Toothpaste Cartoning Machine: The Complete Buying Guide In 2025

Have you ever bought a toothpaste by simply looking at its box? Have you ever asked yourself how these boxes are beautifully packed? It simply happens with the utility of a toothpaste cartoning machine.

While primary packaging has a significant role in toothpaste production, secondary packaging is vital when it comes to branding, information dispensation, and handling. Therefore, you can’t deny the importance of a toothpaste cartoning machine in the personal care or dental care industries.

As a buyer, you must have complete knowledge of a toothpaste cartoning machine to make better selection choices. So, this blog post will delve into its different aspects (working, benefits, applications, and parts) that you may find valuable. Let’s dive right in!

1.How do you define a toothpaste cartoning machine?

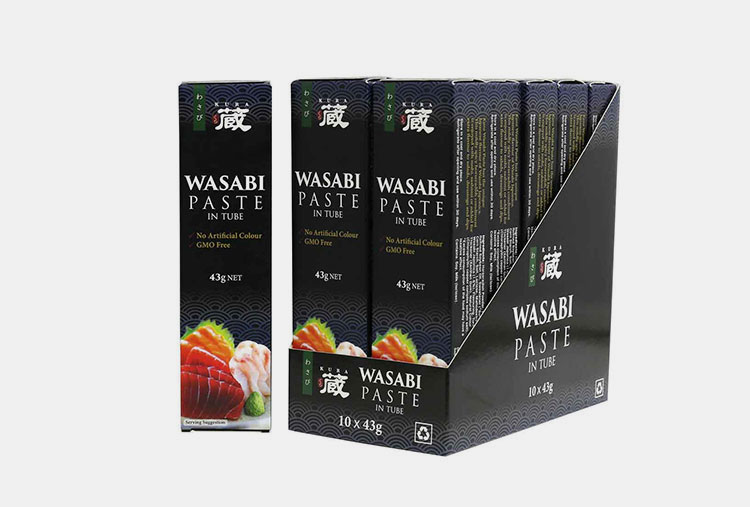

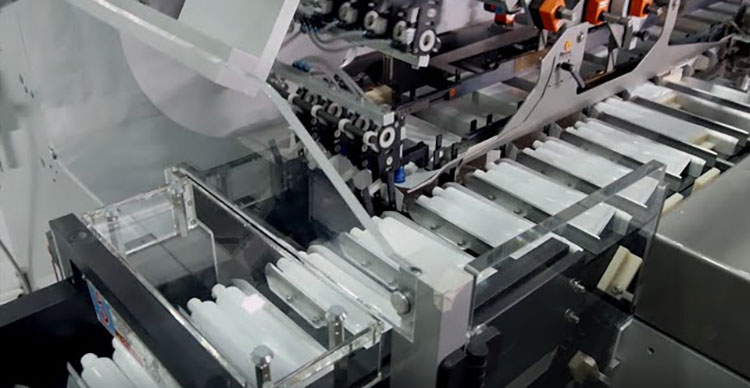

Toothpaste Cartoning Machine

It is equipment that carries out the boxing of toothpaste tubes into the cartons. The toothpaste cartoning machine performs carton erecting, tube loading, carton sealing, printing, and discharging at higher speeds.

It automatically executes every series of steps by its automized electronic and mechanical components. Usually, it is employed at the final packaging stages and creates a strong and durable carton box from a flat piece of cardboard or paperboard and after inserting the toothpaste tubes, it seals the box by tucking the flaps.

2.How does a toothpaste cartoning machine positively impact businesses?

As you know no production line is complete without a toothpaste cartoning machine. Every type of manufacturing sector utilizes this machine in any shape or form due to its cartoning process, which not only offers the highest level of protection to inner contents but also is vital for branding purposes.

Since it has a decisive role in product packaging it positively impacts the success of your business. Here are some reasons why you should integrate a toothpaste cartoning machine in your setups:

Absolute Protection

Absolute Protection

The first and most important purpose of the cartoning process is to protect products. Without their boxed package, they may get squashed, scratched, tarnished, or spilled. Due to the cartoning steps of a toothpaste cartoning machine, you can keep your toothpaste tubes from mechanical and physical damage.

The carton also acts as an additional barrier and safeguards inner toothpaste contents from environmental agents. Thus, you can deliver toothpaste in mint condition to your customers.

Shipment Ease and Logistics

Easy Distribution- Picture courtesy: A’ Design Award

A toothpaste cartoning machine is well-accepted in various sectors because it increases shipment efficiency. You can acquire consistent-sized cartons from this equipment, which are easily stacked and portable. These boxes take up little space if they’re properly arranged. This lowers your shipment expenses.

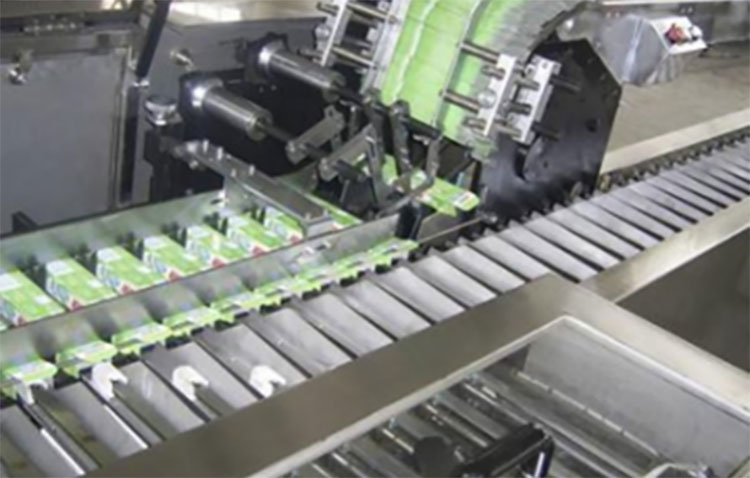

High-Speed Production

Greater production speed- Picture courtesy: LMZ toothpaste

Indeed, one of the biggest advantages of the toothpaste cartoning machine is its rapid processing. With its integration, you can automate every step of your operation and have more inventory at the end day.

This device dramatically improves your process throughput, processing far more cartons per hour than any human team could during the entire shift.

Saves Production Expense

Saves Production Expense- Picture courtesy: Finance Time

What is your most significant wish when running a business? Certainly, it is to distribute more products in the market while saving your cost. Yes, you can achieve this desire with a toothpaste cartoning machine.

It cartons products with unmatched accuracy and decreases material wastage with its precise cutting, folding, and sealing techniques. Moreover, it also lowers your product damage, which ultimately reduces product wastage and saves your costs.

Appealing Brand Aesthetics

Appealing Brand Aesthetics- Picture courtesy: Ireimade

Are you looking for ways to improve your product presentation? Surely, a toothpaste cartoning machine can aid you in this endeavor. This machine goes a long way in boosting your brand perception by yielding professional-looking cartons. In some cases, you can customize your system to add custom prints, embossed patterns, and labels on your boxes.

In this way, you may have a unique brand look, which sets you apart from your competitors.

3.In which industries do you find a toothpaste cartoning machine?

Products of all shapes, sizes, geometries, compositions, and nature are packed in cartons ultimately at the end of packaging. Hence, generally, manufacturers of every industrial unit prefer to have a toothpaste cartoning machine at their hand due to its ability to process a sheer number of cartons. Some major applications of this system are penned in the next section:

Hygiene Industry

Hygiene Industry- Picture courtesy: clossys

A toothpaste cartoning machine is the main packaging equipment in the hygiene industry. Whether, it's whitening toothpaste, herbal toothpaste, mouth gels, conditioners, shampoos, liquid soap, or hand sanitizers, you can load all of these product tubes in cartons. Therefore, a toothpaste cartoning machine is immensely valuable when it comes to shielding tubes from dust, collision, and, sharp edges during long shipments.

Pharmaceutical Industry

Pharmaceutical Industry- Picture courtesy: careAll Product

Ointment tubes, dental creams, healing balms, gels, jellies, and, pastes in carton boxes are conspicuously displayed on the pharmacy’s shelves. These products require extra hygiene and protection. Consequently, a toothpaste cartoning machine is a valuable asset in the pharmaceutical industry for secure and sterile packaging of pharmaceutical tubes in the cartons.

Food Industry

Food Industry- Zoya’s Pantry

It seems hard to believe but you can find a toothpaste cartoning machine in the food industry. With this machine, you can place several food tube products, for food spreads, dressings, condiments, concentrated pastes, etc in vibrant and colorful cartons. This packaging doesn’t only ensure the safety of food goods but also serves as a powerful marketing tool.

Cometic Industry

Cosmetic Industry- Picture courtesy: GIT.net

Many of your favorite beauty products, like face creams, masks, lotions, sunblock, blushes, lipsticks, and gloss come in easy-to-use tube packaging. Many beauty enthusiasts favor tubes because they are travel-friendly and preserve product freshness throughout their lifetime. That said, a toothpaste cartoning machine provides an additional layer of containment and longevity to cosmetic products by packaging them in little sealed boxes.

Chemical Industry

Chemical industry- Picture courtesy: Pascal

You’ve definitely bought chemical tubes in those sturdy cardboard cartons from the market, right? Ever wondered what’s the secret behind this packaging? It is the one and only toothpaste cartoning machine. It dispenses a variety of chemicals, like glues, varnishes, paints, adhesives, grease, sealants, and, many others in robust boxes.

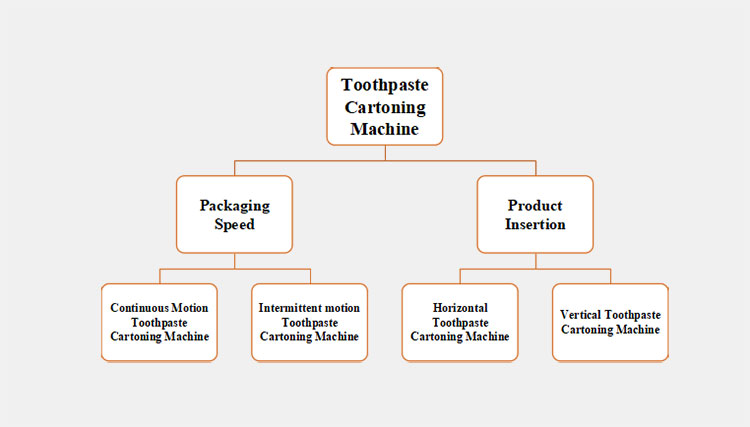

4.What are the classes of a toothpaste cartoning machine?

You might be surprised at the variety of makes and models of a toothpaste cartoning machine in the market. This sheer assortment creates extreme difficulty in the machine selection process. Hence, for your understanding and simplicity in your decision-making, different classes of toothpaste cartoning machines are detailed below.

Based on Packaging Speed

Continuous Motion Toothpaste Cartoning Machine

Continuous Motion Toothpaste Cartoning Machine- Picture courtesy: CAM

This type of toothpaste cartoning machine is well-accepted because of its high-speed processing and carton packaging. It doesn’t stop at any step of operation and executes carton erecting, product loading, and carton sealing synchronously. The reason for its synchronic working is that this equipment features in-sync components, for example, carton sorting, product dispensing, and, sealing systems. A continuous toothpaste cartoning machine is ideal for your production plants if you need more speed per minute.

Intermittent Motion Toothpaste Cartoning Machine

Intermittent Motion Toothpaste Cartoning Machine- Picture courtesy: Gloex

This machine is different from its continuous counterpart since it runs more slowly. It takes a short break at every step of processing and then starts the next step of operation. Due to its intermittent stopping, it is more capable of handling tubes of varying forms, shapes, sizes, and materials.

Thus, you should integrate an intermittent motion toothpaste cartoning machine if you are running medium-sized production lines as it has a moderate level of speed.

Based on Product Insertion

Horizontal Toothpaste Cartoning Machine

AIPAK Horizontal Toothpaste Cartoning Machine

Horizontal toothpaste cartoning machine also known as end-load cartoning machine. The reason for naming it as such is that it typically places tubes from the open side end of the erected cartons. Meaning it horizontally pushes one or more than one tube packaging into cartons. Moreover, the horizontal toothpaste cartoning machine deals with pre-formed cartons instead of forming the cartons.

Another advantage of this equipment is that you can easily pack irregularly shaped tubes.

Vertical Toothpaste Cartoning Machine

Vertical Toothpaste Cartoning Machine- Picture courtesy: EndFlex

There is no need to guess as it is quite obvious. Indeed, this equipment is popular in industries because of its vertical orientation packaging. Hence, you would also know it by the term top load cartoning machine.

The toothpaste tubes are loaded from the top end of the cartons. Consequently, it packs tubes that easily drop down by gravitational force.

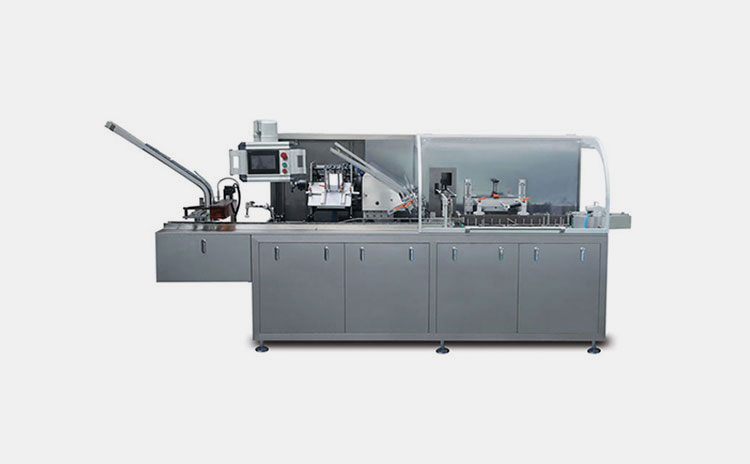

5.What do you know about the working steps of a toothpaste cartoning machine?

Working Steps of AIPAK Toothpaste Cartoning Machine

It's of utmost importance to familiarize yourself with the working steps of a toothpaste cartoning machine if you want to operate it in the right manner. However, it is imperative to understand working stages differ in different models of this equipment. But the fundamental operation of these machines stays the same.

So, let’s get know-how of various working steps of a toothpaste cartoning machine.

| Loading of Blank Cartons | At first, blank cartons stored in the carton storerooms are transferred to the toothpaste cartoning machine via large conveyor systems or operators manually place them on this equipment. These blanks are stacked on the carton magazine. |

| Positioning of Products | After starting the machine, the packed tubes are also transferred to this machine with the assistance of an interconnected conveyor present between a toothpaste filling machine and a toothpaste cartoning machine. These items automatically move on the conveyor of cartoning equipment to travel to the product loading area. |

| Carton Erecting | At this stage, you’ll notice that flat sheets are lifted up by mechanical arms or grippers with the help of vacuum suction cups and are carried to the erecting section. Here carton sheets are positioned upright and transformed into an open box structure using mechanical guides. Afterward, the bottom flap is tucked inward while other top flaps are left open for inserting toothpaste tubes. |

| Product Placement | Now, you’ll see that one or more toothpaste tubes are pushed into assembled cartons using a mechanical pusher. The tubes may be inserted in cartons from its top, side, or end depending upon the equipment configuration. In some device types, you can also place leaflets or promotional materials with tubes into the boxes. |

| Carton Closure | Now the cartons are ready for the sealing stage. The machine automatically folds and closes its top flaps using different methods. In some machines, flaps are interleaved into their required spots to acquire a secure lock. In other systems, glue- either hot or cold- is smeared on the ends of carton flaps for additional security. |

| Discharge of End Cartons | At the end of sealing, you’ll observe that packed cartons are moving to the collection area or are being removed from the machine via conveyors and transferred to batch coding, labeling, or case packing equipment. |

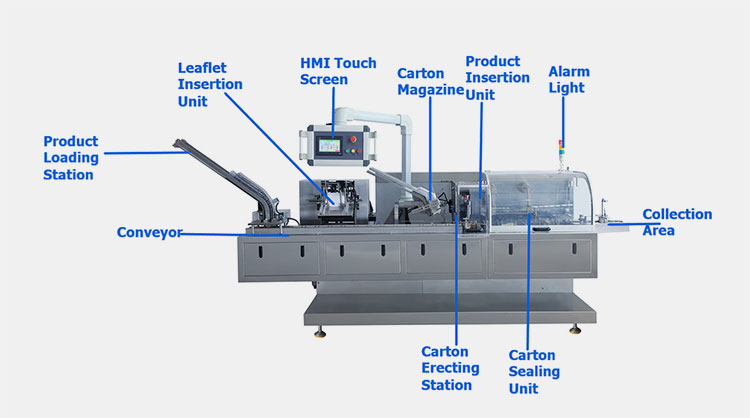

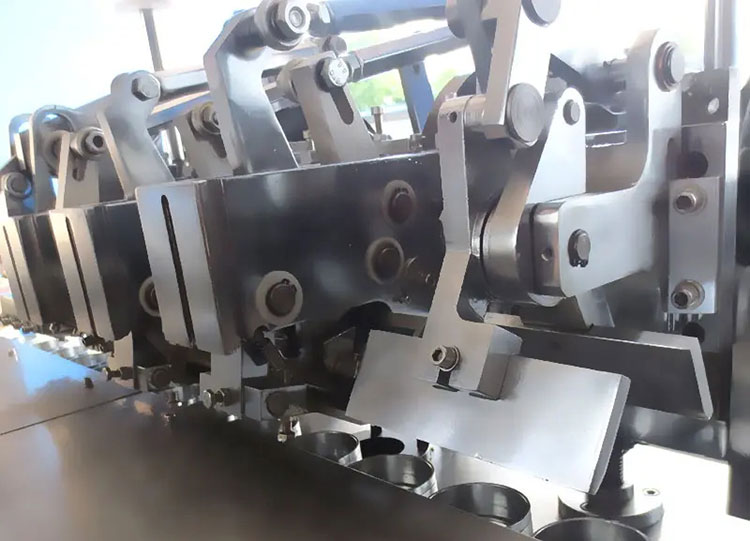

6.Can you enlist major components of a toothpaste cartoning machine?

A toothpaste cartoning machine has several electric and mechanical components that assist in its smooth operation. Hence, for your knowledge, we are enlisting some major parts of this machine in the table below.

Parts of the AIPAK Toothpaste Cartoning Machine

| Product Loading Station | This part is usually found at the one end of the toothpaste cartoning machine. You put toothpaste tubes at the product loading station and from here, they are carried out to other units of machine. |

| Conveyor | It is a large drive belt or roller plate present in the middle section of the equipment. Its function is to drive tubes and cartons to different system units. |

| Leaflet Insertion Unit | Leaflets are pieces of paper on which instructions are printed for the usage of toothpaste. In some types of a toothpaste cartoning machine, the leaflets are positioned on the tubes while they are moving on the conveyor. You’ll find mechanical arms at the leaflet insertion unit, which automatically and consistently positions the leaflet for boxing. |

| HMI Touch Screen | It is an intelligent screen area present in a toothpaste cartoning machine so that you can communicate instructions to the machine. It is programmed with various options for inputting operational parameters. And you can easily modify them depending on your operation needs. It is a compact place where you can look at the working of the whole machine without going to each station. |

| Carton Magazine | Its function is to hold the stacks of blank sheets and gripper collect these sheets one by one from this area and take them to the carton erecting unit. |

| Carton Erecting Station | It is the main component that shapes cardboard sheets into boxes. With the help of a mechanical guide, it carries out the folding of flaps to assemble the box. |

| Product Insertion Unit | This unit of the system smoothly and gently loads the toothpaste tubes into erected boxes without damaging any tube. |

| Alarm Light | It is a safety feature by which you get notified about technical errors or malfunctions in the machine. It lights up in case of a defect in the system. |

| Carton Sealing Unit | How your cartons are fully secured? Well, a carton sealing unit is the part responsible for completely sealing the cartons to prevent falling out of packed contents. It usually tucks in flaps of carton or applies glue to close the carton flaps. Sometimes, tamper-proof tapes are also placed on cartons to discourage carton tampering. |

| Collection Area | Finally, completely sealed cartons are transported to the carton collection area, from where you manually collect cartons and shift them to the distribution bay. |

7.What types of carton materials are handled by a toothpaste cartoning machine?

You surely would have seen cartons made with diverse materials in grocery stores. Manufacturers can customize their toothpaste cartoning machine to create boxes with numerous starting materials. Each material type has its distinct lifetime and branding potential.

Let’s get an idea of carton materials processed by a toothpaste cartoning machine:

Corrugated Cardboard

Corrugated Cardboard- Picture courtesy: Emenac packaging

This material is normally used when you want to pack bulk toothpaste tubes in one carton. It is a sturdy material well-recognized for its superior protection. It is composed of multiple fluted layers that are present between linerboards. However, you’ll see it less commonly in single-unit packaging.

Paperboard

Paper board box of toothpaste

It is the most widely used material when it comes to retail toothpaste packaging. You can utilize either coated or uncoated paperboard for forming cartons. It is very useful due to its less weight, budget-friendliness, and high-quality printing capability. You can also tailor it with special features, such as UV coating, embossing, and foil stamping.

Plastic Laminates

Plastic Laminates- Picture courtesy: Envato

As the name indicates, this material is manufactured with a combination of paperboard with a thin layer of plastic. This laminate material has extra durability and better moisture impermeability; thus, you’ll frequently spot it in markets where humidity is quite light.

8.Can a toothpaste cartoning machine handle a carton with unique features?

In short answer yes. Your toothpaste cartoning machine is capable of handling cartons with exclusive designs. So that you can attain improved customized, enhanced product appeal, and protection. Here are some examples of cartons with unique features processed by this equipment:

Custom Carton Shapes and Sizes

Custom Carton Shapes and Sizes- Picture courtesy: Beach Packaging

If your device has an adjustable feeding system, then it can easily handle cartons with non-standardized cuts. You can erect and fill tapered or angled cartons with high-end folding and product-feeding systems. These customized cartons like hexagonal, curved, or window-cut boxes will surely increase your brand appeal.

Specialty Finishes

Specialty Finishes

You can process cartons with a glossy, matte, or soft-touch finish if your machine has precise feeding components. This prevents the slippage of cartons. With sensitive grippers or robotic arms, you can pack embossed or textured cartons.

Tampered-Evident Features

Tamper evident packaging- Picture courtesy: asahi

Sometimes, there is a need for security features in toothpaste packaging. A toothpaste cartoning machine can place security seals, stickers, and, tear-opening strips on toothpaste cartons to ensure that the carton is not tampered with.

9.How to maintain a toothpaste cartoning machine?

Basically, if you conduct proper maintenance of a toothpaste cartoning machine, it’ll surely run smoothly and for many years to come. It will also reduce your equipment downtime and maximize your machine capability. Hence, for your information, we’re penning basic maintenance steps:

Maintain A Toothpaste Cartoning Machine

| Routine Cleaning | It is vital to clean the toothpaste cartoning machine after every shift to get rid of blockage or foreign objects that may interfere with the working of the system. For cleaning, you must disassemble every removable component, such as glue nozzles. Clean these units with a recommended cleaning solution to remove every type of impurity. Use a damp cloth to wipe out interior parts. |

| Inspection of Machine Components | Add examine every part of the machine in your daily schedule to identify any hidden faults or damage to components. This will assist you in finding machine wear before it's too late and repair it in a timely manner. Also, replace any part if it shows extreme wear. |

| Lubrication | As you are already aware this system has several movable parts, for example, conveyors, grippers, belts, rollers, suction cups, etc. These components should be routinely lubricated and oiled to have a smooth operation. Therefore you must clear out old lubricants and apply new oil to prevent frictional damage. |

10.What factors should you ponder when procuring a toothpaste cartoning machine?

Toothpaste Cartoning Machine

If you want to boost the productivity of your packaging line by installing a reliable toothpaste cartoning machine, then take your time and carefully plan your buying process. Because rushing procurement often results in unsatisfactory purchases.

To aid your decision process, we’re highlighting some essential factors below:

| Machine Throughout | It is one of the most crucial aspects, that should be pondered out when you’re buying a toothpaste cartoning machine. The equipment packaging speed must match the required output. Large-scale manufacturing operations achieve substantial efficiency improvement if you employ a continuous-motion toothpaste cartoning machine in them.

On the other hand, if you’re running a smaller enterprise a device with little throughput capacity will be best. |

| Quality Certifications | The quality compliance of the toothpaste cartoning machine matters a lot if you require top-tier equipment. To ensure the manufacturing quality of a machine, you must first check manufacturer certifications, like GMP, ISO, and HACCP certifications. In this way, you can validate the durability and safety of the equipment. It also helps you in mitigating quality issues in cartoning operations. |

| Product Type | What kind of tubes you are packaging? What are their diameters and length? Are you processing tubes of fixed sizes or is there any variability in your tube sizes? Answering these questions allows you to select the right machine for your packaging needs. |

| Production Line Space | What are the space conditions in your factory? Before going out for purchase you should measure the space proportions in the packaging area. This will aid you in selecting an appropriate toothpaste cartoning machine that can easily occupy your existing space. Also, check the power and air utilization specifications of your potential machine so that you can pick the right system according to your utility setup. |

11.How can you rectify some common technical issues in the toothpaste cartoning machine?

If you belong to the personal care industry, there is the possibility that you rely on a toothpaste cartoning machine to box your toothpaste tubes. However, in some instances, you’ll have malfunctioning in your equipment, which leads to major downtime and puts a pause on production.

But no worries, with training and knowledge of your machinery, you can easily rectify these technical issues. So, let’s check out the potential and their solutions for this system.

Carton Jamming

| Problem | Solution |

This issue is more frequent than you expected. With the incidence of this issue, your production comes to a standstill. If the cartons are lodged in the machine, you’ll have damaged products and wasted resources in your hands. There are several causes for this, for instance, misalignment of cartons, overloading of products in cartons, and defective equipment parts. Also, foreign bits and pieces may lead to the jamming of cartons |

To rectify this problem, you can simply begin by examining any hindrances on the conveyor of the toothpaste cartoning machine. Afterward, you should take a look at the carton magazine to ensure proper alignment of blank carton sheets.

Furthermore, analyze the product insertion step to ascertain the correct number of tubes inserted in a carton. Lastly, check the mobile components of the machine, for example, belts for defects and replace them as required. |

Carton Overturning

| Problem | Solution |

Picture courtesy: ETW You definitely would have encountered overturned cartons during your operation. It transpires when your cartons are not correctly created or closed. Hence, you’ll see spilling of content and packaging faults. There are numerous reasons behind this, like you’ve improperly programmed on HMI control panel, defective or incorrectly configured parts, and also poor sealing operation. |

This issue can be corrected by following simple guidelines. For example, first change the settings of the carton assembly process. In this way, you’re sure of proper carton forming. Secondly, carefully inspect the machine for any damaged or incorrectly positioned parts, such as forming plates or sealing components. Replace or realign them if required. Finally, adjust the sealing settings to have the right sealing strength. |

Inconsistency in Product Loading in Cartons

| Problem | Solution |

It is a routine matter when you’re working with a toothpaste cartoning machine. This issue becomes more prevalent when you’re processing irregularly shaped or sized tubes. This problem occurs when the movement of products is blocked on a conveyor or they are not accurately fed in cartons. This difficulty can stem from a defect in the feeding system, incorrect product dimensions, or, faults in the sensor. |

In this case, you should assess the product feeding component in detail to make sure the conveyor is clear of all obstructions and the product chute is working without any anomaly. Besides this, you should modify the alignment and settings of the feeder so that it can accommodate different-sized and shaped products. If there is an error in the sensor, then calibrate and test them immediately. |

Cartons are not Properly Sealed

| Problem | Solution |

With this problem, you could have major packaging defects and compromised product quality. This problem can typically happen owing to inaccurate machine programming, old and faulty sealing parts, and insufficient application of sealing glue. |

To solve this problem, you should review and adjust the program options of sealing systems. Thus, you can attain excellent seal strength. Also, examine carton sealing parts, for instance, glue spraying nozzles and taping units for wear and tear. Substitute them with new ones if they’re damaged beyond repair. Make sure that glue is uniformly applied across carton flaps to have a lasting sealing. |

Conclusion

To wrap up this detailed guide about a toothpaste cartoning machine, it should be said that this equipment is most versatile and efficient, capable of handling a wide array of toothpaste cartons in a short time. In the modern era, convenience is of utmost importance and with this device, you can easily deliver easy-to-use packaging to your customers and gain their trust. Hence, with some investment, you can have a whole deal of benefits. So, don’t wait and immediately click on the link below and place an order for your desired toothpaste cartoning machine. We, AIPAK are here to serve you at any time and anywhere.

Don't forget to share this post!

Cartoner Related Posts

Cartoner Related Products

Cartoner Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours