Thermoforming Blister Packaging Machine: A Complete Buying Guide in 2025

Do you know which machine is used to pack the tablets, capsules, and other goods? Thermoforming blister packaging machine packaged products with high quality, dependable, long-lasting packaging that guarantees the safety. For sectors including pharmaceuticals, healthcare, and consumer products, a thermoforming blister packaging machines are a more crucial option than ever as the demand for precise and accurate packaging increases.

However, how can you be certain that you are picking the ideal machine for your requirement? As of 2025, buying a thermoforming blister packaging machine requires thorough information about its applications, benefits, components, and many more. If you are looking for a high-quality, less cost-effective packaging machine, then a thermoforming blister packaging machine is the best choice for you.

You are on the right platform to shower yourself with amazing information about this machine. This complete buying guide is about thermoforming blister packaging machines which will help you to choose the right kind of blister packaging machine. Get ready to explore it.

1.What is a thermoforming blister packaging machine?

AIPAK thermoforming blister packaging machine

A thermoforming blister packaging machine is a specialized machine to form blisters, fill them, and seal them. This machine uses plastic sheets. All the processes are done by using heat and pressure. It functions by heating a sheet of plastic. When the sheet gets soften, it molds into different cavities of different sizes, inserting objects such as tablets, electronic devices, or other consumer goods, and sealing them by using materials such as foil and paper board.

2.What are the benefits of using a thermoforming blister packaging machine?

There are numerous reasons why thermoforming blister packaging machine is in demand. Here are the benefits of this machine:

Increased efficiency

Blister formation-Picture courtesy: productionpackagingsyetem.com

This machine makes the blister packs at a very high speed, making hundreds of blister packs in a minute as every machine’s range varies. This increases overall product efficiency and boosts output overall. If you want to minimize the labor cost, then this machine is well-suited for you because it eliminates the need for a manual labor, and its automation design saves money.

Maintaining the potency of products

Potency of tablets- Picture courtesy: aptar.com

Thermoforming blister packaging machine offers a high-quality packaging. These safely and cautiously pack blisters protect your products from external affects, thereby maintain their potency and effectiveness.

Reduce waste material

If you manually feed, cut, and sort blister packs, then a lot of materials will get wasted. But thermoforming blister machine with amazing feature of automation will make your materials less wasted.

Elevate brands

Customized packaging-Picture Picture: origionalmockups

If you want your products eye-catchy, then this machine full demand. It forms blisters of various formats and designs. It enables you to differentiate your products by creating customized packaging designs and formats.

Prevent tampering

Original product without tampering

Blister packs are made in such way that prevent any tampering. If anyone attempts to damage or tear the packaging, the upper blister design will make you aware about tampering and unauthorized access. So, it makes tampered evident blister packs. Therefore, it offers you high-quality goods in their original form.

Low-cost material

PVC roll-Picture Courtesy: Wallis plastic.com

Thermoforming blister packaging machine uses low-cost materials such as PVC, PVDC, and paper board. If you are facing budget tight situation, then buying this machine will prove fruitful.

3.Do you know what industries use thermoforming blister packaging machine?

Thermoforming blister packaging machine provides the above-mentioned benefits. Due to these reasons, various industries go to the option of using thermoforming blister packaging machine. Let’s explore the industries who use this machine.

Pharmaceutical and medical industries

Pharmaceutical Industry

In many pharmaceutical and medical industries, thermoforming blister packaging machine plays an important role to safely and securely package medications in thermoplastic such as, tablets, capsules, and ampoules because it provides sterile environment to them.

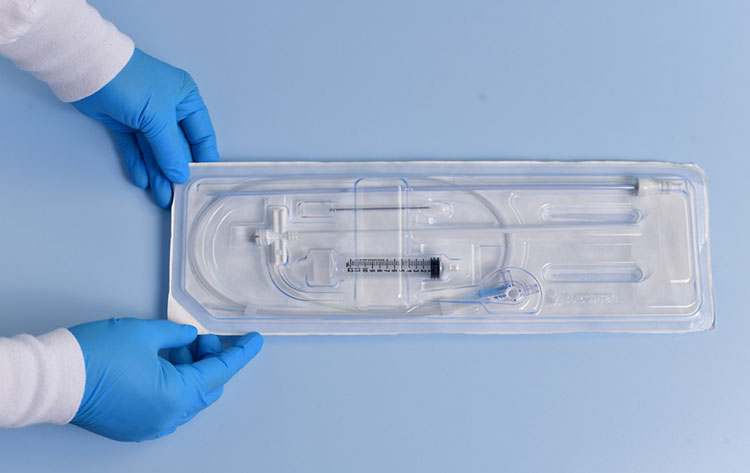

Medical industry

Medical Industry-Picture Courtesy: Plastic inGenuity.com

Medical devices such as injections, syringes etc are used to packed in blister. These machines also used to package MRI such as coil holder, monitoring cables, and X-rays related accessories such as X-rays film, marker, sensor holders etc.

Food industry

Food industry

Have you ever wondered which machine makes plastic bowls, bags, condiment bottles, and jars? These are made by a thermoforming blister packaging machine, which are used by the food industry to keep your food fresh and prevent bacterial contamination.

Consumer goods industry

Consumer goods industry

To provide safe and tempered proof packaging for consumer goods such as toys, house-hold items, electronics, and many other items, consumer goods industry uses thermoforming blister packaging machines.

You might have seen that small electronic device such as USB, battery, and other devices such as computer’s mouse and nuts are packed in plastic shells and blister trays to protect these sensitive items from physical damage.

Automotive industry

Automotive Industry-Picture Courtesy: therange.com

In automotive industry, thermoforming blister packaging machine plays essential role. Small and delicate items such as fuses, connecting wires etc, are packed in impact-resistance packaging.

Agricultural industry

Agricultural Industry-Picture Courtesy: macpack.com

In agricultural products, thermoforming blister packaging machines form clamshells and multi-compartment blister packs, and are used to pack fertilizers, pesticides, herbicides, seeds, and agricultural products. In seed packaging, these packs protect seeds from external factors that could halt their germination rates.

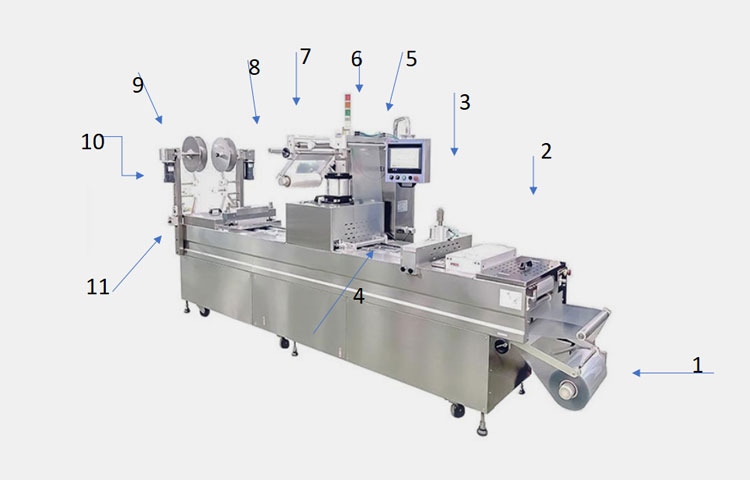

4.Describe the components of thermoforming blister packaging machine?

Components of Thermoforming Blister Packaging Machine

Thermoforming blister packaging machine consists of several key parts, that work together to guarantee accuracy, automation, and premium packaging. A thorough explanation is provided below.

1.Forming film reel

A roll of plastic film, made from thermoplastic materials such as PVC and PET, is held by this component.

2.Forming film preheating

This component heats the plastic film, usually from 150 to 200 centigrade, which is suitable for blister formation. It consists of heating plates to heat plastic film.

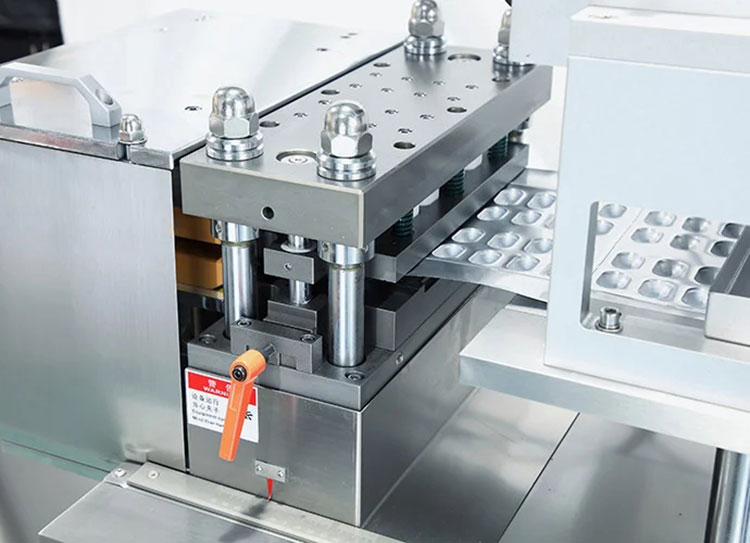

3.Pocket forming

It is molding unit. Here, heated plastic film is a molded in desired shapes using pressure by punch.

4.Auto feeding system

This component automatically feeds the product into the blister packs. Here sensors and conveyor are used for product placement.

5.Missing detects (missing detector)

This component includes sensors and cameras to detect whether the blister pack is properly filled or not.

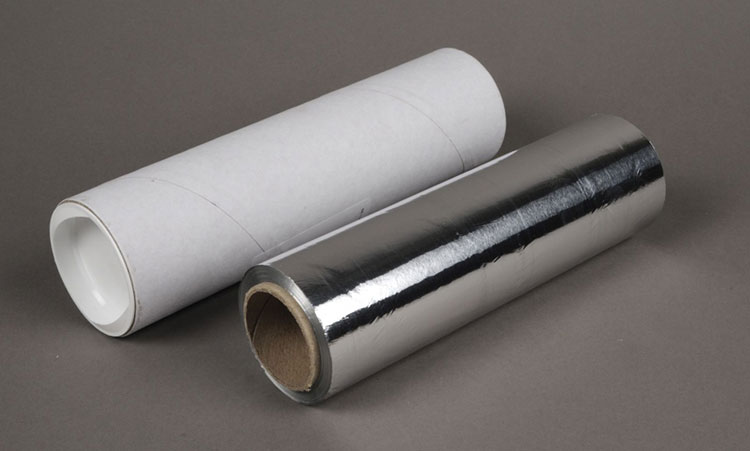

6.Lidding foil reel

The lidding foil reel holds rolls of lidding foil to seal the blister packs. This reel is made of aluminum or paper.

7.Rotary system

Using rotary motion, blister packs are tightly sealed here. It uses pressure and heat to bond the adhesive materials to packs.

8.Coding

Here, expiration date, product codes, and product details are coded here by using different methods such as inject and thermal process.

9.Perforation station

In this component, perforated lines are created between individual blisters for easy separation. Blister packs are cut into desire individual packs.

10.Trimming

Trimming is done to remove extra material from blister packs. Here the final products are stacked for final handling.

11.Rejection

In the rejection component, incomplete and defected blister packs are removed from the production line.

5.How does thermoforming blister packaging machine work?

To run this packaging machine, knowing its working principle is necessary. Following are the working steps of thermoforming blister packaging machine.

Material feeding

The first step is to feed plastic material (PVC, PVDC, and PET) into the machine to start the process. Backing material such as aluminum foil or paperboard is also fed into the machine which will later use for sealing blister packs.

Heating of plastic material

Heating Station

Here the plastic film is heated by using heating plates, upper and lower plates, until it becomes soft. Temperature controllers control heating, to make sure that material achieves pliability without overheating.

Forming cavities

Forming Unit

After heating, the softened plastic moves to the forming station to make blister cavities. Film is held between the upper and lower molds. To push the film down, hot compressed air is released. The lower mold cavities urge the film in the nestle. Finally, the blister cavities are formed.

Feeding products

After blister cavities formation, the next step is to feed the product in cavities. For this, either manual or automatic method is used. In the manual method, operators carefully fed products in cavities. In automatic method of feeding, vibratory feeders or robotic arms are used to feed the product in the cavities.

The products are dawn in a vibratory feeder and fall into cavities. This feeder has brushes that rotate over cavities to ensure each cavity is filled.

Sealing

The next important step is sealing. Already formed blister packs are sealed by using sealing material such as aluminum foil or paperboard. This is done by using heat and pressure.

Cutting and perforation

Perforation station

After sealing, a sheet of blister packs is moved to the cutting station. Punching dies cut sheets into individual packs according to the specifications. Perforations are added between units for easy tearing.

Inspection and quality control

Inspection and quality control are done to check defects. Weight checking detects whether each blister pack has a balanced quantity of products or not. Vision inspection cameras monitor the missing blisters and sealing issues.

Output and stacking

Discharge Chute

The final step is output and stacking. Blister packs are stacked for easy handling and packaging. The conveyor belt conveys the finalized products for labeling, cartooning, and

direct shipment.

6.What are the types of thermoforming blister packaging machine?

Thermoforming blister packaging machines are classified based on forming method, automation, and material compatibility. Let’s dive into this.

Classification based on forming method

Roller-type thermoforming blister packaging machine

AIPAK 260H Roller-Type Thermoforming Blister Packaging Machine

Roller-type thermoforming blister packaging machines are mostly used in the pharmaceutical, food, and consumer goods industries. This machine uses a roller continuously to heat and shape plastic film into blister cavities, and operates with high-speed resulting in higher production.

It is perfect for capsules, tablets, and consumer goods production.

Plate-type thermoforming blister packaging machine

Allpack- DPP 80 Aluminum/PVC Plate-Type Thermoforming Blister Packaging Machine

Plate-type thermoforming blister packaging machine uses two flat-plates to heat plastic film and create blister cavities. Then, these are sealed by a plat-sealing mechanism. It offers great efficiency and deep blister formation. Long-lasting blisters are guaranteed when using this machine having thick packing material.

Vacuum thermoforming blister packaging machine

Vacuum Thermoforming Blister Packaging Machine

It is a simplified type of thermoforming blister packaging machine where the plastic film is heated and shaped in blister cavities by a vacuum sucker. It is perfect for electronic components and industrial parts.

The machine offers precision and minimal material waste.

Based on automation level

Fully automated thermoforming blister packaging machine

AIPAK Fully Automated Thermoforming Blister Packaging Machine

In this type of machine, every process is done automatically and at high speed. Plastic film is heated and formed into blister cavities by using rollers or plates. Then, cavities are filled with products automatically. Formed blisters are sealed using heat and pressure.

The whole process is fast and precise which is ideal for large-scale production.

Semi-automated thermoforming blister packaging machine

Semi-Automated Thermoforming Blister Packaging Machine

Here, both manual and automated processes are done. Plastic foil is heated and shaped into desired cavities automatically, but products in them are fed manually. Cutting and sealing are partially automated. This type of machine is suitable for small and medium -scale production.

7.what are the materials used as thermoform by the thermoforming blister packaging machine?

Did you know which materials you can use as a thermoform in thermoforming blister packaging machine? Here are the following materials you can use.

PVC (Polyvinylchloride)

PVC Rolls

The most important material is PVC. Being a thermoplastic polymer, it can be molded into a variety of shapes and becomes softer when heated before solidifying when cooled. Because of these features, it is perfect for creating blister cavities. It is inexpensive and flexible.

As PVC blisters are transparent, you can see the products from outside. This helps to check product appearance.

PET (Polyethylene terephthalate)

PET Sheet

Polyethylene terephthalate is also used as a thermoform due to its high strength and recyclable nature. It is a strong thermoplastic polymer that becomes pliable when heated, property of being easily molded in blister cavities and accommodates tablets, capsules, and equipment.

Due to its eco-friendly and non-toxic nature, this is used in the healthcare, food and pharmaceutical industries.

PP (Polypropylene)

PP Roll

Thermoforming blister packaging machines use PP due to its excellent heat resistance, chemical stability, and elasticity. Moreover, it is more impact-resistant than hard plastics because it is lightweight and flexible.

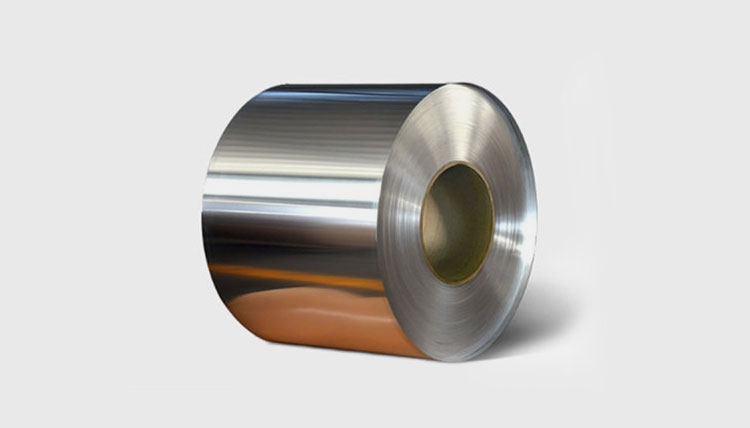

Aluminum foil

Aluminum Roll

Aluminum foil is used to make cold-form blister packs. It provides a protective shield from air, moisture, and oxygen, and is opaque. Because of this, it is the best option for delicate items.

8. What is the difference between thermoforming blister packaging machine and cold-forming blister packaging machine?

Both types of machines are used in pharmaceutical, consumer goods items, and food packaging. However, they differ in working process, materials used, and applications.

Working process

A thermoforming blister packaging machine uses heat and pressure to soften plastic sheets (PVC, PVDC, and PP) and mold it in desired blister cavities. Wherein in cold forming blister packaging machines, mechanical pressure is used to mold aluminum foil into cavities without heat.

Material using

Packaging Materials

Thermoforming blister packaging machine uses PVC, PVDC, and PP for forming blisters. For sealing, sometimes aluminum foil is used. Whereas in cold forming blister packaging machines, aluminum foil is used for both forming layers and as lidding material.

Application

Thermoforming blister packaging machines are used in various industries such as food, pharmaceutical, consumer goods, and nutraceutical industry. While cold forming blister packaging machines are used in pharmaceutical industries where drugs require maximum protection from external factors.

Cost consideration

Cost consideration

Thermoforming blister packaging machine uses low-cost plastic sheet. While cold forming blister packaging machine uses aluminum foil which is expensive compare to plastic sheet.

9.Do you know the things to consider when buying thermoforming blister packaging machine?

There are various factors to consider when you buy a thermoforming blister packaging machine. Following are some important factors.

Budget

Budget -Picture Courtesy: daniaaccounting.com

Choose the type of thermoforming blister packaging machine that suits your budget. Consider the cost of materials, energy consumption, and labor costs. A comprehensive understanding of cost is necessary in buying and operating the machine

Production capacity and speed

A machine should meet your demands whether a machine with high production capacity and speed or a machine with small production and speed. For large-scale industry, a machine with high speed. A slower machine is less expensive and ideal for small-manufacturing sectors.

Machine flexibility and adaptability

When buying this machine considering flexibility and adaptability is important. A machine must accommodate changing production needs and handle various packaging formats such as blister packs, clamshells, and trays.

Easy to clean and maintain

Easy To Clean and Maintain-Picture Courtesy: mesoforming.com

Cleaning and consistent maintenance are necessary for hygiene and safe production. Select a machine with tool-free replacement and self-cleaning instruments to minimize operational costs. If you want to reduce long-term repair costs, invest in a machine with user-friendly maintenance.

Installation space

Machines Installation

Examining the available floor space and making sure the chosen model fits your production space area without creating traffic are crucial steps to consider before buying a thermoforming blister packaging machine.

Conclusion

In 2025, a thorough understanding of machine type, functions, and materials is necessary before buying a thermoforming blister packaging machine. You can invest in machines according to your budget and production demand by considering all the above aspects. If you are looking to buying a machine, then AIPAK is the best choice to consider because it provides efficient and amazing quality machines.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine