features that come under the automated mode. While the least effective mode is the manual mode.

- Mixing mechanism: The rate at which the mixer can thoroughly mix the ingredients to form a homogenous mixture can make or break the efficiency of your machine since it determines the overall timing for the whole process.

- Maintenance of the machine: If the machine has built-in cleansing features, it can save a lot of time as washing the gear used in toothpaste formulation after each batch is reduced.

- The power rate: This refers to the general power usage which should be sufficient to do all the work. Some machine has a limited power capacity which can be annoying when trying to work at a faster pace.

- Relying on basic equipment: This can ruin the machine if not paid attention to properly. In the initial days, the gear is sound and robust, but with time, it can get rusty and worn-out which needs to be replaced or upgraded when necessary. Also, the addition of new parts as per the needs can save the day.

14.What Quality Standards Should Toothpaste Making Machine Meet With?

Toothpaste making machine is a huge investment. You should ensure its quality before buying to guarantee its effective working. This proof comes through the documentation provided by various organizations and bodies that test the product to verify its sound system. Also, such certification serves as proof to the audience too when marketing your formulated products. So here are some of the most important organizations that you can look up to:

- CGMP quality standards: CGMPs (Current Good Manufacturing Practices) establish structures to ensure that production lines and equipment are designed, monitored, and controlled properly. The CGMP guidelines also indicate the identification, durability, consistency, and safety of pharmaceutical formulations by allowing drug companies to have proper control over their manufacturing processes.

- FDA quality standards: The FDA (Food and Drug Administration) intends to expedite the legalisation of such gadgets by authenticating widely used manufacturing processes. Furthermore, the FDA is also attempting to evaluate and track the advancement of the machine's artificial intelligence technologies by performing different laboratory tests on the equipment.

- ISO quality standards: The ISO (International Organization for Standardization) develops all of the necessary documents containing basic criteria, standards, parameters, as well as features that are used to determine that resources, procedures, goods, and services are well-suited to their intended application.

- CE quality standards: When a product is marketed with a CE (Conformité Européenne) tag, it means that it meets all of the Necessary Standards and Regulations from all of the legislation that applies to it. Like all the above-mentioned bodies, it also certifies mechanical equipment with having sufficient standards for manufacturing.

15.What Are The Common Problems During The Toothpaste Making Machine Production Process? How To Solve?

The maintenance of toothpaste making machine is an easy task, but there is also no denying that the machine can fall to errors if not handled carefully. At such times, instead of running to the professionals and hiring them, it is good to understand some basics so that you can fix the issues on your own. Also, some problems are common in every equipment and require only a little knowledge to tackle.

Pay attention to the following commonly occurring problems as they might save you later:

1. The machine fails to start:

One reason why the machine fails to start is that the power is disconnected. Check if all the parts are connected, and all the wires are properly attached to the equipment. Also, make sure the power flow through the electronic box. Always focus on the display panel, and seek professional help if it shows strange information.

2. The machine fails to start in automatic mode

This can happen if there is a blockage in the signals. Check the wires, again. Also, the sensors signal the data. Try resetting the machine. Check if the display panel is working correctly. All of this should solve the problem, but if nothing works, hire a professional.

3. The display panel is acting weird

If this happens, the power cables should be examined since they should be directly aligned. Most of the times, the display panel can only be fixed through the help of an expert and that's why you should seek it in the first place.

16. How To Maintain The Toothpaste Making Machine?

Maintaining your machine is the most important task that should be done on a daily, weekly, and monthly basis. Though the modern machines come with built-in features to maintain themselves, here the talk is about observing different parts of the machine in case any worn-out gear needs replacement. This is necessary since the automated mode of the machine won't be able to recognize it on its own.

So you must follow these steps to make sure your toothpaste making machine is sound and working fine:

- Unplug: Before doing any maintenance, make sure the machine is unplugged and cooled since otherwise there would be risks involved in burning and having a short circuit.

- Dissemble: Take help from the user manual and carefully disassemble all the parts of the machine. If you are seeking assistance from an expert, then it is even more excellent.

- Clean: Now comes the main task. The machine can clean itself but it is better if you look for any residue left inside different parts and clean them properly.

- Upgrade/replace: Carefully observe each part and if anything needs an upgrade. The whole equipment should be rust free and physically vigorous.

- Re-assemble: Lastly, re-assemble all the parts carefully. Check wires and make sure the connection is smooth.