Toner Powder Filling Machine: The Complete Buying Guide In 2025

How to achieve toner powder filling freedom? How to improve the accuracy, productivity and efficiency of toner powder filling so that you can get a better return on your investment? Whether you are a novice in the field of powder filling or an experienced expert, you will definitely have trouble choosing toner powder filling equipment.

This toner powder filling machine guide can provide you with detailed one-on-one guidance on how to choose the right powder filling equipment for yourself with understanding of the equipment, so as to improve your productivity and efficiency. Let’s take a look now!

1.What Is Toner Powder?

Toner Powder-sourced: weemay

Toner powder is a kind of powder specially used for paper printing. It is mainly composed of fine powders such as carbon, iron oxide, silica and some minerals. Different toner powders have different colors. Because it contains different pigments. The main colors of toner powder are black, red, cyan and yellow. Any color can be mixed and modulated by these four colors.

2.What Is Toner Powder Made Of?

Most toner powders on the market are made up of the following elements and materials:

Plastic

Plastic-sourced: safecosmetics

All toner powders are primarily made of plastic. Most manufacturers use 85% to 95% plastic in powder form. This allows the toner to hold an electrical charge, which is key to laser printing.

Black carbon

Black carbon-sourced: saharabizz

The plastic used to make toner powder is transparent, so carbon is added to the mixture to make it black. Carbon also allows the plastic to be printed on paper for a long time, ultimately allowing the printed text to remain on the paper longer.

Silicon dioxide

Silicon dioxide-sourced: azonano

In order for the toner powder to flow freely from the cartridge and spread evenly on the paper, a certain proportion of silica is added to the toner to allow the toner to flow well in the cartridge and spread smoothly on the paper.

Charge control agent

Laser printing requires a precise electrostatic charge. The charge control agent allows the toner to adhere to the device and control the operation of the charge well.

Color pigments

Color pigments-sourced: cosmeticsdesign

The color pigments of a typical ink cartridge are composed of black, red, yellow and cyan. Different proportions and combinations of these four color pigments can produce a variety of colors.

3.What Is Toner Powder Filling Machine?

AIPAK Toner Powder Filling Machine

Toner powder filling machine is a kind of equipment specially used to fill various toner powder into different containers. It can accurately measure and distribute powder products into different containers with high efficiency and quality. In addition to accurate measurement, this equipment can also fill products into different containers, reduce waste and achieve efficient powder filling.

4.What Are The Toner Powder Filling Machine Applications?

Toner powder filling machine can be applied to the following industries:

Pharmaceutical industry

Pharmaceutical industry-sourced: hanningfield

Toner powder filling machine can meet the unique needs of the pharmaceutical industry, filling and sealing different types of powdered drugs and supplements into syringes, vials and pouches of different doses through a high-precision filling system, providing consistent and reliable filling doses for your various needs.

Foods and spices industry

Foods and spices industry-sourced: medicalnewstoday

Toner powder filling equipment can also be applied to the food and seasoning industry, and meet the boxing, bagging and bottle packaging of various fine powders, fragrant powders and granular products, such as salt, sugar seasonings, etc. While achieving high-precision powder filling, it can also eliminate dust generated during the filling process and reduce cross-infection during the material filling process.

Nutraceuticals industry

Nutraceuticals industry-sourced: capsulcn

It can also be used in various dietary supplement industries such as protein powder, milk powder and other materials. It can fill various powders and granules with health properties into various jars or small bags.

Household industry

Household industry-sourced: thewirecutter

All kinds of powder and granular products you need in your life, such as washing powder, powder detergent, powder chemical products, powder disinfectant, etc., can be completed by using toner powder filling machine.

Chemical industry

Chemical industry-sourced: inpaksystems

Due to its reliable design, toner powder filling machine can be used to fill various corrosive or dangerous powders. It not only provides you with more accurate filling effect, but also reduces the risk of operators and protects their safety.

Cosmetics industry

Cosmetics industry-sourced: hearstapps

All kinds of cosmetics, such as eye shadow, loose powder and blush, can be completed by using toner powder filling machine. The whole process of filling cosmetic materials is smooth, safe and reliable.

5.What Are The Benefits Of Toner Powder Filling Machine?

Choose toner powder filling machine, it can achieve efficient filling of various materials for you:

High Precision

High Precision-sourced: altrimex

Equipped with advanced weighing and screw feeding system, toner powder filling machine can feed materials of different fineness from hopper to filling system, and weigh and distribute materials accurately. In this process, no human participation and operation are required, which can improve your efficiency and save costs.

Wide Applicability

Wide Applicability-sourced: preciseceramic

It can handle a variety of materials. Whether it is food materials or pharmaceutical products, such as milk powder, spices, laundry detergent, seasonings or cosmetics and pharmaceutical products, toner powder filling machine can distribute them into containers of various sizes and shapes, such as bags, cans or bottles.

Flexible Filling Range

Flexible Filling Range-sourced: jbtc

With a smarter operating system, toner filling machine can facilitate you to set various filling ranges, speeds and capacities. During filling, it can also facilitate your various adjustment needs to meet your different production needs and product containers, which is very flexible.

Easy Maintenance & Cleaning

Easy Maintenance & Cleaning-sourced: elitemaintenance

The whole equipment is made of stainless steel, which is not only durable but also easy to clean. All hoppers and systems in the equipment can be easily disassembled and installed, which is convenient for your cleaning and later maintenance. It is equipped with a simple operating system to facilitate the operator's operation and control.

6.What Are The Types Of Toner Powder Filling Machines?

Toner powder filling machine mainly are the following categories:

Net weight filling machine

AIPAK net weight filling machine

Net weight filling machine can accurately weigh the required dosage during filling and increase your filling speed. Through different settings and adjustments, it is suitable for your materials of various forms, sizes and densities and containers.

Screw auger filling machine

AIPAK screw auger filling machine

Screw auger filling machine mainly adopts a spiral feeding system. It can rotate the powder material in the hopper into the filling system through the spiral system, so that it can handle different types of powders with an error of not less than 1%. It is suitable for very fine powder filling, such as talcum powder, pharmaceutical powder, etc.

Volumetric cup filling machine

Volumetric cup filling machine-sourced: all-fill

Volumetric cup filling machine is equipped with a measuring cup to facilitate the measurement and distribution of products. It is convenient for you to handle various materials that need to add materials and additives midway, and can achieve economical and affordable powder filling during your filling process.

According to the degree of automation of the equipment, toner powder filling machines are:

Semi-automatic toner powder filling machine

AIPAK semi-automatic toner powder filling machine

Semi-automatic toner powder filling machine can help you fill various powder materials into bottles, cans, cups, barrels, bags and boxes. Unlike the fully automatic type, it requires you to manually load, move containers and adjust the filling amount. This equipment is mainly suitable for small-scale and medium-scale powder product filling.

Automatic toner powder filling machine

AIPAK automatic toner powder filling machine

Automatic toner powder filling machine mainly adopts fully automatic loading, filling, sealing and discharging, etc. With a fully enclosed design, it can well prevent dust pollution and cross infection. While providing high-precision powder filling, it can also provide you with high-efficiency and high-capacity filling capabilities.

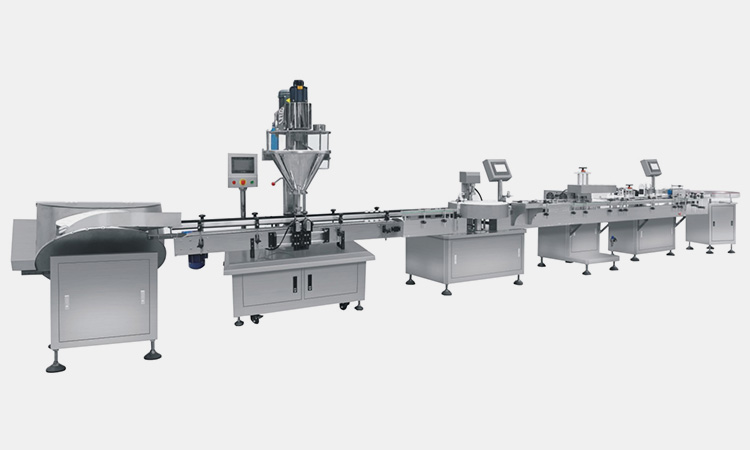

Toner powder filling line

AIPAK toner powder filling line

Toner powder filling line is mainly composed of bottle unscrambler, powder filling machine, capping machine, labeling machine and other equipment. It can complete high-precision bottle filling of various drug powders, milk powder, protein powder, seasoning powders and other powders. It is easy to disassemble and organize, and it can ensure that it meets your filling needs for various materials.

7.What Are The Designs Of Toner Powder Filling Machines?

There are different designs of toner powder filling machine:

Inline

Inline powder filling design-sourced: per-fil

The linear design mainly adopts the assembly line filling method. The filled containers are placed under the nozzle of the hopper in order, and the powder material is filled uniformly and stably.

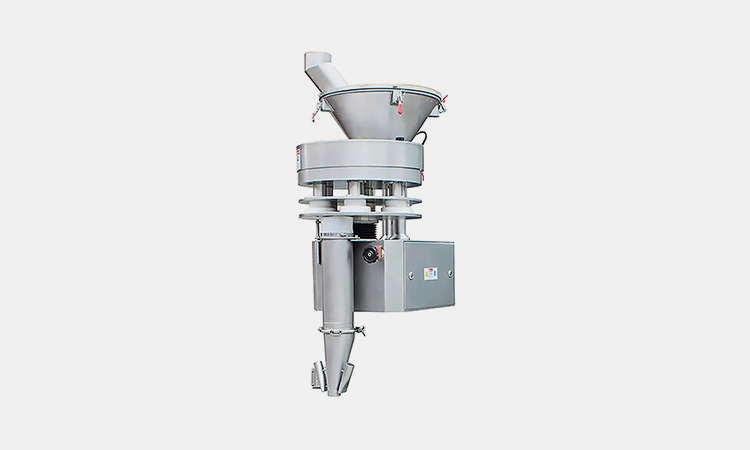

Rotary

AIPAK rotary powder filling design

It mainly adopts the spiral rotation method to distribute the materials. When the container passes under the filling nozzle, the material is distributed and filled around the circular platform of the filling machine. This design is very suitable for manufacturers who need to produce quickly and it can minimize the equipment downtime.

Multi-head

AIPAK multi-head powder filling design

The efficiency of multi-head is very high. It can configure multiple filling nozzles so that your products can achieve the highest accuracy and speed of powder filling in the shortest time. It is suitable for filling large-volume products that require fast and continuous efficiency.

8.What Are The Key Components Of Toner Powder Filling Machine?

The main parts of the Toner powder filling machine include:

Key components of AIPAK toner powder filling machine |

|

| Hopper | The hopper is mainly used to hold and store the powder products that need to be filled. It is mainly composed of a liquid level sensor, a detector and a hopper. When the powder is fed into the filling system, it will be temporarily stored. |

| Filling head | The filling head is also called a filling nozzle. It is mainly used to distribute powder products from the hopper into different packages, such as bags, boxes or bottles. |

| Mechanical drive system | The mechanical drive system is mainly used to control the parts of the machine, including gears, conveyor belts, mechanical motors, etc. Providing linear or rotational mechanical driving force for the entire filling process of the material. |

| Sensor | The sensor can detect the specific dosage of the material distributed during the filling process and accurately distribute the dosage of the material. Ensuring the accuracy of material filling. |

| Intelligent control system | The intelligent control system is mainly composed of a PLC control system and a touch screen interface. Without manual intervention, the operator can set the corresponding filling parameters and procedures according to his needs. |

| Measuring cup or weighing device | Powder filling machines are generally equipped with corresponding weighing devices or measuring cups to ensure that different products can be accurately weighed and distributed. |

| Conveyor belt | Conveyor belts can distribute different containers reasonably and evenly. |

9.How Does Toner Powder Filling Machine Work?

The operation and filling procedure of the Toner powder filling machine are divided into the following basic steps:

Powder loading

Load the powder into the hopper manually or fully automatically.

Set parameters

According to the canning dosage and accuracy you need, adjust on the control panel, set the filling dosage and speed, etc.

Powder distribution and measurement

The auger of the equipment will weigh and measure the powder dosage, and feed the controlled powder dosage into the canning mouth. Different powder filling may use different powder metering methods.

Container filling

The measured powder will be guided and filled into the container in a fixed dosage. When the set fixed powder capacity is filled into the container, the container will be sent to the next sealing step.

Sealed box packaging

The conveyor belt will seal the container filled with powder dosage stably for subsequent packaging.

10.What Machines Can Be Added To Integrated WithToner Powder Filling Machine to form A Complete Production Line?

Toner powder filling line mainly consists of bottle unscrambler, powder filling machine, capping machine, labeling machine.

Bottle unscrambler

AIPAK bottle unscrambler

Using semi-enclosed mode, bottle unscrambler can help you sort plastic, metal and non-fragile bottles quickly and efficiently. After sorting, the containers that need powder filling can be sent to the powder filling machine through the rotating table and conveyor belt. With advanced sorting effects, this equipment may offer you efficient whole bottle capabilities without human intervention.

Capping machine

AIPAK capping machine

Capping machine can meet your various bottle container capping requirements and can be applied to various industries. It can independently complete the placement and tightening of various bottle caps in large quantities and accurately control the sealing of the bottle caps. For bottle caps of different shapes and materials, capping machine can efficiently and quickly complete the tightening and sealing of the bottle caps you need.

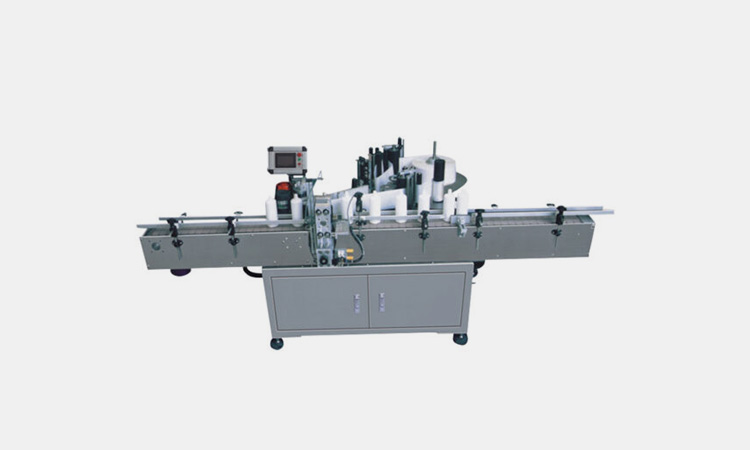

Labeling machine

AIPAK labeling machine

Labeling machine can complete multifunctional labeling of various PET bottles, plastic bottles, glass bottles and metal bottles. It can be widely used in pharmaceutical, electronic, cosmetic, beverage, food, plastic, daily chemical and other industries. While providing you with neat, uniform and beautiful labeling, it can also reduce packaging procedures and improve production efficiency.

11.How To Perform Toner Powder Filling Monitoring During Operation?

Perform a good toner powder filling monitoring during operation can offer you a good products quality and efficiency.

Check if the powder overflows during filling

Powder overflows during filling-sourced: honorpack

Ensure the smoothness and efficiency of powder filling;

Make sure the nozzle is aligned and there is no blockage or leakage during the filling process;

Pay attention to whether the machine has an alarm

If the machine has an alarm, respond to the alarm in time;

If necessary, pause the machine to solve the problem;

12.What Are The Safety Tips For Using Toner Powder Filling Machine?

When operating a powder filling machine, pay attention to the following safety points:

Wear protective equipment

Wear protective equipment-sourced: technopackcorp

Wear personal protective equipment, including gloves, masks, goggles and dust glasses, etc.;

These can protect personal safety and prevent dust pollution;

Avoid overloading

Avoid overloading-sourced: jbtc

Do not use more materials than the machine can bear;

If the material is overloaded, it is easy to cause equipment failure;

Safely handle electrical components

Make sure the equipment is properly grounded before using it;

Avoid using wet hands to operate mechanical equipment to prevent leakage;

Thoroughly train operators

Thoroughly train operators-sourced: technopackcorp

Thoroughly and in detail train operators on safety procedures and machine control;

Reduce risks and errors in operation;

13.What Are The Maintenance And Cleaning Tips For Toner Powder Filling Machine?

Daily maintenance of the equipment can extend the service life and use of the equipment. The maintenance recommendations for the equipment are:

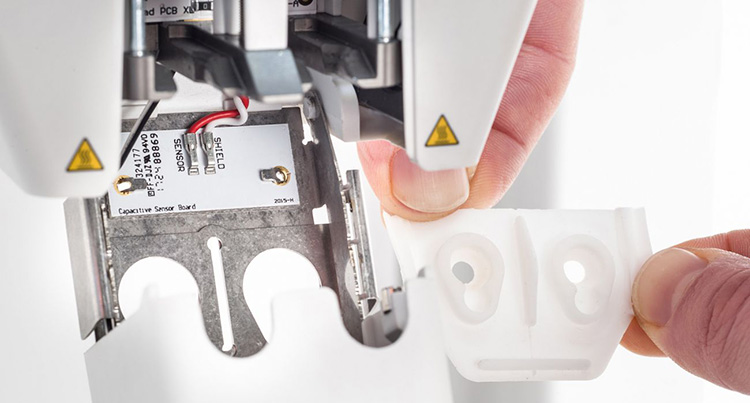

Inspect and replace worn parts

Inspect and replace worn parts-sourced: makerbot

You need to regularly inspect the equipment parts, including seals, bearings, augers, etc. Damaged or worn parts need to be replaced in time to ensure that the equipment can run smoothly.

Lubricate moving parts

Lubricate moving parts-sourced: msdlubricants

After replacing and inspecting the equipment parts, proper lubrication should be performed to reduce friction between the parts. This not only prolongs the service life of the parts, but also ensures that it runs efficiently without noise.

Update software regularly

Update software regularly-sourced: faronics

In order to allow you to access the latest features and perform program replacement and changes at any time, the equipment software needs to be updated and adjusted regularly. This can avoid performance impact.

Calibration check

Perform regular calibration checks on the equipment to ensure that the equipment can maintain high accuracy during filling and is not affected by changes in material materials.

Effective cleaning

Perform deep cleaning of the equipment regularly. Disassemble the parts, then remove surface dirt and dust, and use maintenance fluid to prevent wear of the equipment.

14.How To Optimize Your Toner Powder Filling Machine Performance?

In order to achieve the best effect of powder filling, you can make adjustments from the following aspects:

Auger speed adjustment

Auger speed adjustment-sourced: capsulcn

Adjust the auger speed according to the different properties of powder. For fine or fluid powders, you can adjust to a lower speed appropriately. For coarser or denser materials, the speed can be increased appropriately to maintain the best production level.

Filling cup depth

Filling cup depth-sourced: vtops

In order to ensure that the adopted container can be filled with powders of different volume densities and to ensure that each cup has a suitable capacity, the uniformity and weight of the material filling in the filling cup should be set before filling.

Filling cycle

Setting the filling cycle of the equipment can better coordinate the degree of fit between the container and the material, so that the filling of the material is more stable and smooth, and the filling time is shortened.

Vibration setting

Adjust the vibrator in the equipment so that the filled powder can be evenly distributed in the container.

15.How To Choose Your Own Toner Powder Filling Machine?

Being able to choose a powder filling machine that suits your material or product will effectively improve your production performance and the quality of material filling. To help you make a better decision, here are a few key points for your reference:

Powder types

Powder types-sourced: iapack

Divide the materials you need to fill by different powder types, such as free-flowing powder, non-free-flowing powder, and hygroscopic powder, so as to choose a powder filling machine suitable for different materials.

Production volume

Production volume-sourced: forbropack

From small to medium and large scale, you can choose different automated equipment. Small scale can use manual filling equipment, medium scale can choose semi-automatic powder filling equipment, large scale can choose fully automatic or powder filling line.

Budget

Budget-sourced: due

Take your budget into consideration and study the ratio between cost and benefit, so that you can choose a type of equipment that suits your budget and can get a high return.

16.What Are The Future TechnologiesFor Toner Powder Filling Machine?

In the future, the research focus of toner powder filling machine is:

Automation enhancement

Automation enhancement-sourced: pulse

In the future, saving labor and relying more on automation and intelligent systems are the research focuses. More advanced control systems can optimize filling speed and increase production.

Intelligent technology

Intelligent technology-sourced: online

Integrating AI into powder filling equipment can not only optimize filling speed and accuracy, but also make products consistent and improve product quality.

More safety

Whether it is protecting operations, reducing risks, and increasing safety, such as how to handle sensitive or dangerous powders, it is also the focus of research. This can improve the safety of operators and reduce human errors.

Conclusion:

When choosing and using toner powder filling machine, it is most important to improve the filling accuracy and efficiency of the product while ensuring safety. Through this toner powder filling machine guide, you may know that being able to keep up with industry trends and obtain relevant real-time information is also very important.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine